DOI:10.19476/j.ysxb.1004.0609.2018.07.06

热爆合成-自发熔渗TiC/Fe3Al复合材料的形成机理与磨损性能

迟 静,李 敏,王淑峰,郭延章,吴 杰

(山东科技大学 材料科学与工程学院,青岛 266590)

摘 要:采用热爆合成-自发熔渗方法快速制备TiC/Fe3Al复合材料,通过相组成和显微组织的演变分析复合材料的形成过程,探讨TiC的生成及长大机制,并对复合材料的滑动摩擦磨损性能进行研究。结果表明:Ti、C热爆合成为TiC多孔压坯,Fe3Al熔体自发渗入压坯孔隙;TiC在熔体中进行溶解-析出,结晶为初生TiC和共晶TiC。进入TiC晶格的Fe优先吸附在{100}晶面上,使其表面能降低,初生TiC形貌由{111}八面体转变为{100}立方体。TiC生长机制为小平面晶的台阶侧向生长,自发熔渗较快的冷却速度使生长台阶增多,形成叠层生长。TiC/Fe3Al复合材料的滑动磨损率为2.7×10-7 g/s,比Fe3Al的下降31.7%。磨损机理研究表明TiC有效抑制了剥层磨损,使复合材料的耐磨损性能提高。

关键词:TiC/Fe3Al;热爆合成;自发熔渗;生长机制;磨损

文章编号:1004-0609(2018)-07-1320-08 中图分类号:TB331 文献标志码:A

Fe-Al系金属间化合物熔点高,密度低,抗氧化和耐腐蚀性能优异,成本低廉,在航空航天、能量转换和高温过滤等方面具有重要的应用价值,目前,研究最多的是DO3-Fe3Al和B2-FeAl两种类型[1-4]。然而,高温强度低和室温脆性大阻碍了Fe-Al金属间化合物的实际应用。近年来,通过添加TiC颗粒与之形成复合材料,有效改善了上述不足[4-8];同时,有研究指 出[7-8],由于TiC的高硬度,TiC增强Fe-Al基复合材料有望具有优良的耐磨损性能,在要求磨损抗力高的工业领域应用前景广阔。

TiC增强复合材料的制备方法主要有燃烧合成法[9]、熔体反应法[10]、自发熔渗法[6, 11]和粉末冶金法[12]等。其中,自发熔渗法利用某些熔体与TiC颗粒良好的浸润性和热力学相容性,可在无外加压力的条件下,通过熔体自发渗入TiC压坯而形成致密复合材料。GAO等[13-14]、SUBRAMANIAN等[15]采用该方法成功制备出TiC/Fe-Al、TiC/Ni-Al复合材料,并对材料性能进行了研究。高明霞[11]研究认为,高温Fe3Al熔体对TiC压坯具有极强的渗透力,在持续加热的条件下,Fe3Al熔化瞬间即渗入压坯,整个过程在几十秒内完成。目前,自发熔渗TiC增强复合材料的研究多集中于制备工艺和材料性能,对于该过程中TiC的生长机制还缺乏深入探讨。此外,文献[6, 11, 13-15]中报道的自发熔渗法均是以TiC为原料,而TiC陶瓷颗粒塑性小,不易压制成型,还另需依靠等静压、预烧结等方式才能获得压坯。

另一方面,Ti粉和C粉塑性强,易于压制,利用燃烧合成法能够使两者快速反应生成为TiC。该方法以Ti-C体系反应释放的热量维持自身进程,能耗低、速度快(数秒内完成),但制备的材料存在较多孔隙,致密性不佳。然而值得注意的是,范群成[16]观察到燃烧合成的TiC颗粒之间呈轻微烧结状态;宋谋胜[17]对Ti-C体系燃烧合成的研究表明,TiC颗粒相互挤压紧密;并指出引燃方式会影响产物形态,热爆合成的TiC晶粒要明显小于自蔓延合成的TiC晶粒。由此可知,Ti和C热爆合成的产物是由紧密接触的TiC颗粒和孔隙构成,这与TiC粉经压制后的特点相似,因此可用作自发熔渗压坯。此外,热爆合成法中较高的燃烧温度会使杂质充分挥发,能有效避免以TiC粉为原料在压坯成型过程中受到的污染。

本文作者将自发熔渗与燃烧合成两种方法相结合,以Ti粉和C粉为原料,热爆合成为TiC多孔压坯,Fe3Al高温熔体随即自发渗入,获得TiC颗粒增强Fe3Al复合材料。分析了TiC/Fe3Al复合材料的物相组成和显微组织,通过对制备过程中各阶段产物的研究,揭示了复合材料的形成过程,探讨了TiC的生成及长大机制,并考察了TiC对Fe3Al摩擦磨损性能的影响。

1 实验

将Ti粉(粒度为50~75 μm)和C粉(粒度为10~40 μm)按照摩尔比1:1均匀混合,75 MPa压力下压制,获得尺寸为直径20 mm×10 mm的压坯,相对密度为55%。实验使用自制热爆合成-自发熔渗设备,图1所示为实验示意图。将压坯放入中频感应线圈芯部的耐火坩埚内,Fe3Al块体安装在坩埚上方的自动升降臂上,Fe3Al与Ti、C混合粉末的质量比为4:1,实验在氩气气氛中进行,感应功率2.5 kW。实验开始约10 s (620 ℃),出现炫目的强烈火焰,持续燃烧3~4 s后现象消失。随即下降Fe3Al块体置于坩埚内的压坯上,Fe3Al块体逐渐变形出现熔化迹象(实验时间30 s,温度1510 ℃),待Fe3Al块体全部熔化后(实验时间120 s)停止加热,获得TiC/Fe3Al复合材料,标记为S120(下标120为实验时间,本实验中试样均按此方式标记)。为研究复合材料的形成过程和TiC的演变规律,在完全相同的实验条件下,分别在火焰消失时(实验时间为15 s)、Fe3Al块体变形开始熔化时(实验时间为30 s)和Fe3Al块体熔化中期(实验时间为75 s)停止加热,快速水淬后获得试样S15、S30和S75。

利用X射线衍射仪(XRD,D/Max 2500PC)对试样进行物相分析,采用场发射高分辨扫描电镜(FESEM, Nova Nano SEM450)观察显微组织,用电子探针(EPMA,JXA-8230)配置的X射线能量色散谱仪(EDS)检测微区成分;在多功能摩擦磨损试验机(UMT-3)上进行滑动摩擦实验,对磨球为YG硬质合金(90HRA),法向加载200 N,滑动速度10 mm/s,滑动时间3600 s。用精度为0.1 mg的电子天平称量磨损质量损失,以单位时间的磨损质量损失评价材料的耐磨损性能。

图1 热爆合成-自发熔渗实验示意图

Fig. 1 Schematic diagram of thermal explosion synthesis- pressureless melt infiltration

2 结果与分析

2.1 TiC/Fe3Al复合材料的物相组成和显微组织

图2所示为TiC/Fe3Al复合材料(S120)的XRD谱。从图2可知,试样的物相组成为TiC和Fe3Al,这表明以Ti粉和C粉为原料,利用热爆合成-自发熔渗的方法获得了TiC增强Fe3Al复合材料。以α-Al2O3为内标物质,利用K值法[18]计算出试样中Fe3Al的质量分数为78.5%,与原料配比相近。

图2 TiC/Fe3Al复合材料(S120)的XRD谱

Fig. 2 XRD pattern of TiC/Fe3Al composite(S120)

图3 TiC/Fe3Al复合材料(S120)的FESEM照片

Fig. 3 FESEM images of TiC/Fe3Al composite (S120) in low (a) and high (b) magnification

图3(a)所示为TiC/Fe3Al复合材料(S120)的微观形貌,放大后可见3种典型组织(见图3(b)):暗色基体(标记为A组织)、规则块体(标记为B组织)和密集细小颗粒(标记为C组织)。EDS结果(见图4(a))表明A主要由Fe和Al元素组成,其中Al的摩尔分数为28%。根据Fe-Al二元合金相图[19],Al的摩尔分数在25%~32%范围内的Fe-Al合金为DO3结构的Fe3Al,与XRD分析结果相符合(见图2)。从图4(a)还可以看出,Fe3Al中溶入了微量的Ti和C元素。图4(b)、(c)显示B组织和C组织的成分组成相同,主要为Ti和C,结合XRD谱确定两者为TiC相(见图2)。其中,B组织为初生TiC,呈规则四边形块状,弥散分布于Fe3Al基体上;而C组织是共晶TiC相,呈细粒或短棒状,聚集分布在Fe3Al晶界,相互连接为网状。

图4 图3中显微组织的EDS成分分析

Fig. 4 EDS analysis results of different zones shown in Fig. 3

2.2 TiC/Fe3Al复合材料的形成机理

图5所示为不同制备阶段所获得试样的XRD谱,揭示了热爆合成-自发熔渗过程中物相的演变过程。试样S15的物相为TiC,这表明原料Ti-C体系被激发,反应生成了TiC。由于Ti和C的混合粉末压坯全部位于中频感应线圈内,压坯整体进行反应燃烧,属于典型的热爆合成。热力学反应生成焓(ΔΗ)计算结果表 明[20],Ti+C→TiC为强放热反应,瞬间释放大量热量,因此在实验中观察到强烈燃烧火焰。本实验中热爆合成的引燃温度(620 ℃)明显低于单一热场条件下的引燃温度(1100 ℃)[21],分析认为这跟磁场的作用有关,磁场对物质具有活化效应,从而加速了Ti、C原子的扩散速度,强化燃烧过程,使反应在较低温度下发生[22]。试样S30由TiC和Fe3Al两种物相组成,表明Fe3Al块体熔化,并向下渗入多孔TiC压坯中。试样S75的物相组成与S30的一样,也与最终试样S120 的相同(见图2),这说明在熔渗过程中Fe3Al与TiC没有发生反应生成其他新相,只是随着实验时间的延长,Fe3Al的熔渗加剧,复合材料中Fe3Al含量增多。

图5 试样S15、S30、S75的XRD谱

Fig. 5 XRD patterns of S15, S30 and S75 samples

图6所示为不同制备阶段所获得试样的FESEM像,反映了复合材料显微组织的形成过程。由图6(a)中S15的微观形貌可以看出,热爆合成的TiC压坯结构疏松,存在较多的孔隙,TiC晶粒呈似椭圆形;试样的断口形貌(见图6(b))显示TiC的晶粒和晶界存在较多微小孔隙,这是由燃烧合成的技术特性造成的[16]。对本实验而言,孔隙为Fe3Al熔体提供渗入通道,更利于TiC/Fe3Al复合材料的自发熔渗制备。在S30中,Fe3Al块体熔化,进入压坯孔隙(见图6(c)),同时可发现孔隙内的Fe3Al基体上有细小粒状共晶TiC析出,彼此相互连接成网状。文献[11, 15]指出,TiC在Fe-Al系高温熔体中具有一定的溶解度,图4(a)的EDS结果显示Fe3Al中含有Ti、C元素,也证实了TiC向Fe3Al熔体发生了溶解。此时,Fe3Al熔体渗入时间短,TiC溶解少,凝固过程中Ti、C元素以共晶形式析出。在S75中(见图6(d)),除了共晶TiC,还出现了规则四边形的初生TiC(见图6(d)中箭头所指)。由此可知,随实验时间延长,椭圆形TiC溶解充分,熔体中Ti、C元素增多,TiC会以初晶和共晶两种形式析出。

图6 不同试样的显微组织

Fig. 6 Microstructures of samples

根据上述分析可以得出,热爆合成-自发熔渗TiC/Fe3Al复合材料(S120)的形成过程:原料Ti、C粉末经热爆合成为由椭圆形TiC晶粒构成的多孔压坯,Fe3Al熔体渗入压坯孔隙,TiC向熔体发生充分溶解,分解为Ti和C元素。在冷却凝固过程中,熔体中的Ti和C重新结晶为TiC析出,首先析出的是初生TiC;初生TiC的不断形成造成熔体中Ti、C含量降低,在降温过程中继而析出共晶TiC。

TiC 的空间群为Fm3m,立方面心格子,NaCl型结构。根据晶体生长定律,晶面的表面能越高,其法向生长速率越快,在生长过程中越容易消失,而低表面能的晶面则得以保留,构成晶体的最终形貌。在TiC结构中,晶面{110}、{100}和{111}的表面能依次降低[23-24],因此最低表面能的{111}晶面构成了TiC的平衡形貌,即八面体。而实际的晶体形貌是由晶体内部结构和外部生长环境共同决定的,当生长环境偏离平衡状态后,晶体形貌就可能发生改变。图4(b)~(c)中的EDS结果显示,TiC中含有微量的Fe元素,这表明Fe3Al熔体中的Fe进入了TiC晶格。聂金凤[25]指出,晶体中的杂质原子会改变晶面表面能,影响晶体形貌。Ⅷ族过渡型元素,如Fe和Ni,主要是依靠与C轨道电子杂化,以形成σ键的方式进入TiC晶格。TiC的原子排列方式为立方紧密堆积,密置面{111}是极性面,即一层晶面只由一种原子构成,C或Ti依次交替出现在每层{111}晶面上;而{100}晶面则由Ti和C两种原子组成,因此,Fe原子会优先吸附在{100}面上。Fe原子的吸附使{100}表面能降低,生长速度减慢,{111}面因生长较快而逐渐缩小,形成由{100}和{111}聚合的缺顶立方体形貌(见图7(a));当{111}面最终消失时,TiC成为由{100}面构成的立方体(见图7(b)),因此初生TiC的二维形貌为规则四边形块体。

图7 TiC的生长形貌

Fig. 7 Growth morphologies of TiC

TiC熔化熵很高,Jackson因子为5~7,属于晶体学的小平面晶[7, 22, 25]。TiC/Fe3Al复合材料中初生TiC棱角分明,呈现出典型的小平面特征,这说明自发熔渗过程中TiC的生长机制没有发生改变,为小平面晶的台阶侧向生长,即固/液界面上的二维晶核或螺旋位错等缺陷提供生长台阶,熔体中TiC的生长基元依靠此台阶附着于生长界面而向其侧面扩展进行生长。TiC的生长基元为[TiC6]八面体[17],即6个Ti原子位于八面体的角顶,1个C原子位于八面体中心。当生长基元铺满一层晶面后,又会在其上形成新的生长台阶,继续侧向生长。通常,冷却速度增大时,生长界面上的二维晶核和缺陷会显著增加[20],导致生长台阶数目增多。由于自发熔渗降温快,所以生长台阶密度大,一层晶面未铺满时在其上就已有新的生长台阶形成,这就意味着晶面在侧向生长的同时又在垂直方向层层堆叠,因此在TiC形貌上出现了叠层生长,如图7(c)所示。

2.3 TiC/Fe3Al复合材料的摩擦磨损性能

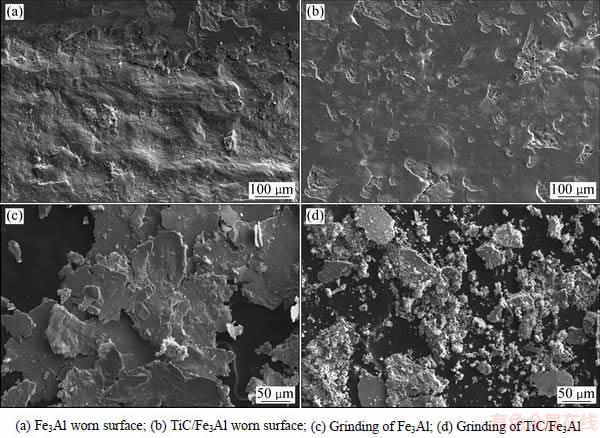

以未添加TiC的Fe3Al作为参比样,与TiC/Fe3Al复合材料进行滑动摩擦磨损对比实验。结果显示TiC/Fe3Al的摩擦因数为0.38,明显低于Fe3Al的(见图8);其磨损率为2.7×10-7 g/s,比Fe3Al的下降31.7%,这表明Fe3Al与TiC复合提高了材料的耐磨损性能。图9所示为两种材料的磨损表面形貌和磨屑形貌,Fe3Al磨损表面(见图9(a))存在大量的剥落坑,部分区域的剥落坑相互连接成为大面积的剥落层;磨屑为片状(见图9(c)),尺寸超过了100 μm。相比而言,TiC/Fe3Al的磨损程度明显减弱(见图9(b)),剥落坑呈弥散分布,很少彼此连接;片状磨屑尺寸相对较小,另外还出现了块状磨屑(见图9(d))。

摩擦过程中在外加载荷作用下,对磨球与试样之间相对滑动,造成Fe3Al表面发生塑性剪切变形。伴随着变形的逐渐积累,在Fe3Al表层形成裂纹。裂纹一旦形成,就会在外界载荷的周期性作用下,不断扩展,当其最终从某些薄弱位置剪切时,就以片状磨屑的形式剥落,摩擦表面形成剥落坑。经过长时间的往复摩擦,剥落坑数目增多,面积增大,相互连接时即成为磨损严重的剥落层。当添加TiC后,硬度高的TiC成为耐磨骨架,抵抗外加载荷,减弱了Fe3Al的塑性变形。同时,弥散分布的TiC还对裂纹扩展起到阻碍作用,因此,TiC/Fe3Al复合材料磨损程度减轻,未形成大面积的剥落,片状磨屑尺寸较小。此外,在长时间的摩擦作用下,TiC会因疲劳磨损与Fe3Al的结合力下降,当其不能被继续固结时,便从磨损表面脱离。脱落的TiC颗粒在高载荷的作用下不能及时排出,会停留在摩擦界面充当磨粒,与摩擦副构成三体磨损。TiC磨粒对复合材料的显微切削,产生了块状磨屑。由上可知,Fe3Al与TiC形成复合材料,虽增加了显微切削磨损,但有效抑制了剥层磨损,因此表现出优异的耐滑动磨损性能。

图8 FeAl和TiC/Fe3Al摩擦因数随时间的变化曲线

Fig. 8 Changing curves of friction coefficient with time for Fe3Al and TiC/Fe3Al

图9 TiC/Fe3Al和Fe3Al的磨损表面形貌和磨屑形貌

Fig. 9 Morphologies of worn surfaces and grindings of TiC/Fe3Al and Fe3Al

3 结论

1) 利用Ti-C体系的高放热反应和Fe3Al熔体与TiC良好的浸润性,采用热爆合成-自发熔渗方法快速制备了TiC/Fe3Al复合材料。

2) Ti-C混合粉末热爆合成为多孔TiC压坯,TiC向Fe3Al熔体发生溶解,分解为Ti和C,在冷却过程中Ti和C重新结晶为TiC而析出,规则四边形的初生TiC弥散分布,细粒状的共晶TiC聚集在Fe3Al晶界。

3) 熔体中的Fe进入TiC晶格,优先吸附在{100}面上,使其表面能降低,生长速度变缓,因此,初生TiC由八面体的平衡形貌演化为立方体的生长形貌。TiC依靠台阶侧向生长机制从Fe3Al熔体中结晶长大,自发熔渗的快速冷却导致TiC在侧向生长的同时又在垂直方向层层堆叠,形成叠层生长。

4) TiC/Fe3Al复合材料的摩擦因数为0.38,磨损率为2.7×10-7 g/s,均明显低于Fe3Al的。TiC增加了显微切削磨损,但有效抑制了剥层磨损,提高了复合材料的耐滑动磨损性能。

REFERENCES

[1] ITOI T, MINETA S, KIMURA H, YOSHIMI K, HIROHASHI M. Fabrication and wear properties of Fe3Al-based composites[J]. Intermetallics, 2010, 18(11): 2169-2177.

[2] WANG Qian, LENG Xue-song, YANG Tian-hao, YAN Jiu-chun. Effects of Fe-Al intermetallic compounds on interfacial bonding of clad materials[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 279-284.

[3] 徐文雷, 孙扬善, 丁绍松. CVp和TiCp颗粒增强Fe3Al基合金的显微组织和力学性能[J]. 中国有色金属学报, 2001, 11(1): 150-153.

XU Wen-lei, SUN Yang-shan, DING Shao-song. Effects of VC and TiC particles on mechanical properties and microstructure of Fe3Al-based alloys[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 150-153.

[4] ARCHANA M S, SRIKANTB V V S S, JOSHI S V, JOARDAR J. Influence of applied pressure during field-assisted sintering of Ti(C,N)-WC-FeAl based nanocomposite[J]. Science Direct, 2015, 41: 1986-1993.

[5] KARANTZALIS A E, LEKATOU A, GEORGATIS E, ARNI Z, DRACOPOULOS V. Solidification observations of vacuum arc melting processed Fe-Al-TiC composites: TiC precipitation mechanisms[J]. Materials Characterization, 2011, 62: 1196-1204.

[6] GAO M X, OLIVERRA F J, Pan Y, BAPTISTA J L, VIEIRA J M. Mechanical properties and microstructure of Fe40Al/TiC composites with low content of intermetallic[J]. Materials Science Forum, 2004, 455/456: 239-243.

[7] 陈 瑶, 王华明. 激光熔覆TiC增强FeAl金属间化合物基复合材料涂层磨损性研究[J]. 稀有金属材料与工程, 2003, 32(10): 840-843.

CHEN Yao, WANG Hua-ming. Wear resistance of laser clad reinforced FeAl intermetallic matrix composite coatings[J]. Hare Metal Materials and Engineering, 2003, 32(10): 840-843.

[8] 王耀华, 高清振, 张晓南, 李启峰. Fe-Al/TiC激光熔覆层的高温摩擦磨损和氧化性能[J]. 机械工程材料, 2011, 35(5): 39-42.

WANG Yao-hua, GAO Qing-zhen, ZHANG Xiao-nan, LI Qi-feng. High temperature friction and wear and oxidation properties of Fe-Al/TiC laser cladding layer[J]. Materials for Mechanical Engineering, 2011, 35(5): 39-42.

[9] JIN Shen-bao, SHEN Ping, ZHOU Dong-shuai, JIANG Qi-chun. Self-propagating high-temperature synthesis of nano-TiCx particles with different shapes by using carbon nano-tube as C source[J]. Nanoscale Research Letters, 2011, 6: 515-521.

[10] NIE Jin-feng, WU Yu-ying, Li Peng-ting, LI Hui, LIU Xiang-fa. Morphological evolution of TiC from octahedron to cube induced by elemental nickel[J]. Cryst Eng Comm, 2012, 14: 2213-2221.

[11] 高明霞. TiC基Fe-Al、Ni-Al金属间化合物复合材料的自发熔渗制备和结构性能研究[D]. 杭州: 浙江大学, 2004: 55-56.

GAO Ming-xia. Fabrication of TiC matrix Fe-Al and Ni-Al intermetallics composites by spontaneous melt infiltration and the investigation of the microstructure and properties of the composites[D]. Hangzhou: Zhejiang University, 2004: 55-56.

[12] 龙坚战, 夏艳萍, 陈 冲, 陆必志, 易茂中, 武文花. Al含量对TiC-Fe钢结硬质合金组织与性能的影响[J]. 中国有色金属学报, 2016, 26(2): 383-391.

LONG Jian-zhan, XIA Yan-ping, CHEN Chong, LU Bi-zhi, YI Mao-zhao, WU Wen-hua. Effects of Al content on microstructure and mechanical properties of TiC-Fe alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 383-391.

[13] GAO M X, OLIVEIRA F J, PAN Y, YANG L, BAPTISTA J L, VIEIRA J M. Strength improvement and fracture mechanism in Fe40Al/TiC composites with high content of TiC[J]. Intermetallics, 2005, 13(5): 460-466.

[14] GAO M X, PAN Y, OLIVERIRA F J, BAPTISTA J L, VIEIRA J M. Interpenetrating microstructure and fracture mechanism of NiAl/TiC composites by pressureless melt infiltration[J]. Materials Letters, 2004, 58: 1761-1765.

[15] SUBRAMAIAN R, SCHNEIBEL J H. FeAl-TiC cermets-melt infiltration processing and mechanical properties[J]. Materials Science and Engineering A, 1997, 239/240: 633-639.

[16] 范群成. 用燃烧波淬熄法对自蔓延高温合成机理的研究[D]. 西安: 西安交通大学, 2000: 27-33.

FAN Qun-cheng. A study on mechanism of self-propagating high-temperature synthesis by combustion front quenching technique[D]. Xi’an: Xi’an Jiaotong University, 2000: 27-33.

[17] 宋谋胜. 燃烧合成TiC、ZrC晶体的形成过程与生长动力学研究[D]. 上海: 上海交通大学, 2009: 31-39.

SONG Mou-sheng. Investigation of the formation process and growth kinetics of combustion synthesized TiC and ZrC crystals[D]. Shanghai: Shanghai Jiao Tong University, 2009: 31-39.

[18] 周 玉. 材料分析方法[M]. 北京: 机械工业出版社, 2004: 1-331.

ZHOU Yu. Materials analysis methods[M]. Beijing: China Machine Press, 2004: 1-331.

[19] KARANTZALIS A E, LEKATOU A, GEORGATIS E, ARNI Z, DRACOPOULOS V. Solidification observations of vacuum arc melting processed Fe-Al-TiC composites: TiC precipitation mechanisms[J]. Materials Characterization, 2011, 62: 1196-1204.

[20] 曹 磊. 熔铸法制备TiC/Ti-6Al-4V复合材料组织与力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2010: 29-34.

CAO Lei. Research on microstructure and mechanical properties of TiC/Ti-6Al-4V composites fabricated by melting-casting process[D]. Harbin: Harbin Institute of Technology, 2010: 29-34.

[21] SAIDI A, CHRYSANTHOU A, WOOD J V. Characterizes of the combustion synthesis of TiC and Fe-TiC composites[J]. Journal of Materials Science, 1994, 29: 4993-4998.

[22] 杨 屹. 基于场激发的Fe-Ti-C三元系燃烧行为研究[D]. 成都: 四川大学, 2004: 28-80.

YANG Yi. Study on the combustion behaviour of Fe-Ti-C systems based on a field activation[D]. Chengdu: Sichuan University, 2004: 28-80.

[23] XIA You-nan, XIONG Yu-jie, LIM B, SKRABALAK S E. Shape-controlled synthesis of metal nanocrystals: Simple chemistry meets complex physics[J]. Angewandte Chemie (International Edition), 2009, 48: 60-103.

[24] FANG Li-hong. First-principles study of bulk and (001) surface of TiC[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 857-862.

[25] 聂金凤. 铝合金中TiC生长与演变及硼掺杂改性的研究[D]. 济南: 山东大学, 2013: 47-50.

NIE Jin-feng. Study on the growth, evolution and boron-doping modification of TiC in Al alloys[D]. Jinan: Shandong University, 2013: 47-50.

Formation mechanism and wear properties of TiC/Fe3Al composites by thermal explosion synthesis and spontaneous melt infiltration

CHI Jing, LI Min, WANG Shu-feng, GUO Yan-zhang, WU Jie

(College of Materials Science and Engineering, Shandong University of Science and Technology, Qingdao 266590, China)

Abstract: TiC/Fe3Al composites were fabricated rapidly by the combination of thermal explosion synthesis and spontaneous melt infiltration. The formation mechanism based on the phase composition and microstructure evolution process, TiC growth mechanism, sliding friction and wear properties of the resultant materials were investigated systematically. The molten Fe3Al spontaneously infiltrates the pores of porous TiC compacts prepared by thermal explosion synthesis using Ti and C powders, resulting in the creation of TiC/Fe3Al composites. The formation of TiC in final products can be attributed to dissolution-precipitation mechanism, i.e., TiC dissolves in Fe3Al melt and decomposes into Ti and C, the latter reacts in the molten pool and precipitates the primary TiC and eutectic TiC during the cooling process. Fe atoms can enter the TiC lattice and be adsorbed preferentially at the {100} crystal plane, giving rise to reduce the surface energy of the {100} plane, so, the morphology of primary TiC changes from {111} octahedron to {100} cube. The TiC growth pattern is lateral growth of facet crystals, tending to grow layer by layer depend on more growth steps provided by the high cooling rate during the fabricate process. The sliding wear rate of TiC/Fe3Al composites is 2.7×10-7 g/s, decreased by 31.7% compared with that of Fe3Al. The wear mechanism indicates that the wear resistance of the composites can be improved noticeably because the addition of TiC may effectively inhibit the delamination wear.

Key words: TiC/Fe3Al; thermal explosion synthesis; pressureless melt infiltration; growth mechanism; wear

Foundation item: Project(14-7-2-42-gx) supported by the Technological Innovation Construction Program of Qingdao City, China; Project(ZR2014EMM009) supported by the Natural Science Foundation of Shandong Province, China

Received date: 2017-05-10; Accepted date: 2018-03-18

Corresponding author: WU Jie; Tel: +86-532-86057927; E-mail: wujie0537@163.com

(编辑 龙怀中)

基金项目:青岛市技术创新平台建设计划资助项目(14-7-2-42-gx);山东省自然科学基金资助项目(ZR2014EMM009)

收稿日期:2017-05-10;修订日期:2018-03-18

通信作者:吴 杰,副教授,博士;电话:0532-86057927;E-mail:wujie0537@163.com