DOI: 10.11817/j.issn.1672-7207.2017.08.033

结构参数对闭式内冷油腔填充率的影响

邓立君1,王志明1,刘永启2

(1. 山东大学 能源与动力工程学院,山东 济南,250061;

2. 山东理工大学 交通与车辆工程学院,山东 淄博,255049)

摘要:为了研究内冷油腔结构参数及内冷油腔位置对填充率的影响,利用计算流体力学对内冷油腔内两相流的控制方程进行求解,并通过活塞内冷油腔进出油流量动态实验对模拟结果进行验证。研究结果表明:随着内冷油腔进出口截面积、内冷油腔进出油孔的长度和喷嘴流量的变化,内冷油腔的填充率分别呈现不同的变化;内冷油腔位置上移使得内冷油腔填充率增大,传热系数反而减小。在不同的曲轴转角下,内冷油腔的填充率不同,内冷油腔的传热系数也随之呈现相同的变化趋势,并在爆发压力工况对应的曲轴转角时达到最大。

关键词:内冷油腔;两相流;填充率;传热系数

中图分类号:TK422 文献标志码:A 文章编号:1672-7207(2017)08-2224-07

Effect of structural parameters on fill ratio of closed cooling gallery

DENG Lijun1, WANG Zhiming1, LIU Yongqi2

(1. School of Energy & Power Engineering, Shandong University, Jinan 250061, China;

2. School of Traffic & Vehicle Engineering, Shandong University of Technology, Zibo 255049, China)

Abstract: To study the influence of the structural parameters of the oil cooling gallery and the position change of the oil cooling gallery on the filling ratio, the control equation of two phase flow was solved by computational fluid dynamics (CFD), and the simulation results were validated against the special experiment results of the flow of the oil cooling gallery in the piston. The investigation shows that with the change of the cross-sectional area of the import and export of oil cooling gallery, the changes in the length of import and export oil hole, the nozzle flow rate, and the fill ratio of oil cooling gallery are different. The upward displacement of the oil cooling gallery position leads to the increase in the fill ratio and the decrease in the heat transfer of oil cooling gallery. The results also show that the fill ratio and the heat transfer coefficient of oil cooling gallery are influenced by the crank angles, and these two parameters have the same trend of change with the crank angle, and meanwhile, reach the maximum value in the maximum peak pressure condition.

Key words: cooling gallery; two phase flow; fill ratio; oil heat transfer

高温燃气与活塞顶面通过对流和辐射2种方式传递热量,从而使活塞的热负荷显著增高[1-2]。为了解决活塞热负荷过高的问题,采用内冷油腔设计的内燃机活塞,利用冷却油在油腔里的不断振荡以加强冷却。国内外学者研究发现,内冷油腔的位置和结构影响了活塞顶部和活塞销孔部位的温度及其可靠性[3-5]。内冷油腔对活塞的冷却是一个瞬时变化的过程,单纯的稳态计算不能实时地反映喷油冷却不同时刻的情况。PAN等[6]将内冷油腔简化为二维模型,对其往复运动时的运动特性进行研究;FU等[7]对三维模型下内冷油腔的振荡特性进行进一步研究;仲杰等[8-9]利用CFD动网格技术和VOF两相流模型,对内冷油腔的传热特性进行了数值计算;张卫正等[10-14]更进一步对多相流的振荡特性、强化传热以及计算模型进行了研究,WANG等[15-16]研究了内冷油腔内添加不同介质对振荡特性和传热特性的影响。因此,内燃机活塞内冷油腔的动态模拟成为近年来研究的热点。本文作者利用计算流体力学软件,采用数值模拟和活塞内冷通道进出油流量实验的方法,综合研究了内冷油腔填充率的影响因素,并分析填充率对传热系数的影响以及内冷油腔的填充率和换热系数随着曲轴转角的变化规律,从而为活塞内冷油腔结构的优化提供依据。

1 控制方程

由于喷油流量的限制以及活塞运动特性,活塞的内冷油腔内不会只存在机油,而是机油与空气同时独立存在。随着机油的喷入,一部分机油占据空气所在的空间。忽略油的蒸汽相,将其简化为两相流,并假定内冷油腔进油口内机油和空气并列流动,且内冷油腔内两相流体相间阻力也足够大,不发生融合的现象,同时忽略机油和空气两相间的热传递。那么可以得到冷却机油、空气和壁面之间的流动传热控制方程如下。

组分方程:

(1)

(1)

式中:t为时间;u为速度,i=x,y,z。

假设内冷油腔中只有2种组份,机油和空气。当 ,油腔内只有空气没有机油;当

,油腔内只有空气没有机油;当 ,油腔内只有机油没有空气;当

,油腔内只有机油没有空气;当 ,油腔内既有空气也有机油,而且机油和空气的关系如下:

,油腔内既有空气也有机油,而且机油和空气的关系如下:

(2)

(2)

连续性方程:

(3)

(3)

动量方程:

(4)

(4)

能量方程:

(5)

(5)

式中:ɑ为相的体积分数;ρ和μ分别为流体的密度和动力黏性系数;g为重力加速度;Fi为体积力;E为能量;T为温度。ρ和μ取决于每个控制单元中相的体积分数,E和T以质量平均变量处理。

2 边界条件

内冷油腔内流体的振荡主要是活塞流体的惯性引起的,横向运动对内冷油腔内流体的影响较小,因而计算中假设活塞往复运动只发生在垂直方向,流场和热应力场的稳态作为活塞往复运动的初始条件。利用计算流体力学软件(Fluent)进行数值模拟,设置重力选项,湍流模型选k-ε模型;喷油入口采用速度入口边界条件,机油出口采用压力出口边界条件,壁面采用温度壁面边界;机油属性定义为密度860 kg/m3,动力黏度为温度的函数。

内冷油腔换热系数的计算一般采用由管流试验数据综合出来的经验公式[17]。对于闭式内冷油腔,一般油腔为直立环型,进出油孔分别在2个销座旁,冷却油从喷油嘴高速喷入油腔进油孔中,并随活塞高频往复振荡后从出油孔返回油底壳。本文数值计算中,传热系数的计算采用的是EVANS等[18-19]经验公式[19]的平均值,如下式所示:

(6)

(6)

式中:Nu为壁面上流体的无量纲温度梯度;L为内冷油腔的特征长度,m;D为内冷油腔的特征直径,m。

KAJIWARA等[19]给出了内冷油腔总传热系数分为3个部分,其中振荡传热系数为

(7)

(7)

式中:R为活塞1/2的冲程,m;Ne为发动机速度,r/min;F为内冷油腔的填充率。

3 结果与分析

为了研究内冷油腔填充率对于活塞内冷油腔传热系数的影响,通过不同的参数设置改变其内流体的填充率以产生不同的振荡特性。

3.1 进出油口截面积对填充率的影响

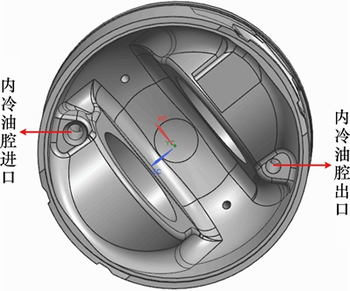

建立带内冷油腔活塞的三维模型,通过对内冷油腔设置不同的进出油口,改变进入和流出内冷油腔的流量,以改变内冷油腔内流体的振荡特性。根据给定的内燃机、活塞和内冷油腔相关参数,计算内冷油腔的填充率和传热系数,研究内冷油腔不同的进出油口截面积对内冷油腔填充率以及传热系数的影响。为了更好地对比内冷油腔填充率和其传热系数的关系,填充率和传热系数在Y轴的左右两边分别显示。内冷油腔进出口示意图如图1所示。

图1 内冷油腔进出口示意图

Fig. 1 Schematic diagram of inlet and outlet of oil cooling gallery

3.1.1 出油口面积不变

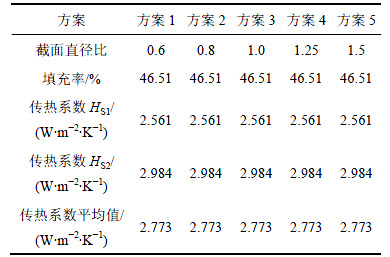

假设喷嘴喷油压力不变,且任何时刻机油都能全部喷入内冷油腔进油口。固定出油口面积,根据带内冷油腔内燃机活塞的设计标准,内冷油腔进油口的面积应该等于或适当大于出油口的面积。进出口直径比值方案设置如表1所示。其中:传热系数HS1为采用EVANS and HAY经验公式得到的传热系数,传热系数HS2为采用Kajiwara经验公式得到的传热系数。

表1 不同进出口截面积的内冷油腔

Table 1 Oil cooling gallery with different inlets and outlet section areas

计算结果显示:若出油口面积不变,无论进油口面积怎么改变也不会影响填充率。结果表明,当出口流量不变时,内冷油腔的填充率由进口流量决定,进口面积对其没有影响,而且内冷油腔的传热系数也没有变化。

3.1.2 进油口面积不变

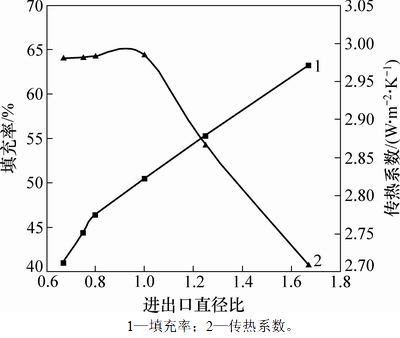

对同一个内燃机活塞模型,保持其他参数不变, 固定进油口直径为5.6 mm,设置不同的出油口直径进行模拟计算,其内冷油腔的填充率和传热系数结果如图2所示。

图2 进油口固定时进出口截面积对流动与换热的影响

Fig. 2 Influence of inlet and outlet section area on flow and heat transfer with fixed inlet and outlet

通过对比计算可知:随出口面积减小,流出的流体随之减少,使得同一曲轴转角时留在内冷油腔的流体增多,内冷油腔的填充率增大。随填充率增加,内冷油腔传热系数先呈现增大趋势,从比值为1.0后开始呈下降趋势;当比值为1.0时,内冷油腔中的机油填充率在50%左右,振荡冷却传热效果最好,与以往研究结论一致,由此可知,当内冷油腔进出油口面积相同时的结果最佳。

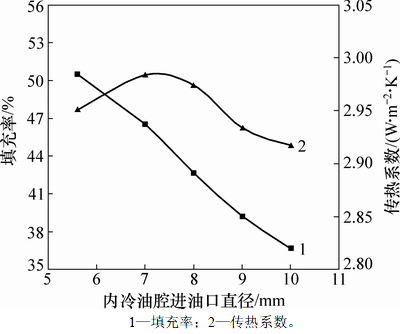

3.1.3 同时改变进出油口的面积

选择同样的进出油口面积,同时改变进出油口的直径(变化范围5~10 mm)以改变其面积,其对比内冷油腔填充率和传热系数的结果如图3所示。由图3看出:同时减小内冷油腔进出油口的面积,使得留在内冷油腔内的流体增多,填充率增大。但当进出口面积过小时,内冷油腔内的流体太多会影响其振荡效果,使得冷却效果受到影响。计算结果显示:当进出口直径为7 mm时振荡效果最好,传热系数最大。

通过以上模拟计算结果可知:合理选择进出油口的面积,确保冷却油道中有50%左右的填充率(一般指体积填充率),可获得较好的振荡效果,从而得到较高的传热系数,达到更好冷却的目的。

图3 相同的进出口截面积下对流动与换热的影响

Fig. 3 Effects on flow and heat transfer under same inlet and outlet section

3.2 活塞内冷油腔进出油孔长度对填充率的影响

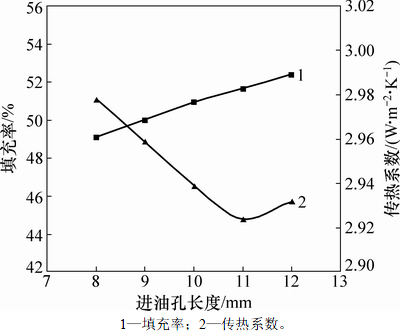

通过改变内冷油腔进出油孔的长度,改变进入和流出内冷油腔流体的体积,以改变内冷油腔内流体的振荡特性。根据实际工程应用中活塞对称结构的设计,本文的模拟方案设为同时改变进出油孔长度来研究进出油孔长度对填充率和传热的影响。设定进出油孔长度范围为8~12 mm,同时改变进出油孔的长度,设置几个不同的方案进行数值模拟,分析内冷油腔的进出油孔长度对填充率的影响,结果如图4所示。

图4 不同进出油孔长度时内冷油腔内流体的流动特性

Fig. 4 Flow characteristics of fluid in oil cooling gallery under different inlets and outlet lengths

由图4可知:同时增加或减少内冷油腔进出油孔的长度,喷入内冷油腔内的流率不变,同一时间内冷油腔内的流体体积增大,内冷油腔的填充率则增大,而传热系数随之减小。内冷油腔进出油口的长度对填充率和传热系数影响较小,经对比可知,对于本文的研究对象,当长度为8 mm时,传热效果最佳。

3.3 喷嘴流量对填充率的影响

内冷油腔进出油口直径和进出油口长度相同,分别设为7 mm和8 mm。通过不同的方法改变喷嘴流量,如改变喷嘴直径、喷嘴处的压力,从而改变内冷油腔的填充率,进而影响内冷油腔内流体的振荡特性。

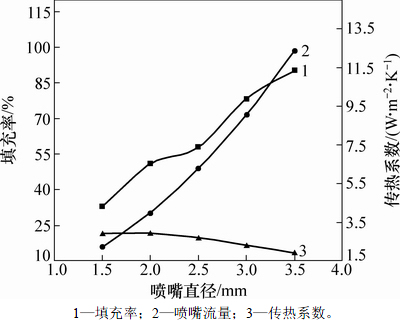

3.3.1 喷嘴直径对喷嘴流量的影响

通过改变喷嘴直径(变化范围为1.5~3.5 mm),改变喷嘴的流率,以改变进入和流出内冷油腔的流量,进而改变内冷油腔的填充率,同时影响内冷油腔内流体的振荡特性,设定喷嘴压力为0.3 MPa,模拟结果如图5所示。

图5 不同的喷嘴直径时内冷油腔内的流动特性

Fig. 5 Flow characteristics of fluid in oil cooling gallery under different nozzle diameters

通过对比计算可知:随着喷嘴直径的增加,喷嘴的流率随之增加,内冷油腔的填充率也随之增大。当喷嘴直径为2 mm时,内冷油腔的填充率达到50%以上,而且此时传热系数最大,冷却效果最好。

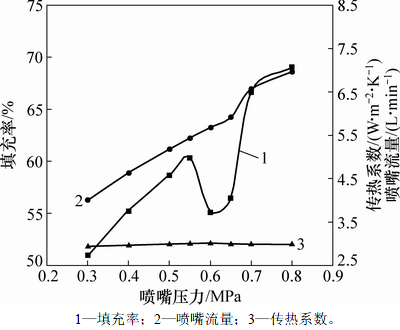

3.3.2 喷嘴压力对喷嘴流量的影响

设定喷嘴直径为2 mm,通过改变喷嘴压力的大小,改变喷嘴的流率,以改变进入和流出内冷油腔的流量,进而改变内冷油腔的填充率,同时影响内冷油腔内流体的振荡特性。计算结果如图6所示。从图6可见:喷嘴流量随喷嘴压力的增大而增大,而且喷嘴流量增大会使内冷油腔填充率增大。但是当喷嘴压力增大至0.6 MPa时,随喷嘴流量增加,填充率反而减小,传热系数随之增大。结果表明:并不是压力越大,填充率越高,传热系数越高;当喷嘴压力为0.6 MPa时,传热系数最高,活塞获得的冷却效果最佳。

图6 不同的喷嘴压力时内冷油腔内的流动特性

Fig. 6 Flow characteristics of fluid in oil cooling gallery under different nozzle pressures

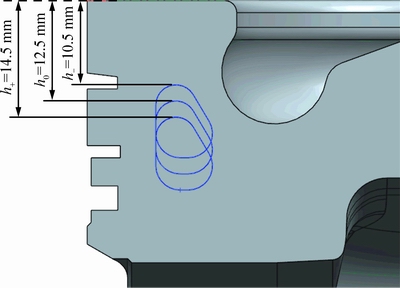

3.4 活塞内冷油腔位置对填充率的影响

改变内冷油腔在活塞中的垂直位置,内冷油腔的温度、应力以及疲劳强度都会随之改变。计算内冷油腔在活塞中不同垂直位置时内冷油腔的填充率和传热系数,分析内冷油腔的垂直位置对冷却效果的影响。内冷油腔位置的示意图如图7所示。

图7 内冷油腔位置示意图

Fig. 7 Schematic diagram of position of oil cooling gallery

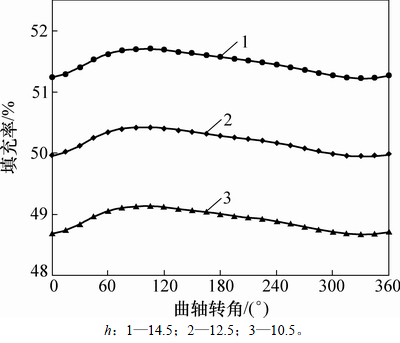

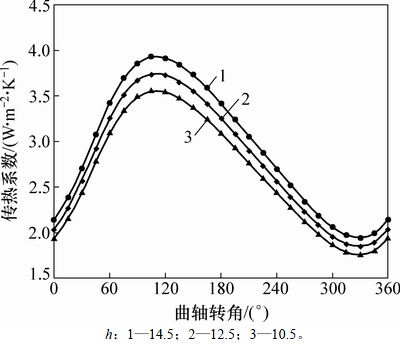

通过计算得到内冷油腔位置不同时内冷油腔的平均填充率和传热系数随曲轴转角的变化规律分别如图8和图9所示。

对比图8和图9可知:随着内冷油腔位置的上移,同一曲轴转角时内冷油腔的填充率减小。不同曲轴转角时,内冷油腔的传热系数在爆发压力工况附近达到最大,与填充率的最大值更好对应;且随着内冷油腔位置的上移,同一曲轴转角时内冷油腔的传热系数增大,这是因为填充率的减少使得机油振荡更强烈,加强了换热。

图8 不同内冷油腔位置时填充率随曲轴转角的变化

Fig. 8 Variation of fill ratio with changing of crank angle at different positions of oil cooling gallery

图9 不同内冷油腔位置时传热系数随曲轴转角的变化

Fig. 9 Variation of heat transfer with changing of crank angle at different positions of oil cooling gallery

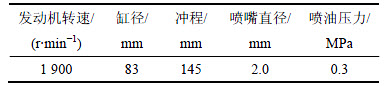

3.5 实验验证

为了验证计算数据的准确性,通过动态活塞内冷油腔进出油流量试验模拟内燃机运行过程中机油喷嘴出口位置与活塞冷却油腔进口的角度及空间位置,对各影响因素中最佳方案的活塞内冷通道进出口流量进行测量,将得到的实测数据与模拟结果进行对比,验证数值模拟结果的准确度。试验时发动机的运行工况和参数如表2所示。图10所示为活塞内冷通道进出油流量动态试验原理图。

表2 试验工况与参数

Table 2 Test conditions and parameters

图10 内冷油腔进出油流量动态试验原理图

Fig. 10 Dynamic test schematic diagram of flow of oil cooling gallery

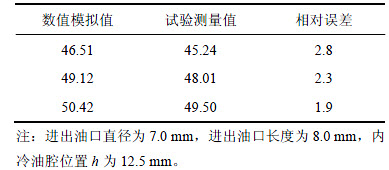

试验中,在喷油嘴出口处安装流量计,内冷油腔的出口处接软管,同时在试验台下端放置收集容器,以便测量从内冷油腔的回油量。然后根据试验中接油盘得到的流量与喷嘴处流量计得到的油量,计算内冷油腔的平均填充率。内冷油腔填充率的数值模拟结果和试验测量计算结果对比如表3所示。由表3可知:内冷油腔进出口模拟计算得到的油量与实测流量值的相对误差在误差允许的范围内(<5%),因此,本文的数值模拟结果具有较好的工程应用性。

表3 内冷油腔填充率实测结果与模拟值的对比

Table 3 Comparison of measured results and simulated values of filling rate in colling gallery

4 结论

1) 增大进油口截面积和出油口截面积的比值、内冷油腔进出油孔的长度,内冷油腔的填充率会随之增大;保持进出口截面积比值不变,减小进出口截面积,内冷油腔的填充率也会相应增大,且传热系数随填充率的变化趋势一致。对于闭式内冷油腔,当两侧进出油孔长度为8.0 mm时,传热系数最大,冷却效果最佳。

2) 喷嘴压力和喷嘴直径的增大都会使得喷嘴流量增加,内冷油腔进出口不变,随内冷油腔进口流入内冷油腔的流体增多,内冷油腔的填充率增大。内冷油腔传热系数的变化表明,当喷嘴直径为2 mm时,内冷油腔的填充率达到50%以上,而且此时传热系数最大,冷却效果最好。

3) 随着内冷油腔位置上移使得内冷油腔填充率减小,传热系数反而增大;对于任意位置的内冷油腔,当曲轴转角不同时,内冷油腔的填充率也不同,内冷油腔的传热系数也随之呈相同趋势的变化,且在爆发压力工况时,对应的曲轴转角达到最大。

参考文献:

[1] BHAGAT A R, JIBHAKATE Y M, CHIMOTE K. Thermal analysis and optimization of IC Engine piston using finite element method[J]. Gas, 2012, 4(2): 2919-2921.

[2] AGARWAL A K, GOYAL S K, SRIVASTAVA D K. Time resolved numerical modeling of oil jet cooling of a medium duty diesel engine piston[J]. International Communications in Heat and Mass Transfer, 2011, 38(8): 1080-1085.

[3] 吕彩琴, 苏铁熊. 活塞冷却油腔位置对活塞强度的影响[J]. 内燃机, 2009(1): 4-9.

L Caiqin, SU Tiexiong. Influence of piston oil cooling gallery position to the piston strength[J]. Internal Combustion Engine, 2009(1): 4-9.

Caiqin, SU Tiexiong. Influence of piston oil cooling gallery position to the piston strength[J]. Internal Combustion Engine, 2009(1): 4-9.

[4] 原彦鹏, 王月, 张卫正, 等. 冷却油腔位置改变对活塞温度场的影响[J]. 北京理工大学学报, 2008, 28(7): 585-588.

YUAN Yanpeng, WANG Yue, ZHANG Weizheng, et al. A study on the effect upon the piston temperature field through changing the position of the cooling gallery[J]. Transactions of Beijing Institute of Technology, 2008, 28(7): 585-588.

[5] DENG Lijun, LIU Yongqi, WANG Zhiming, et al. Optimization of the location of the oil coolinggallery in the diesel engine piston[J]. The Open Mechanical Engineering Journal, 2016, 10(1): 126-134.

[6] PAN Jinfeng, NIGRO R, MATSUO E. 3-D modeling of heat transfer in diesel engine piston cooling galleries[C]// SAE 2005 World Congress & Exhibition. Detroit, Michigan, 2005: 1644-1654.

[7] FU W S, LIAN S H, HAO L Y. An investigation of heat transfer of a reciprocating piston[J]. International Journal of Heat and Mass Transfer, 2006, 49(23): 4360-4371.

[8] 仲杰. 活塞喷油振荡冷却的稳, 瞬态模拟计算及活塞温度场分析[D]. 济南: 山东大学能源与动力工程学院, 2012: 36-46.

ZHONG Jie. Piston cooling oil oscillation of steady, transient simulation and analysis of temperature field of piston[D]. Jinan: Shandong University. School of Energy & Power Engineering, 2012: 36-46.

[9] 吴倩文, 庞铭, 解志民, 等. 活塞振荡冷却流动传热特性的研究[J]. 农业装备与车辆工程, 2015, 53(10): 17-22.

WU Qianwen, PANG Ming, XIE Zhimin, et al. The simulation study of flow and heat transfer characteristics in piston oscillating cooling system[J]. Agricultural Equipment & Vehicle Engineering, 2015, 53(10): 17-22.

[10] 张卫正, 曹元福, 原彦鹏, 等. 基于CFD的活塞振荡冷却的流动与传热仿真研究[J]. 内燃机学报, 2010, 28(1): 74-78.

ZHANG Weizheng, CAO Yuanfu, YUAN Yanpeng, et al. Simulation study of flow and heat transfer in oscillating cooling pistons based on CFD[J]. Transactions of CSICE, 2010, 28(1): 74-78.

[11] 曹元福, 张卫正, 杨振宇, 等. 活塞开式内冷油腔振荡流动传热特性研究[J]. 汽车工程, 2014, 36(5): 546-551.

CAO Yuanfu, ZHANG Weizheng, YANG Zhenyu, et al. Study on flow and heat transfer characteristics of open oscillating oil cooling gallery of piston[J]. Automotive Engineering, 2014, 36(5): 546-551.

[12] 曹元福, 张卫正, 杨振宇, 等. 封闭空腔中多相流振荡传热特性的数值模拟[J]. 化工学报, 2012, 64(3): 891-896.

CAO Yuanfu, ZHANG Weizheng, YANG Zhenyu, et al. Numerical simulation of oscillating heat transfer characteristics in cavity partly filled with cooling liquid[J]. Ciesc Journal, 2012, 64(3): 891-896.

[13] 朱海荣, 张卫正, 原彦鹏. 多相流振荡传热湍流数值模型的比较研究[J]. 车用发动机, 2014(6): 8-12.

ZHU Hairong, ZHANG Weizheng, YUAN Yanpeng et al. Comparative study on numerical model of turbulent heat transfer in multiphase flow[J]. Vehicle Engine, 2014(6): 8-12.

[14] 朱海荣, 张卫正, 原彦鹏. 考虑湍流模型差异的高强化活塞振荡冷却效果研究[J]. 内燃机工程, 2016, 37(2): 78-82.

ZHU Hairong, ZHANG Weizheng, YUAN Yanpeng et al. Study on oscillating cooling effect of highly-intensified piston considering turbulence model difference[J]. Chinese Internal Combustion Engine Engineering, 2016, 37(2): 78-82.

[15] WANG Peng, L Jizu, BAI Minli, et al. Numerical simulation on the flow and heat transfer process of nanofluids inside a piston cooling gallery[J]. Numerical Heat Transfer, Part A: Applications, 2014, 65(4): 378-400.

Jizu, BAI Minli, et al. Numerical simulation on the flow and heat transfer process of nanofluids inside a piston cooling gallery[J]. Numerical Heat Transfer, Part A: Applications, 2014, 65(4): 378-400.

[16] WANG Peng, BAI Minli, L Jizu, et al. Comparison of multi-dimensional simulation models for nanofluids flow characteristics[J]. Numer Heat Transfer B, 2013, 63(1): 62-83.

Jizu, et al. Comparison of multi-dimensional simulation models for nanofluids flow characteristics[J]. Numer Heat Transfer B, 2013, 63(1): 62-83.

[17] BUSH J E, LONDON A L. Design data for “cocktail shaker” cooled pistons and valves[C]//National Powerplant and Transportation Meetings. California, 1965: 446-459.

[18] EVANS G A, HAY N. Heat transfer model for the cocktail shaker piston[C]//CIMAC. Vienna, 1979: 1-18.

[19] KAJIWARA H, FUJIOKA Y, NEGISHI H. Prediction of temperatures on pistons with cooling gallery in diesel engines using CFD tool[R]. World Congress & Exhibition. Warrendale, 2003: 986-992.

(编辑 陈爱华)

收稿日期:2016-09-22;修回日期:2016-12-21

基金项目(Foundation item):山东省自然科学基金资助项目(ZR2016EEB36)(Project(ZR2016EEB36) supported by the Natural Science Foundation of Shandong Province)

通信作者:王志明,博士,教授,从事内燃机工作过程的研究;E-mail:zhiming@sdu.edu.cn