文章编号:1004-0609(2016)-04-0891-10

腰果壳油摩擦粉对树脂基摩擦材料性能的影响

刘伯威1, 2,匡湘铭2,刘 咏1,杨 阳2,唐 兵2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 湖南博云汽车制动材料有限公司,长沙 410205)

摘 要:腰果壳油摩擦粉是树脂基摩擦材料中广泛应用的摩擦性能调节剂。通过改变摩擦材料中腰果壳油摩擦粉组分含量,研究腰果壳油摩擦粉对树脂基摩擦材料的理化、机械、摩擦磨损及制动噪声性能的影响。结果表明:随着摩擦粉含量增加,摩擦材料的气孔率、压缩变形量增大,pH值、密度、硬度和冲击强度减小。通过执行SAE J2521和SAE J2522程序进行台架实验,表明摩擦粉的加入可提高并稳定摩擦材料的摩擦因数,同时有效降低刹车片制动过程噪声发生概率。摩擦材料中摩擦粉添加量7%(质量分数)时,摩擦材料冲击强度3.36 kJ/m2,名义摩擦因数0.36,平均磨损厚度0.53 mm,噪音发生概率为14.4%,刹车片综合性能最佳。

关键词:腰果壳油摩擦粉;树脂基;摩擦材料;摩擦磨损

中图分类号:TB333 文献标志码:A

随着汽车工业的发展,人们对车辆的运行速度、安全性、舒适度和环保化等提出了更高的要求。摩擦副的性能在某种程度上限制了汽车高速化与重载化的发展,因此进一步提高制动用摩擦材料(刹车片、闸片等)的综合性能对汽车工业发展具有重要意义[1-4]。树脂基摩擦材料是一种高分子多元复合材料,化学结构、凝聚态结构、交联网络和共混组分等具有灵活的可设计性,可满足当前的运行高速化、车体轻量化和负荷重载化等复杂制动工况。该材料由粘结剂(树脂与橡胶)、增强体和摩擦性能调节剂三大类组分及其他填料构成。粘结剂是将各摩擦材料组分粘结起来,增强体的主要作用是使材料具有一定的力学强度和韧性。摩擦性能调节剂用来改善和调节摩擦材料的性能,包括增摩剂、减摩剂和其他性能调节剂,在摩擦材料中可调节摩擦材料摩擦因数、耐磨、耐温性能和减少对对偶的损伤。其中摩擦粉是改善摩擦性能的有效组分[5-7]。由于腰果壳油摩擦粉成本低、性能优越, 国内外摩阻材料中已得到广泛应用,在盘式和鼓式刹车片用作稳定剂,作为改善摩擦性能和降低噪音有效组分[8-9]。

美国Cardolite公司于1939年发明用腰果壳油(Cashew)制造摩擦粉,20世纪40年代初被应用于摩擦材料中。腰果壳油摩擦粉是一种以腰果壳油为原料的高分子化合物,腰果壳油从腰果壳中柔软的蜂窝状结构中提取,是一种天然生物材料,为红褐色粘性液体,主要含有腰果酸和少量的腰果(间)二酚以及甲基衍生物[10]。腰果酸经过热处理脱羧可得到产物腰果酚。腰果酚可代替或部分代替苯酚用于制造环氧固化剂、液体酚醛树脂或粉末状的热固性酚醛树脂。和苯酚结构比较,腰果酚间位上带有一不饱和含15个碳原子烃基侧链,侧链上双键可发生聚合反应。受羟基和不饱和烃基链共轭作用影响,腰果酚核上羟基和烃基邻位及对位反应活性点得以保留。腰果酚经化学聚合反应,固化及高温处理,可生产具有优异黏弹性的有机摩擦粉。

近年来,国内专门研究腰果壳油摩擦粉或腰果壳液在摩擦材料中的应用报道很少,在国外研究较多。CHO等[11]研究了腰果壳油摩擦粉含量对摩擦材料硬度、气孔率和摩擦磨损性能的影响。研究表明摩擦材料配方中加入摩擦粉可降低摩擦材料的硬度,同时能稳定摩擦因数。但存在不足:腰果壳油摩擦粉耐热性差,350 ℃后会逐渐分解。JANG等[12]通过调整配方中树脂和腰果壳油摩擦粉两种有机成分含量进行分析。实验数据表明摩擦粉含量从10%提高到12%(体积分数),材料摩擦因数的波动幅度减小,更稳定。KIM等[13]将配方中腰果壳液含量由8%提高到24%(体积分数)后,摩擦材料硬度明显下降,气孔率、压缩率提高,摩擦过程中真实接触面积增大使摩擦因数提高。得出结论在配方中加入一定量腰果壳液,能使摩擦材料保持低硬度,高气孔率,有效降低刹车片噪声发生概率。到目前为止,几乎没有见到腰果壳油摩擦粉对摩擦材料整体性能尤其噪音性能影响的研究报道。本文作者系统地研究了腰果壳油摩擦粉含量对摩擦材料理化和力学性能的影响,且首次通过台架试验数据分析了其对摩擦材料摩擦磨损和噪音性能的影响,以期为研究高性能的汽车摩擦材料提供参考依据。

1 实验

1.1 摩擦粉的理化性质

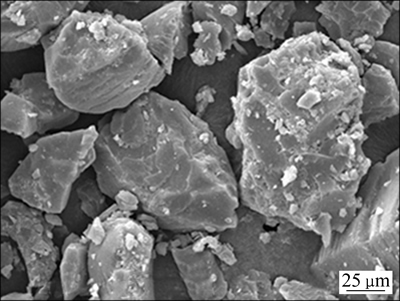

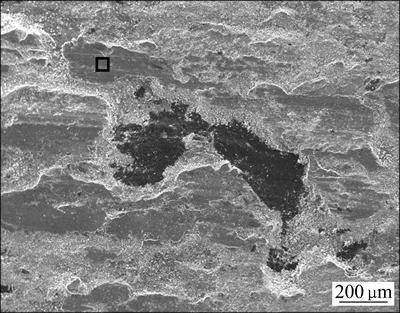

腰果壳油摩擦粉由卡德莱公司生产,全部过筛(孔径为380 μm),丙酮提取物结果≤2%(质量分数,下同),灰分结果≤3%,pH值为3,掺杂15%炭黑进行改性。其显微形貌如图1所示。

图1 腰果壳油摩擦粉SEM像

Fig. 1 SEM image of cashew dust

1.2 原料及试样配方

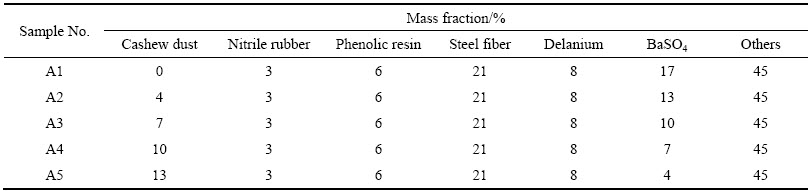

摩擦材料组分包括粘结剂、增强纤维、摩擦性能调节剂及填料等。具体配比列于表1,同时调节腰果壳油摩擦粉和沉淀BaSO4的含量以保证各组分总含量不变,配制A1、A2、A3、A4和A5试样,配方详见表1。其中腰果壳油摩擦粉在配方中含量变化为0~13%。沉淀BaSO4是一种在摩擦材料中广泛使用的低价填充料,莫氏硬度为3~3.5,化学性质稳定,属于重质填料,所占体积分数不大。对摩擦材料的摩擦磨损和噪声性能影响不明显。因此,5个基本配方中腰果壳油摩擦粉含量变化是影响摩擦材料制动性能变化主要因素。

1.3 刹车片制备和配方

根据表1的5个基本配方配料,用自制简易高速混料机混料,混料时间为3 min,混料机转速为1400 r/min。选择03款本田雅阁前(D465)刹车片作为样品型号,称量170 g混合料,在旺达JFY60型小型气压机上采用一次成型方式模压成型,压制温度为(160±5) ℃,压力为11.5 MPa,再经热处理、后续机加工制得成品。

1.4 热分析及性能测试

摩擦粉热质量损失在德国Netzsch公司生产的热重分析仪进行,样品质量10 mg,升温速率10 ℃/min,加热至1000 ℃,氮气为载气。

根据QC/T 583-1999汽车制动器衬片显气孔率试验方法,采用浸油法测量样品开孔气孔率。试样的硬度在HR-150A型洛氏硬度计上进行测量,压头为直径12.7 mm的钢球,施加力980 N。根据ISO 6310道路车辆制动衬片压缩应变试验方法,在美国Link公司生产的Model 1620型压缩性能试验机上,测试室温时刹车片样品16 MPa压缩载荷下的变形量,以此评价摩擦材料的可压缩性。冲击强度测试按GB 5763-2008在XCJ-4型冲击强度试验机上进行,试样尺寸为6 mm×10 mm×55 mm。根据JC/T 685-1998摩擦材料密度试验方法,采用阿基米德原理排水称量法测量刹车片样品的密度。根据JASO C458-1986汽车制动衬片、制动块和离合器表面pH值试验规程,用pH计测量摩擦材料的pH值。摩擦磨损性能测试按照程序SAE J2522,在美国LINK 3000型惯性台架试验机上进行,刹车片样品安装在1/4制动器总成上,采用液压制动方式,测试摩擦材料样品在不同制动速度、制动压力、制动温度下摩擦性能的变化情况。采用日本JSM-6490LV型扫描电子显微镜,对试验后的摩擦块样品表面形貌进行分析,并采用Phoenix EDAX 2000型能谱分析仪(EDX)对摩擦块样品表面进行成分分析。摩擦材料制动噪声测试按照程序SAE J2521,在美国LINK 3900型NVH惯量实验台上进行,测试制动速度、制动压力、制动温度及制动方向等试验条件对制动噪声发生的影响。

表1 摩擦材料的基本成分

Table 1 Basic composition of friction material

2 结果与分析

2.1 腰果壳油摩擦粉热重分析

热重分析是指在程序控制温度下测量待测样品的质量与温度变化关系的一种热分析技术,用来研究材料的热稳定性和组份。汽车在高速度、高负荷、高频次刹车时,刹车片的温度急剧升高,会造成材料中的有机物如树脂、摩擦粉等分解,产生水、气体小分子以及有机成分分解后残留在摩擦材料表面形成润滑膜,致使摩擦因数急剧降低,引起高温衰退,降低刹车效能[14]。因此,进行腰果壳油摩擦粉的差热-热重分析对研究摩擦材料在制动过程中的热变化具有重要意义。

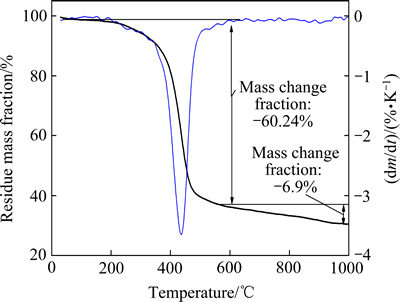

图2所示为摩擦粉在N2氛围下的TG-DTG曲线,TG曲线表示样品质量的变化,DTG是TG的一次微分曲线。摩擦粉主要有3个质量损失区,第一质量损失区200 ℃以前可认为是由脱水引起的质量损失峰;然后在380~553 ℃范围内质量损失明显,此阶段为主质量损失区,说明腰果壳油摩擦粉在此温度段发生了剧烈的裂解反应。据文献[15]报道:此温度范围,芳香环上侧链—C15H13碳链结构发生断裂生成甲烷、丙烷、丁烷等气体。侧链断裂后芳香环结构有甲基酚、甲苯、二甲苯、乙基甲苯和二甲苯酚等物质,同时苯、甲苯、苯酚等逸出量随着温度的升高会急剧增加,进一步发生链断和解聚反应;第三质量损失区是裂解后期即炭化阶段。最后固体残留量约为32%。通过图2分析得到摩擦粉样品热分解温度在380 ℃以上。相比较而言,本试验所用摩擦粉其耐热性能高于摩擦材料中的其他有机组分,如酚醛树脂、丁腈橡胶等。这是因为所用摩擦粉是掺杂纳米炭黑进行了改性,其热分解温度提高。纳米炭黑因其特殊的小尺寸效应本身具有良好的耐高温性能,又是一种良好的热导体,腰果壳油摩擦粉通过纳米炭黑进行改性后,摩擦材料在高温下可将产生的热量通过纳米炭导出,有利于摩擦面热量的扩散,降低了局部高温而起到保护作用[16-18]。

图2 腰果壳油摩擦粉在氮气氛围中的TG-DTG曲线

Fig. 2 TG-DTG curves of cashew dust in nitrogen atmosphere

2.2 腰果壳油摩擦粉含量对摩擦材料理化性能的影响

表2所列为不同摩擦粉含量对摩擦材料理化性能的影响。由表2可知,摩擦粉含量增加,摩擦材料的pH值略有降低,原因是腰果壳油摩擦粉的pH值为3,显酸性,而其替代物是中性的硫酸钡,所以随摩擦粉含量的增加,摩擦材料的pH值逐渐降低。摩擦材料的密度随摩擦粉含量的增加而减小,这是因为腰果壳油摩擦粉的密度为 1.10~1.15 g/cm3,小于替代物硫酸钡密度(4.5 g/cm3)。因此,随着腰果壳油摩擦粉的加入,摩擦材料的密度降低。

摩擦材料的气孔由开、闭口气孔两部分组成。能被液体填充的,称开口气孔,而闭口气孔则不能被液体填充。开、闭口气孔两者所充气体之和与试样总体积的比值,称为真气孔率,开口气孔体积与总体积的比值为显气孔率。通常只测定显气孔率,简称气孔率。表2中摩擦材料气孔率随摩擦粉含量的增加先显著增大后趋于稳定。腰果壳油摩擦粉的形貌如图1所示,其表面粗糙疏松,且因其特殊的空间结构而具有一定的弹性和韧性,热膨胀系数大,在1×10-4 m/K以上。混合料在经热压和热处理制成摩擦材料的过程中,摩擦粉会有一定的热形变,由于其热膨胀系数比其他组分的大得多,所以受热后比摩擦材料中其他组分体积膨胀更大,而在冷却过程中,因膨胀系数不同,导致摩擦粉和其他组分间形成空隙,因此气孔率增大。

表2 不同摩擦粉含量试样的理化性能

Table 2 Physical and chemical properties of samples with different cashew dust contents

2.3 腰果壳油摩擦粉含量对摩擦材料力学性能的影响

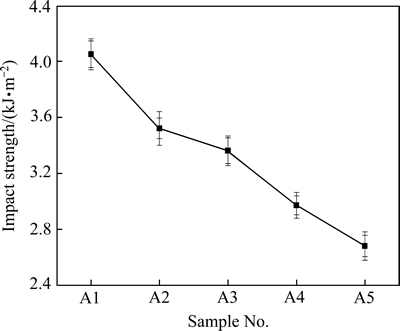

图3所示为不同含量的摩擦粉对摩擦材料冲击强度的影响。冲击强度数值误差在±0.12内,从图3中可看出加入摩擦粉后摩擦材料冲击强度呈减小趋势。原因有二点:一是腰果壳油摩擦粉是完全固化后的树脂化合物,并经过纳米炭黑改性,活性基团被封锁,与摩擦材料中的其他组分不能形成有效化学键[19-20];二是加入摩擦粉后摩擦材料体积密度逐渐变小,摩擦块气孔率增大,内部气孔增加,因而材料结构强度降低。

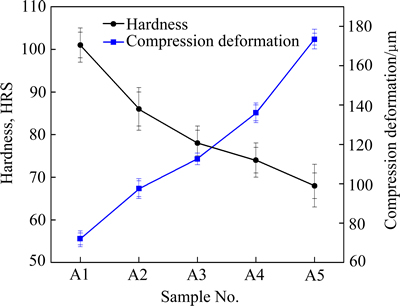

腰果壳油摩擦粉含量对摩擦材料的硬度和压缩变形量的影响如图4所示。摩擦粉因其特殊的结构,韧性大、弹性好,类似于橡胶颗粒,因而随着摩擦粉含量的增加,摩擦材料的体积密度降低,气孔率增大,在洛氏硬度测试中摩擦材料表现出弹性变形能力越强,测试出来的硬度值越低。刹车片的硬度对摩擦对偶的压紧力大小有一定的匹配性,在满足制动工况的前提下,刹车片的硬度以低为好,对降低对偶磨损,改善制动的平稳性和舒适性有益。摩擦材料的压缩变形量与硬度呈反比关系,硬度越低,在外载荷作用下变形量越大。因此,随着摩擦粉含量的增加,材料的压缩变形量增大。

图3 不同摩擦粉含量试样的冲击强度

Fig. 3 Impact strength of samples with different cashew dust contents

图4 不同摩擦粉含量试样的硬度和压缩变形量

Fig. 4 Hardness and compression deformation of samples with different cashew dust contents

2.4 腰果壳油摩擦粉含量对摩擦材料摩擦和磨损性能的影响

执行SAE J2522标准考察摩擦材料在不同制动速度、制动压力、制动温度下摩擦性能的变化情况。因试验数据较多,本文作者只对名义摩擦因数和最低摩擦因数进行分析讨论,并具体分析刹车片第一次高温衰退时摩擦因数随摩擦粉含量的变化情况,讨论摩擦粉在摩擦材料使用过程中的热变化。

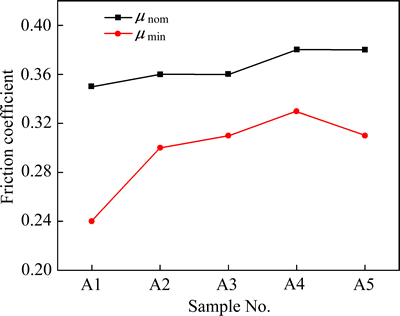

2.4.1 摩擦粉含量对摩擦材料名义摩擦因数和最低摩擦因数的影响

图5所示为摩擦粉含量对摩擦材料名义摩擦因数(μnom)和最低摩擦因数(μmin)的影响。随着摩擦粉含量的增加,试样的名义摩擦因数逐渐增大后稳定在0.38。最低摩擦因数先增大后减小。名义摩擦因数体现了摩擦材料的整体摩擦因数水平,最低摩擦因数则代表了材料的抗热衰退能力。由图5可知,添加腰果壳油摩擦粉的试样A2、A3、A4和A5名义摩擦因数和最低摩擦因数都大于未添加摩擦粉试样A1的。因为同摩擦材料其他组分相比,腰果壳油摩擦粉的结构中有长的脂肪链,使其具有良好的柔韧性、延展性和易变形性,因而在刹车工况下能增加摩擦材料的真实接触面积,与摩擦对偶件贴合性良好。

图5 不同摩擦粉含量试样的摩擦因数

Fig. 5 Friction coefficients of samples with different cashew dust contents

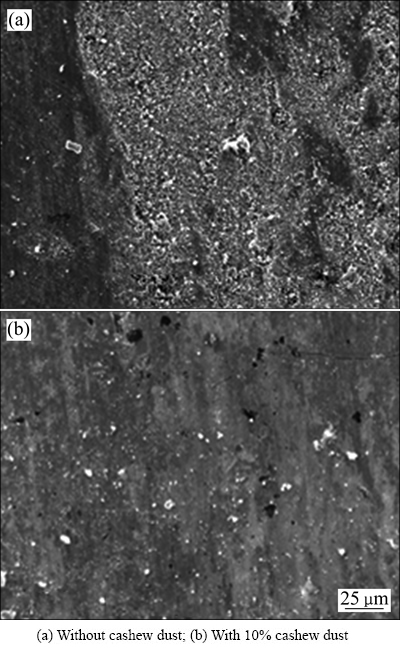

图6所示分别为含0和10%(质量分数)摩擦粉的A1和A4试样在执行SAE J2522试验标准后摩擦面的形貌特征。从图6(a)可见,摩擦表面凹凸不平,没有摩擦膜出现,摩擦副主要以微凸体接触为主,摩擦力来源于磨粒的犁削力,因而材料的名义摩擦因数和最低摩擦因数都低。从图6(b)可见,试样表面摩擦膜完整均匀,摩擦力主要来源于摩擦膜的粘着作用。由于摩擦副的真实接触面积大,产生的粘着力也大,因而名义摩擦因数和最低摩擦因数都高。同时结合摩擦粉的热质量损失曲线分析可知,本研究所用摩擦粉耐热性良好,380 ℃以下不发生结构分解。因此,摩擦材料中加入摩擦粉可改善制动对速度的过分敏感,保持制动的平稳性,提高摩擦因数[21-22]。当摩擦粉含量继续增加到13%时,材料的最低摩擦因数降低,这是因为摩擦材料中的摩擦粉因含量过多而形成磨屑,被空气氧化分解,释放出小分子和水等,在摩擦面上形成润滑膜,降低摩擦材料的摩擦因数。

图6 不同试样摩擦表面形貌

Fig. 6 Friction surface morphologies of different samples

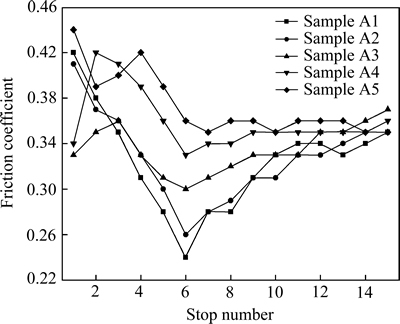

2.4.2 摩擦粉含量对摩擦材料抗热衰退性能的影响

通过分析不同含量摩擦粉试样在第一次衰退过程中摩擦因数的变化曲线,可进一步了解腰果壳油摩擦粉的热稳定性对刹车片高温摩擦因数的影响。不同含量摩擦粉对摩擦材料在一衰过程中摩擦因数的影响如图7所示。从图7中曲线分析,5个试样的摩擦因数整体趋势是衰退初期降低,在第6次左右制动时摩擦因数达到最低点,然后逐渐升高或趋于平稳。其中没有添加摩擦粉的试样A1在第6次制动时摩擦因数为0.24,为最小值。而随着摩擦粉含量的增加,从试样A2至A5,最小摩擦因数依次升高,试样A5的最小摩擦因数为0.35,为最大值。这表明本研究中所使用的经纳米炭黑改性的腰果壳油摩擦粉可提高摩擦材料的抗热衰退性能。

在执行SAE J2522标准进行第一次衰退试验中,第6次制动时要求制动盘的初温为400 ℃,刹车后盘的温度会升高到500 ℃以上,此时摩擦块的表面温度也基本上接近500 ℃。在500 ℃的高温下,摩擦材料中的有机成分会急速分解,如酚醛树脂和摩擦粉等裂解产生甲苯、二甲苯等芳香族化合物,同时也释放出甲烷、丙烷等小分子,以及因氧化燃烧而产生水、二氧化碳等气体,这些物质一部分散逸到空气中,一部分留在摩擦材料的表面而形成润滑性能良好的油膜,从而显著降低摩擦因数。

图7 不同摩擦粉含量试样在第一次衰退程序摩擦因数的变化曲线

Fig. 7 Friction coefficient of samples with different cashew dust contents in Fade 1

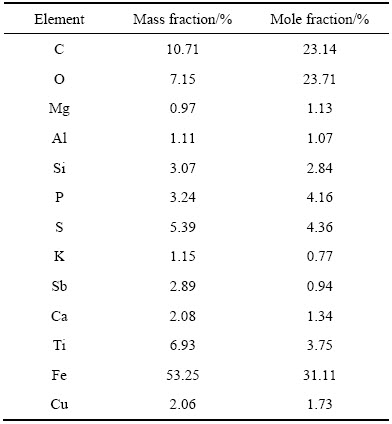

添加10%摩擦粉的试样A4在执行SAE J2522标准试验后其摩擦面的SEM像和能谱分析分别如图8和表3所示。由图8和表3可见,Fe元素在表面成分中占到53.25%,Ti元素达到6.93%,远高于原配方中Fe和Ti元素的含量,这说明高温下材料中的有机物被分解成小分子挥发掉或被氧化,留下的主要是金属成分或其他非挥发性的无机物。

图8 试样A4在执行SAE J2522程序后SEM像

Fig. 8 SEM image of sample A4 after SAE J2522 test

表3 试样A4在执行SAE J2522程序后的能谱分析

Table 3 EDAX analysis of sample A4 after SAE J2522 test

在第一次衰退程序的后期,A4和A5摩擦材料的摩擦因数没有大的波动,较平稳。这是因为在经历过高温后,多余的有机物被氧化挥发,残存在摩擦面上的残炭物与其他的磨屑产生协同作用,形成稳定的摩擦膜,增加了与对偶件的真实接触面积,因而保证了制动的平稳性,摩擦因数基本保持不变。试样A1、A2、A3、A4和A5的摩擦因数波动范围分别为0.24~0.42、0.26~0.41、0.30~0.37、0.33~0.42和0.35~0.44,摩擦因数波动幅度 Δμ分别为 0.18、0.15、0.07、0.09和0.09,其中试样A3的Δμ最小,而试样A1的摩擦材料中没有加入摩擦粉,波动幅度最大。结果表明:加入摩擦粉后,摩擦材料的摩擦因数波动幅度变小,摩擦因数更稳定,制动更平稳。

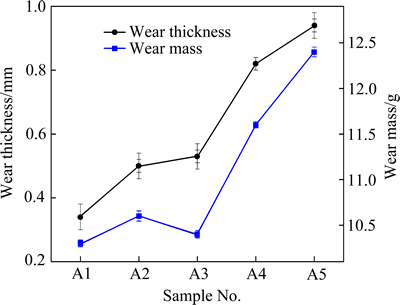

2.4.3 腰果壳油摩擦粉含量对摩擦材料磨损性能的影响

图9表明随着摩擦粉含量的增加,摩擦材料的厚度和质量磨损增大,相比较摩擦材料中沉淀BaSO4组分,腰果壳油摩擦粉分解温度低,380 ℃后逐渐分解,所以加入腰果壳油摩擦粉,会加大摩擦材料的磨损。总体来说,摩擦材料在低温时以磨粒磨损和粘着磨损为主,在320 ℃以上高温时摩擦粉、橡胶粉和酚醛树脂等有机物开始热分解,犁切磨损和疲劳磨损有所增加[23-24]。摩擦粉同摩擦材料其他组分粘结性差,也是摩擦磨损增大的一个原因。试样A3和A2比较,试样A3的磨损厚度比试样A2的大,磨损质量却相反,这是因为摩擦块A3的密度要比A2的小。综合考虑摩擦材料力学和摩擦磨损性能。腰果壳油摩擦粉的加入量以7%时比较适宜,此时摩擦材料冲击强度为3.36 kJ/m2,名义摩擦因数0.36,磨损厚度0.53 mm。

图9 不同摩擦粉含量试样的磨损厚度及磨损质量

Fig. 9 Wear thickness and wear mass of samples with different cashew dust

2.5 腰果壳油摩擦粉含量对摩擦材料制动噪声的影响

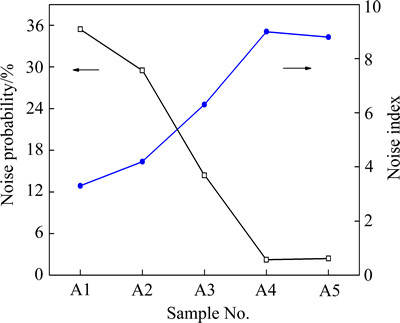

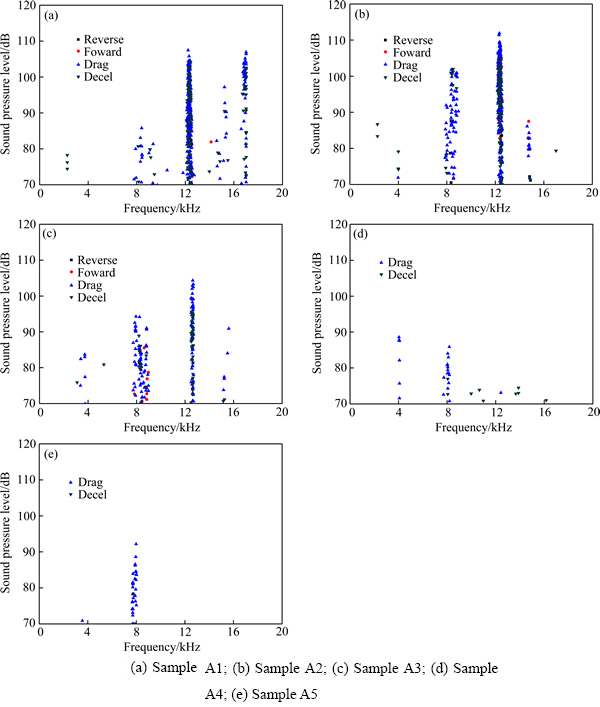

执行SAE J2521噪声试验标准考察摩擦材料在不同制动速度、制动温度、制动压力、制动方向等试验条件下,摩擦材料制动噪声的发生情况。本研究的刹车片型号为03款本田雅阁前片,试验制动器类型为不带悬架的1/4总成,因此将声音频率范围为2000~ 17000 Hz,分贝值为70 dB以上的制动声音记为制动噪声。不同摩擦粉含量的摩擦材料制动噪声发生概率、评分及制动噪声频率分布情况如图10和图11所示。

由图10可知,当摩擦粉的含量由0增加到13%时,制动噪声的发生概率逐渐降低后趋于稳定,相应的综合评分升高。当摩擦粉含量为10%时,制动噪声发生概率2.2%,为最低值,噪声评分9.0分,为最高值。

图10 不同摩擦粉含量试样的制动噪声发生概率及评分值

Fig. 10 Brake noise probability of occurrence and noise index of samples with different cashew dust contents

图11 不同摩擦粉含量试样制动噪声发生情况

Fig. 11 Brake noise occurrence of samples with different cashew dust contents

由图11可看出,试样A1在正转、反转、减速和拖磨程序段都出现制动噪声,在12400 Hz和17000 Hz出现多次且噪声强度高达110 dB的尖叫声。添加摩擦粉的各个试样,在正反转、减速过程中的噪声减少,试样A5只在拖磨过程中出现噪声。各个试样的噪声出现主要频段在8000 Hz、12400 Hz和17000 Hz附近。随着摩擦粉含量增加,8000 Hz频段的噪声先增加后降低;12400 Hz和17000 Hz两个频段的噪声概率和强度都降低,这说明加入摩擦粉对降低这两个频率段的噪声发生有改善作用

[25]。

综合分析图10和图11可知,腰果壳油摩擦粉的加入可以有效降低摩擦材料制动噪声的发生概率和强度。主要原因是摩擦材料中的酚醛树脂、丁腈橡胶等有机物在320 ℃及以上的温度会出现大量分解氧化,导致摩擦因数急剧下降,制动力矩降低,刹车出现打滑、粘啃和表面不平等现象,因而产生不同程度的噪声;在多次刹车后的高压和高温的双重作用下,其表层出现硬化、碳化等异化现象,使得摩擦材料中硬度较高的材料对刹车对偶件工作面的损伤加大,摩擦层失去原有的特性,整个摩擦扭矩下降。本研究所加入的改性腰果壳油摩擦粉在380 ℃以上才开始分解,由于其较大的热膨胀系数,增大了真实接触面积,稳定了刹车扭矩,因此可以减少制动噪声的产生;同时腰果壳油摩擦粉由于其化学结构具有优异弹性和高塑性,及热膨胀系数的不匹配性,其添加可有效提高摩擦材料的气孔率,吸收摩擦振动、减小噪声的发生概率。

3 结论

1) 腰果壳油摩擦粉作为树脂基摩擦材料性能组分,随着其含量的增加,摩擦材料的气孔率、压缩变形量增大,密度、硬度和冲击强度减小,同时摩擦材料pH值呈减小趋势。

2) 添加经纳米炭黑改性的腰果壳油摩擦粉,摩擦材料的名义摩擦因数和磨损率呈现出一致升高趋势,而最低摩擦因数先升高后降低,添加量10%(质量分数)左右出现拐点。

3) 随着腰果壳油摩擦粉含量的增加,制动噪声发生概率和噪声强度降低,并且高频率噪声逐渐消失。添加量超过10%后,噪声发生概率值趋于平稳。

4) 摩擦材料中腰果壳油摩擦粉的添加量以7%左右为宜,材料的力学性能好,摩擦磨损性能优异,制动噪声发生概率低。

REFERENCES

[1] THAKARE M R, WHARTON J A, WOOD R J K, MENGER C. Effect of abrasive particle size and the influence of micro structure on the wear mechanisms in wear-resistant materials[J]. Wear, 2012, 276/277(4): 16-28.

[2] CHAN D, STACHOWIAK G W. Review of automotive brake friction materials[J]. Institution of Mechanical Engineers: Journal of Automobile Engineering, 2004, 218: 953-966.

[3] VUKOLO L A. Investigation of brake blocks made of update composite frictional materials[J]. Friction and Wear, 1995, 16(1): 78-82.

[4] 欧阳鸿武, 张 新, 陈 欣, 余文焘. 粉末冶金盘式汽车摩擦片热压成形的数值模拟与实验研究[J]. 中国有色金属学报, 2005, 15(4): 531-535.

OUYANG Hong-wu, ZHANG Xin, CHEN Xin, YU Wen-tao. Numerical and experimental study on hot press of powder metallurgical disk brake pad[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 531-535.

[5] 高喜军, 尚文博, 高知辉, 王虎彪, 刘玉成, 沈生龙, 马云海. 碳纤维增强摩擦材料的设计与研究[J]. 材料导报, 2015, 29(1): 82-86.

GONG Xi-jun, SHANG Wen-bo, GAO Zhi-hui, WANG Hu-biao, LIU Yu-cheng, SHEN Sheng-long, MA Yun-hai. Design and research of carbon fiber reinforced friction materials[J]. Materials Review, 2015, 29(1): 82-86.

[6] LEE P W, FILIP P. Friction and wear of Cu-free and Sb-free environmental friendly automotive brake materials[J]. Wear, 2013, 302(1/2): 1404-1413.

[7] HO S C, CHERN L J H, JU C P. Effect of fiber addition on mechanical and tribological properties of a copper/phenolic- based friction material[J]. Wear, 2005, 258: 861-869.

[8] CHUNG K, HONG Y. Friction and wear properties of scrap tire/potassium hexatitanate whisker composites[J]. Journal of Industrial and Engineering Chemistry, 2013, 19: 1234-1240.

[9] 赵 剑, 卫 民, 蒋剑春. 腰果壳油改性摩擦材料用酚醛树脂的研究进展[J]. 生物质化学工程, 2011, 45(3): 47-52.

ZHAO Jian, WEI Min, JIANG Jian-chun. The state of the art of friction materials from phenol formaldehyde resin modified with cashew nut shell liquid[J]. Biomass Chemical Engineering, 2011, 45(3): 47-52.

[10] 刘国际, 张 勇, 刘 伟, 雒廷亮, 徐 丽. 腰果酚的应用研究进展[J]. 材料导报, 2012, 26(5): 90-94.

LIU Guo-ji, ZHANG Yong, LIU Wei, LUO Ting-liang, XU Li. Research progress on application of cardanol[J]. Materials Review, 2012, 26(5): 90-94.

[11] CHO M Y, KIM S J, KIM D, JANG H. Effects of ingredients on tribological characteristics of a brake lining: An experimental case study[J]. Wear, 2005, 258(11): 1682-1687.

[12] JANG H, LEE J S, FASH J W. Compositional effects of the brake friction material on creep groan phenomena[J]. Wear, 2001, 251: 1477-1483.

[13] KIM Y C, CHO M H, KIM S J, JANG H. The effect of phenolic resin, potassium titanat, and CNSL on the tribological properties of brake friction materials[J]. Wear, 2008, 264(3/4): 204-210.

[14] BIJWE J, NIDHI, MAJUMDAR N, SATAPATHY B K. Influence of modified phenolic resins on the fade and recovery behavior of friction materials[J]. Wear, 2005, 259: 1068-1078.

[15] 戴 燕, 谭卫红, 胡立红, 马 艳, 蔡燕燕. TG-DSC-MS联用研究不同气氛下腰果壳油改性热塑性酚醛树脂的热裂解特性[J]. 分析测试学报, 2013, 33(4): 387-394.

DAI Yan, TAN Wei-hong, HU Li-hong, MA Yan, CAI Yan-yan. Investigation on thermal decomposition behaviors of cashew nut shell liquid modified thermoplastic phenolic resin by TG-DSC-MS coupling techniques at different atmospheres[J]. Journal of Instrumental Analysis, 2013, 33(4): 387-394.

[16] CHOI M H, CHUNG I J, LEE J D. Morphology and curing behaviors of phenolic resin-layered silicate nanocomposites prepared by melt intercalation[J]. Chemistry of Materials, 2000, 12(10): 2977-2983.

[17] 赵小玲, 齐暑华, 杨 辉, 张 剑, 杨贵忠. 高性能化改性酚醛树脂的研究进展[J]. 工程塑料应用, 2003, 31(11): 63-66.

ZHAO Xiao-ling, QI Shu-hua, YANG Hui, ZHANG Jian, YANG Gui-zhong. Advance in the research of the modified phenolic resin with high property[J]. Engineering Plastics Application, 2003, 31(11): 63-66.

[18] 黄俊钦, 林有希. 耐高温改性酚醛树脂基复合摩擦材料研究进展[J]. 工程塑料应用, 2014, 42(1): 116-120.

HUANG Jun-qin, LIN You-xi. Research progress on high temperature resistant modified phenolic resin matrix composite friction materials[J]. Engineering Plastics Application, 2014, 42(1): 116-120.

[19] GOPAL P, DHARANI L R, BLUM F D. Load, speed and temperature sensitivities of a carbon-fiber-reinforced phenolic material[J]. Wear, 1995, 181/183: 913-921.

[20] 王 璐, 苏 堤. 偶联剂改性硅灰棉对树脂基摩擦材料摩擦学性能的影响[J]. 粉末冶金材料科学与工程, 2014, 19(1): 71-76.

WANG Lu, SU Di. Effect of coupling modified silica fume cotton on the tribology capability of resin-based friction materials[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(1): 71-76.

[21] 吴 斌. 新型缩比惯性台架的研制及试验方法的研究[D]. 长春: 吉林大学, 2012: 1-79.

WU Bin. New development of scale test machine and the research of test method[D]. Changchun: Jilin University, 2012, 1-79.

[22] HANDA Y, KATC T. Effect of Cu powder, BaSO4 and cashew dust on the wear and friction characteristics of automotive brake pads[J]. Tribology Transactions, 1996, 39(2): 346-353.

[23] 葛 波, 何春霞, 刘军恒, 徐伟悦, 陆德荣. 碳粉粒度对腰果壳油改性PF基摩擦材料性能的影响[J]. 工程塑料应用, 2015, 43(5): 7-12.

GE Bo, HE Chun-xia, LIU Jun-heng, XU Wei-yue, LU De-rong. Effect of particle size of carbon powder on properties of cashew nut oil modified phenolic resin matrix friction materials[J]. Engineering Plastics Application, 2015, 43(5): 7-12.

[24] 周海滨, 姚萍屏, 肖叶龙, 张忠义, 陈凌寒, 贡太敏, 赵 林, 左晓婷. SiC颗粒强化铜基粉末冶金摩擦材料的表面形貌特征及磨损机理[J]. 中国有色金属学报, 2014, 24(9): 2272-2279.

ZHOU Hai-bin, YAO Ping-ping, XIAO Ye-long, ZHANG Zhong-yi, CHEN Ling-han, GONG Tai-min, ZHAO Lin, ZUO Xiao-ting. Characteristics and wear mechanism of copper-based powder metallurgy friction materials reinforced by SiC particle[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2272-2279.

[25] 周 伟. SAE J2521在轻型车盘式制动器噪声分析中的应用[J]. 装备制造技术, 2013, 11: 193-194, 213.

ZHOU Wei. Application of SAE J2521 in the noise analysis of light-duty car disc brake[J]. Equipment Manufacturing Technology, 2013, 11: 193-194, 213.

Effects of cashew dust on performances of resin-based friction material

LIU Bo-wei1, 2, KUANG Xiang-ming2, LIU Yon1, YANG Yang2, TANG Bing2

(1. State Key Laboratory of Powder Metallurgy,Central South University, Changsha 410083, China;

2. Hunan Boyun Automobile Brake Material Co., LTD., Changsha 410205, China)

Abstract: Cashew dust is a very important organic filler in the friction materials industry due to its respective characteristic. The effects of cashew dust on physical, chemical, friction, wear and noise performances of resin-based friction material were studied. The results show that apparent porosity and compression deformation of friction material are improved, as well as pH, density, hardness and impact strength are reduced with the increase of cashew dust content. The results of bench test using SAE J2521 and SAE J2522 test procedure show that the use of cashew dust makes stability of friction coefficient become more stable or friction coefficient become higher, which can reduce probability of noise occurrence during the braking period. Through analyzing the experimental results, when the content of cashew dust is 7% (mass fraction), the overall properties of friction material are the optimum: the impact strength is 3.36 kJ/m2, the average coefficient of friction is 0.36, the thickness loss is 0.53 mm, the noise frequency is 14.4%.

Key words: cashew dust; resin based; friction material; friction and wear

Foundation item: Project(621020009) supported by the State Key Laboratory’ Special Foundation

Received date: 2015-10-29; Accepted date: 2016-04-05

Corresponding author: LIU Bo-wei; Tel: +86-731-88122568; E-mail: kuangxiangming1988@163.com

(编辑 王 超)

基金项目:国家重点实验室专项经费(621020009)

收稿日期:2015-10-29;修订日期:2016-04-05

通信作者:刘伯威,副教授;电话:0731-88122568;E-mail: kuangxiangming1988@163.com