低品位铜矿浸出液除铁及纳滤浓缩铜的研究

王红军1, 2,刘久清1,周钦1,何俊颖1

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 中国瑞林工程技术有限公司,江西 南昌,330031)

摘要:针对某铜矿湿法炼铜中目前生物浸出液Cu2+质量浓度低、Fe3+质量浓度高导致后续萃取和电积效率降低的问题,采用中和水解法及超滤、纳滤处理工艺对其生物浸出液进行除铁和铜富集。通过实验考察除铁温度和pH对铜损率、除铁率、纳滤操作压力、温度以及浓缩倍数对膜通量和铜离子截留率的影响。研究结果表明:中和水解除铁最佳条件是温度为30 ℃,pH为3.0~3.2;纳滤较佳操作条件是运行压力为15×105 Pa,温度为30 ℃,流量为18 L/min;在此条件下,对某铜矿堆浸厂生物浸出液进行中和水解除铁和超滤、纳滤处理后,Cu2+质量浓度由187 mg/L提高到542 mg/L,铜铁质量浓度比由原来的1:4提高到1:1;该工艺具有操作简单、能耗低、环保等优点,对于湿法炼铜中减少萃取乳化现象及提高电积效率均有重要意义。

关键词:生物浸出液;除铁;纳滤;铜浓缩

中图分类号:TQ028.8 文献标志码:A 文章编号:1672-7207(2014)12-4111-05

Iron removal and copper concentrate by nanofiltration for bioleaching solution of low grade copper mine

WANG Hongjun1, 2, LIU Jiuqing1, ZHOU Qin1, HE Junying1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. China Nerin Engineering Co. Ltd., Nanchang 330031, China)

Abstract: Due to low mass concentration of copper and high mass concentration of iron in the bioleaching solution that decrease the efficiencies of solution extraction and electrowinning during copper hydrometallurgy in a copper mine, iron removal and copper enrichment on bioleaching solution of the copper mine were carried out by neutralizing hydrolysis, ultrafiltration and nanofiltration. The effects of temperature and pH on copper loss rate and iron removal rate as well as effects of nanofiltration operating pressure, temperature and concentration times on flux and rejection rate of Cu2+ were studied. The results show that the optimum conditions of iron removal include temperature 30 ℃, pH between 3.0 and 3.2 and the optimum conditions of nanofiltration include pressure 15×105 Pa, temperature 30 ℃, flow rate 18 L/min. After treatment on bioleaching solution in a copper heap leaching plant under these conditions, the mass concentration of Cu2+is enhanced from 187 mg/L to 542 mg/L with the ratio of mass concentration of copper and iron increases from 1:4 to 1:1.The process of operating simplicity, low energy consumption and environmental protection have great significance on reducing emulsifications in solution extraction and enhancing efficiency of electrowinning.

Key words: bioleaching solution; iron removal; nanofiltration; copper concentrate

目前,国内铜矿采用生物浸出—溶剂萃取—电积(BL—SX—EW)的湿法提铜工艺[1],但浸出液中的Fe离子和悬浮微粒导致溶剂萃取过程中出现严重界面乳化问题[2-3],而且浸出液铜质量浓度远低于工艺设计要求[4],致使后续的萃取、电积工艺受到明显影响。Fe离子的去除主要有铁矾法[5]、针铁矿法[6]、赤铁矿法[7]、磷酸盐法[8]和中和水解法[9],其中中和水解法条件温和,操作简单,是目前工业普遍的除铁方法;而金属离子的富集主要有沉淀法[10]和离子交换法[11]等方法,但湿法炼铜中低品位矿浸出液铜离子质量浓度低,采用这些方法富集铜成本高、工艺繁琐,而新兴的膜技术[12-13]则可以使浸出液同时实现净化和有价金属离子浓缩,在国外的Asacro Ray,BHP San Manuel和Mexicana de Canane等[14]矿山浸出液处理中效果显著,是一种高效、环保、节能的新方法。为此,本文作者采用中和法除铁和膜浓缩对湿法炼铜生物浸出液进行处理,并对其过程进行研究。

1 实验

1.1 实验原料及试剂

本实验的实验原料是某铜矿生物浸出液,其主要水质情况如表1所示。中和水解法除铁试剂为工业石灰(Ca(OH)2的质量分数≥80%)。

表1 某铜矿生物浸出液主要水质情况

Table 1 Constitutions on bioleaching solution from a copper mine

1.2 实验仪器及装置

实验仪器为TAS-990原子吸收分光光度计、哈希DR5000台式可见分光光度计、pHS-3C pH计、DDS-11A型电导率仪、HH-8数显恒温水浴锅、S212-30-恒速搅拌器。

实验装置为超滤膜(有效膜面积为2.60 m2)、纳滤膜(有效膜面积为1.77 m2)。

1.3 实验方法

1.3.1 中和水解法除铁

取500 mL某铜矿生物浸出液于恒温水浴锅的烧杯中,设定温度为25~35 ℃,转速为300~500 r/min,缓慢加入工业石灰,调节pH至不同值后,反应15 min。反应结束后抽滤,检测滤液Cu离子、Fe离子和Ca离子质量浓度,考察不同终点pH对铜损率和除铁率的影响。

1.3.2 膜浓缩富集

除铁液仍含有大量的悬浮颗粒和胶体,直接进纳滤浓缩极易导致纳滤膜孔堵塞,因此,先将除铁液经滤袋(平均孔径为5 μm)过滤后,再经超滤进一步过滤其中的悬浮颗粒及大部分胶体。超滤操作参数依据文献及经验值,控制进料压力为6×105 Pa,流量为17 L/min,温度为30 ℃。浓缩倍数为10倍。将预处理后的料液进行纳滤浓缩,保持流量恒定,考察纳滤操作压力、温度、浓缩倍数对纳滤渗透通量、Cu2+的截留率的影响。

1.4 分析方法

膜通量Jw计算公式为

(1)

(1)

其中:Jw为膜通量(L/(m2·h));S为滤速(s·L-1);A为膜面积(m2),纳滤膜A=1.77 m2。

截留率R计算公式为

(2)

(2)

其中: 和

和 分别为纳滤浓缩时取得的浓缩液和渗透液的离子质量浓度(mg·L-1)。在实验室条件下,Cu2+,Fe3+和Ca2+质量浓度均采用TAS-990原子吸收分光光度计测定;在工业中试阶段,Cu2+和Fe3+质量浓度采用美国哈希 DR5000台式可见分光光度计测定。

分别为纳滤浓缩时取得的浓缩液和渗透液的离子质量浓度(mg·L-1)。在实验室条件下,Cu2+,Fe3+和Ca2+质量浓度均采用TAS-990原子吸收分光光度计测定;在工业中试阶段,Cu2+和Fe3+质量浓度采用美国哈希 DR5000台式可见分光光度计测定。

2 实验结果与讨论

2.1 除铁实验

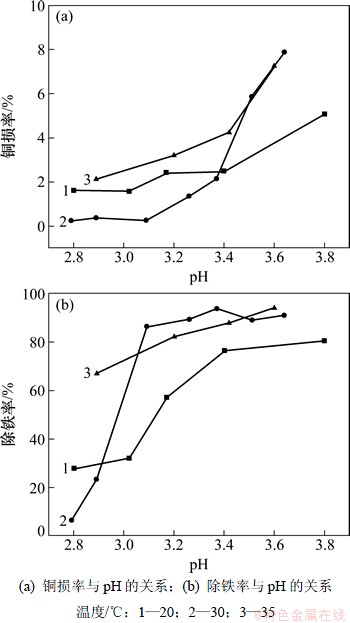

考察不同pH对铜损率和除铁率的影响,结果如图1所示。

由图1可知:铜损率和除铁率均随着pH的增大而增大。这是因为pH增大,Cu2+和Fe3+均出现不同程度的水解,在温度为30 ℃,控制pH在3.0~3.2之间时,除铁率达到80%以上,而铜损率在2%以下。因此,最佳除铁条件如下:温度为30 ℃,终点pH为3.0~3.2。

2.2 膜浓缩实验

2.2.1 超滤浓缩预处理

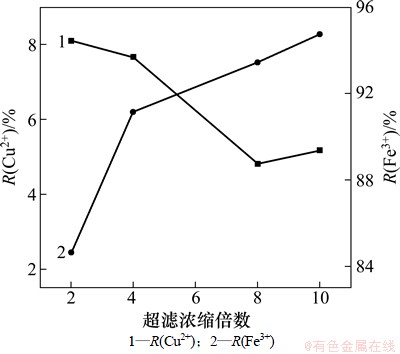

对滤袋过滤后的除铁液进行超滤浓缩,进一步去除除铁液中的悬浮颗粒及大部分胶体,超滤浓缩倍数对Cu2+和Fe3+截留率的影响如图2所示。

由图2可知:随着超滤浓缩倍数的增大,Cu2+截留率由8%变为5%,而Fe3+截留率逐渐增大。这是因为超滤膜孔径在0.001~0.02 μm之间,对金属离子没有截留作用;而超滤浓缩过程中浓缩液的pH逐渐升高,使得铁离子以Fe(OH)3胶体的形式析出,被超滤膜截留。

图1 不同温度下pH对铜损率及除铁率的影响

Fig. 1 Effects of pH on copper loss rate and iron removal rate at different temperatures

图2 超滤浓缩倍数对Cu2+和Fe3+截留率的影响

Fig. 2 Effects of ultrafiltration concentrating times on rejection of Cu2+ and Fe3+

2.2.2 纳滤浓缩富集铜

对预处理后的除铁液进行纳滤浓缩,考察进料压力、温度和浓缩倍数对纳滤分离效果的影响,得到纳滤较佳的运行条件。

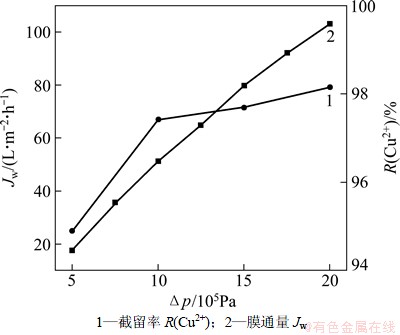

1) 运行压力对纳滤分离性能的影响。当温度为30 ℃、流量为18 L/min时,压力△p对纳滤通量Jw及铜离子截留率R的影响如图3所示。

图3 纳滤运行压力对膜通量及Cu2+截留率R(Cu2+)的影响

Fig. 3 Effects of nanofiltration operating pressure on flux and rejection of Cu2+

从图3可以看出:纳滤通量(Jw)随着进料压力的增大呈线性增长的趋势。这一现象可以用非平衡热力学模型解释:

(3)

(3)

式中:Lp为纯水透过系数(水渗透率),m·s-1·Pa-1;△p为膜两侧操作压力差,Pa;σ为膜反射系数;△π为膜两侧溶质渗透压力差。

由式(3)可知纳滤通量(Jw)和操作压力(△p)呈线性关系。纳滤是以压力为驱动力的分离过程,在低压区,纳滤通量(Jw)与操作压力(△p)呈正相关线性关系;从图3可以得到:随着运行压力的增大,铜离子截留率增大。考虑到能耗和经济性,选择压力为15×105 Pa为较佳进料压力,此时,Cu2+截留率达到98.27%。

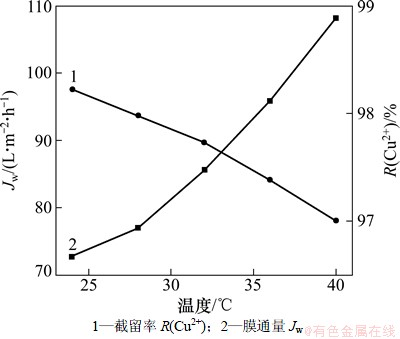

2) 运行温度对纳滤分离性能的影响。当压力为15×105 Pa、流量为18 L/min时,温度对纳滤通量Jw及铜离子截留率R的影响如图4所示。

由图4可以看出:温度对纳滤的分离性能影响较大,纳滤渗透通量Jw随着温度的增大而增大,而Cu2+截留率R(Cu2+)随着温度的增大而呈线性下降。这是因为温度升高,纳滤膜的膜孔会变得疏松,对料液的截留阻力减小,含有金属离子的盐分更易进入渗透液中。虽然温度的升高增加了单位时间内料液的处理量,但铜离子的截留率随之降低,并且纳滤膜是由高分子聚合物制备而成,温度过高导致膜孔疏松,甚至使其截留功能失效,影响纳滤膜的寿命。综合能耗及纳滤膜的温度使用范围,选择纳滤较佳操作温度为30 ℃。

图4 纳滤运行温度对膜通量Jw及Cu2+截留率R(Cu2+)的影响

Fig. 4 Effects of nanofiltration operating temperature on flux and rejection of Cu2+

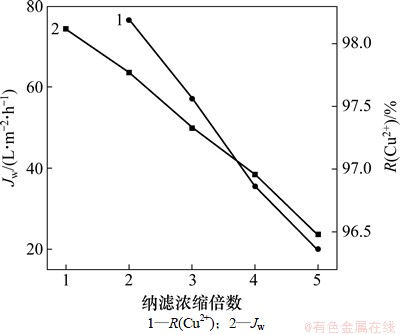

3) 纳滤浓缩倍数对纳滤分离性能的影响。当压力为15×105 Pa、温度为30 ℃、流量为18 L/min时,纳滤浓缩倍数对纳滤通量Jw及铜离子截留率R(Cu2+)的影响如图5所示。

图5 纳滤浓缩倍数对膜通量及Cu2+截留率R(Cu2+)的影响

Fig. 5 Effects of nanofiltration concentrating times on flux and rejection of Cu2+

由图5可知:膜通量(Jw)随着浓缩倍数(N)增加而降低。这一现象可用优先吸附-毛细孔流模型来解释:

(4)

(4)

(5)

(5)

由式(4)和式(5)可知:溶液质量浓度增大,溶液的渗透压(△π)也随之增大,从而膜通量(Jw)随之减小。因此,随着溶液质量浓度的增大,膜通量(Jw)会呈下降趋势。由图5可知:随纳滤浓缩倍数的增大,纳滤对铜离子截留率降低;当浓缩至理论倍数的5倍时,Jw为21.24 L/(m2·h),Cu2+截留率R(Cu2+)为96.3%。

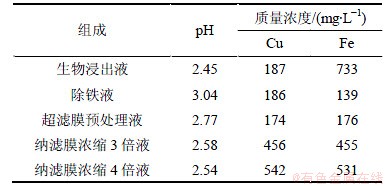

2.3 工业中试

在某铜矿堆浸厂,按照实验室最佳条件,对其生物浸出液进行中试放大实验(考虑工业生产实际情况,中和水解除铁时加入质量分数为1.5‰的聚丙烯酰胺(PAM)溶液使除铁渣快速沉降)。结果如表2所示。

表2 某铜矿生物浸出液中试结果

Table 2 Pilot-scale test results of bioleaching solution from a copper mine

由表2可知:调节pH为3.04中和水解除铁时,铜损率仅为0.42%,而除铁率高达80.97%;纳滤浓缩4倍后,Cu2+质量浓度由187 mg/L提高到542 mg/L,质量浓度提高近3倍;铜铁质量浓度比由原来的1:4提高到1:1,这对于减少萃取乳化现象及提高电积效率均有重要意义。

3 结论

1) 采用中和水解法对某铜矿生物浸出液进行除铁,除铁最佳条件如下:温度为30 ℃,终点pH为3.0~3.2。在此最佳条件下,铜损率低于2%,除铁率达到80%以上。

2) 除铁液经滤袋-超滤预处理后,除铁液中的Fe3+形成Fe(OH)3胶体被进一步去除,而Cu2+损失不大;纳滤浓缩最佳实验条件是:运行压力为15×105 Pa,温度为30 ℃,流量为18 L/min。在此条件下,对某铜矿堆浸厂的生物浸出液进行除铁和膜浓缩后,Cu2+质量浓度由187 mg/L提高到542 mg/L,质量浓度提高近3倍,且铜铁比由原来的1:4提高到1:1,这对于减少萃取乳化现象及提高电积效率均有重要意义。

参考文献:

[1] 袁城, 黄万抚, 邹莲花. 阳离子聚丙烯酰胺在湿法炼铜中的应用研究[J]. 有色金属科学与工程, 2012, 3(3): 40-42, 79.

YUAN Cheng, HUANG Wanwu, ZOU Lianhua. Applying cationic polyacrylamide to copper hydrometallurgy[J]. Nonferrous Metals Science and Engineering, 2012, 3(3): 40-42, 79.

[2] 刘媛媛. 谦比希湿法炼铜厂生产实践[J]. 中国有色冶金, 2009(4): 195-197.

LIU Yuanyuan. Production practice in Chambishi copper hydrometallurgy plant[J]. China Nonferrous Metallurgy, 2009(4): 195-197.

[3] 陈爱良, 邱冠周, 赵中伟, 等. 从含铜铁的生物浸出液中选择性萃取铜的试验研究[J]. 矿冶工程, 2008, 28(3): 76-80.

CHEN Ailiang, QIU Guanzhou, ZHAO Zhongwei, et al. Study on selective extraction of copper from bio-leaching solution containing copper and iron[J]. Mining and Metallurgical Engineering, 2008, 28(3): 76-80.

[4] 刘久清. 德兴铜矿湿法炼铜工艺现状及存在问题[J]. 湿法冶金, 2001, 20(3): 123-126, 132.

LIU Jiuqing. Status and problems of copper hydrometallurgy in Dexing copper mine[J]. Hydrometallurgy of China, 2001, 20(3): 123-126, 132.

[5] 朱永良. 热酸浸出-低污染沉矾工艺的生产实践[J]. 有色矿冶, 2014, 30(2): 38-42.

ZHU Yongliang. Hot acid leaching-low contamination alum precipitation production practice[J]. Nonferrous Mining and Metallurgy, 2014, 30(2): 38-42.

[6] 陈国宝, 杨洪英, 周立杰, 等. 针铁矿法从铜钴矿生物浸出液中除铁的研究[J]. 有色金属(冶炼部分), 2013(3): 1-3.

CHEN Guobao, YANG Hongying, ZHOU Lijie, et al. Study on goethite deironization from bioleaching solution of Cu-Co ore[J]. Nonferrous Metals (Extractive Metallurgy), 2013(3): 1-3.

[7] 岳明, 孙宁磊, 邹兴, 等. 锌浸出液三价铁直接水解赤铁矿法除铁的探讨[J]. 中国有色冶金, 2012(4): 80-85.

YUE Ming, SUN Ninglei, ZOU Xing, et al. The discussion on hydrolysis precipitation of ferric oxide directly from ferric-ion rich zinc leachate[J]. China Nonferrous Metallurgy, 2012(4): 80-85.

[8] 杨秋菊, 刘久清, 蒋彬, 等. 高铁低铜溶液磷酸盐除铁工艺[J]. 中南大学学报(自然科学版), 2012, 43(10): 3763-3768.

YANG Qiuju, LIU Jiuqing, JIANG Bin, et al. Technique of removing iron by phosphate in high iron-low copper solution[J]. Journal of Central South University (Science and Technology), 2012, 43(10): 3763-3768.

[9] 刘美荣, 周桂英, 温建康. 复杂微生物浸出液生物成矾法净化除铁的研究[J]. 稀有金属, 2012, 36(3): 459-465.

LIU Meirong, ZHOU Guiying, WEN Jiankang. Iron purification by formation of jarosite in complex bioleaching solution[J]. Chinese Journal of Rare Metals, 2012, 36(3): 459-465.

[10] 李国安, 饶先发. 电镀污泥中有价金属的湿法回收技术[J]. 世界有色金属, 2014(6): 37-39.

LI Guoan, RAO Xianfa. Hydrometallurgy recovery technology of valuable metals in electroplating sludge[J]. World Nonferrous Metals, 2014(6): 37-39.

[11] 杨亮, 赵中伟, 陈爱良, 等. 从钼酸铵溶液中除去砷的研究[J]. 中南大学学报(自然科学版), 2011, 42(8): 2193-2197.

YANG Liang, ZHAO Zhongwei, CHEN Ailiang, et al. Research on arsenic removal from ammonium molybdate solution[J]. Journal of Central South University (Science and Technology), 2011, 42(8): 2193-2197.

[12] Florian E, Modesti M, Ulbricht M. Preparation and characterization of novel solvent-resistant nanofiltration composite membranes based on crosslinked polyurethanes[J]. Ind Eng Chem Res, 2007, 46(14): 4891-4899.

[13] Sabba N, Akretche D E. Use of membranes in copper hydrometallurgy[J]. Desalination, 2006(193): 422-425.

[14] ZHOU Choumou, SHI Yalan, SUN Changsheng, et al. Thin-film composite membranes formed by interfacial polymerization with natural material sericin and trimesoyl chloride for nanofiltration[J]. J Memb Sci, 2014, 471(7): 381-391.

(编辑 陈灿华)

收稿日期:2014-04-30;修回日期:2014-06-22

基金项目(Foundation item):国家自然科学基金资助项目(20806094);湖南省自然科学基金资助项目(10JJ5007);长沙市科技局重点资助项目(K1403019-11)(Project(20806094) supported by the National Natural Science Foundation of China; Project(10JJ5007) supported by the Hunan Natural Science Foundation of China); Project(K1403019-11) supported by Key Plan on Science and Technology Bureau of Changsha, China)

通信作者:刘久清(1974-),男,江西广丰人,博士,副教授,从事膜制备和分离技术的研究;电话:0731-88836633;E-mail:jiuqing_liu@163.com