文章编号:1004-0609(2013)S1-s0408-05

热处理对温拉拔TiNi合金丝相变和记忆功能的影响

王 健,金 伟,刘羽寅

(中国科学院 金属研究所,沈阳 110016)

摘 要:通过示差扫描量热仪、电子拉伸机研究热处理对温拉拔态Ti-49.8%Ni合金丝相变、拉伸性能和记忆效应的影响。结果表明:在低于450 ℃进行热处理,合金丝降温时发生独立的R相变和马氏体相变;热处理温度达到500 ℃,在降温过程中R相变消失,只发生马氏体相变。温拉拔态合金丝室温抗拉强度超过1 540 MPa。与马氏体相比,合金丝在母相状态下变形能够获得更高的恢复应变和恢复应力,母相状态下变形量达到12%时恢复应变超过8%;变形量16%时恢复应力为602 MPa。

关键词:TiNi合金;温拉拔;热处理;拉伸性能;恢复应变;恢复应力

中图分类号:TG156 文献标志码:A

Effects of heat treatment on transformation and memory function of warm-drawn TiNi alloy wire

WANG Jian, JIN Wei, LIU Yu-yin

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The effects of the heat treatment on transformation, tensile property and shape memory effects for Ti-49.8Ni warm-drawn wire were investigated by differential scanning calorimeter (DSC) and electronic tensile machine. The results show that R phase and martensitic phase transformations have occurred respectively during cooling course when the heat treatment temperature is lower than 450 ℃, and A→M transformation happens without A→R transformation on cooling course when the heat treatment temperature came up to 500 ℃. The tensile strength exceeds 1 540 MPa for the warm-drawing alloy wire. The recovery strain and the recovery stress are higher than those of the martensitic phase, when deformed at austenitic phase stage, the recovery strain exceeds 8% with deformation amount of 12%, and the recovery stress reaches 602 MPa with deformation amount of 16%.

Key words: TiNi alloy; warm-drawn; heat treatment; tensile properties; recovery strain; recovery stress

TiNi形状记忆合金因其良好的力学性能和记忆功能而得到广泛应用[1-5],随着装备制造技术的不断进步,对TiNi合金元件的力学性能和形状记忆功能提出了更高要求。目前,国内学者对直径大于0.5 mm的TiNi合金丝、棒材进行了大量研究[6-9]。而关于直径小于0.5 mm的TiNi合金细丝的性能报道很少。在国外,TiNi细丝已经在空间机敏机构中得到了应用[10]。本文作者选用TiNi合金的名义成分为Ti-49.8%Ni,采用温拉拔工艺制备出直径为0.3 mm,抗拉强度超过1 540 MPa的高强TiNi合金细丝,研究热处理对其拉伸性能和记忆功能的影响。

1 实验

以纯度为99.7%的海绵Ti和99.9%的电解Ni为原料,采用真空感应熔炼,锭型为10 kg。铸锭经锻造、轧制、最终温拉拔成d 0.3 mm的丝材。通过示差扫描量热仪测定热处理后合金丝的相变过程,升、降温速率为20 ℃/min,用切线法在DSC曲线上确定相变温度。在电子试验机上测定拉拔态和热处理态合金丝在不同温度下的拉伸性能;通过改变预变形温度测定合金丝在母相及马氏体相状态下的恢复应变和恢复应力,应变速率为5×10–4 s-1。

2 结果与分析

2.1 热处理温度对相变行为的影响

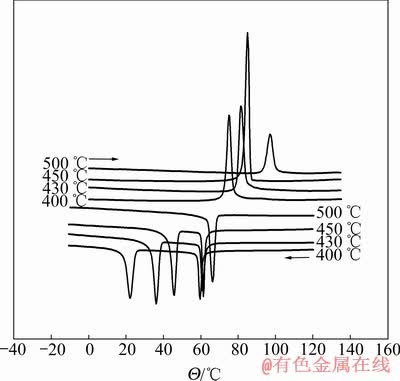

Ti-49.8Ni合金分别于真空加热至400、430、450和500 ℃,然后进行空冷处理,其DSC曲线如图1所示。

图1 热处理态Ti-49.8Ni丝的DSC曲线

Fig. 1 DSC curves of heat-treated Ti-49.8Ni wire

由图1可知,Ti-49.8Ni合金丝经热处理后,在-20~140 ℃冷却/加热时出现尖锐的相变峰。热处理温度不超过450 ℃,合金丝降温时发生独立的R相变和马氏体相变;随着热处理温度升高,合金丝内部回复过程加快,缺陷密度降低,其周围形成的应力场对马氏体相变阻碍减小,因而马氏体相变温度迅速提高,而R相变过程中产生的体积效应远小于马氏体相变过程中的,其相变过程受应力场影响小[11],所以相变温度随热处理温度变化不明显。热处理温度达到500 ℃,降温时只发生单一的马氏体相变,R相变消失。在400~500 ℃热处理温度范围内,合金丝升温时只发生逆马氏体相变,热处理温度升高,逆马氏体相变温度逐渐升高,相变滞后降低,具体相变温度值见表1。

2.2 变形温度对拉伸性能的影响

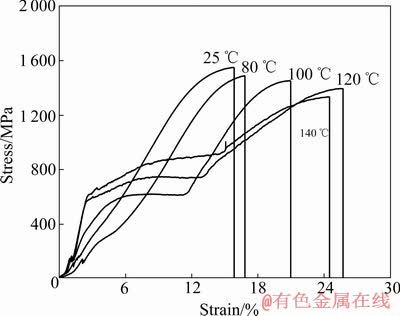

图2所示为温拉拔态Ti-49.8Ni合金丝在不同温度下拉伸后的应力—应变曲线。从图中可知,变形温度对合金丝的变形行为有明显影响,应力—应变曲线随变形温度的不同分为两类,变形温度不高于80 ℃,应力—应变曲线呈近似加工硬化形态,25 ℃时抗拉强度超过1 540 MPa;变形温度升高后强度略有下降,但依然保持在较高的水平;在此变形温度区间内塑性较差,伸长率低于18%。变形温度升至100 ℃,变形行为发生明显变化。合金丝弹性变形后出现明显的屈服平台,所以塑性得到大幅提高,伸长率超过20%;随变形温度升高,屈服强度逐渐增加,抗拉强度降低,但依然超过1 300 MPa。

图3所示为Ti-49.8Ni温拉拔丝经真空(450 ℃, 20 min,空冷)处理后,其屈服强度、抗拉强度和伸长率随变形温度的变化。从图中可以看出,变形温度提高后Ti-49.8Ni的屈服强度不断上升,变形温度升至150 ℃时,σ0.2接近700 MPa,抗拉强度σb随变形温度的升高而降低,伸长率δ则先升后降,并在140 ℃达到最高值57.9%。

由以上结果可知,提高变形温度虽然降低了Ti-49.8Ni合金丝的抗拉强度,但是大幅度地提高了其屈服强度和塑性。所以针对Ti-49.8Ni温拉拔丝热处理后室温屈服强度过低的问题,可以通过升高变形温度来提高其屈服强度和伸长率。

2.3 热处理温度对Ti-49.8Ni合金丝的拉伸性能影响

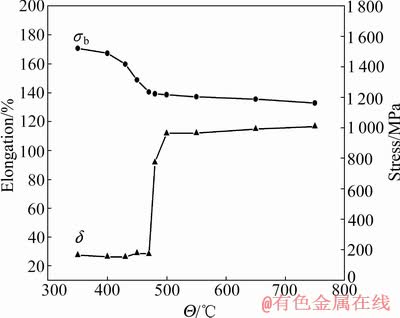

Ti-49.8Ni温拉拔丝经不同温度处理后的室温拉伸性能如图4所示。可以看出,合金丝的抗拉强度和塑性随热处理温度升高发生明显的变化。热处理温度在350~470 ℃时,随着温度升高,抗拉强度迅速降低,350 ℃时σb为1 520 MPa,470 ℃时降至1 237 MPa;高于470 ℃后,热处理温度对强度的影响迅速减弱,σb随温度升高而降低的幅度明显趋缓。于750 ℃热处理后σb为1 165 MPa。

热处理温度不超过470 ℃时,合金丝的塑性变化不明显,δ略低于30%;热处理温度超过470 ℃后,合金丝的塑性得到明显改善。伸长率突然大幅上升,于500 ℃热处理后,δ达到111.9%,继续提高热处理温度,伸长率增加不明显,稳定在110%左右。

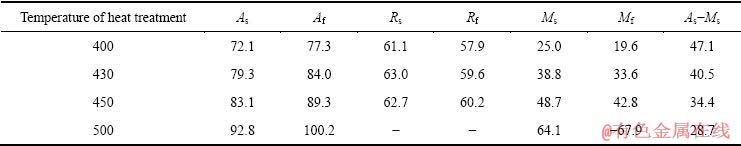

表1 Ti-49.8Ni合金丝的相变温度

Table 1 Transformation temperatures of Ti-49.8Ni alloy wire (Unit: ℃)

图2 不同温度下Ti-49.8Ni温拉拔丝的应力—应变曲线

Fig. 2 σ—ε curves of Ti-49.8Ni wire deformed at different temperatures

图3 Ti-49.8Ni合金丝在不同温度下的拉伸性能

Fig. 3 Tensile properties of Ti-49.8Ni alloys wire deformed at different temperatures

图4 热处理态Ti-49.8Ni合金丝在不同温度下的拉伸性能

Fig. 4 Tensile properties of heat-treated Ti-49.8Ni wire at different temperatures

2.4 热处理时间对拉伸性能的影响

图5所示为Ti-49.8Ni温拉拔丝经真空(450 ℃, x (x=5、10、15、20、25、30) min,空冷)处理后的室温拉伸性能。

图5 热处理时间对Ti-49.8Ni合金丝的拉伸性能的影响

Fig. 5 Effects of heat-treated time on tensile properties of Ti-49.8Ni alloys wire

结果表明,热处理时间不超过30 min,屈服强度σ0.2和抗拉强度σb变化不明显。短时间热处理(5 min)后合金丝塑性最好,δ超过30%;热处理时间为10~ 25 min时,伸长率变化不明显,热处理时间超过25 min后,伸长率开始下降。

所以Ti-49.8Ni合金丝经温拉拔后,在450 ℃处理时间不超过30 min时,热处理对其强度影响不明显。热处理时间在10~25 min范围内塑性变化不明显。

2.5 马氏体相的恢复应变和恢复应力

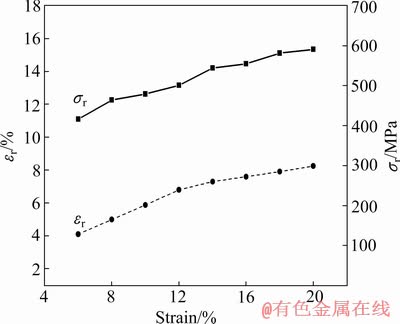

由图6可知,Ti-49.8Ni温拉拔丝经真空(450 ℃,20 min,空冷)处理后,室温下的状态为马氏体,对合金丝施以不同变形量后卸载,不约束位移升温测定恢复应变,约束位移升温测定恢复应力。其恢复应变、恢复应力与变形量的关系如图6所示。

图6 马氏体相的恢复应变、恢复应力与变形量的关系

Fig. 6 Relationships among εr—εt and σr—εt at martensitic phase

由图6可知,处于马氏体相的Ti-49.8Ni合金丝,在室温下变形量由6%增至20%的过程中,恢复应力和恢复应变均随变形量增加而持续上升。在20%变形量时,恢复应力σr达到590 MPa;恢复应变εr由4.1%增至8.2%。根据变化速率将恢复应变分为两个阶段,变形量低于12%时,恢复应变增加较快,变形量超过12%后,随着变形量的继续增大,恢复应变的升高趋势变慢。

变形量超过12%后恢复应变增加趋势变缓,其原因是拉伸变形量持续增加会导致合金丝内部产生严重塑性变形,引入大量形变缺陷,导致应力诱发马氏体稳定化。升温发生形状恢复时,由于形变缺陷周围应力场对逆相变的抑制,新增加的变形量大部分因发生塑性变形而不能发生形状恢复,难以对恢复应变的增加产生贡献,所以恢复应变量增加缓慢。

2.6 母相的恢复应变和恢复应力

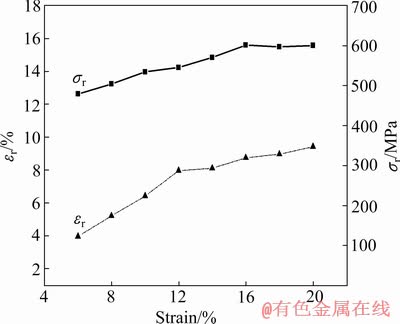

Ti-49.8Ni合金丝经真空(450 ℃,20 min,空冷)处理后,测定其母相状态下恢复应变、恢复应力与变形量的关系。将试样在环境室中先加热使其完全转变为母相,再将试样温度降至80℃,测得的恢复应变和恢复应力随变形量的变化结果如图7所示。

图7 母相相下恢复应变、恢复应力与变形量的关系

Fig.7 Relationships among εr—εt and σr—εt at austenitic phase

由图7可知,母相状态下Ti-49.8Ni合金丝恢复应变和恢复应力随变形量的变化趋势与马氏体相类似,变形量在6%~20%之间变化时,σr和εr随变形量增加逐渐上升。与马氏体相比,变形量相同时母相发生形状恢复时能够产生更高的恢复应变,变形量达到12%时,恢复应变超过了8%。在变形量为20%时,恢复应变达到了9.4%。同样,母相状态下变形产生的恢复应力高于马氏体的恢复应力;变形量为16%时,恢复应力σr达到602 MPa,继续增加变形量,恢复应力趋于稳定,变化不明显。

4 结论

1) Ti-49.8Ni合金经温拉拔后,在低于450 ℃进行热处理,降温时发生独立的R相变和马氏体相变;热处理温度为500 ℃,降温时R相变消失,发生单一的马氏体相变。在400~500 ℃热处理温度范围内,合金丝升温时只发生逆马氏体相变。

2) Ti-49.8Ni合金经温拉拔后,丝材室温下应力—应变曲线呈明显的加工硬化特征,没有明显的屈服平台出现,抗拉强度超过1 540 MPa。

3) Ti-49.8Ni合金丝经450 ℃处理后,分别在马氏体相和母相状态下变形,母相状态下可以获得更高的恢复应变和恢复应力;母相状态下变形量达到12%时,恢复应变超过8%;变形量为16%时,恢复应力达到602 MPa。

REFERENCES

[1] 贺志荣, 宫崎修一. Ni含量对TiNi形状记忆合金相变行为的影响[J]. 金属学报, 1996, 32(4): 351-355.

HE Zhi-rong, MIYAZAKI S. Effects of Ni content on transformation behavior of TiNi shape memory alloy [J]. Acta Metallurgica Sinica, 1996, 32(4): 351-355.

[2] OTSUKA K, REN Xiao-bing. Rencent developments in the research of shape memory alloys [J]. Intermetallics, 1999(7): 511-528.

[3] 谭 璐, 常程康, 毛大立. 形状记忆合金在微创介入医疗领域中的应用[J]. 上海金属, 2005, 27(1): 35-39.

TAN Lu, CHANG Cheng-kang, MAO da-li. The application of shape memory alloy to the medical treatment of minimal invision [J]. Shanghai Metals, 2005, 27(1): 35-39.

[4] 耿 芳, 石 萍, 杨大智. NiTi 形状记忆合金在生物医用领域的研究进展[J]. 功能材料, 2005, 36(1): 11-13.

GENG Fang, SHI Ping, YANG Da-zhi. Review on the development of the NiTi shape memory alloy as biolmaterial [J]. 2005, 36(1): 11-13.

[5] 商泽进, 王忠民, 尹冠生, 郑碧玉. 超弹性TiNi形状记忆合金棒材力学行为[J]. 稀有金属材料与工程, 2009, 38(3): 460- 464.

SHANG Ze-jin, WANG Zhong-min, YIN Guan-sheng, ZHENG bi-yu. An experimental study on the mechanical behavior of superelastic TiNi shape memory alloy bars [J]. Rare Metal Materials and Engineering, 2009, 38(3): 460-464.

[6] 赵连城, 郑玉峰. 形状记忆和超弹性钛镍合金的发展和应用[J]. 中国有色金属学报, 2004, 14(1): 323-326.

ZHAO Lian-cheng, ZHENG Yu-feng. Development and application of nickel-titanium alloys with shape memory and superelasticity [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 323-326.

[7] LAHOZ R, GRACIAVILLA L,  J A. Training of the two-way shape memory effect by bending in NiTi alloys [J]. Journal of Engineering Materials and Technology—Transactions of the ASME, 2002, 124(4): 397-401.

J A. Training of the two-way shape memory effect by bending in NiTi alloys [J]. Journal of Engineering Materials and Technology—Transactions of the ASME, 2002, 124(4): 397-401.

[8] 贺志荣, 周敬恩, 宫崎修一. 固溶时效态TiNi合金相变行为与Ni含量的关系[J]. 金属学报, 2003, 39(6): 617-622.

HE Zhi-rong, ZHOU Jing-en, MIYAZAKI S. Relationship between transformation behavior and Ni content in solution-aged TiNi alloys [J]. Acta Metallurgica Sinica, 2003, 39(6): 617-622.

[9] 谢超英, 赵连城, 雷廷权. Ti51.8at.Ni形状记忆合金中Ti3Ni4相的析出过程[J]. 航空学报, 1991, 12(7): 395-400.

XIE Chao-ying, ZHAO Lian-cheng, LEI Ting-quan, Precipitation process of Ti3Ni4 phase in Ti-51.8at%Ni shape memory alloy [J]. Acta Aeronautica Et Astronautica Sinica, 1991, 12(7): 395-400.

[10] KIM J I, LIU Y, MIYAZAKI S. Ageing-induced two-stage R-phase transformation in Ti-50.9at%Ni [J]. Acta Materialia, 2004, 29(2): 160-164.

[11] EUGENE R. FOSNESS, STEVEN J. BUCKLEY, WAYLON F. GAMMILL. Deployment and release devices efforts atheair force research laboratory space vehicles directorate [C]// AIAA Space 2001-Conferece and Exposition. Albuquerque, NM, 2001: 28-30.

(编辑 方京华)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:王 健,助理研究员;电话;024-23971956;E-mail: jianw@imr.ac.cn