MnO2对8YSZ低温活化烧结及其性能的影响

周宏明1,李淼磊2,郭雁军1,李荐1,贾晓慧1,罗海棠1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 航空航天学院,湖南 长沙,410083)

摘要:以MnO2为8YSZ的烧结助剂,研究MnO2含量和烧结工艺参数对8YSZ活化烧结及其性能的影响。采用阿基米德排水法、维氏显微硬度仪、电子万能试验机对烧结块体的致密度、硬度和抗弯强度进行分析,并使用扫描电子显微镜(SEM)、X线衍射分析(XRD)对其微观形貌和相组成进行表征。实验结果表明:块体的致密度随着MnO2含量的增加而逐渐增加,当MnO2添加量为3%时获得了最好的烧结效果;随着温度的升高,块体致密度也逐渐增加,在1 300 ℃烧结4 h时,致密度达到了98.59%;在此条件下,样品的硬度与抗弯强度均为最佳,分别为1 830.21(HV)与235.46 MPa。

关键词:8YSZ;MnO2;低温烧结;微观结构;力学性能

中图分类号:TQ174 文献标志码:A 文章编号:1672-7207(2012)04-1254-07

Effect of MnO2 on sintering ability and properties of 8YSZ

ZHOU Hong-ming1, LI Miao-lei2, GUO Yan-jun1, LI Jian1, JIA Xiao-hui1, LUO Hai-tang1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Aeronautics and Astronautics, Central South University, Changsha 410083, China)

Abstract: Using MnO2 as sintering aids, the influence of MnO2 content and sintering process on sintering ability and properties of 8YSZ were investigated. Archimedes principle, hardness-testing devices and universal-testing machine was employed to measure the relative density, hardness and bending strength of the sintered bulk. XRD and SEM were also used to analyze the crystallographic phase, microstructure of the sintered bulk. The results show that the relative density of the sintered bulk increases with the increase of the proportion of MnO2. The best sintering ability is obtained when 3%MnO2 is doped. The relative density of the sintered bulk also increases as the temperature rises. The relative density reaches 98.59%, and the hardness and flexural strength reach 1830.21(HV) and 235.46 MPa respectively, when the sintering temperature is 1 300 ℃ and soaking time is 4 h.

Key words: 8YSZ; MnO2; low temperature sintering; microstructure; mechanical property

含8%(质量分数)Y2O3部分稳定的ZrO2(8YSZ)具有较低的热导率、良好的力学性能(如高的抗弯强度与断裂韧性)已被广泛用于制备热障涂层的表层陶瓷隔热材料[1]。目前开发出一系列新的涂层制备技术,如电泳沉积法[2-4],料将喷涂法[5-6],浸涂法[7]等。与传统的涂层制备方法相比,这些方法具有很多显著的优点,如能够精确控制涂层的化学成分与厚度,不受部件形状的限制,所需设备简单。但是由于8YSZ的烧结温度在1 400 ℃以上,烧结温度过高,不仅金属基体难以承受,且同时增加了生产成本。为了降低生产成本,降低烧结温度是一条有效途径。通常,降低陶瓷粉末烧结温度的方法有2种,常用的方法是减小粉料的颗粒尺寸,采用超细粉料作原料[6-7],但这种方法工艺复杂,成本高。另一种方法是通过加入合适的烧结助剂,这些助剂在烧结过程中会产生液相[8-9],或形成置换固溶体,使晶格畸化从而活化晶格、形成空穴或迁移原子,以及使晶格产生变形,起到活化烧结作用[10],从而促进了致密化过程,使得材料在较低的温度下能烧结致密。有关氧化锆陶瓷的低温烧结的研究在20世纪80年代才开展起来, 最初的研究起步于研究杂质对氧化锆陶瓷的烧结特性和力学性能的影响。后来,人们开始往氧化锆中添加一些烧结助剂,以期降低氧化锆陶瓷的烧结温度。目前,低温烧结研究主要集中在通过添加烧结助剂,在烧结的过程中形成液相以达到降低烧结温度的目的。如Louis等[11]通过在3Y-TZP中添加CuO,在烧结的过程中形成了瞬时液相,使烧结温度大大降低。孙义海等[12]通过在3Y-TZP中添加CAS(CaO–Al2O3-SiO2)玻璃,在1 300 ℃下烧结时致密度达到99.4%,并取得良好的力学性能。但采用液相烧结机制来降低陶瓷烧结温度,会在陶瓷样品中产生第二相,从而降低陶瓷的力学性能。为此,本文作者通过设计烧结助剂成分,使陶瓷以缺陷活化烧结的机制来降低烧结温度。由于Mn4+与Al3+半径相差不大,且含有变价元素,能够与A12O3形成不同类型的固溶体,变价作用增加了A12O3的晶格缺陷,活化晶格,使基体易于烧结,因此MnO2常作为氧化铝的烧结助剂[13-14]。Mn4+的半径与Zr4+的相差不大,能够与8YSZ形成置换固溶体,因此,以MnO2为8YSZ的烧结助剂,研究MnO2含量和烧结工艺参数对8YSZ活化烧结及其性能的影响。

1 实验

1.1 试剂

实验试剂为8YSZ粉末(99.5%),粒径为0.5 μm左右,杭州万景新材料有限公司生产;MnO2(分析纯,济南嘉裕化工有限公司生产)。

1.2 实验过程

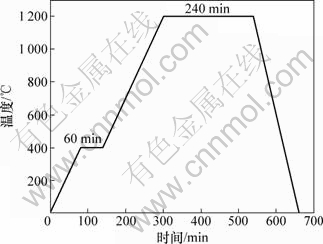

以8YSZ粉末为基本原料,加入不同含量的MnO2,以无水乙醇为球磨介质球磨混合24 h后,在80 ℃下干燥,过孔径为150 μm筛得到8YSZ-MnO2粉末,加入2%(质量分数)的聚乙烯醇作为黏结剂,然后在20 MPa下压制成型,将获得样品置入高温炉(KSY-12D-18,湖南顶立科技有限公司生产)在空气中进行无压烧结。烧结温度曲线如图1所示。具体工艺为以5 ℃/min的升温速率升至400 ℃保温1 h脱胶,再升温至1 200~1 400 ℃,保温4 h,最后随炉冷却,获得致密化的样品。样品中各组分组成(质量分数)见表1。

将烧结致密化的样品用金相砂纸(600~1200号)进行抛光处理,然后进行热腐蚀处理(将样品在低于烧结温度100 ℃下热处理10~30 min),以获得在扫描电镜下可见的晶界。

表1 8YSZ样品的化学组成

Table 1 Chemical composition of 8YSZ samples %

图1 烧结温度曲线

Fig.1 Sintering temperature curve

1.3 分析方法

采用SIEMENSD-500型X线全自动衍射仪对产物作相结构分析。采用Cu Kα辐射,工作电压为40 kV,工作电流为250 mA,扫描范围为20°~80°,扫描速度为5(°)/min。

用混合法进行理论密度ρt的计算:

(1)

(1)

其中,w1和w2分别为8YSZ和MnO2的质量分数;ρ1和ρ2分别为8YSZ和MnO2的密度,ρ1=5.90 g/cm3;d2=5.026 g/cm3;采用阿基米德排水法测烧结块体的实际密度ρa,致密度R=(ρa/ρt)×100%。

使用显微硬度仪测量显微硬度。采用Sirion 200型场发射扫描电子显微镜(Scanning Electron Microscope, SEM)观察样品的显微结构与形貌。用三点弯曲法测量其抗弯强度,将样品加工成35 mm×4 mm×3 mm(长×宽×高)的试条,测量跨距为30 mm,加载速率为0.5 mm/min。

2 结果和讨论

2.1 烧结性能

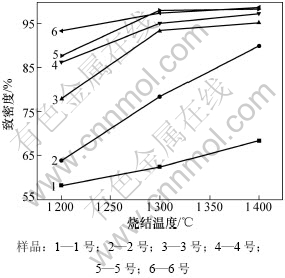

图2所示为添加不同配比的MnO2样品的致密度与烧结温度的关系。

图2 具有不同烧结助剂的8YSZ的致密度与烧结温度的关系

Fig.2 Relative density of 8YSZ as function of aid content and sintering temperature

从图2可以看出,加入MnO2后,样品的密度均有不同程度的提高。在实验烧结温度范围内,样品的致密度随温度的升高而增加。样品的致密度随MnO2含量的增加而增大,在MnO2含量为3%时具有最好的烧结性能,在1 200 ℃时致密度已达到93.35%,在 1 300 ℃时,致密度达到98.59%。当添加量达到5%时,致密度不再上升,这可能是由于MnO2的添加量过多,出现了异常的不连续的晶粒生长,这种异常的不规则的晶粒生长导致烧结后期晶界与气孔分离,使得大量的气孔在新形成的大晶粒内部形成,这些晶粒内部的气孔增加了扩散的距离,从而阻碍了致密化[15]。

MnO2的添加能够提高8YSZ的烧结性能,这是由于Mn4+的离子半径为53×10-12 m,Zr4+的半径为72×10-12 m,两者半径相差约为26%,能够形成有限置换固溶体[16-19]。Mn有不同的价态,因此存在一系列复杂的氧化物与氢氧化物。Mn的易于变价导致产生了很多缺陷和非化学计量化合物。因此,有着不同价态的Mn离子可以置换Zr阳离子,从而导致了空位的形成或多余电子的产生。同时固溶体的形成使晶格畸化,增加结构缺陷,这些都使得扩散激活能降低,有利于离子扩散,加速了烧结块体的致密化,使得烧结温度降低。

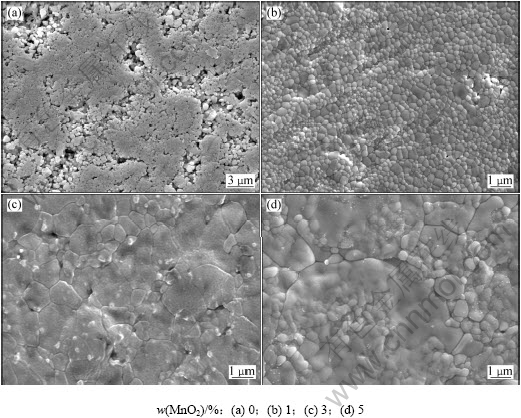

2.2 显微结构与相分析

图3所示为1 300 ℃下烧结的8YSZ添加不同含量烧结助剂的样品经过抛光与热腐蚀的表面SEM照片。从图3可以看出,没有添加烧结助剂的8YSZ在1 300 ℃下烧结得到的样品结构疏松,粉末颗粒外形基本未发生变化,粉末颗粒大部分只是发生了黏结,烧结仅仅停留在第1阶段。在添加了烧结助剂MnO2之后,样品的致密化程度的大大得到提高,都形成了清晰的晶粒。从图3(a)可以看出,添加剂含量为1%时,得到的晶粒非常细小,大约只有几十纳米,同时表面有少量气孔分布在晶粒之间。随着添加剂含量增加至3%,晶粒发生不均匀生长,在局部范围内大晶粒被小晶粒包围,晶界线条尖锐。当添加剂含量增加至5%时,晶粒达到了5 μm以上。这是由于Mn离子取代Zr的位置,使得在烧结过程中,单个晶粒内部形成了快速扩散通道,快速扩散通道的形成使得晶粒长大的过程得到加强。烧结助剂添加量越大,扩散通道越多,晶粒长大也就越迅速。另外,从图3还可以看出,在1 300 ℃下烧结得到的样品晶界上并无第二相出现,说明MnO2与ZrO2形成了固溶体。

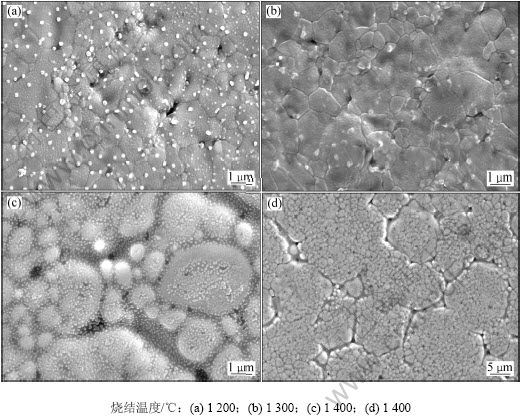

图4所示为不同烧结温度下的8YSZ+3%MnO2样品表面形貌的SEM照片,其中,图4(c)与(d)为同等烧结条件下不同放大倍数的扫描照片。从图4(a)可以看出,在1 200 ℃下,晶粒比较细小,晶粒之间有气孔存在,随着温度升高,离子的振动能量增加,扩散得到加强,致密化速率加快,因此烧结块体致密度逐渐增大,气孔几乎消失,晶粒也随之发生长大,在1 300 ℃下(图4(b)),一部分晶粒已经发生了明显长大,达到1 μm以上。从图4(d)可以看出,在1 400 ℃下,晶粒的粒径达到10 μm以上。

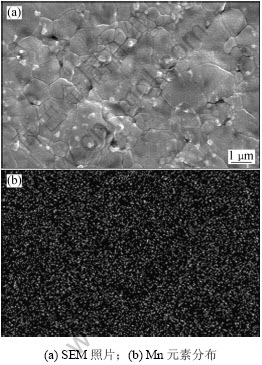

图5所示为8YSZ+3%MnO2在1 300 ℃下烧结的SEM照片及Mn元素的面分布照片。从图5可以看出:Mn元素在基体中分布非常均匀,没有出现偏析,这说明Mn元素已经完全固溶在氧化锆基体中。

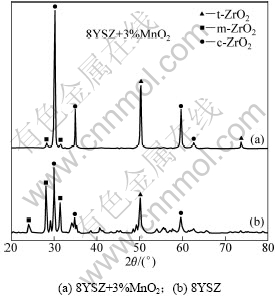

图6所示为8YSZ与添加3%MnO2样品的XRD图谱。从图6(b)可以看出:在添加了烧结助剂之后,为单一的氧化锆衍射峰,未见MnO2相。结合SEM图片与Mn元素的能谱分析结果(图5)可知:MnO2与氧化锆形成了固溶体,其烧结机理为缺陷活化烧结。同时从图6也可看出,在添加了MnO2之后,氧化锆的单斜相大大减少,大部分转化为立方相(c相)与四方相(四方相),这可能是由于Mn4+取代Zr4+会引起单斜相向四方相与立方相的转变。

图3 添加剂含量不同的样品表面形貌的SEM照片

Fig.3 SEM photographs of samples with different contents of additives

图4 不同烧结温度下的8YSZ+3%MnO2样品表面形貌的SEM照片

Fig.4 SEM photographs of 8YSZ+3%MnO2 samples with different temperatures

图5 8YSZ+3%MnO2在1 300 ℃下的SEM照片与Mn元素分布

Fig.5 SEM micrograph and Mn element distribution of 8YSZ+3%MnO2 sintered at 1 300 ℃

图6 8YSZ与8YSZ+3%MnO2烧结块体的XRD谱

Fig.6 XRD patterns of 8YSZ and 8YSZ+3%MnO2 samples

2.3 力学性能

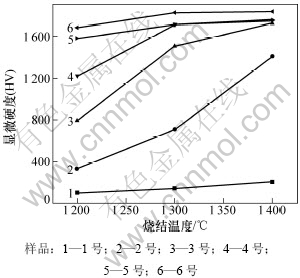

图7所示为8YSZ+MnO2样品硬度与烧结温度的关系。从图7可以看出,在添加了烧结助剂之后,样品的硬度获得了大幅度提高,随着烧结助剂含量的增加,样品的硬度逐渐增大,同时,样品的硬度随着烧结温度的升高而逐渐增大。这与致密度的变化规律类似。从以上分析可知,在烧结的过程中,MnO2与ZrO2形成了置换固溶体,并没有第二相产生。对于相同成分样品,其化学键类型与强度相同,而温度越高,致密度越高,孔隙率越低,因此硬度增大。对于相同温度而成分不同的样品,随着烧结助剂含量增加,样品内部晶格缺陷增加,但化学键类型并未发生变化,缺陷的形成,增加了位错移动的阻力,陶瓷的塑性变形变的困难,且随着烧结助剂含量的增加,致密度升高,因此陶瓷的硬度增加。

图7 8YSZ样品的硬度与烧结温度的关系

Fig.7 Hardness of 8YSZ samples as function of sintering temperature

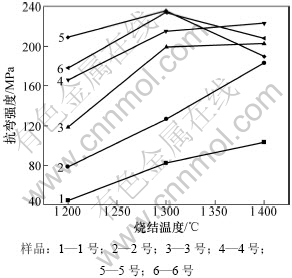

图8所示为8YSZ+MnO2样品抗弯强度与烧结温度的关系。从图8可以看出:样品的抗弯强度随着MnO2含量的增加而增强;在添加剂含量为3%以下时,样品的抗弯强度随着温度的升高而增强,但添加量为3%以上时,样品的抗弯强度先随着温度上升,当温度达到1 400 ℃时,抗弯强度反而有所下降。根据格里菲斯等式[16]:

(2)

(2)

(3)

(3)

其中:σf为抗弯强度;P0=0.395,n=1.15,P为气孔率,Y为形状因子,c0为初始裂纹长度。从式(1)和(2)可知,样品的抗弯强度与气孔率成反比。而根据Hall-petch公式[12]:

(4)

(4)

式中:σo为无限大单晶的强度;k为系数;d为晶粒直径。从式(3)可知,陶瓷材料的抗弯强度与晶粒粒径成反比。由于烧结助剂与基体形成了固溶体,并无第二相生成,因此样品的强度主要取决于孔隙率与晶粒尺寸。随着添加剂含量增加,致密度逐渐增加,晶粒逐渐长大,在添加剂含量小于3%,致密度的增强效应大于晶粒长大带来的减弱效应,因此,抗弯强度逐渐增加;当烧结助剂含量达到5%时,致密度基本未发生变化,而晶粒却发生了急剧长大,因此强度有所下降。同样,随着温度升高,致密度升高,晶粒也发生长大,样品抗弯强度随着温度升高而增加,温度达到1 400 ℃时,抗弯强度不再上升。

图8 8YSZ样品的抗弯强度与烧结温度的关系

Fig.8 Flexural strengthen of 8YSZ samples as function of sintering temperature

3 结论

(1) 在8YSZ中引入MnO2为烧结助剂,由于Mn4+取代Zr4+而形成置换固溶体,起到活化烧结作用,从而降低烧结温度。在1 300 ℃,烧结时间为4 h时,致密度达到了98.59%。

(2) 致密度随着MnO2含量的增加而增大,在配比为8YSZ+3%MnO2时有最好的烧结性能。当添加剂含量达到5%时,在不同温度下烧结,致密度不再增加。样品的致密度均随着温度的升高而增加。

(3) 在实验条件范围内,样品的硬度变化规律与致密度变化规律基本一致。在添加剂含量为3%以下时,样品的抗弯强度随着MnO2含量的增加而增大,随着温度的升高而增大;当添加量为3%以上时,在 1 200~1 400 ℃时,样品的抗弯强度先增大后降低。

参考文献:

[1] 谢冬柏, 王福会. 热障涂层研究的历史与现状[J]. 材料导报, 2002, 16(3): 7-14.

XIE Dong-bai, WANG Fu-hui. History and current state of thermal barrier coating research[J]. Materials Review, 2002, 16(3): 7-14.

[2] Wang Z C, Shemilt J, Xiao P. Fabrication of ceramic composite coatings using electrophoretic deposition, reaction bonding and low temperature sintering[J]. Journal of the European Ceramic Society, 2002, 22: 183-189.

[3] Lu X J, Xiao P. Constrained sintering of YSZ/Al2O3 composite coatings on metal substrates produced from eletrophoretic deposition[J]. Journal of the European Ceramic Society, 2007, 27: 2613-2621.

[4] van der Biest O, Joos E, Vleugels J. Electrophoretic deposition of zirconia layers for thermal barrier coatings[J]. J Mater Sci, 2006, 41: 8086-8092.

[5] Nguyen P, Harding S. Experimental studies on slurry based thermal barrier coatings[C]//5th Australasian Congress on Applied Mechanics. Brisbane, 2007: 545-550.

[6] 周健儿, 李家科. FeCrAl合金表面高温抗氧化陶瓷涂层的制备[J]. 硅酸盐学报, 2005, 33(9): 1089-1093.

ZHOU Jian-er, LI Jia-ke. Preparation of high-temperature oxidation resistant ceramic coating on FeCrAl-alloy[J]. Journal of the Chinese Ceramic Society, 2005, 33(9): 1089-1093.

[7] ZHU Qing-shan, FAN Bao-an. Low temperature sintering of 8YSZ electrolyte film for intermediate temperature solid oxide fuel cells[J]. Solid State Ionics, 2005, 176: 889-894.

[8] Boutz M M R, Winnubst A J A, Burggraaf A J. Yttria-ceria stabilized tetragonal zirconia polycrystals: Sintering, grain growth and grain boundary segregation[J]. Journal of the European Ceramic Society, 1994, 13(2): 89-102.

[9] Theunissen G S A M, Winnubst A J A, Burggraaf A J. Sintering kinetics and microstructure development of nanoscale Y-TZP ceramics[J]. Journal of the European Ceramic Society, 1993, 11(4): 315-324.

[10] 孙义海, 张玉峰, 郭景坤. 低温烧结3Y-TZP陶瓷的微观结构与力学性能[J]. 硅酸盐学报, 2002, 30(3): 267-274.

SUN Yi-hai, ZHANG Yu-feng, GUO Jing-kun. Microstructure and mechanical properties of 3Y-TZP ceramics by low temperature sintering[J]. Journal of the Chinese Ceramic Society, 2002, 30(3): 267-274.

[11] 孙义海, 张玉峰, 郭景坤. 低温烧结高性能2Y-TZP材料[J]. 无机材料学报, 2002, 17(6): 1227-1232.

SUN Yi-hai, ZHANG Yu-feng, GUO Jing-kun. Low temperature sintered 2Y-TZP materials with high performance[J]. Journal of Inorganic Materials, 2002, 17(6): 1227-1232.

[12] Horn D S, Messing G L. Anisotropic grain growth in TiO2-doped alumina[J]. Mater Sci Eng A, 1995, 195: 169-178.

[13] Winnubst L, Ran S. Analysis of reactions during sintering of CuO-doped 3Y-TZP nano-powder composites[J]. Journal of the European Ceramic Society, 2009, 29: 2549-2557.

[14] SUN Yi-hai, ZHANG Yu-feng, GUO Jing-kun. Microstructure and bending strength of 3Y-TZP ceramics by liquid-phase sintering with CAS addition[J]. Ceramics International, 2003, 29: 229-232.

[15] Erkalfa H, Misirli Z, Baykara A. Densification of alumina at 1 250 °C with MnO2 and TiO2 additives[J]. Ceramics International, 1995, 21: 345-348.

[16] Sathiyakumar M, Gnanam F D. Influence of MnO2 and TiO2 additives on density, microstructure and mechanical properties of Al2O3[J]. Ceramics International, 2002, 28: 195-200.

[17] Erkalfa H, Misirh Z, Demirci M, et al. The densification and microstructural development of A12O3 with manganese oxide addition[J]. Journal of the European Ceramic Society, 1995, 15: 165-171.

[18] Thomas O, Alexander Z. Evolution of Young’s modulus, strength, and microstructure during liquid-phase sintering[J]. J Am Ceram Soc, 1998, 81(7): 1852-1860.

[19] 吴振东, 叶建东. 添加剂对氧化铝陶瓷的烧结和显微结构的影响[J]. 兵器材料科学与工程, 2002, 25(1): 68-72.

WU Zheng-dong, YE Jian-dong. Effects of additives on sintering behavior and microstructure of A12O3[J]. Ordnance Material Science and Engineering, 2002, 25(1): 68-72.

(编辑 赵俊)

收稿日期:2011-03-05;修回日期:2011-06-02

基金项目:湖南省国际合作重点项目(2008WK2005);中国博士后基金特别资助项目(200801350);教育部博士点新教师基金资助项目(200805331062);湖南省科技计划项目(2010FJ4061)

通信作者:周宏明(1974-),男,湖南茶陵人,博士,副教授,从事生物及高温涂层材料研究;电话:0731-88877173;E-mail:ipezhm@yahoo.com.cn