热等离子体制备与球化超细难熔金属粉的研究进展

来源期刊:中国有色金属学报2020年第9期

论文作者:叶凯 梁风 姚耀春 马文会 杨斌 戴永年

文章页码:2011 - 2022

关键词:热等离子体;超细难熔金属粉;制备;球化

Key words:thermal plasma; ultrafine refractory metal powder; preparation; spheroidization

摘 要:本文首先介绍了直流电弧等离子体制备纳米钨粉、纳米钼粉等难熔金属纳米粉的研究进展。该方法制备的难熔金属纳米粉具有纯度高、分散性好、粒径小且粒度分布均匀等特点,但难以连续制备,规模化生产难度大。其研究趋势是优化等离子体设备的设计,找到最佳的合成工艺。另外,重点叙述了射频等离子体球化难熔金属粉的研究现状。所制备的球形微粉球化率高,流动性、振实密度与松装密度等性能优异,能实现可控地连续化制备。指出了其研究重点为找到进料速率、载气速率与高球化率、高性能的产物之间的平衡,以更快的速率制备出高品质的产物。最后,对热等离子体制备与球化超细难熔金属粉向着高品质、低成本、大规模可控制备的发展方向进行了展望。

Abstract: In this paper, the fabrication of tungsten nanopowders, molybdenum nanopowders, and other refractory metal nanopowders using direct current arc plasma were introduced firstly. The products have high purity, good dispersibility, small particle size and uniform particle size distribution. However, it’s difficult for continuous and large-scale preparation. So, it needs to optimize the design of plasma equipment to find the best synthetic process. In addition, the research status of the radio frequency plasma spheroidized refractory metal powder is described. The product that can be controlled and continuously prepared, has the advantages of high spheroidization rate, flowability, tap density and apparent density. The focus is to find the balance between the feed rate, the carrier gas rate and the high nodularity, high performance and quality products. Finally, the development direction of thermal plasma preparing and spheroidizing ultrafine refractory metal powder with high quality, low cost and large scale controllable preparation is prospected.

DOI: 10.11817/j.ysxb.1004.0609.2020-37618

叶 凯1, 2,梁 风1, 2, 3,姚耀春1, 2,马文会1, 2, 3,杨 斌1, 2, 3,戴永年1, 2, 3

(1. 昆明理工大学 真空冶金国家工程实验室,昆明 650093;

2. 昆明理工大学 云南省有色金属真空冶金重点实验室 昆明650093;

3. 昆明理工大学 省部共建复杂有色金属资源清洁利用国家重点实验室,昆明 650093)

摘 要:本文首先介绍了直流电弧等离子体制备纳米钨粉、纳米钼粉等难熔金属纳米粉的研究进展。该方法制备的难熔金属纳米粉具有纯度高、分散性好、粒径小且粒度分布均匀等特点,但难以连续制备,规模化生产难度大。其研究趋势是优化等离子体设备的设计,找到最佳的合成工艺。另外,重点叙述了射频等离子体球化难熔金属粉的研究现状。所制备的球形微粉球化率高,流动性、振实密度与松装密度等性能优异,能实现可控地连续化制备。指出了其研究重点为找到进料速率、载气速率与高球化率、高性能的产物之间的平衡,以更快的速率制备出高品质的产物。最后,对热等离子体制备与球化超细难熔金属粉向着高品质、低成本、大规模可控制备的发展方向进行了展望。

关键词:热等离子体;超细难熔金属粉;制备;球化

文章编号:1004-0609(2020)-09-2011-11 中图分类号:TB31;O539 文献标志码:A

难熔金属指熔点高于1650 ℃并有一定储量的金属,主要有钨、钛、钼等。难熔金属及其相关材料具有高熔点、优异的导电性、导热性与抗腐蚀性,已被广泛应用于电子工业、化学工业以及军工等领域中[1]。但高品质难熔金属纳米粉的制备一直是工业上的难题。直流电弧等离子体法是一种合成高纯度纳米材料的有效方法[2],已在碳纳米材料的制备领域取得了诸多进展[3-6]。中心电弧区高达1×104 K的温度可以使难熔金属阳极迅速升华,经过冷凝-成核-长大的过程后即可获得纯度高、分散性好、粒径小且粒度分布均匀的难熔金属纳米粉。通过改变等离子体气体压力、电流等实验参数,可对难熔金属纳米颗粒的粒径和产率进行控制。

热喷涂、3D打印等球形超细难熔金属粉的热门应用领域要求其具有高流动性与优异的分散性,但传统的工业方法难以实现高性能球形超细难熔金属粉的制备[7]。射频等离子体因其温度高、能量密度大及气氛可控等优势成为了球化难熔金属粉的有效手段。该方法获得的超细难熔金属粉的球化率高达100%,且可以通过改变进料速率与载气速率、等离子体压力等条件控制球化率与粒径大小。借助等离子体模拟与诊断等手段,找到最佳合成条件,在保证产物高品质的前提下提高制备速率,是当前研究的关键。这对进一步推动热等离子体在难熔金属粉球化工业中的应用具有重要意义。

本文主要介绍了热等离子体制备与球化超细难熔金属粉的研究进展。指出了该方法的优势与不足,提出了相应的解决方案,并对热等离子体在难熔金属深加工工业中的应用前景进行了展望。

1 难熔金属纳米粉的制备

目前,工业上制备难熔金属纳米粉的方法主要有高能球磨法、蒸发法与化学还原法等[8],但这些方法制备出的难熔金属纳米粉粒度较大、纯度不够高,且分散性较差。直流电弧等离子体等热等离子体方法能够很好地克服这些问题,制备出高品质的难熔金属纳米粉。直流电弧等离子体装置如图1所示[9],与制备纳米镍粉类似[10]。由于钨的熔点最高,通常选取钨棒作为阴极;阳极为难熔金属铸块。将反应室抽至真空,通入适当压力的等离子体气体,设置好放电电流后开始电弧放电。等离子体区域的高温会使阳极难熔金属块开始升华,形成难熔金属蒸气,随后流动到温度较低的区域重新冷凝成核、长大,最终在腔体内壁收集到难熔金属纳米粉。

KASSAEE等[11]使用直流电弧法制备了两种晶相的纳米钨颗粒α-W与β-W。实验选取直径2 mm、长度40 mm的片状钨棒作为电极,放电电流在40~160 A之间;放电介质选用氮气、空气与蒸馏水等,分别探究电流与放电介质等实验条件对纳米钨的形貌与尺寸的影响。实验结果表明,在氮气气氛下放电得到的纳米钨粉纯度最高,且在电流为100 A时粒径最小。该产物为球形α-W相的纳米钨颗粒,粒度分布窄,平均粒径为68 nm,远小于化学还原法制备的平均粒径在400~500 nm之间的非晶钨颗粒。

LIU等[12]以纯钛块为原料,乙醇作为碳源,采用直流电弧等离子体法在Ar气氛下制备了石墨包覆结构的钛纳米颗粒。阳极与阴极分别为钛锭与钨针。将反应室抽真空后通入16 kPa的Ar与40 mL的乙醇,在60 A的电流下放电4 h。放电结束后,将产物置于Ar气氛下钝化24 h以减少其表面氧化。最后,在水冷室顶部的沉积物中收集到粒径范围在10~30 nm的石墨包覆结构的钛纳米颗粒。该方法制备的产物具有球形的核-壳结构,介电性能优异,是一种极具前景的电磁波屏蔽材料。

笔者课题组也进行了热等离子体制备难熔金属纳米粉的相关研究,采用直流电弧等离子体法制备了纳米钨粉和纳米钼粉。实验选用纯钨棒/钼棒作为阳极,在H2和Ar混合气体下放电,最后在腔体内壁收集平均粒径分别为23.7 nm与27 nm的纳米钨粉和钼粉,粒度分布均匀,团聚较少,具有较规则的球形结构。

采用直流电弧等离子体法制备难熔金属纳米粉时,需要注意以下问题:1) 难熔金属阳极沸点高,需要达到一定输入功率,才能使阳极表面温度高于沸点从而开始升华。故应选取适当的气体压力和电流来进行放电操作;2) 难熔金属纳米粉极易氧化,制备完成后,应选取合适的惰性气体与钝化时长,对其进行钝化处理,减少其氧化;3) 高温下难熔金属可能会与等离子体气体发生化学反应,生成相应的化合物。需要对难熔金属的性质进行深入了解,选取合适种类的等离子体气体进行电弧放电。

射频感应热等离子体也可以用于制备难熔金属纳米粉。ZHANG等[13]使用了射频感应热等离子体合成了平均粒径小于50 nm的纳米钨粉。该实验使用粒径范围在20~150 μm的APT(仲钨酸铵)为前驱体,Ar与H2分别作为等离子体气体与还原剂。将前驱体APT粉末通过载气(H2)送入等离子体炬中,等离子体炬的功率保持30 kW恒定。反应结束后可在腔体底部收集到粒度分布均匀的球形纳米钨粉。实验结果表明,改变进料速度可以控制产物的纯度,调节淬火速率可以控制颗粒的尺寸:较低进料速率下所制备的纳米钨粉纯度更高,较高淬火速率时获得的产物粒径更小。RYU等[14]也采用了类似的方法,选取APT作为原料在H2等离子体炬中制备了粒径小于50 nm的球形纳米钨粉。本工作所采用的射频热等离子体工艺相比传统方法的多步工艺更加直接,等离子体区域的高温使APT粉末迅速挥发,随后快速淬火形成纳米钨粉。中科院过程工程所的袁方利课题组[15]使用氢射频等离子体还原仲钨酸铵制备纳米钨粉。该方法所制备的纳米钨粉粒径范围在20~100 nm之间,具有良好的分散性与高烧结活性。综上所述,射频等离子体制备难熔金属纳米粉具有操作流程简单和尺寸可控等优势。氢等离子体产生的活性粒子有效强化了内部的还原反应,有利于获得粒度分布均匀的难熔纳米金属颗粒。通过原料粒度的筛选和优化等离子体温度梯度分布等工艺,可进一步提高产物的纯度和粒度均一性。

热等离子体法可以制备出化学还原法等其他方法难以获得的高品质难熔金属纳米粉,整个制备过程操作简单、环境友好;产物具有纯度高、粒径小及粒度分布均匀等优点,且可以通过改变等离子体气体组成、压力、电流等实验条件对其粒径和粒度分布进行控制。但该方法对设备要求较高,难以连续制备,目前距离大规模工业化应用尚有较大距离。下一步研究应着重于分析难熔金属纳米颗粒的成核与生长机理,找到合成难熔金属纳米粉的最佳工艺条件,并通过优化等离子体设备设计等手段,使热等离子体法能够更好地应用于工业生产之中。

图1 用于制备难熔金属纳米粉的直流等离子体系统装置图[9]

Fig. 1 Schematic diagram of DC plasma device for preparing refractory metal nanopowders[9]

2 难熔金属粉的热等离子体球化

射频等离子体法是球化难熔金属粉的一种高效手段[16]。该方法通常选用无规则形状的难熔金属粉作为原料,通过载气将其注入等离子体炬中;经过熔化-凝固-淬火等过程后,最终制备出粒径小于原料粉末的球形难熔金属粉。与直流电弧等离子体制备难熔金属纳米粉不同,射频等离子体球化的物理过程是熔融颗粒的凝固淬火,而直流电弧制备纳米粉的物理过程是金属升华成蒸气后的冷凝成核。因此,射频等离子体球化工艺无需使金属产生蒸气的高温。在工业生产中要求球形粉末粒径小、粒度分布均匀,且其是否具有高球化率、振实密度与松装密度有着更高的要求。相比于制备难熔金属纳米粉,热等离子体法在难熔金属粉球化领域的应用更加广泛。采用射频等离子体对难熔金属粉进行球化前后的粒径、振实密度与松装密度的变化已总结如表1所列。从表1中可以发现,球化后产物的粒径有所下降,振实密度等性能都较原料粉末有了大幅提高。下面将重点介绍几位研究者采用射频等离子体法球化难熔金属粉的研究进展。

2.1 钨粉的热等离子体球化

球形超细钨粉具有高烧结活性、优异的分散性及流动性等特点,在烧结过程中收缩均匀,有利于获得致密度高的胚体[22-23]。其应用范围主要有热喷涂、高温流体过滤材料和等离子体第一壁材料等[24-25]。WANG等[26]使用射频感应等离子体制备了可满足于添加剂制造工艺要求的球形超细钨粉并探究了球化前后钨粉的流动性与吸收系数等性能的变化。实验装置如图2所示,主要由等离子体发生器、反应室、冷却室、送粉系统、收粉系统和分离器组成。整个球化过程分为三个步骤:1) 原料钨粉脱水预处理后使用筛分仪对干粉进行筛选,选出粒度分布窄的钨粉进行球化;2) 向射频等离子体发生器中通入13.8 kPa的Ar以产生等离子体,功率设置为40 kW恒定;3) 通入载气将钨粉送入等离子体炬中,当粉末通过高温区时,完全熔化形成球形金属液滴,凝固后即可收集到球形超细钨粉。对球化前后钨粉的分析结果表明,球化后的钨粉的平均粒径和氧含量均有所降低,吸收系数提高了15%,球形钨粉的流动性、压缩性与渗透性等也均优于原料钨粉的。该方法制备的球形钨粉的特性很好地满足了添加剂制造工艺的要求,具有广阔的工业应用前景。

表1 射频等离子体球化难熔金属粉前后的性能变化总结

Table 1 Summary of performance changes before and after RF plasma spheroidization of refractory metal powders

图2 用于球化钨粉的射频感应等离子体系统装置图[26]

Fig.2 Schematic diagram of RF induction plasma system for spheroidizing tungsten powders[26]

HAN等[27]通过射频等离子体法原位合成了球形超细钨粉、钨纳米颗粒和附着有钨纳米颗粒的球形超细钨粉。实验选用质量比1:1的W/WO3混合微粉作为原料,通入Ar、H2与N2的混合气体中。其中,Ar、H2分别为载气和鞘气,N2则起到淬火气体的作用。等离子体功率为28 kW恒定,进料速率为5 g/min。反应结束后对产物进行超声与干燥处理,即可得到附有钨纳米颗粒的球形超细钨粉。钨纳米颗粒附着在球形超细钨粉表面起到了均相烧结活化剂的作用,能有效降低烧结温度,提高烧结体性能。中科院过程工程所的袁方利课题组[28]使用30 kW的射频等离子体设备来制备球形钨粉。由于在高振荡频率和大输入功率下钨粉的熔融液滴相互碰撞结合更加剧烈,产物球形钨粉的平均粒径较原料的钨粉有所增大。

研究表明,影响球形钨粉球化率和产物性能的实验因素主要为进料速率。ZI等[17]采用射频等离子体球化技术获得了流动性好、松装密度高的球形超细钨粉。实验选用Ar作为等离子体气体(中心气、鞘气和载气),通入辅助气体(H2)以提高等离子体气体的导热性。等离子体功率保持在15 kW,进料速率为4~25 g/min,探究其对球形颗粒的粒径、流动性和松装密度的影响。实验结束后在粉末收集器中得到了球形超细钨粉。不同进料速率制备的球形超细钨粉的SEM像如图3所示。结果表明,进料速率对产品粉末的球化率、粒度和各项性能有着重要影响:随着进料速率的降低,球化率逐渐提高,流动性与松装密度也随之增大,平均粒径从74 μm下降至36.6 μm。

合肥工业大学的张久兴教授课题组[29]采用射频等离子体球化技术对形状不规则的钨粉进行球化处理,并探究了进料速率对球化效果的影响。实验结果表明,低的进料速率能提高钨粉的球化率,但过低的进料速率会导致粉末在等离子体高温区停留时间过长,造成表面气化,使球形粉末表面吸附大量的纳米颗粒。故应选取合适的进料速度,在保证球形钨粉表面光滑的前提下获得更大的球化率。该课题组[30]还采用类似的射频等离子体技术制备球形超细钨粉,并通过放电等离子烧结法获得了钡钨阴极多孔钨基体。该球形钨粉表面光滑,球化率高达98%以上。与原料钨粉相比,所制备的多孔钨基体的孔隙更加规则,具有更均匀的孔隙分布,开孔率也有所提高。

图3 不同进料速率制备的球形超细钨粉的SEM像[17]

Fig. 3 SEM images of spherical ultrafine tungsten powders prepared at different feed rates

选择粒径小且具有较窄粒度分布的原料钨粉,有利于提高球形钨粉产物的各项性能。北京科技大学的秦明礼教授等[31]使用气流磨分散、分级技术与射频等离子体相结合的方法制备球形超细钨粉,解决了由于原料钨粉团聚所导致的球化过程难以控制、产物粒径大与粒度分布宽等问题。经气流磨破碎与分散处理后的钨粉具有更小的粒径与更窄的粒度分布,保证了产物的高球化率与窄粒度分布。该方法解决了原料钨粉粒径过大、粒度分布不均匀等问题,有效提高了球形钨粉产物粒度分布的均匀性,是工业化生产球形钨粉的理想方案。

等离子体数值模拟是探究钨粉颗粒球化过程机理的有效手段。ZHU等[32]采用射频等离子体制备了球形超细钨粉并通过等离子体数值模拟研究了钨粉颗粒在球化过程中的熔化、凝固和长大等行为。通过真空泵将反应室压力抽到40 kPa,随后将等离子体气体(Ar)注入等离子体炬中。点火后,逐渐增大功率与总气体流量以保持等离子体稳定,并将原料钨粉通过载气(Ar)运送到等离子体高温区域的粉末注射探针。原料钨粉在等离子体高温区域熔化后于等离子体出口处凝固,最终收集到平均粒径为20 μm的球形钨粉。作者对等离子体区域的温度与速度场进行了模拟计算后得到以下结论:1) 钨粉颗粒在冷却区的生长速率高于等离子体高温区; 2) 射频等离子体系统中钨液滴的碰撞聚结是钨粉颗粒生长的主要原因;3) 在射频等离子体系统中选择适当的实验参数,可以在预期的粒度分布范围内获得具有高球化率的超细钨粉。通过等离子体数值模拟手段对钨粉的球化机理进行探究,找出适合钨粉颗粒长大的温度和速度区间从而优化热等离子体的工艺参数,有利于实现高球化率、性能优异的球形钨粉的大规模可控制备。

综上所述,采用射频等离子体球化钨粉可以获得粒径更小、性能更优的球形超细钨粉。该方法通过改变进料速率与载气速率能够对产物的球化率与粒度进行控制,具有大规模连续化生产的潜力。采用射频等离子体球化钨粉时需注意以下两点:1) 球化的原料钨粉粒径不宜过大,且应具有较窄的粒度分布;2) 过快的载气速率与进料速率会使原料钨粉在等离子体炬中的滞留时间缩短,导致球化率降低。故应选取适当的进料速率与载气速率来进行钨粉的射频等离子体球化。

2.2 钛粉的热等离子体球化

钛是一种极具发展前景的工程材料,具有强度密度比高、流动性好、生物相容性好、高温强度高等优点[33-35]。基于球形超细钛粉的相关材料已被广泛应用于3D打印、航空航天、石油化工、海洋工程以及生物医疗等[36-40]领域。古忠涛等[18]使用射频等离子体制备了球形超细钛粉。该研究选取粒径80~100 μm的海绵状钛粉作为原料,通过载气输送到Ar等离子体炬中,改变进料速率、载气速率与原料钛粉的粒度分布,探究这些因素对球化率与产物性能的影响。结果表明,进料速率与载气速率越大,原料钛粉在等离子体炬中的停留时间越短,球化率越低,产物的振实密度、松装密度也随之降低。此外,应选择尺寸较小、粒度分布均匀的原料钛粉,经球化后才能获得粒径小且粒度分布均匀的球形超细钛粉。

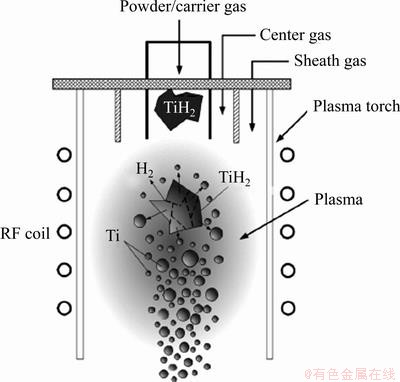

北京科技大学的郭志猛教授团队在钛粉的射频等离子体球化领域开展了一系列研究。该团队[19]采用射频等离子体对TiH2粉末进行球化,获得了平均粒径远小于原料粉末的超细钛粉。该球化过程与使用原料钛粉时不同,TiH2粉末在等离子体区域受热分解后形成球形超细钛粉,整个过程更加复杂。本实验使用Ar作为中心气体和鞘层气体,将平均粒径133.56 μm的原料TiH2粉末轴向注入等离子体炬中,待其熔化与凝固过程完成后在热交换室的底部收集到了平均粒径仅为33.34 μm的球形超细钛粉。TiH2粉末的球化机理如图4所示。当TiH2粉末注入等离子体高温区后,吸收能量过快,导致发生剧烈的脱氢反应;由于其结构疏松、脆性大,在脱氢反应中无法瞬间承受大量氢气的压力,被破碎成细粉;细粉在等离子体高温区加热熔化,经凝固、淬火后形成球形超细钛粉。该方法的球化率可达100%,且获得的球形钛粉分散性好、表面光滑,松装密度与流动性都较TiH2粉末有大幅提高。该团队的盛艳伟等[41]也采用类似的方法成功将粒径范围100~250 μm的TiH2粉末球化为了20~50 μm的球形钛粉。初始产物主要为Ti和残余的TiH相,经过真空脱氢处理后,即可得到表面光滑的单相球形钛粉。脱氢与球化的共同作用使TiH2粉末转变为超细球形钛粉,其优势为脱氢反应产生的氢活性粒子可以有效增强球化过程,提高产物粒度分布的均一性。

图4 射频等离子体球化TiH2粉的机理图[19]

Fig. 4 Mechanism diagram of spheroidizing TiH2 powders by RF plasma[19]

TiAl合金是一种新型的轻质高温合金材料,在航空航天领域具有广阔的应用前景。氧含量较高、形状不规则一直是TiAl 基合金粉末制备工艺的难题。北京科技大学的路新等[42]采用射频等离子体球化与高能球磨结合的工艺制备了球形TiAl合金粉末。产物球化率可达到100%,粒度分布均匀,且内部致密无孔洞。实验结果表明,球形TiAl 合金粉末的氧含量随着粒度的降低而升高。通过改变输入功率和进料速率,可以对产物的粒度和氧含量进行控制,实现高纯度的球形TiAl 合金粉末的可控制备。

2.3 钼粉的热等离子体球化

钼具有良好的导电性与导热性,热膨胀系数小,高温环境下力学性能优异[43-45],在冶金工业、航空航天、军事工业等领域有着广泛应用[46-48]。球形超细钼粉相对于普通钼粉形貌更规则、粒径更小、流动性更佳[49],已成为钼粉制备及应用的研究热点。

西安建筑科技大学的王快社教授团队[20]以不规则钼粉为前驱体,采用射频等离子体制备了结构致密的球形超细钼粉。球化后获得的超细钼粉的平均粒径由72 μm减小到62 μm,振实密度由2.7 g/cm3提高到了6.2 g/cm3。北京科技大学的郭志猛教授团队[21]使用射频等离子体制备了球形超细钼粉。团聚的不规则钼粉经等离子球化处理后得到了表面光滑、分散性良好的球形钼粉。粉末的粒度分布变窄,松装密度和振实密度均有显著提高:松装密度由1.58 g/cm3提高到5.18 g/cm3,振实密度由2.32 g/cm3提高到了6.68 g/cm3,实现了钼粉的球化、致密化、细化和纯化。

金堆城钼业的研究人员也开展了钼粉球化的相关工作,重点探究了钼粉的热等离子体球化过程中球化率、产物性能与输入功率、送粉速率之间的平衡问题。陈强等[50]采用60 kW的射频等离子体炬制备球形钼粉,探究了输入功率与送粉速率对制备高致密度球形钼粉的影响。过低的输入功率和过大的送粉速率使钼粉颗粒表面无法完全熔融球化,导致钼粉流动性降低和松装密度减小;而过高的输入功率和过小的送粉速率会导致钼粉颗粒的完全熔融而不是表面熔融,使球形钼粉的粒度过细,发生团聚,同样会降低其流动性与松装密度。因此,选择适当的输入功率与送粉速率,是热等离子体法制备流动性好、松装密度高球形钼粉的关键。付小俊等[51]采用热等离子球化工艺制备球形超细钼粉,并与高温还原法、喷雾造粒法制备的球形钼粉进行了比较。结果表明,热等离子法制备的球形钼粉更加均匀致密,流动性好,松装密度更高。

HAN等[52]采用射频热等离子体结合粉末粉碎工艺,以废钼片为原料制备了球形超细钼粉。实验首先将钼片废料经过机械抛光后粉碎成小块,再采用锤式球磨工艺将其磨成细颗粒。对这些颗粒进行机械筛分,选择粒径45 μm以下的颗粒作为射频热等离子体球化的原料,使用载气(Ar)将原料钼粉以5 g/min的进料速率注入等离子体炬中,等离子体功率保持28 kW恒定。实验结束后收集到了平均粒径为10 μm的球形超细钼粉。但其粒度分布不够均匀,这是由于粉碎废钼片制得的原料钼粉粒度分布较分散导致的。该研究为高效处理钼等难熔金属废料提供了一种很好的思路,但需进一步改进粉末粉碎工艺,提高产物粒度分布的均匀性。

在射频等离子体制备球形钼粉的过程中,提高输入功率、减小进料速率与载气速率都有利于减小淬火速率,增大钼粉颗粒在生长区间的停留时间,使其能被充分球化,提高产物的球化率、流动性和松装密度。借助数值模拟等手段可计算出钼粉颗粒最佳淬火率的范围,改变输入功率、进料速率和载气速率等条件来控制淬火速率,可实现高球化率、性能优异的球形钼粉的可控制备。

热等离子体球化难熔金属粉是获得高性能球形超细难熔金属粉的有效手段,其特点是球化过程可控、球化率可达到100%,且产物球形度高、分散性好,流动性、松装密度与振实密度等性能也较原料粉末有大幅提高。找到球化难熔金属粉的最佳实验参数,在保证产物高品质的前提下实现高速率球化,是当前热等离子体球化难熔金属粉的研究重点。

3 结语与展望

热等离子体是制备与球化超细难熔金属粉的有效手段。使用热等离子体法制备难熔金属纳米粉有以下优势:1) 产物纯度高,粒径小,粒度分布较均匀;2) 制备过程简单,对环境友好;3) 可通过改变电流与等离子体气体种类、压力等参数实现对粒径、产率的控制。但该方法仍然存在着产率较低、难以实现连续制备、生产设备要求高等不足。针对以上问题,需要通过优化等离子体设备来提升反应器所能承受的工作压力,并设计出连续供给装置,提高制备过程中电弧的稳定性、难熔金属纳米粉制备的产率和连续性。同时,还应探究纳米颗粒的生长机理与最佳合成条件,最终实现热等离子体法对难熔金属纳米粉的低成本、大规模的工业化生产。

近年来,球形超细难熔金属粉在3D打印、热喷涂、生物医疗、航空航天等领域的应用发展势头迅猛,对球形超细粉末的性能要求也越来越高。使用射频等离子体球化无规则形状、粒径较大的难熔金属粉,最终获得的超细粉末具有规则的球形结构,球化率可达100%;所得样品的流动性好,振实密度、松装密度也较原料有了大幅提高,可以满足相关应用的高要求。但采用射频等离子体球化难熔金属粉时存在以下现象:增大进料速率与载气速率,产物的球化率会降低,振实密度等性能也随之下降。故采用射频等离子体很难实现高性能难熔金属粉的快速球化。对此,我们可以通过借助等离子体模拟与诊断等手段,探究难熔金属微颗粒在等离子体炬中的生长机理,找到输入功率、进料速率、载气速率与高球化率、高性能的产物之间的平衡,得到射频等离子体球化难熔金属粉的最佳工艺参数,推动射频等离子体技术对在高制备速率、高性能的球形超细难熔金属粉工业化上的大规模应用。

超细难熔金属粉的制备与球化在难熔金属深加工工业中占有重要的比重。提高超细难熔金属粉的性能、减小制备过程的污染排放,对于提升难熔金属深加工企业的经济效益和我国难熔金属深加工行业的竞争力都有着重大的意义。热等离子法是超细难熔金属粉的制备与球化的有效方法。加大热等离子体法制备与球化超细难熔金属粉的研究力度,降低生产成本,推进该技术的大规模的工业化生产,必将推动我国整个难熔金属深加工行业的又好又快发展。

REFERENCES

[1] 刘辉明, 范景莲, 田家敏, 游 峰. 超细钨粉的研究与应用[J]. 中国钨业, 2009, 24(1): 29-32.

LIU Hui-ming, FAN Jing-lian, TIAN Jia-min, YOU Feng. The preparation process and application of superfine tungsten powder[J]. China Tungsten Industry, 2009, 24(1): 29-32.

[2] 叶 凯, 梁 风, 姚耀春, 马文会, 杨 斌, 戴永年. 直流电弧等离子体法制备纳米材料的研究进展[J]. 材料导报, 2019, 33(4): 1089-1098.

YE Kai, LIANG Feng, YAO Yao-chun, MA Wen-hui, YANG Bin, DAI Yong-nian. A survey on preparation of nanomaterials by DC arc plasma[J]. Materials Reports, 2019, 33(4): 1089-1098.

[3] LIANG F, SHIMIZU T, TANAKA M, CHOI S, WATANABE T. Selective preparation of polyhedral graphite particles and multi-wall carbon nanotubes by a transferred arc under atmospheric pressure[J]. Diamond and Related Materials, 2012, 30: 70-76.

[4] LIANG F, TANAKA M, CHOI S, WATANABE T. Investigation of the relationship between arc-anode attachment mode and anode temperature for nickel nanoparticle production by a DC arc discharge[J]. Journal of Physics D, 2016, 49(12): 125201.

[5] LIANG F, TANAKA M, CHOI S, WATANABE T. Formation of different arc-anode attachment modes and their effect on temperature fluctuation for carbon nanomaterial production in DC arc discharge[J]. Carbon, 2017, 117: 100-111.

[6] ZHANG D, YE K, YAO Y C, LIANG F, QU T, MA W H, YANG B, DAI Y N, WATANABE T. Controllable synthesis of carbon nanomaterials by direct current arc discharge from the inner wall of the chamber[J]. Carbon, 2019, 142: 278-284.

[7] 郭双全, 葛昌纯, 冯云彪,周张健. 低成本等离子体球化技术制备热喷涂用球形钨粉的工艺研究[J]. 粉末冶金工业, 2010, 20(3): 1-4.

GUO Shuang-quan, GE Chang-shun, FENG Yun-biao, ZHOU Zhang-jian. Research on low-cost plasma spheroidization technology for spherical tungsten powder used in thermal spraying[J]. Powder Metallurgy Industry, 2010, 20(3): 1-4.

[8] 叶 凯, 梁 风, 姚耀春, 马文会, 杨 斌, 戴永年. 纳米镍粉的制备与应用的发展趋势[J]. 化工进展, 2019, 38(5): 2252-2261.

YE Kai, LIANG Feng, YAO Yao-chun, MA Wen-hui, YANG Bin, DAI Yong-nian. Development trend of preparation and application of nickel nanopowder[J]. Chemical Industry and Engineering Progress, 2019, 38(5): 2252-2261.

[9] CHO Y S, MOON J W, CHUNG K C, LEE J G. Synthesis of nickel and copper nanopowders by plasma arc evaporation[J]. Journal of Korean Powder Metallurgy Institute, 2013, 20(6): 411-424.

[10] SU F M, QIU X C, LIANG F, TANAKA M, QU T, YAO Y C, MA W H, YANG B, DAI Y N, HAYASHI K, WATANABE T. Preparation of nickel nanoparticles by direct current arc discharge method and their catalytic application in hybrid Na-air battery[J]. Nanomaterials, 2018, 8: 684-696.

[11] KASSAEE M Z, SOLEIMANI A S, BUAZAR F. Diverse tungsten nanoparticles via arc discharge[J]. Journal of Manufacturing Processes, 2010, 12(2): 85-91.

[12] LIU X G, GENG D Y, JIANG J J, DU J, YANG F, XIE Z G, KANG D J, ZHANG Z D. High dielectric loss in graphite-coated Ti nanocapsules[J]. Journal of Nanoscience and Nanotechnology, 2010, 10(4): 2366-2369.

[13] ZHANG H, BAI L, HU P, YUAN F L, LI J L. Single-step pathway for the synthesis of tungsten nanosized powders by RF induction thermal plasma[J]. International Journal of Refractory Metals and Hard Materials, 2012, 31: 33-38.

[14] RYU T, SOHN H Y, HWANG K S, FANG Z Z. Chemical vapor synthesis (CVS) of tungsten nanopowder in a thermal plasma reactor[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(1): 149-154.

[15] 袁方利, 金化成, 侯果林, 白柳杨, 丁 飞, 李保强, 陈运法. 高频热等离子体制备特种粉体研究进展[J]. 过程工程学报, 2018, 18(6): 28-34.

YUAN Fang-li, JIN Hua-cheng, HOU Guo-lin, BAI Liu-yang, DING Fei, LI Bao-qiang, CHEN Yun-fa. Progress on preparation of special powders using hf thermal plasma[J]. The Chinese Journal of Process Engineering, 2018, 18(6): 28-34.

[16] YU C F, ZHOU X, WANG D Z, LINH N V, LIU W. Study on the RF inductively coupled plasma spheroidization of refractory W and W-Ta alloy powders[J]. Plasma Science and Technology, 2018, 20(1): 131-138.

[17] ZI X H, CHEN C, WANG X, WANG P W, ZHANG X Y, ZHOU K C. Spheroidisation of tungsten powder by radio frequency plasma for selective laser melting[J]. Materials Science and Technology, 2017, 34(6): 735-742.

[18] 古忠涛, 叶高英, 刘川东, 童洪辉. 射频感应等离子体制备球形Ti粉的工艺[J]. 核动力工程, 2010, 31(1): 13-17.

GU Zhong-tao, YE Gao-ying, LIU Chuan-dong, TONG Hong-hui. Process for titanium powders spheroidization by RF induction plasma[J]. Nuclear Power Engineering, 2010, 31(1): 13-17.

[19] WANG J J, HAO J J, GUO Z M, WANG Y M. Preparation of spherical tungsten and titanium powders by RF induction plasma processing[J]. Rare Metals, 2015, 34(6): 431-435.

[20] LIU X P, WANG K S, HU P, CHEN Q, VOLINSKY A A. Spheroidization of molybdenum powder by radio frequency thermal plasma[J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(11): 1212-1218.

[21] 盛艳伟, 郭志猛, 郝俊杰, 邵慧萍, 王玉明. 射频等离子体制备球形Mo粉的研究[J]. 粉末冶金工业, 2011, 21(6): 6-10.

SHENG Yan-wei, GUO Zhi-meng, HAO Jun-jie, SHAO Hui-ping, WANG Yu-ming. Characterization of spherical molybdenum powders by RF plasma processing[J]. Powder Metallurgy Industry, 2011, 21(6): 6-10.

[22] KIRAN U R, KUMAR M P, SANKARANARAYANA M, SINGH A K, NANDY T K. High energy milling on tungsten powders[J]. International Journal of Refractory Metals and Hard Materials, 2015, 48: 74-81.

[23] OUARAS K, LOMBARDI G, COUEDEL L. Microarcing- enhanced tungsten nano and micro-particles formation in low pressure high-density plasma[J]. Physics of Plasma, 2019, 26(2): 023705.

[24] WANG F, HUANG J. Performance characterization and improvement of tungsten coating atmospheric plasma sprayed with submicron powder[J]. Surface and Coatings Technology, 2014, 254: 61-64.

[25] 吴 桐, 唐建成, 叶 楠, 卓海鸥, 薛滢妤, 周旭升. 碳辅助氢还原制备纳米钨粉的工艺及机理[J]. 中国有色金属学报, 2016, 26(5): 1027-1033.

WU Tong, TANG Jian-cheng, YE Nan, ZHUO Hai-ou, XUE Ying-yu, ZHOU Xu-sheng. Preparation technology and mechanism of tungsten nano-powders by carbon assisting hydrogen reduction[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1027-1033.

[26] WANG L Z, WU J J, ZHANG D J. Properties evolution of additive manufacture used tungsten powders prepared by radio frequency induction plasma[J]. International Journal of Refractory Metals and Hard Materials, 2017, 67: 90-97.

[27] HAN C, NA H, KIM Y, CHOI H. In-situ synthesis of tungsten nanoparticle attached spherical tungsten micro- powder by inductively coupled thermal plasma process[J]. International Journal of Refractory Metals and Hard Materials, 2015, 53: 7-12.

[28] 白柳杨, 金化成, 袁方利, 李晋林. 高频感应热等离子体在微细球形粉体材料制备中的应用[J]. 高电压技术, 2013(7): 34-40.

BAI Liu-yang, JIN Hua-cheng, YUAN Fang-li, LI Jin-lin. Application of radio-frequency induction thermal plasma in fine spherical powder preparation[J]. High Voltage Engineering, 2013(7): 34-40.

[29] 邱振涛, 胡 可, 韩翠柳, 杨芝, 张久兴. 感应等离子体球化处理难熔金属(W、Cr)粉末的研究[J]. 稀有金属与硬质合金, 2017(4): 24-30.

QIU Zhen-tao, HU Ke, HAN Cui-liu, YANG Zhi, ZHANG Jiu-xing. Study on induction plasma spheroidization of refractory metal (W, Cr) powders[J]. Rare Metals and Cemented Carbides, 2017(4): 24-30.

[30] 胡 可, 邱振涛, 杨新宇, 张久兴. 等离子体球化处理和放电等离子烧结制备的钡钨阴极多孔钨基体[J]. 稀有金属材料与工程, 2019, 48(2): 256-261.

HU Ke, QIU Zhen-tao, YANG Xin-yu, ZHANG Jiu-xing. Porous tungsten matrix for Ba-W cathode prepared by plasma spheroidization process and spark plasma sintering[J]. Rare Metal Materials and Engineering, 2019, 48(2): 256-261.

[31] 秦明礼, 李 睿, 陈 铮, 章 林, 章雨峰, 陈鹏起, 黄 化, 鲁慧峰, 贾宝瑞, 曲选辉. 一种窄粒度分布球形钨粉的制备方法: 中国, CN201710842720.6[P]. 2017-09-28.

QIN Ming-li, LI Rui, CHEN Zheng, ZHANG Lin, ZHANG Yu-feng, CHEN Peng-qi, HUANG Hua, LU Hui-feng, JIA Bao-rui, QU Xuan-hui. Method for preparing narrow-grained distribution spherical tungsten powder: China, CN201710842720.6[P]. 2017-09-28.

[32] ZHU H L, TONG H H, CHENG C M, LIU N. Study on behaviors of tungsten powders in radio frequency thermal plasma[J]. International Journal of Refractory Metals and Hard Materials, 2017, 66: 76-82.

[33] POPESCU S, JERBY E, MEIR Y, BARKAY Z, ASHKENAZI D, MITCHELL J A, GARREC J L, NARAYANAN T. Plasma column and nano-powder generation from solid titanium by localized microwaves in air[J]. Journal of Applied Physics, 2015, 118(2): 023302.

[34] XU X Y, HAN Y F, LI C F, NASH P, MANGABHAI D, LU W J. Flow behavior and processing map of forging commercial purity titanium powder compact[J]. Journal of Materials Research, 2015, 30(8): 1056-1064.

[35] JANMANEE P, MUTTAMARA A. Surface modification of tungsten carbide by electrical discharge coating (EDC) using a titanium powder suspension[J]. Applied Surface Science, 2012, 58(19): 7255-7265.

[36] ARABNEJAD S, JOHNSTON B, TANZER M, PASINI D. Fully porous 3D printed titanium femoral stem to reduce stress-shielding following total hip arthroplasty[J]. Journal of Orthopaedic Research, 2016, 35(8): 1774-1783.

[37] 金和喜, 魏克湘, 李建明, 周建宇, 彭文静. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2): 280-292.

JIN He-xi, WEI Ke-xiang, LI Jian-ming, ZHOU Jian-yu, PENG Wen-jing. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292.

[38] TAWANCY H M. On the hydrogen embrittlement of commercially pure alpha titanium: an example from the petrochemical industry[J]. Journal of Materials Engineering and Performance, 2016, 26(2): 1-10.

[39] GOLAZ B, MICHAUD V, LAVANCHY S, MANSON J A. Design and durability of titanium adhesive joints for marine applications[J]. International Journal of Adhesion and Adhesives, 2013, 45: 150-157.

[40] KWASNIAK P, PURAA J, ZWOLINSKA M, WIECINSKI P, SKARZYNSKI H, OLSZEWSKI L, MARCZAK J, GRABACZ H, KURZYDLOWSKI K J. Laser and chemical surface modifications of titanium grade 2 for medical application[J]. Applied Surface Science, 2015, 336: 267-273.

[41] 盛艳伟, 郭志猛, 郝俊杰, 邵慧萍, 王述超. 射频等离子体制备球形钛粉[J]. 稀有金属材料与工程, 2013, 42(6): 1291-1294.

SHENG Yan-wei, GUO Zhi-meng, HAO Jun-jie, SHAO Hui-ping, WANG Shu-chao. Preparation of micro-spherical titanium powder by RF plasma[J]. Rare Metal Materials and Engineering, 2013, 42(6): 1291-1294.

[42] 路 新, 刘程程, 朱郎平, 何新波, 郝俊杰, 曲选涛. 高能球磨与射频等离子体球化制备TiAl合金球形微粉[J]. 稀有金属材料与工程, 2013, 42(9): 1915-1920.

LU Xin, LIU Cheng-cheng, ZHU Lang-ping, HE Xin-bo, HAO Jun-jie, QU Xuan-tao. Fabrication of micro-fine spherical TiAl alloy powder by high-energy ball milling and radio frequency plasma spheroidization[J]. Rare Metal Materials and Engineering, 2013, 42(9): 1915-1920.

[43] KUBISZTAL J, BUDNIOK A, LASIA A. Study of the hydrogen evolution reaction on nickel-based composite coatings containing molybdenum powder[J]. International Journal of Hydrogen Energy, 2007, 32(9): 1211-1218.

[44] WANG X Q, ZHUANG F, SUN Y J, LIU J H, LI J, ZHAO H. The systematic control of polyhedral Mo powder formation with different particle sizes[J]. JOM, 2011, 63(12): 41-43.

[45] CHHILLAR P, AGRAWAL D, ADAIR J H. Sintering of molybdenum metal powder using microwave energy[J]. Powder Metallurgy, 2008, 51(2): 182-187.

[46] XIE H F, LI F G, WANG Y F, FU J B. Study on dynamic recrystallization behavior of powder metallurgy molybdenum[J]. Rare Metal Materials and Engineering, 2011, 40(4): 669-672.

[47] ZOPPI G, BEATTIE N S, MAJOR J D, MILES R W, FORBES I. Electrical, morphological and structural properties of RF magnetron sputtered Mo thin films for application in thin film photovoltaic solar cells[J]. Journal of Materials Science, 2011, 46(14): 4913-4921.

[48] LIU B, BAI P K, LI Y X. Preparation and selective laser sintering mechanism of polymer-coated Mo powder[J]. Advanced Materials Research, 2010, 148/149: 511-514.

[49] JIANG X L, BOULOS M. Induction plasma spheroidization of tungsten and molybdenum powders[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(1): 13-17.

[50] 陈 强, 冯鹏发, 武 洲, 胡 林. 高致密球形钼粉制备工艺研究[J]. 中国钼业, 2013, 37(4): 48-51.

CHEN Qiang, FENG Peng-fa, WU Zhou, HU Lin. Study on preparation technology of high-density spheiucal molybdenum powder[J]. China Molybdenum Industry, 2013, 37(4): 48-51.

[51] 付小俊, 曾 毅, 张俊利. 不同方式制备高流动性、大松比钼粉特性研究[J]. 粉末冶金技术, 2016, 34(6): 413-416.

FU Xiao-jun, ZENG Yi,ZHANG Jun-li. Study on the characteristics of molybdenum powders with fine flowbility and high bulk density prepared by different ways[J]. Powder Metallurgy Technology, 2016, 34(6): 413-416.

[52] HAN C, KIM B, CHOI H.In-situmolybdenum nano-attached particle synthesis from spent Mo scrap[J]. Journal of Nanoscience and Nanotechnology, 2014, 14(10): 8000-8004.

YE Kai1, 2, LIANG Feng1, 2, 3, YAO Yao-chun1, 2, MA Wen-hui1, 2, 3, YANG Bin1, 2, 3, DAI Yong-nian1, 2, 3

(1. The National Engineering Laboratory for Vacuum Metallurgy, Kunming University of Science and Technology, Kunming 650093, China;

2. Key Laboratory for Nonferrous Vacuum Metallurgy of Yunnan Province, Kunming University of Science and Technology, Kunming 650093, China;

3. State Key Laboratory of Complex Nonferrous Metal Resources Clear Utilization, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: In this paper, the fabrication of tungsten nanopowders, molybdenum nanopowders, and other refractory metal nanopowders using direct current arc plasma were introduced firstly. The products have high purity, good dispersibility, small particle size and uniform particle size distribution. However, it’s difficult for continuous and large-scale preparation. So, it needs to optimize the design of plasma equipment to find the best synthetic process. In addition, the research status of the radio frequency plasma spheroidized refractory metal powder is described. The product that can be controlled and continuously prepared, has the advantages of high spheroidization rate, flowability, tap density and apparent density. The focus is to find the balance between the feed rate, the carrier gas rate and the high nodularity, high performance and quality products. Finally, the development direction of thermal plasma preparing and spheroidizing ultrafine refractory metal powder with high quality, low cost and large scale controllable preparation is prospected.

Key words: thermal plasma; ultrafine refractory metal powder; preparation; spheroidization

Foundation item: Projects(11765010, 51704136) supported by the National Natural Science Foundation of China; Project(2016FB087) supported by the Applied Basic Research Project of Yunnan Province, China; Project(2018HA006) supported by the Academy of Liberal Exploration Fund of Yunnan Province, China

Received date: 2019-08-16; Accepted date: 2020-04-28

Corresponding author: LIANG Feng; Tel: +86-15198797858; E-mail: liangfeng@kust.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(11765010,51704136);云南省应用基础研究面上项目(2016FB087);云南省院士自由探索基金资助项目(2018HA006)

收稿日期:2019-08-16;修订日期:2020-04-28

通信作者:梁 风,教授,博士;电话:15198797858;E-mail:liangfeng@kust.edu.cn