润磨强化硫酸渣制备氧化球团的技术及机理

白国华1,周晓青2,范晓慧1,李建臣1

(1. 中南大学 资源加工与生物工程学院,湖南 长沙,410083;

2. 中冶长天国际工程有限责任公司 工艺分院,湖南 长沙,410007)

摘要:从硫酸渣本身特点出发,对硫酸渣制备氧化球团的特点及润磨在球团制备过程中的作用机理进行研究。研究结果表明:无润磨的硫酸渣生球强度极差,水分较高,润磨可改善硫酸渣的粒度组成、比表面积,降低生球的孔隙率,从而有效降低膨润土用量,大幅提高生球的强度及降低生球的水分;润磨也能提高硫酸渣颗粒活性,增加颗粒与颗粒之间的接触点,使质点利于扩散,从而改善硫酸渣球团的焙烧性能,润磨后的球团在焙烧温度为1 150 ℃、焙烧时间为10 min的条件下,便可获得抗压强度大于3 kN/个的球团,大大降低了球团的焙烧温度。使用硫酸渣能生产出优质的球团供高炉使用。

关键词:硫酸渣;球团;润磨;综合利用

中图分类号:TF046 文献标志码:A 文章编号:1672-7207(2011)06-1509-07

Enhancing technology and mechanism of oxidized pellet prepared from pyrite cinder by moisture grinding

BAI Guo-hua1, ZHOU Xiao-qing2, FAN Xiao-hui1, LI Jian-chen1

(1. School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Process Division, Changtian International Engineering Corporation, MCC, Changsha 410007, China)

Abstract: In connection with characteristic of pyrite cinder, the characteristic of oxidized pellet prepared from pyrite cinder and the mechanism of moisture grinding on pellet preparation were studied. The results show that the strength of green balls is very low, and the moisture of green balls is fairly higher without moisture grinding. Moisture grinding is an effective means to improve the strength and reduce the moisture of green ball with the less dosage of bentonite by improving size distribution, specific surface area and lowering the porosity of green balls. Moisture grinding can improve the roasting performance of pyrite cinder pellet by improving the surface energy of pyrite cinder and increasing contact points between particles, which has the advantages of diffusion. The compressive strength of pellets overruns 3 kN per pellet with moisture grinding after roasted at 1 150 ℃ for 10 min. The roasting temperature can be greatly reduced. The high quality oxidized pellet can be produced as a blast furnace feed by using pyrite cinder.

Key words: pyrite cinder; pellet; moisture grinding; multipurpose utilization

硫酸渣为硫精矿在沸腾炉内700~1 000 ℃焙烧制取硫酸后的残渣,每生产1 t的硫酸将产生0.6~1.0 t的硫酸渣,如果硫精矿入炉品位低,生产工艺不合理,硫酸渣的产量将更多[1]。硫铁矿焙烧制酸是我国生产硫酸的主要方式,我国硫酸渣的产量长期较高,其中仅有部分硫酸渣作为水泥添加剂得到应用,其余的硫酸渣均自然堆积或择地掩埋。硫酸渣中的酸性物质酸化土地,污染水源,危害动植物的生长,对环境危害极大,因此,综合利用硫酸渣对环境保护具有重大意义[2-3]。硫酸渣中丰富的铁资源对我国铁矿资源不足,长期依赖于进口的现状具有重大的利用价值,许多学者对此进行广泛的研究[4-5]。随着现代选矿技术的进步以及新设备的推广使用,用精选后得到的硫精矿生产硫酸,所得硫酸渣铁品位能达到60%以上,杂质含量亦进一步降低,可直接用于生产球团。王雪松等[6-8]对硫酸渣的物质组成及矿物特性进行了深入研究,认为硫酸渣属典型的人造矿物,其矿物特性与天然铁矿石存在较大差异。很多学者对硫酸渣应用于钢铁行业进行了试验研究[9-12],研究表明球团是硫酸渣用作钢铁原料最适宜的手段,但技术上还有一定难度。本文作者采用高品位硫酸渣作为原料,将硫酸渣本身特性与硫酸渣在球团生产过程中的特点联系起来,系统说明硫酸渣制备球团的技术特点及润磨预处理对硫酸渣球团制备的强化机理,为更广泛的应用硫酸渣制备氧化球团提供技术支持和理论依据。

1 原料及研究方法

1.1 原料

研究所用的硫酸渣来自陕西某化工厂,其化学成分(质量分数,%)为:全铁TFe 61.60,FeO 12.81,SiO2 6.46,Al2O3 1.77,CaO 0.68,MgO 0.31,S 0.90,P 0.01,烧损 3.10;粒度低于0.074 mm的硫酸碴质量分数为71.6%,低于0.044 mm的质量分数为59.2%,低于0.010 mm的质量分数为36.0%。所用膨润土为钠基膨润土,Na2O含量为1.55%,其物理性能指标为:吸蓝量36.5 g/(100 g),蒙脱石含量67.87%,胶质价100%,膨胀容13.2 mL/g,各项指标均较好。

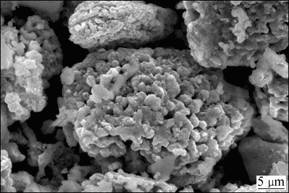

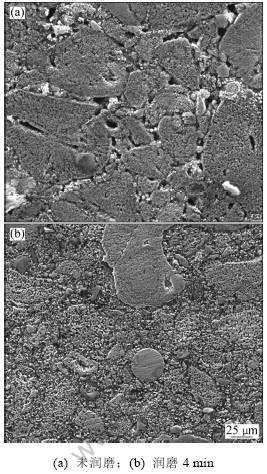

试验所用硫酸渣肉眼下呈黑色,粉末状,含水量较高。检测硫酸渣的主要物理性能发现:硫酸渣的最大分子水及最大毛细水含量均较高,分别为10.26%和29.03%,静态成球性指数为0.55,属中等成球性;硫酸渣的孔隙率较大,其堆密度仅1.21 g/cm3,孔隙率达0.72,比表面积为1.17 m2/g。图1所示为硫酸渣的扫描电镜照片。从图1可以看出:硫酸渣颗粒表面粗糙,毛细孔洞发达,正是这一特点造成硫酸渣持水能力、堆密度及孔隙率不同于天然铁矿石。而造成硫酸渣这一特点的原因为:硫酸渣为硫精矿焙烧的产物,硫在焙烧中溢出,生成的铁氧化物未能结晶完善,使硫酸渣呈多孔结构。

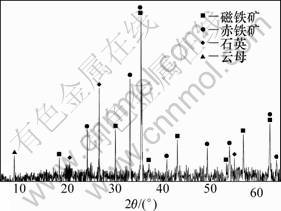

硫酸渣的X线衍射图谱见图2。硫酸渣经镜下鉴定和X线衍射分析综合研究表明:样品中铁矿物种主要是磁铁矿和赤铁矿,其次为半假象-假象赤铁矿;硫主要以黄铁矿形式存在,少量为黄铜矿和石膏,但含量较低;脉石矿物主要为石英和黑云母,经统计主要矿物的体积分数见表1。

图1 硫酸渣的扫面电镜照片

Fig.1 SEM image of pyrite cinder

图2 硫酸渣的X线衍射图谱

Fig.2 XRD pattern of pyrite cinder

表1 硫酸渣中主要矿物含量(体积分数)

Table 1 Major mineral constituent of pyrite cinder %

1.2 研究方法

本研究的主要流程为:原料性能检测—造球试 验—焙烧试验—机理分析探讨。原料性能将采用扫描电子显微镜、光学显微镜及X线衍射分析等手段进行分析检测。造球试验每次以原料干质量5 kg进行配料,膨润土按一定比例外配,将硫酸渣与膨润土进行人工混匀,混匀后进入润磨机润磨,润磨后混合料进入圆盘造球机人工造球,取直径为9~15 mm的生球作为合格生球,测定其落下强度、抗压强度、生球水分及爆裂温度。焙烧试验在卧式管状电炉中进行,而机理分析将结合电子显微镜、光学显微镜等手段进行讨论。

造球设备为1 000 mm×200 mm(直径×边高)圆盘造球机,倾角为45°,转速为28 r/min。采用500 mm×500 mm(直径×厚度)的无级调速润磨机,润磨机转速为35~40 r/min,介质充填率为12%。管状电炉由炉膛直径为50 mm的1个铁铬铝丝电阻炉和1个硅碳管电阻炉对接而成,前者作预热用,后者作焙烧用,试验时将在烘箱中已烘干的干燥球装入瓷舟中,按预先制定好的操作制度进行预热焙烧试验。在试验过程中,以满足高炉生产要求为指标,生球的抗压强度大于10 N/个,落下强度大于3 次/(0.5 m),爆裂温度大于400 ℃;成品球的抗压强度大于2.5 kN/个。

2 试验结果

2.1 造球试验

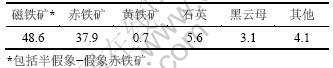

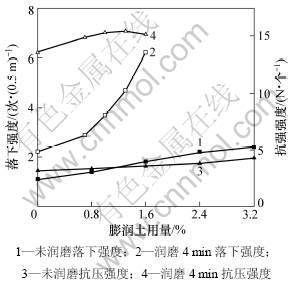

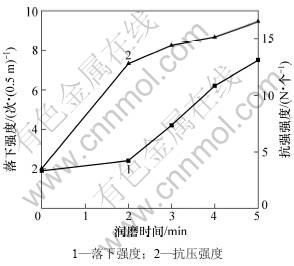

对硫酸渣造球性能的研究结果见图3和图4,造球时间均为10 min。图3所示为润磨前后膨润土用量对硫酸渣球团强度的影响,可以看出:没有润磨时,硫酸渣直接用于造球,生球的落下强度和抗压强度均较低,随膨润土用量的增加变化不大,即使膨润土用量增加至3.2%,其强度依然远不能满足生产要求,而且生球的水分较高,达20%以上,爆裂温度较高,高于600 ℃;而当经过了润磨4 min之后,硫酸渣生球的强度得到了明显的提高,随膨润土用量的增加,生球落下强度迅速提高,生球抗压强度的增加没有落下强度的增加明显。润磨4 min后,在膨润土用量达到1%时,落下强度接近4 次/(0.5 m),抗压强度15 N/个左右。

图3 润磨前后膨润土用量对硫酸渣生球强度的影响

Fig.3 Effect of bentonite dosage on drop strength of green ball before and after moisture grinding

图4 润磨时间对硫酸渣生球强度的影响

Fig.4 Effect of moisture grinding time on strength of green ball

图4所示为润磨时间对硫酸渣生球强度的影响,膨润土用量为1.6%。从图4可以看出:润磨能有效改善生球强度。随着润磨时间的延长,生球的落下强度逐渐增加;而生球的抗压强度经过润磨,便能提高到10 N/个以上,继续延长润磨时间抗压强度增幅减小。研究还发现,润磨可使硫酸渣生球水分降低至14%以下,与未润磨时相比,降低了6%;延长润磨时间,生球的爆裂温度降低,润磨时间在4 min以内时,爆裂温度仍能在500 ℃以上。

综合图3和图4可见:润磨是改善硫酸渣的造球性能,提高生球强度,降低生球水分的有效手段。润磨4 min,膨润土用量可降低至1.0%,可获得落下强度为3.7次/(0.5 m),抗压强度15.61 N/个,生球水分13.40%,爆裂温度555 ℃的生球指标。

2.2 焙烧试验

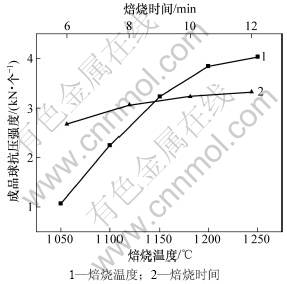

图5所示为焙烧制度对成品球强度的影响,所用生球是膨润土用量为1.0%,润磨时间为4 min的条件下制备的生球。图6所示为润磨时间对成品球强度的影响,所用球团的膨润土用量为1.0%,焙烧温度1 150 ℃,焙烧时间10 min。在950 ℃温度下预热10 min。

从图5可以看出:随焙烧温度和焙烧时间的增加,球团抗压强度逐渐提高,但温度的升高及时间的延长到一定程度后抗压强度增加的幅度均逐渐减小;焙烧温度的对球团抗压强度的影响要比焙烧时间明显。总的看来,经润磨后的硫酸渣球团表现出极好的焙烧性能,在焙烧温度为1 150 ℃,焙烧时间为10 min时,可获得抗压强度为3.23 kN/个的成品球团,焙烧温度较正常的铁矿球团降低近100 ℃。该成品球的铁品位为61.90%,能够满足高炉的要求。

图5 焙烧温度和焙烧时间对成品球抗压强度的影响

Fig.5 Effect of roasting temperature and roasting time on compressive strength of fire pellet

图6 润磨时间对成品球抗压强度的影响

Fig.6 Effect of moisture grinding time on compressive strength of fired pellet

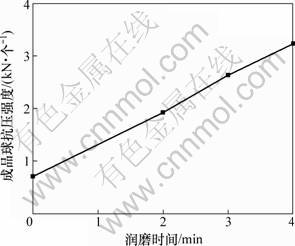

从图6可以看出:润磨时间对硫酸渣成品球抗压强度的影响非常明显,没有经过润磨的球团在同样的焙烧温度下,强度不到1 kN/个;而随着润磨时间的延长,球团的抗压强度明显提高,可见润磨是硫酸渣球团焙烧温度明显降低的重要原因。

3 机理探讨

3.1 强化生球质量机理

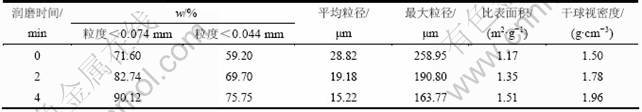

表2所示为润磨时间对硫酸渣粒度组成、比表面积及干球密度的影响,其中干球视密度为干球内部算上其内部孔隙的密度,测量方法为:用游标卡尺测量干球直径折算出体积,再称得球的质量计算而得,多测几组取平均值。

由表2可以看出:硫酸渣经过润磨,粒度组成发生相当大的变化,细粒级含量迅速增加,润磨4 min的硫酸渣,粒度<0.074 mm含量超过90%,达到90.12%,平均粒径从28.82 μm降至15.22 μm,与此同时硫酸渣的比表面积也由原矿的1.17 m2/g提高到了1.51 m2/g。许多研究表明:原料的粒度愈小,且有合适的粒度组成,则生球中粒子排列越紧密,其形成的毛细管平均直径也越小,所以,产生的毛细压就越大,生球的强度就越高。

润磨后硫酸渣的干球密度也得到较大提高,从未磨时的1.50 g/cm3提高到1.96 g/cm3,这说明润磨时硫酸渣球团愈加紧密,这可以从图7得到验证。图7所示为润磨前后硫酸渣球团内部的扫描电镜照片,可以看出:没有润磨的球团内部结构比较松散,颗粒与颗粒之间缝隙较大,粘结不够紧密,各颗粒之间尚能分辨清楚;润磨后的硫酸渣干球内部结构更加致密,润磨所产生的更多微细颗粒分布于大颗粒之间,使颗粒与颗粒之间的空隙大幅减小,许多颗粒之间形成集团,颗粒的边缘已很难分清。可以想象,没有润磨的硫酸渣成球时,由于原料本身的多孔结构,生球构造疏松,承受压力的能力较弱,抗压强度和落下强度低,且颗粒本身毛细孔丰富,因而生球的水分高,同时水分受热蒸发时,水蒸气能迅速通过丰富的毛细孔排出,所有爆裂温度高;润磨之后,原料中抗压能力小的颗粒首先被破碎,微细粒级大量提高,生球中颗粒排列更紧密,使生球强度提高,毛细孔大幅减少,因而生球水分降低。但是,硫酸渣颗粒蜂窝煤状结构并不能完全改变,所以,生球爆裂温度有所降低,但仍然保持较高的水平。

表2 润磨时间对硫酸渣粒度、比表面积及干球密度的影响

Table 2 Effect of moisture grinding time on granularity, surface area and density of pyrite cinder

图7 润磨前后硫酸渣干球内部扫描电镜照片

Fig.7 SEM images of dry ball’s interior of pyrite cinder before and after moisture grinding

3.2 强化成品球质量机理

3.2.1 人造矿的作用

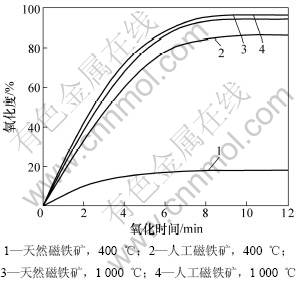

许多研究已经表明[13]:人造磁铁矿及赤铁矿在形成过程中没有完整的晶粒长大过程,其结晶程度要比天然的磁铁矿或赤铁矿差得多,但是,正是由于其晶格缺陷和不完善,在焙烧时要表现出更好的反应性能,能在较低的温度下开始发生反应。

对于人造磁铁矿,它具有不完整的晶格结构,氧化时固溶体形成得非常迅速,因此,在低温下就能形成γ-Fe2O3,且它的反应性要比天然磁铁矿的反应性强很多。人造磁铁矿在400 ℃时的氧化度接近天然磁铁矿在1 000 ℃时的氧化度,如图8所示。同样地,人造赤铁矿其晶格缺陷也比天然矿石的要多,其在较低的温度下颗粒便能彼此靠近,形成连接桥,使颗粒明显长大。硫酸渣中的磁铁矿和赤铁矿正是属于典型的人造矿物,黄铁矿在沸腾炉中焙烧使温度没有达到生成赤铁矿或磁铁矿的结晶温度,因而,生成的赤铁矿和磁铁矿晶格很不完善,硫酸渣球团反应的活性要高于天然矿石球团反应的活性,它们在较低温度下便具有天然矿在高温时的反应性能。

图8 氧化气氛下焙烧天然磁铁矿和人工磁铁矿的氧化度

Fig.8 Degree of oxidation of crude magnetite and artificial magnetite in oxidizing atmosphere

3.2.2 润磨的作用

润磨能改善硫酸渣成品球团抗压强度的原因,首先在于它能增加物料的活性[14]。润磨使物料粒度变小,比表面积增加,润磨所做的功部分转化为表面能存储于新生表面之上,显然润磨之后的物料表面能量更高。在硫酸渣球团焙烧过程中,并不是所有分子同时反应,而是反应活性较高的先反应,因而润磨之后的球团其整体活性强,更容易发生扩散反应和结晶。

再者,润磨使球团更加紧密,接触点明显增加。在图7中可以看到润磨前后硫酸渣球团内部的结构情况,润磨后颗粒与颗粒之间接触点更多,结构更加致密。物体发生固相反应时,质点的扩散首先发生在点与点接触的地方,未润磨时硫酸渣球团内部孔隙大,点与点接触少,焙烧时即时达到了球团内固相反应的温度和赤铁矿结晶的温度。由于很难扩散使晶粒长大,不能有大面积的赤铁矿晶粒聚合体,球团内部晶粒的链接较差(见图9(a)),因而很难获得较高的强度;润磨后的球团颗粒与颗粒之间接触点明显增加,反应时更容易发生扩散,大量的微晶键链接发育长大形成片晶,并且聚合转变为Fe2O3再结晶的成片状赤铁矿(见图9(b)),这样的固结形式可以保证球团获得较高的物理强度。

图9 焙烧温度为1 150 ℃未润磨与润磨后成品球显微结构(100倍,反光,Fe2O3(白色),孔洞(黑色))

Fig.9 Microstructures of fired pellet before and after moisture grinding at roasting temperature of 1 150 ℃

3.2.3 硫的氧化放热

硫酸渣球团中残余硫的氧化放热也是硫酸渣球团焙烧温度显著降低的一个重要因素。硫酸渣中残余硫主要存在形式为黄铁矿(FeS2),黄铁矿在氧化焙烧时很容易产生分解反应,黄铁矿的开始反应温度较低;当温度较低时(400~600 ℃),黄铁矿便能开始发生如下反应[15]:

4FeS2+11O2=2Fe2O3+8SO2 (1)

ΔG=-3 339.3+0.310T

3FeS2+8O2=Fe3O4+6SO2 (2)

ΔG=-2 384.6+0.167T

从式(1)和式(2)的热力学函数来看,黄铁矿的热效应相当大。以黄铁矿氧化为赤铁矿(见式(1))为例,将其与碳的氧化反应(见式(3))及磁铁矿氧化为赤铁矿(见式(4))时放热进行比较。若本研究中硫全部与黄铁矿形式存在,则0.9%的硫完全氧化放出的热量将与原料中含1.4%的C或含58.4%的Fe3O4氧化时放出的热量相同。

C+O2=CO2 (3)

ΔG=-110.5+0.018T

4Fe3O4+O2=6Fe2O3 (4)

ΔG=-479.5+0.267T

以上的计算结果表明:硫酸渣中以黄铁矿形式残存S较容易被脱除,含量虽低,但其氧化放出的热量不容忽视。犹如磁铁矿球团焙烧时其氧化放热可以对其氧化固结起推动作用一样,硫酸渣中的残余S氧化放热也可以对硫酸渣球团的焙烧固结提供很大部分热量,进而降低焙烧温度,减小能耗。且黄铁矿氧化反应新生成的赤铁矿和磁铁矿具有更高的活性和迁移能力,更有利于促进球团内部结晶与再结晶的进行。所以,硫酸渣中残留黄铁矿氧化放热也是促进硫酸渣球团焙烧温度降低的一个重要因素。

4 结论

(1) 硫酸渣为典型的人造矿物,其物化性能与天然磁铁矿和赤铁矿有很大差异,主要表现为其疏松多孔,持水能力强,孔隙率大。

(2) 由硫酸渣直接制备球团所得生球强度低,生球水分较高。润磨能破坏硫酸渣疏松多孔的结构,改善硫酸渣粒度组成,降低球团内部的孔隙率,从而有效提高硫酸渣生球的强度,降低生球水分,降低膨润土用量。润磨时间为4 min时,膨润土用量可降至1.0%,所得生球各项指标均能满足生产要求。

(3) 硫酸渣本身结晶不完善,润磨能增强硫酸渣活性,增加球团内部颗粒间接触点,有利于质点扩散形成连接桥,加上硫酸渣残余硫的氧化放热,润磨后硫酸渣球团表现出良好的焙烧性能。其在1 150 ℃焙烧10 min,成品球团强度达3 kN/个以上,焙烧温度较天然铁矿降低近100 ℃,有利于减小能耗。

(4) 硫酸渣由于本身特性,其球团的制备与天然铁矿石有些差异,但润磨可强化硫酸渣生球及成品球的质量,使全硫酸渣能制备出物理强度和化学成分满足生产要求的球团,这技术对于减小硫酸渣对环境的破坏及扩大钢铁原料来源具有重大意义。

参考文献:

[1] 唐达高. 硫酸烧渣生产球团的技术探讨[J]. 中国资源综合利用, 2006, 24(7): 5-7.

TANG Da-gao. Research on pyrite cinder used in pellet production[J]. China Resources Comprehensive Utilization, 2006, 24(7): 5-7.

[2] Fellet G, Marchiol L. The application of phytoremediation technology in a soil contaminated by pyrite cinders[J]. Ecological Engineering, 2007(35): 207-214.

[3] Marchiol L, Fellet G, Perosa D. Removal of trace metals by sorghum bicolor and helianthus annuus in a site polluted by industrial wastes: A field experience[J]. Plant Physiology and Biochemistry, 2007(45): 379-387.

[4] 郑雅杰, 陈梦君, 黄桂林. 硫铁矿烧渣制备钾铁蓝[J]. 中南大学学报: 自然科学版, 2006, 37(2): 252-256.

ZHENG Ya-jie, CHEN Meng-jun, HUANG Gui-lin. Preparation of potassium iron blue from pyrite cinder[J]. Journal of Central South University: Science and Technology, 2006, 37(2): 252-256.

[5] 刘心中, 杨新春, 董凤芝, 等. 硫酸烧渣综合利用[J]. 金属矿山, 2002, 37(9): 51-54.

LIU Xin-zhong, YANG Xin-chun, DONG Feng-zhi, et al. Comprehensive utilization of burned slags of sulphuric acid making[J]. Metal Mine, 2002, 37(9): 51-54.

[6] 王雪松. 黄铁矿烧渣的物质组成及利用[D]. 北京: 北京科技大学环境工程系, 1993: 1-79.

WANG Xue-song. The mineral form and utilization of pyrite cinder[D]. Beijing: University of Science and Technology Beijing. Department of Environmental Engineering, 1993: 1-79.

[7] 王雪松, 张德海, 任允芙. 黄铁矿烧渣的特性及其利用[J]. 环境工程, 1999, 18(1): 58-61.

WANG Xue-song, ZHANG De-hai, REN Yun-fu. Characteristics of pyrite cinder and its application[J]. Environmental Engineering, 1999, 18(1): 58-61.

[8] 胡宾生, 王雪松, 李亮, 等. 铜陵硫酸渣的矿物特征及在磁化焙烧过程中的变化[J]. 矿产综合利用, 1998(2): 35-38.

HU Bin-sheng, WANG Xue-song, LI Liang, et al. The mineralogy of Tongling pyrite cinder and its transition during magnetic roasting[J]. Multipurpose Utilization of Mineral Resources, 1998(2): 35-38.

[9] 陈铁军, 张一敏. 全硫酸渣生产氧化球团试验研究及工业应用[J]. 钢铁研究, 2005(1): 1-4.

CHEN Tie-jun, ZHANG Yi-min. Experiments of acid pellet using treated pyrite slag and its commercial application[J]. Research on Iron and Steel, 2005(1): 1-4.

[10] 许斌, 庄剑鸣, 白国华, 等. 硫酸烧渣综合利用新工艺[J]. 中南工业大学学报: 自然科学版, 2000, 31(3): 215-218.

XU Bin, ZHUANG Jian-ming, BAI Guo-hua, et al. A new way of comprehensive utilizing of pyretic slag[J]. Journal of Central South University of Technology: Nature Science, 2000, 31(3): 215-218.

[11] Viňals J, Balart M J, Roca A. Inertization of pyrite cinders and co-inertization with electric arc furnace flue dusts by pyroconsolidation at solid state[J]. Waste Management, 2002, 22(7): 773-782.

[12] Loo C E. Mechanism of low-temperature reduction degradation of iron ores inters[J]. Transactions of the Institution of Mining and Metallurgy, 1994, 103(2): 126-128.

[13] 傅菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996: 283-290.

FU Ju-ying, JIAN Tao, ZHU De-qing. Principle of sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996: 283-290.

[14] Kawatra S K, Ripke S J. Effects of bentonite fiber formation in iron ore pelletization[J]. Mineral Processing, 2002(65): 14l-149.

[15] 魏祥松. 硫铁矿烧渣特性及综合利用[J]. 化工地质, 1994, 16(3): 205-207.

WEI Xiang-song. Characteristics and utilization of the smelter slags from smelted pyrite ores[J]. Geology of Chemical Minerals, 1994, 16(3): 205-207.

(编辑 杨幼平)

收稿日期:2010-05-25;修回日期:2010-08-29

基金项目:新世纪优秀人才支持计划项目(NCET-05-0690)

通信作者:白国华(1953-),男,陕西榆林人,硕士,副教授,从事烧结球团及资源综合利用的研究;电话:13973180163;E-mail:baiguohua@tom.com