文章编号: 1004-0609(2006)03-0447-06

激光强化铸铁活塞环的磨损性能

张庆茂1, 刘文今2

(1. 华南师范大学 光子信息技术广东省高校重点实验室, 广州 510631;

2. 清华大学 机械工程系 激光加工研究中心, 北京 100084)

摘 要: 为降低活塞环、 缸套摩擦副的磨损和改善配副性, 采用激光熔覆和电镀技术在球墨铸铁表面分别制备原位析出颗粒增强金属基复合材料表层和镀铬层。 分别以激光熔覆和镀铬强化的球墨铸铁为上试样, 灰铸铁为下试样, 模拟活塞环和缸套的工作环境, 进行SRV快速磨损实验。 实验结果表明: 镀铬活塞环和灰铸铁缸套配副, 摩擦系数在0.1170~0.1332范围内变化, 且随摩擦时间的延长, 摩擦系数逐渐增加, 其磨损机制为粘着磨损; 在相同的工艺条件下, 激光熔覆强化的活塞环与灰铸铁配副, 摩擦系数在0.067~0.085范围内变化, 随摩擦时间的延长逐渐降低, 其磨损机制为微切削。

关键词: 活塞环; 原位析出; 激光熔覆; 摩擦系数; 配副性 中图分类号: TG159.99

文献标识码: A

Wear performance of cast iron piston rings strengthened by laser

ZHANG Qing-mao1, LIU Wen-jin2

(1. Laboratory of Photonic Information Technology, South China Normal University,

Guangzhou 510631, China;

2. The Center of Laser Processing, Department of Mechanical Engineering,

Tsinghua University, Beijing 100084, China)

Abstract: In order to decrease the wear of piston rings and cylinder liners, and improve partner adaptability, the laser cladding and electroplating techniques were adopted to prepare in-situ precipitation particle reinforced metal matrix composite coatings and chromium-plated coatings on the nodular cast iron matrix. By simulating the operating conditions of piston rings and cylinder liner, the optimal SRV tests were carried out using laser cladding and chromium-plated strengthening piston rings as upper samples and grey cast iron as under samples, respectively. The results show that the friction coefficient (0.1170-0.1332) between the chromium-plated piston rings and cast iron cylinder liners increases with the increase of wear time, and the mechanism is adhesive wear. On the other hand, the laser cladding processes reduce the wear losses of the piston ring and partner cylinder liner and have the lower friction coefficient (0.067-0.085), which reduces with the increase of wear time, and the wear mechanism is micro-cutting.

Key words: piston ring; in-situ precipitation; laser cladding; friction coefficient; partner adaptability

缸套和活塞环是内燃机中一对重要的摩擦副, 其摩擦学性能的优劣直接影响着内燃机的功率输出、 使用寿命、 燃油和润滑油的消耗以及燃烧排放等重要指标。 随着发动机向高速、 高效、 大负荷方向的发展, 由于经常处于高温、 高压和高冲击的负荷工作状态, 缸套-活塞环摩擦副的工作条件更加苛刻。 因此, 要求活塞环具有更高的耐磨性和可靠性, 与缸套良好的配副性。 为提高活塞环的磨损性能, 除改变材质和优化结构形状外, 主要采用表面强化处理, 如镀铬、 喷涂、 离子氮化、 化学复合镀和激光强化技术等[1-6]。 目前, 由于激光强化技术可以直接作用在基体表面或通过添加高性能的材料, 利用其快速加热和冷却的特性在低等级材料表面制备具有优异性能的表层, 因此激光技术正越来越受到广泛的重视[7-13]。

本文作者利用优化的激光熔覆(FeCSiB+Zr+Ti)材料体系和工艺体系[14, 15]、 传统镀铬两种强化工艺在球墨铸铁基体材料表面分别制备原位析出颗粒增强金属基复合材料和镀铬表层, 并加工成标准的SRV 上试样, 以普通灰铸铁为配副, 在 SRV实验机上模拟活塞环、 缸套的工作状态, 进行SRV摩擦学对比实验。 测量摩擦副磨损量和摩擦系数。 并利用扫描电子显微镜观察磨痕的形貌, 研究了不同配副条件下的磨损机制。

1 实验

1.1 材料

激光熔覆和镀铬两种强化工艺用基体材料为球墨铸铁, SRV摩擦学实验的缸套材料为灰铸铁。 激光熔覆材料为自行研制的具有良好成形性的FeCSiB系合金粉末, 添加适当比例的强碳化物形成元素Zr和Ti。

1.2 方法及工艺条件

采用PRC 3kW快轴流CO2激光器、 国产数控激光加工机床进行激光熔覆实验, 实验过程中侧吹氩气保护熔池。 激光加工工艺参数列于表1。 激光熔覆试棒的直径为15.4mm, 长为150mm, 强化带位置开槽宽为2.5mm, 深为0.4mm。 在进行激光熔覆处理前, 试棒上预置FeCSiB+Zr+Ti合金粉末, 预置粉末层堆高0.7~2mm。 激光熔覆后, 经精磨、 切断制备成标准的SRV磨损实验试样。

表1 激光加工工艺参数

Table 1 Laser processing parameters

镀铬试棒的直径为15.1mm, 长为150mm, 在强化带位置开宽为2.5mm, 深为0.15mm的槽, 然后进行镀铬处理, 最后精磨到直径为15mm, 再切断, 制得4个镀铬强化标准的SRV磨损实验试样。 为了模拟真正的镀铬活塞环, 镀铬活塞环试样在某活塞环有限公司加工, 并采用与该公司镀铬活塞环产品完全相同的电镀工艺。

缸套试样是直接从离心铸造出来的缸套上截取的, 试样毛坯为12.5mm×12.5mm×55mm的试块, 为满足SRV实验试样的要求, 加工成18mm×12mm×7.88mm的试块, 同时需要设计达到SRV试验机要求的试样的卡具。 设计的卡具具有便于拆卸, 定位准确, 卡具与下试样间采用过盈配合以保证定位, 卡具材料为普通低碳钢的特点。 上下试样及卡具的加工精度按照SRV试验机要求的标准完成, 以确保上下试样的装配精度。

磨损实验在Optimal SRV高速往复磨损试验机完成, 实验设备示意图如图1所示。 实验规范如表2所列。 采用Talysurf 5-120表面形貌仪测量试样磨痕断面曲线上各点纵坐标, 每点间距为1.25μm, 测量范围1500个点。 在计算机上使用AutoCAD软件完成磨痕断面曲线的精确还原, 再与初始表面拟合, 最终利用AutoCAD编程计算出径向磨损量。 以活塞环和配对气缸套的最大径向磨损量作为评价绝对磨损量的标准。 Optimal SRV磨损试验机自动全程记录并显示摩擦系数。 本研究以进入正常磨损实验后至实验结束前(30min)的数据列出摩擦系数的范围和平均值。 在扫描电子显微镜下观察环套表面经Optimal SRV摩擦磨损后的微观形貌, 分析划伤、 犁沟及因金属粘着的转移、 脱落状态, 探索环、 套副的磨损机制。

图1 SRV磨损试验机示意图

Fig.1 Schematic diagram of SRV wear test machine

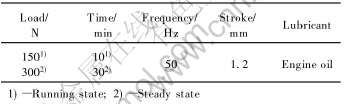

表2 SRV摩擦学参数

Table 2 SRV test parameters for measuring wear performances

2 结果与分析

2.1 磨损性能

以灰铸铁为配副的SRV实验结果如表3所列。 在实验过程中, 镀铬上试样与其配副在30min稳定磨损期内已经发生了严重的粘着磨损。 因此, 表3中的数据实际上为发生粘着磨损前10min计算出的数据。

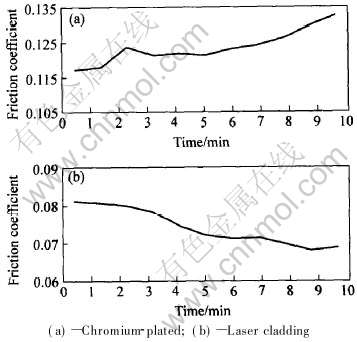

SRV实验结果表明, 在与灰铸铁缸套配副时, 镀铬环-缸套摩擦副不论摩擦系数、 摩擦力以及环-套双方径向磨损量均高于激光熔覆强化的环、 套摩擦副。 激光熔覆原位析出颗粒增强的活塞环较镀铬强化的活塞环具有较好的摩擦磨损特性和配副性, 摩擦系数和摩擦力均下降了40%~60%, 环的径向磨损下降了35%、 而缸套径向磨损量下降了89%。 各对配副在稳定磨损期, 摩擦系数随摩擦时间的变化趋势如图2所示。 当摩擦副进入稳定磨损期以后, 激光熔覆强化后的试样与配副间的摩擦系数呈下降趋势, 显示了其优异的摩擦磨损性能; 而镀铬环与配副间的摩擦系数具有较大的波动, 且摩擦随时间的增加, 摩擦系数在测量的最后10min增加得更加显著。

图2 不同配副磨损期后10min的摩擦系数变化曲线

Fig.2 Change curves of coefficient of different friction couples during final 10min

2.2 磨损机制

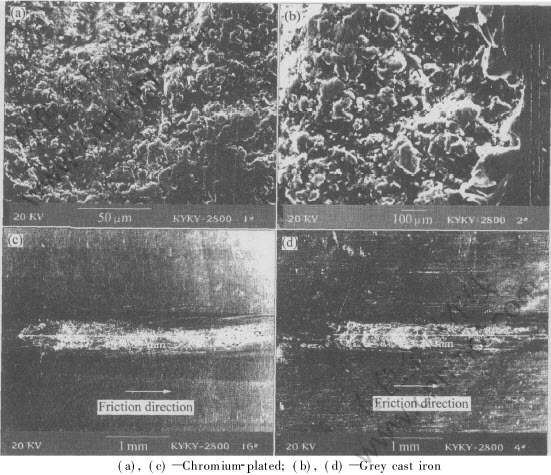

图3所示为镀铬试样与配副灰铸铁下试样进行SRV实验后, 在扫描电镜下观察到的试样表面磨痕形貌。 由图3可看出, 在镀铬上试样及配副灰铸铁下试样上均有较深的犁沟, 并发生了严重的粘着磨损。 在镀铬上试样的粘着磨损区域, 镀铬层明显发生了撕裂和剥落, 局部区域的镀铬层完全剥落, 且可清晰地看到球墨铸铁的基体组织; 而灰铸铁下试样上由于粘着磨损造成表层组织的撕裂, 并且次表层组织在塑性变形和挤压的情况下反复挤压成 形, 多数成为球状。 镀铬上试样发生粘着磨损的磨痕尺寸明显大于下试样灰铸铁。

图4所示为活塞环试样和灰铸铁缸套配副的磨痕形貌。 由图4可看出, 激光熔覆试样的磨痕是比较浅的, 试样表面非常光洁, 表面呈现出类似抛光浸蚀后所观察到的金相组织。 与其配副的灰铸铁下试样没有明显的磨痕及塑性变形, 且具有很高的光洁度, 可以清晰地看到铸铁组织中的片状石墨(见图4(b))。 激光熔覆强化上试样及其配副的磨损机制为微切削。

3 讨论

由不同配副的磨痕分析结果可看出, 目前广泛应用于内燃机上的镀铬强化活塞环在与灰铸铁配副时发生了严重的粘着磨损。 图5所示为镀铬层的显微组织形貌。 由图5可看出, 镀铬层的组织致密, 硬度较高(HV0.2750~850), 抗磨粒磨损能力较好。 但正是由于组织致密, 且为单相组织, 在与铸铁配副时摩擦副间不能形成连续的油膜, 从而造成局部金属与金属的直接接触, 形成较大的摩擦系数和摩擦热。 随着温度的提高, 在压力作用下, 当热量达到一定程度时, 摩擦副间产生原子间的相互扩散, 甚至局部熔化, 摩擦副发生局部粘合。 当摩擦产生的应力达到结合强度时, 产生撕裂, 造成粘着磨损。 发生粘着磨损的标志为存在物质转移。 从镀铬层的剥落情况看, 由于镀铬层与基体不是冶金结合, 结合力小, 不能有效地传递应力, 在发生粘着磨损时, 局部甚至出现镀铬层的完全剥落。 这一结果与前面SRV的实验结果相一致

表3 以灰铸铁为配副的SRV实验结果

Table 3 SRV results of different coatings paired with grey cast iron

图3 镀铬层磨痕的SEM像

Fig.3 SEM images of as-plated Cr worn scars

图4 激光强化层磨痕的SEM像

Fig.4 SEM images of laser strengthened worn scars

图5 镀铬层的显微组织

Fig.5 Microstructure of as-plated Cr coating

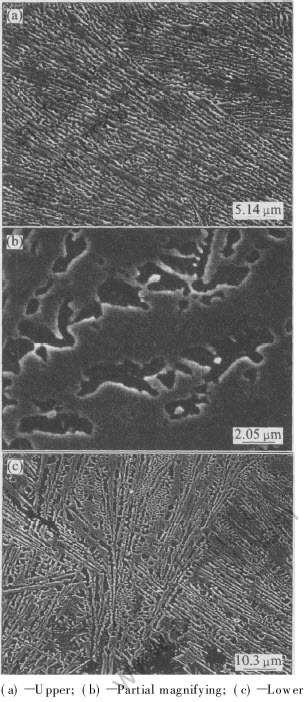

激光熔覆制备的原位析出颗粒增强金属基复合材料表层与基体呈冶金结合, 结合强度高, 显微硬度为HV0.2900~1400, 典型的熔覆层显微硬度变化曲线如图6所示。 激光强化层的显微组织特征是以细小的共晶莱氏体为基底, 上面分布着先共晶渗碳体, 并有少量的原位颗粒析出(见图7)。 其强化层中不仅含有大量的合金渗碳体, 而且还有马氏体、 残余奥氏体和原位析出的颗粒[16, 17]。 马氏体增加基体的硬度和强度, 对摩擦副的早期磨损有一定的作用, 对细小颗粒还有支撑作用。 磨损表面由这些细小的渗碳体支撑, 可以有效地防止产生磨粒磨损; 强化层中的奥氏体在磨损过程中先磨损成为凹坑, 以保证油膜的连续性, 同时也防止产生粘着磨损。 奥氏体的另一作用是作为软相可作为能量吸收单元, 当吸收一定的能量后, 转变为马氏体, 使应力得以释放, 阻止了裂纹的形成与扩展。 从垂直于磨损表面的方向看, 可以看到激光熔覆层的过共晶组织, 大量的合金渗碳体形成网架结构, 起到了支撑磨损表面作用和屏蔽、 遮挡的作用, 形成非光滑的第一磨损面。 弥散析出的细小颗粒起定扎位错的作用, 强化了基体, 因此, 表现出优异的磨损性能。

图6 激光熔覆层的显微硬度

Fig.6 Microhardness of laser clad coating

图7 激光熔覆层的组织形貌

Fig.7 Morphologies of laser cladding

4 结论

1) 镀铬强化层在与灰铸铁配副进行磨损过程中, 摩擦系数随磨损时间的增加逐渐上升, 摩擦系数在0.1170~0.1332范围内变化。 磨损机制为严重的粘着磨损, 表明镀铬强化活塞环与铸铁缸套的配副性较差。

2) 激光熔覆强化活塞环与灰铸铁缸套配副时, 表现出良好的耐磨性和配副性, 配副双方的磨损都大幅度降低。 与灰铸铁配副进行磨损过程中, 摩擦系数随磨损时间的增加逐渐下降, 摩擦系数在0.067~0.085范围内变化, 磨损机制为微切削。

REFERENCES

[1]Carlos E P. The use of selective plasma nitriding on piston rings for performance improvement[J]. Materials and Design, 2003, 24(2): 131-135.

[2]SUN Zhuo, ZHANG Pei-jun, ZHAI Le-heng, et al. Multi-layer compound coating on cast iron piston ring by multi-arc and magnetron sputtering ion compound plating technique[J]. Surface and Coatings Technology, 2000, 131(1-3): 422-427.

[3]Rastegar F, Richardson D E. Alternative to chrome: HVOF cermet coatings for high horse power diesel engines[J]. Surface and Coatings Technology, 1997, 90(1-2): 156-163.

[4]Friedrich C, Berg G, Broszeit E, et al. PVD CrxN coatings for tribological application on piston rings[J]. Surface and Coatings Technology, 1997, 97(1-3): 661-668.

[5]Priest M, Taylor C M. Automobile engine tribology - approaching the surface[J]. Wear, 2000, 241(2): 193-203.

[6]Yoon K K, Kim W B, Na S J. Shape deformation of a piston ring groove by laser surface hardening[J]. Surface and Coatings Technology, 1996, 78(1-3): 157-167.

[7]LI Qiang, OUYANG Jia-hu, LEI Ting-quan, et al. Recent development in laser cladding of materials surface[J]. Material Science and Technology, 1996, 4(4): 22-3610.

[8]Gassmann R C. Laser cladding with (WC+W2C)/Co-Cr-C and (WC+W2C)/Ni-B-Si composites for enhanced abrasive wear resistance[J]. Material Science and Technology, 1996, 12(8): 691-696.

[9]Baker T N, Xin H, Hu C, et al. Design of surface in situ metal-ceramic composite formation via laser treatment[J]. Material Science and Technology, 1994, 10(6): 536-544.

[10]Tjong S C, Ma Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites[J]. Material Science and Engineering, 2000, 29: 49-113.

[11]Wang H, Xia W, Jin Y. A study on abrasive resistance of Ni-based coatings with a WC hard phase[J]. Wear, 1996, 195(1-2): 47-52.

[12]Sidhu B S, Puri D, Prakash S. Mechanical and metallurgical properties of plasma sprayed and laser remelted Ni-20Cr and Stellite-6 coatings[J]. Journal of Materials Processing Technology, 2005, 159(3): 347-355.

[13]Riabkina-Fishman M, Zahavi J. Laser alloying and cladding for improving surface properties[J]. Applied Surface Science, 1996, 106: 263-267.

[14]ZHANG Qing-mao, HE Jin-jiang, LIU Wen-jin, et al. Investigation on microstructural characteristics and properties of (1.2%Zr+40%WC)/FeCSiBRE layer produced by laser cladding[J]. Transactions of the China Welding Institution, 2002, 23(4): 43-48.

[15]ZHANG Qing-mao, HE Jin-jiang, LIU Wen-jin, et al. Investigation on microstructural characteristics of ZrC-reinforced metal matrix composite layer produced by laser cladding[J].Transactions of the China Welding Institution, 2002, 23(2): 22-24, 58.

[16]ZHANG Qing-mao, HE Jin-jiang, LIU Wen-jin, et al. The microstructural characteristics and properties of (2.4%Zr+1.2%Ti+15%WC)/FeCSiB layer produced by laser cladding[A]. Deng S S, Okada T, Behler K, et al. Laser in Material Processing and Manufacturing[C]. Shanghai: The International Society for Optical Engineering and Chinese Optical Society, 2002. 253-258.

[17]ZHANG Qing-mao, HE Jin-jiang, LIU Wen-jin, et al. Investigation on the microstructural characteristics of ZrC-reinforced composite coating produced by laser cladding[J]. Surface and Coatings Technology, 2003, 160(2-3): 140-146.

收稿日期: 2005-08-24; 修订日期: 2005-12-09

作者简介: 张庆茂(1966-), 男, 教授, 博士

通讯作者: 张庆茂, 教授; 电话/传真: 020-85211433; E-mail: zhangqm66@263.net

(编辑李艳红)