DOI: 10.11817/j.ysxb.1004.0609.2020-37626

高强铝合金锻件组织均匀性的低温小变形调控

胡建良1,王 欢1,薄 宏2,吴秀江1,黄始全3,金 淼1

(1. 燕山大学 机械工程学院,秦皇岛 066004;

2. 燕山大学 材料科学与工程学院,秦皇岛 066004;

3. 中南大学 高性能复杂制造国家重点实验室,长沙 410083)

摘 要:为解决大型铝合金航空结构件在传统热模锻工艺下出现的表层心部组织不均匀问题,采用低温小变形工艺对锻件的组织均匀性进行调控。利用热/力模拟实验机、电子背散射衍射、透射电子显微镜等实验手段研究低温小变形工艺对高强铝合金锻件晶粒组织演变的影响规律。结果表明:随着变形温度的升高,锻件的动态回复加剧,小角度晶界含量先增加后减少,位错形态经历位错缠结、位错胞,以及位错胞合并长大形成亚晶的过程。经过变形温度为200 ℃、变形量为20%的低温小变形及固溶处理后,锻件表层晶粒得到了有效细化。最终,获得高强铝合金锻件组织均匀性的低温小变形调控新方法。

关键词:低温小变形;静态再结晶;位错形态;组织均匀性

文章编号:1004-0609(2020)-11-2560-10 中图分类号:TG316.3 文献标志码:A

7XXX系铝合金因具有高强韧、塑性加工性能好及可热处理强化等优点,在车辆工业和工兵装备,特别是在航空航天领域得到了广泛的应用[1-3]。然而,大型模锻件在成形过程中,由于模具温度较低,导致工件温度内热外冷及变形不均匀,从而引起锻件表层和心部的组织性能差异较大,甚至由于表层组织性能缺陷导致锻件成批报废,造成巨大的经济损失[4]。

目前,实现晶粒细化的方法主要有高温+大变形激发材料发生动态再结晶[5-6]和调控析出相的分布以增加再结晶形核数量[7-10]。如SAKAI等[11]利用多向模锻工艺对7074铝合金进行了总应变量为6.3的高温大变形研究,结果表明,在较低的应变速率下,合金发生了连续动态再结晶,实现了晶粒组织的细化。SU等[12]的研究表明,细晶粒的形成是由大应变引起的连续动态再结晶导致的,随着应变量的累积,小角度晶界逐渐产生并不断向大角度晶界转变,导致平均取向角增加,从而实现晶粒的细化。左锦荣等[13]通过两阶段轧制工艺对7055铝合金进行预变形调控其第二相析出的研究,结果表明,由于球化的MgZn2析出相对位错及亚晶界的钉扎作用,导致合金在退火过程中形成大量亚结构。并且,在后续的热处理过程中,大量的小角度晶界转化为大角度晶界,实现了铝合金的晶粒细化。SHEN等[14]的研究表明,纳米级析出相能够促进位错的增殖,提高再结晶驱动力。同时,析出相为再结晶提供形核点,促进再结晶的发生,实现了晶粒的均匀细化。

然而,诱发动态再结晶需要高温和大变形,能量消耗巨大,而调控析出相往往需要多道次变形,工艺复杂且生产效率低,因此探究大型铝合金模锻件组织均匀性调控新方法十分必要。不同于常规高温+大变形细化组织的技术思路,本文提出通过低温小变形工艺调控铝合金锻件表层位错密度,并与后续热处理工艺相匹配,细化锻件表层晶粒组织,从而实现铝合金锻件组织均匀性调控。

1 实验

实验所用材料为7050高强铝合金,其化学成分如表1所列。

将铝合金方坯加热至450 ℃并保温2 h,在模锻液压机进行常规热模锻实验,变形量为50%,获得表层心部不均匀晶粒组织的锻件,如图1所示。将锻件沿锻造方向加工成d 8 mm×12 mm的圆柱试样,在Gleeble-3800热/力模拟实验机上进行低温小变形实验,变形温度为150、200和300 ℃,应变速率为1 s-1,变形量为20%。将变形后试样进行固溶处理,固溶工艺为:固溶温度470 ℃,固溶时间2 h。通过电子背散射衍射技术(EBSD)观察试样表层和心部的晶粒组织,并通过透射电子显微镜(TEM)分析位错及亚结构的演变规律。

表1 7050铝合金的合金成分

Table 1 Chemical composition of 7050 aluminum alloy (mass fraction,%)

2 结果与分析

2.1 低温小变形对铝合金锻件微观组织的影响

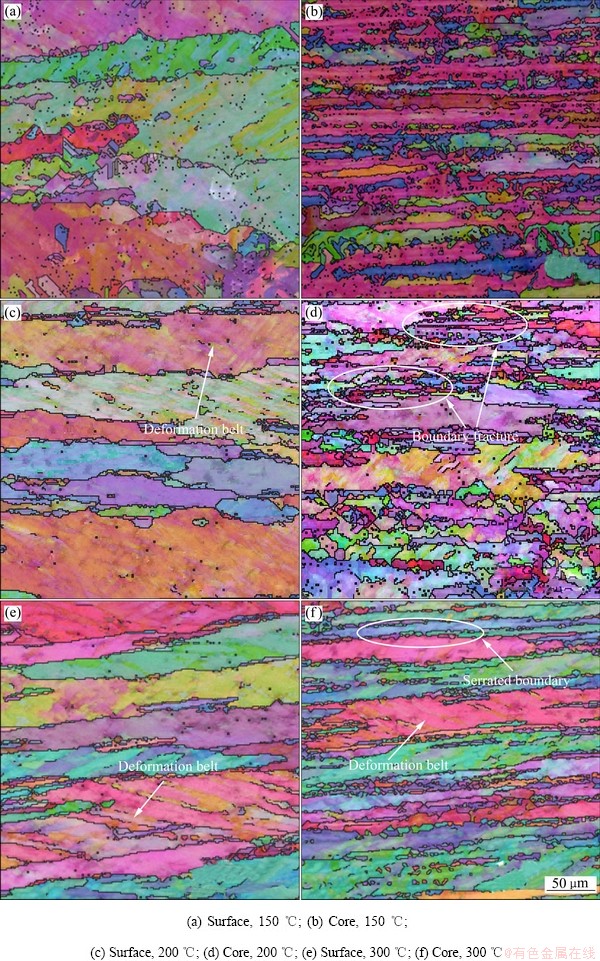

对不同低温小变形工艺条件下的7050铝合金锻件进行EBSD分析,实验结果如图2所示。在不同变形温度条件下,铝合金锻件的表层和心部存在着明显的组织差异。变形温度为150 ℃时,表层组织未发生明显变化(见图2(a)和(b))。当变形温度升高至200 ℃,表层粗大晶粒组织内部出现条纹状的变形带,且与变形方向呈45°角(见图2(c))。随着变形温度的进一步升高,在变形晶粒内部形成了由大角度晶界分隔的变形带。与锻件表层相比,锻件心部组织被进一步压缩,晶粒宽窄不一,部分晶界甚至出现断裂和重叠(见图2(d))。随着变形温度的升高,锻件心部晶粒逐渐变宽,且部分晶界呈现锯齿状(见图2(f)),这是因为随着变形温度的升高,合金的动态回复现象加剧,大量位错发生滑移和攀移,晶界迁移也更加容易进行。此外,在变形过程中,粗大难溶的析出相粒子沿晶界不均匀分布,部分晶界被钉扎,造成晶界迁移困难,而未被钉扎晶界的迁移不受影响,因此导致晶界宽窄不一,呈现锯齿状。

图3所示为不同变形温度条件下7050铝合金锻件取向差角分布图,为消除噪点对实验结果准确性的影响,本文只统计了取向差角大于5°的数据[15]。其中,小角度晶界所占比例用fLAGBs表示。从图3可以看出,变形后组织中存在大量的小角度晶界,锻件心部取向差角分布更为连续,锻件表层的晶界取向在20°~30°区间的比例明显较低。在不同的变形温度条件下,fLAGBs存在明显差异,锻件表层组织fLAGBs在13.6%到19.3%之间,锻件中心组织fLAGBs在15.7%到22.4%之间。锻件表层组织fLAGBs从150 ℃变形条件下的16.3%升高到200 ℃变形条件下的19.3%,当变形温度继续升高到300 ℃时,fLAGBs降低到13.6%。锻件心部组织的fLAGBs变化具有相同的规律,从150 ℃变形条件下的15.7%升高到200 ℃变形条件下的22.4%,经300 ℃温度变形后,fLAGBs下降到15.9%。相关研究表明,fLAGBs升高意味着动态回复过程加剧[16-18],当变形温度从150 ℃升高到200 ℃,由于位错的滑移、攀移更加容易进行,大量位错相互排列形成位错胞或亚晶结构,这些亚结构的边界均为小角度晶界,这是fLAGBs增加的主要原因。随着变形温度进一步升高,动态回复进一步加强,位错运动加剧,部分位错胞发生合并长大,导致亚结构边界比例减少。

图1 不均匀晶粒组织的锻件图

Fig. 1 7A85 aluminum forging with nonuniform microstructure

图2 不同变形温度条件下7050铝合金锻件的EBSD图

Fig. 2 EBSD diagram of 7050 aluminum forging at different deformation temperatures

图4所示为不同变形温度条件下7050铝合金锻件心部的TEM像,从图中可以看出,随着变形温度的升高,位错缠结现象逐渐消失,合金内部的位错密度逐渐降低。当变形温度为150 ℃时,大量的位错相互缠结(见图4(a))。随着变形温度的升高,动态回复现象加剧,位错的运动更加容易进行,异号位错相互抵消,同时大量缠结在一起的位错通过滑移、攀移等运动形成位错墙,最终形成位错胞(见图4(b))。当变形温度进一步升高到300 ℃,动态回复进一步加剧,位错胞发生合并长大(见图4(c))。此外,在锻件基体内部有大量弥散细小的第二相析出,并限制位错和晶界的迁移运动。

图3 不同变形温度条件下7050铝合金锻件取向差角分布图

Fig. 3 Misorientation angle distributions of 7050 aluminum forging at different deformation temperatures

2.2 固溶处理对铝合金锻件微观组织的影响

图5所示为经过低温小变形和固溶处理后的7050铝合金锻件的EBSD像。在较低变形温度条件下,材料内部的再结晶程度很高,并且出现再结晶长大的迹象,如图5(a)和(b)所示。经200 ℃变形并固溶后,锻件表层及心部再结晶程度均较高,且组织更加均匀细小,如图5(c)和(d)所示。当变形温度在300 ℃,锻件表层和心部组织均未发生明显再结晶,只是在晶界附近存在细小的再结晶晶粒,且呈链式分布(见图5(e)和(f))。有研究表明,静态再结晶的主要机制是应变诱导晶界迁移,通过晶界的膨胀和迁移,形成无位错的再结晶区域[19-20]。静态再结晶是形变储能释放的过程,形变储能决定了再结晶程度。金属在变形过程中所积累的能量与其内部的位错密度成正比例关系[21]。结合图4可以得出,随着变形温度的升高,锻件内部的位错密度逐渐降低,在150 ℃变形时,形变储能最高。因此,固溶处理不仅可以使锻件发生静态再结晶,而且导致再结晶晶粒的长大,而300 ℃变形时,因动态回复使位错大量消失,形变储能降低,不足以支撑锻件发生再结晶。

图4 不同变形温度条件下7050铝合金锻件心部TEM像

Fig. 4 TEM images of core layer of 7050 aluminum forging at different deformation temperatures

图6所示为固溶处理后7050铝合金锻件表层及心部大小角度晶界的分布及小角度晶界含量的变化情况。由图6可知,不同变形温度条件下,锻件表层仍具有较高的fLAGBs,这表明锻件表层仍具有较多的未再结晶区域。且锻件表层大小角度晶界的分布呈双峰型,小角度晶界与大角度晶界的过渡是连续的,这说明小角度晶界在持续向大角度晶界转化。锻件心部大小角度晶界分布与锻件表层有所不同,在变形温度为150 ℃和200 ℃时,锻件心部的大小角度晶界呈单峰型分布,小角度晶界基本上已经完全转化为大角度晶界,表明锻件的中心发生了完全的静态再结晶。当变形温度升高到300 ℃,锻件心部的大小角度晶界也呈现双峰型分布,小角度晶界并未完全转化为大角度晶界。

当变形温度为150 ℃和200 ℃时,此时锻件形变储能较高,经固溶处理后,锻件表层和心部组织的fLAGBs普遍较低,分别为2.4%、1.2%和2.3%、1.5%。当变形温度升高到300 ℃时,锻件内部动态回复加强,锻件表层和心部经固溶处理后fLAGBs达到了7.4%和3.8%。变形温度的升高意味着位错的运动加剧,大量的位错相互抵消,导致后续固溶过程中没有足够的形变储能使小角度晶界完全转化为大角度晶界,最终造成合金再结晶不完全。此外,从图4(c)中观察到,锻件经300 ℃变形后,基体中存在着大量弥散分布的第二相,第二相粒子会钉扎位错和晶界,阻碍小角度晶界向大角晶界的转化和晶界的迁移[22],这也是在较高温度变形时7050铝合金锻件难以发生完全再结晶的重要原因。

2.3 组织均匀性判定

对经低温小变形和热处理后的7050铝合金锻件的表层及心部组织进行了晶粒度统计,并分别计算出各个等级下晶粒个数占统计晶粒总个数的百分比,其结果如表2所列。

根据表2中的数据,提出均匀化系数K,类比数理统计中的方差公式对均匀化系数进行计算,K值越小则均匀化程度越高,均匀化系数K的计算式为:

(1)

(1)

式中:G为晶粒度;g为平均晶粒度;q为各个晶粒度所占百分比。计算结果记录于表3。

图5 固溶处理后7050铝合金锻件的EBSD像

Fig. 5 EBSD images of 7050 aluminum forging after solution treatment

图6 固溶处理后7050铝合金锻件的取向差角分布图

Fig. 6 Misorientation angle distributions of 7050 aluminum forging after solution treatment

表2 晶粒度统计

Table 2 Grain size statistics

表3 不同变形条件下均匀化系数K

Table 3 Homogeneity K at different deformation temperatures

从表3可以看出,变形温度为200 ℃时,7050铝合金锻件经热处理后其表层及心部组织差别最小。

3 结论

1) 随着变形温度的升高,7050铝合金在变形过程中动态回复逐渐加剧,锻件表层和心部的小角度晶界含量均先增加后减少,显微组织演变经历由大量位错无规则排列到形成位错胞及位错胞合并长大的过程。

2) 7050铝合金的再结晶程度主要取决于形变储能的多少,随着变形温度的升高,合金内部的位错密度逐渐降低,形变储能减少,再结晶程度降低。由于形变储能的降低及第二相粒子的钉扎作用,经固溶处理后的7050铝合金锻件表层及心部的小角度晶界含量随着变形温度的升高而升高。

3) 合适的低温小变形工艺能实现7050铝合金锻件晶粒组织的均匀性调控。在变形量为20%、应变速率为1 s-1条件下,7050铝合金锻件组织均匀性调控的最佳变形温度为200 ℃。

REFERENCES

[1] TOLGA D, COSTAS S. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[2] NEWMAN J C, ANAGNOSTOU E L, RUSK D. Fatigue and crack-growth analyses on 7075-T651 aluminum alloy coupons under constant-and variable-amplitude loading[J]. International Journal of Fatigue, 2014, 62: 133-143.

[3] LI Cheng-bo, WANG Shao-lin, ZANG Duan-zheng, LIU Sheng-dan, SHAN Zhao-jun, ZHANG Xin-ming. Effect of Zener-Hollomon parameter on quench sensitivity of 7085 aluminum alloy[J]. Journal of Alloys and Compounds, 2016, 688: 456-462.

[4] 李蓬川. 大型航空模锻件的生产现状及发展趋势[J]. 大型铸锻件, 2011, 2: 39-45.

LI Peng-chuan. Production status and development trend of heavy aviation die forging[J] Heavy Castings and Forgings. 2011, 2: 39-45.

[5] 胡建良, 易幼平, 宋雷钧, 金 淼, 薄 宏. 航空接头锻件低速等温模锻成形及其塑性变形微观机理[J]. 中国有色金属学报, 2017, 27(11): 2260-2266.

HU Jian-liang, YI You-ping, SONG Lei-jun, JIN Miao, BO Hong. Low speed isothermal forging and microcosmic mechanism analysis of plastic deformation of aviation joint forging[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(11): 2260-2266.

[6] GUO Fei, ZHANG Ding-fei, YANGH Xu-sheng, JIANG Lu-yao, PAN Fu-sheng. Strain-induced dynamic precipitation of Mg17Al12 phases in Mg-8Al alloys sheets rolled at 748 K[J]. Materials Science and Engineering A, 2015, 636(11): 516-521.

[7] NAM C Y, HAN J H, CHUNG Y H, SHIN M C. Effect of precipitates on microstructural evolution of 7050 Al alloy sheet during equal channel angular rolling[J]. Materials Science& Engineering A, 2003, 347(1/2): 253-257.

[8] HUO W T, SHI J T, HOU L G, ZHANG J S. An improved thermo-mechanical treatment of high-strength Al-Zn-Mg-Cu alloy for effective grain refinement and ductility modification[J]. Journal of Materials Processing Technology , 2017, 239: 303-314.

[9] ZUO J R, HOU L G, SHI J T, CUI H, ZHUANG L Z, ZHANG J S. Effect of deformation induced precipitation on grain refinement and improvement of mechanical properties AA 7055 aluminum alloy[J]. Materials Characterization, 2017, 130: 123-134.

[10] BURANOVA Y, KULITSKIY V, PETERLECHNER M, MOGUCHEVA A, KAIBYSHEV R, DIVINSKIA G S, WILDE V. Al3(Sc,Zr)-based precipitates in Al-Mg alloy: Effect of severe deformation[J]. Acta Materialia, 2017, 124: 210-224.

[11] SAKAI T, MIURA H, GOLOBORODKO A, SITDIKOV O. Continuous dynamic recrystallization during the transient severe deformation of aluminum alloy 7475[J]. Acta Materialia , 2009, 57(1): 153-162.

[12] SU N, GUAN R G, WANG X, WANG Y X, JIANG W S, LIU H N. Grain refinement in an AlEr alloy during accumulative continuous extrusion forming[J]. Journal of Alloys and Compounds, 2016, 680: 283-290.

[13] 左锦荣, 侯陇刚, 史金涛, 崔 华, 庄林忠, 张济山. 两阶段轧制变形过程中高强铝合金析出相与晶粒结构演变及其对性能的影响[J]. 金属学报, 2016, 52(9): 1105-1114.

ZUO Jin-rong, HOU Long-gang, SHI Jin-tao, CUI hua, ZHUANG Lin-zhong, ZHANG Ji-shan. Precipitates and the evolution of grain structures during double-step rolling of high-strength aluminum alloy and related properties[J]. Acta Metallurgica Sinica, 2016, 52(9): 1105-1114.

[14] SHEN Y F, GUAN R G, ZHAO Z Y, MISRA R D K. Ultrafine-grained Al-0.2Sc-0.1Zr alloy: The mechanistic contribution of nano-sized precipitates on grain refinement during the novel process of accumulative continuous extrusion[J]. Acta Materialia, 2015, 100: 247-255.

[15] 杨 平. 电子背散射衍射技术及其应用[M]. 北京: 冶金工业出版社, 2007: 5-36.

YANG Ping . Electron backscattered diffraction technology and application[M]. Beijing: Metallurgical Industry Press, 2007: 5-36.

[16] 胡 静, 林栋樑. EBSD技术研究Ni-48Al金属间化合物超塑变形组织演变[J]. 稀有金属材料与工程, 2011, 40(4): 665-668.

HU Jing, LIN Dong-liang. EBSD study on the microstructural evolution of Ni-48Al alloy during superplastic deformation[J]. Rare Metal Materials and Engineering, 2011, 40(4): 665-668.

[17] 郭苗苗, 刘新宝, 朱 麟, 张 琦, 刘剑秋. 基于EBSD技术的P91钢蠕变过程中小角度晶界演化行为表征[J]. 材料导报, 2018, 32(10): 1747-1751.

GUO Miao-miao, LIU Xin-bao, ZHU Lin, ZHANG Qi, LIU Jian-qiu. Characterization of small-angle grain boundary evolution during creep of P91 steel using EBSD technique[J]. Materials Reports, 2018, 32(10): 1747-1751.

[18] 姜雁斌, 郭诗锦, 谢建新. 金包铜复合微丝拉拔过程中组织与性能的演变[J]. 中国有色金属学报, 2017, 27(9): 1838-1847.

JIANG Yan-wu, GUO Shi-jin, XIE Jian-xin. Evolution of microstructure and mechanical properties of gold cladding copper micro-wire during drawing[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1838-1847.

[19] GUTIERREZ C E J, HERNANDEZ M M G, SALINAS R A, AGUILAR C J, REYES D I. An EBSD investigation on the columnar grain growth in non-oriented electrical steels assisted by strain induced boundary migration[J]. Materials Letters, 2019, 252: 42-46.

[20] PRITHIV T S, BHUYAN P, PRADHAN S K, SARMA V S, MANDAL S. A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy[J]. Acta Materialia, 2018, 146: 187-201.

[21] JAFARI M, JAMSHIDIAN M, ZIAEI R S. A finite-deformation dislocation density-based crystal viscoplasticity constitutive model for calculating the stored deformation energy[J]. International Journal of Mechanical Sciences, 2017, 128/129: 486-498.

[22] 方华婵, 刘 滩, 朱佳敏, 肖 鹏. 微量镱和过渡元素对Al-Zn-Mg-Cu超强合金晶界特征和性能的影响[J]. 中国有色金属学报, 2019, 29(7): 1348-1359.

FANG Hhua-chan, LIU Tan, ZHU Jia-min, XIAO Peng. Effects of minor Yb and transition element on grain boundary character and properties of super strength Al-Zn-Mg-Cu alloys[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(7): 1348-1359.

Novel method of microstructure homogeneity regulation of high strength aluminum forging

HU Jian-liang1, WANG Huan1, BO Hong2, WU Xiu-jiang1, HUANG Shi-quan3, JIN Miao1

(1. School of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China;

2. School of Materials Science and Engineering, Yanshan University, Qinhuangdao 066004, China;

3. State Key Laboratory of High Perfermance Complex Manufacturing, Central South University, Changsha 410083, China)

Abstract: In order to solve the problem of uneven surface structure in the center of large aluminum alloy aviation structure parts under the traditional hot die forging process, the low temperature small deformation process was used to control the microstructure uniformity of the forging. The effects of microstructure homogeneity regulation were investigated by means of thermal/force simulation machine, electron backscatter diffraction and transmission electron microscopy. The results show that with the increase of deformation temperature, the dynamic recovery of forging is intensified and the content of small-angle grain boundary increases and then decline. The dislocation morphology of aluminum forging changes from dislocation entanglement to dislocation cell, and gradually turns into subgrain. After the small deformation process and solution treatment at a deformation temperature of 200 ℃ and a deformation of 20%, the surface grains of the forging are effectively refined. Finally, the novel method is obtained for the microstructure homogeneity regulation of high strength aluminum forging.

Key words: small deformation process at low temperature; static recrystallization; dislocation morphology; microstructure uniformity

Foundation item: Projects(51401179, 51675465) supported by the National Natural Science Foundation of China; Projects(E2015203116, E2019203075) supported by the Natural Science Foundation of Hebei Province, China; Project(BJ2019001) supported by the Top Young Talents Project of the Education Department of Hebei Province, China; Project(Kfkt2017-07) supported by the State Key Laboratory Program of High Performance Complex Manufacturing, China

Received date: 2019-11-07; Accepted date: 2020-05-28

Corresponding author: JIN Miao; Tel: +86-335-8052253; E-mail: jmiao@ysu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51401179,51675465);河北省自然科学基金资助项目(E2015203116,E2019203075);河北省教育厅青年拔尖人才计划项目(BJ2019001);高性能复杂制造国家重点实验室开放课题项目(Kfkt2017-07)

收稿日期:2019-11-07;修订日期:2020-05-28

通信作者:金 淼,教授,博士;电话:0335-8052253;E-mail:jmiao@ysu.edu.cn