不同载荷和对偶下C/C-Cu复合材料的摩擦磨损性能

冉丽萍,易茂中,王朝胜,易振华,杨 琳

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:以炭纤维针刺整体毡为预制体,用化学气相渗透(CVI)、浸渍/炭化(I/C)的方法制备密度和基体炭不同的C/C多孔坯体,采用真空熔渗将铜合金液渗入C/C坯体中制备C/C-Cu复合材料,研究试验条件对复合材料摩擦磨损性能影响。研究结果表明:随着时间的延长,C/C-Cu复合材料摩擦因数趋于稳定;随着载荷的增加,摩擦因数和体积磨损先增后减,当载荷为80 N时达到最大值;试样摩擦因数和体积磨损与对偶件有关,当采用硬度较高的40Cr钢为对偶件时,试样摩擦因数随着时间的延长而增加并趋于稳定,且磨损量最大;当采用硬度低的黄铜和紫铜为对偶件时,试样摩擦因数随着时间变化不大,与紫铜对偶时的磨损量最小;C/C-Cu复合材料的磨损机制主要为磨料磨损、粘着磨损,采用40Cr钢作对偶时氧化磨损加大。

关键词:C/C-Cu复合材料;C/C坯体;熔渗铜;摩擦;磨损

中图分类号:TB332 文献标识码:A 文章编号:1672-7207(2007)04-0595-07

Wear behavior of C/C-Cu composites under different loads

and couple parts

RAN Li-ping, YI Mao-zhong, WANG Chao-sheng, YI Zhen-hua, YANG Lin

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:C/C-Cu composites were fabricated by infiltrating molten Cu to different C/C preforms which were prepared by chemical vapor infiltration(CVI), resin impregnation and carbonization (I/C). The friction and wear behavior of the composites was researched by wear test. The results show that the friction coefficients of the composites increase and reach stable value eventually as the time increases. With the increase of test loads, the friction coefficients and bulk wear loss increase at first and get to maximum under 80 N and then decrease. The friction coefficients and the bulk wear loss are related to the couple parts. As the test time increases, the friction coefficient of the composite increases using 40Cr steel with higher hardness as couple parts and does not change very much using copper and brass copper as couple parts. The friction coefficient and bulk wear loss of the composites using 40Cr steel as couple parts are greater than that using copper as couple parts. The main wear mechanisms of the composite are abrasive wear and adhesion wear, and oxidation wear is more serious when using 40Cr steel as couple parts.

Key words:C/C-Cu composites; C/C preforms; molten copper infiltration; friction; wear

电机电刷等滑动导电材料要求有良好的导电性和耐磨性[1-2]。采用Cu或Ag制备的第1代电刷具有良好的导电性,但耐磨性不理想。采用Cu-Ni等合金或Cu-石墨复合材料制备的第2代电刷较好地提高了耐磨性,但降低了导电性。采用炭纤维-石墨-Ag基复合材料制备的第3代电刷各种性能都比较理想,但工艺复杂、成本太高[3]。研究表明,C/C复合材料具有优良的耐磨性和一定的导电性[4-6],Cu具有较高的导电、导热性及优良的工艺性能。用C和Cu制备的复合材料具有优良的导电、导热性,在无油润滑条件下具有良好的减摩和耐磨性能[7-12],能满足其性能要求。目前,生产中制备C/Cu复合材料的工艺大致分为固相法和液相法[13-14]。固相法主要包括粉末冶金法、热压法等;液相法主要为浸渗法。固相法存在的问题是成本高,炭纤维分散难,C与Cu润湿性差;而传统的液相浸渗法为炭纤维与有机溶剂结合做成预制块放入模具,将金属液倒入模具中,待有机溶剂挥发,金属液进入预制件而制得复合材料,但该法由于润湿问题效果不太理想。有关C/C坯体制备C/C-Cu复合材料的研究未见报道。在此,本文作者通过添加合金元素的方法改善C与Cu的润湿性,将Cu熔渗到多孔的C/C复合坯体中制备C/C-Cu复合材料,研究实验条件对其摩擦磨损性能的影响,探索把C/C-Cu复合材料作为电刷材料的可能性。

1 实验方法

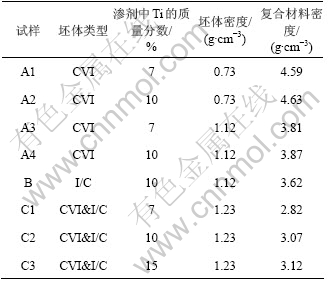

以密度为0.5~0.6 g/cm3的聚丙烯腈炭纤维针刺整体毡为预制体,用化学气相渗透(CVI)、浸渍/炭化(I/C)的方法制备不同密度和不同基体炭的C/C多孔坯体,其坯体制备工艺见文献[15]。熔渗在真空炉中进行,熔渗剂是纯度99%以上、粒度为50~75 μm的铜粉和钛粉,按不同质量分数混合后,与C/C坯体置于石墨坩埚中,在1 300 ℃进行熔渗制备出C/C-Cu复合材料。复合材料的坯体类型和密度如表1所示。

表1 C/C复合材料的坯体类型和密度

Table 1 Type and density of C/C perform and composites

将所制备的C/C-Cu复合材料和电炭厂提供的J204电刷材料通过线切割加工成20 mm×12 mm×6 mm的试样进行摩擦磨损实验。磨损实验在MM-2000型环-块摩擦磨损试验机;采用硬度分别为58HRC,123HBS,92HBS的40Cr钢、黄铜、紫铜为对偶,载荷分别为50,80和100 N;摩擦线速度为0.42 m/s,实验时间为10 h。

2 结果与讨论

2.1 载荷对滑动摩擦磨损性能的影响

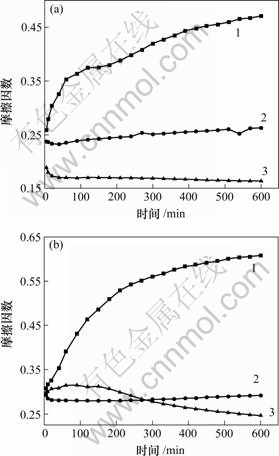

图1所示为C1和C3试样与40Cr对偶时在不同载荷下摩擦因数随时间的变化关系。可以看出,随着时间的延长,材料的摩擦因数逐渐增大并趋于稳定,但在不同的载荷下,摩擦因数随时间的变化趋势有所不同。从图1还可看出,载荷为50 N时摩擦因数较低,载荷为80 N时摩擦因数增大较多,但当载荷为100 N时,摩擦因数反而降低。因为更大的载荷,使材料中的C相更快地暴露到表面,对材料起到自润滑的作用,而且更快地在表面形成光滑的摩擦膜,使摩擦因数反而降低。对其他坯体和不同成分的渗剂熔渗制备的复合材料的摩擦因数研究有相似的结果。从表2可以看出,无论何种坯体、何种渗剂,渗Cu制备复合材料的体积磨损量随载荷的变化规律与此相同,即载荷为50 N时较低,载荷为80 N时磨损量增加;载荷到100 N时,摩擦因数减小,同时,体积磨损也随着减小。而电刷材料J204在载荷为50 N时与40Cr对偶10 h的体积磨损量为6.7 mm3,远高于C/C-Cu复合材料的体积磨损量。

(a) C1试样; (b) C3试样

1-50 N; 2-80 N; 3-100 N

图1 不同试样采用40Cr钢对偶时摩擦因数随时间的变化曲线

Fig.1 Relationship between friction coefficient of

different samples and time under different loads using 40Cr as couple part

表2 复合材料在不同载荷下摩擦10 h材料的体积磨损量

Table 2 Bulk wear loss of composites after wear 10 h under different loads

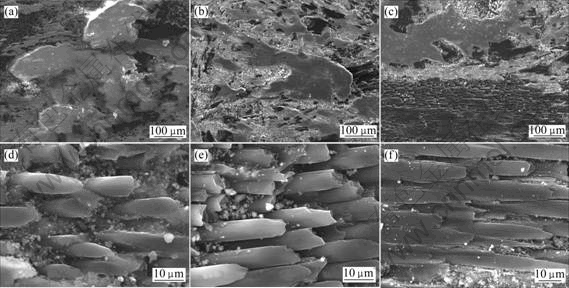

图2所示为C1试样在不同载荷下的摩擦磨损形貌。可以看出,在不同载荷下都形成了摩擦膜,炭纤维也不同程度被磨损,炭纤维增加了摩擦件和材料的点接触,且炭纤维具有自润滑的作用,正是由于具有自润滑作用的磨屑膜的形成和炭纤维的共同作用,使材料有较好的摩擦性能。

(a) 50 N,摩擦膜形貌;(b) 80N摩擦膜形貌;(c) 100 N摩擦膜形貌;(d) 50 N,炭纤维的磨损形貌;

(e) 80 N,炭纤维的磨损形貌;(f) 100 N,炭纤维的磨损形貌

图2 不同载荷下40Cr钢对偶摩擦10 h 后C1试样的摩擦膜形貌和炭纤维的磨损形貌

Fig.2 Images of wear film and carbon fiber of sample C1 after wearing 10 h under different loads using 40Cr as couple part

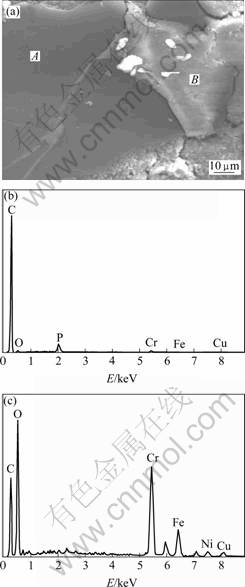

从图2(a)~(c)可见,载荷较低时,形成的磨屑膜较多,磨屑较少;随着载荷的增大,到80 N时,磨屑增多,磨屑膜面积减小;但是,随着载荷的继续增大,到100 时,磨屑膜面积又有增加,而且金属氧化膜增加,如图3所示。与40Cr钢对偶对磨的磨屑膜有2种形态:一种为黑色光滑的磨屑膜(见图3(a)中A部分);另一种为颜色较浅、具有白亮色斑点的磨屑膜,(见图3(a)中B部分)。能谱分析表明黑色磨屑膜主要以C为主,氧化程度较小,白色磨屑膜C相相对减少,金属Fe,Cr和Cu等成分增加,且氧含量较高,这是因为对偶和材料上的金属被氧化产生氧化膜。

(a) 摩擦膜形貌;(b) A点的能谱分析结果;(c) B点的能谱分析结果

图3 C1试样采用40Cr钢对偶在50 N载荷下摩擦膜形貌及其能谱分析

Fig.3 Image of wear film and energy spectrums of sample C1 under load of 50 N using 40Cr as couple parts

从图2(d)~(f)可以看出,在摩擦过程中炭纤维都不同程度地被磨损。载荷为50 N时,对偶件与炭纤维接触部分较小,磨损集中在炭纤维的一小段,导致炭纤维磨损;载荷为80 N时,炭纤维磨损增多;100 N时,炭纤维与对偶之间的接触面积增大,磨损分散在较长一段的炭纤维上,磨损反而减小,炭纤维对促进摩擦磨损性能的贡献也增加较多,形成较为光滑和完整的摩擦表面。

通常认为减摩耐磨材料的组织应当是在软的塑性基体上分布着许多硬颗粒的异质结构。在正常载荷作用下,凸出在摩擦表面的硬质相直接承受载荷,而软相起着支撑硬相的作用。因为是硬相发生接触和滑动摩擦,所以,摩擦因数和磨损都很小;又因为硬相被支持在软基体之上,所以,易于随基体变形而不致于擦伤相互摩擦的表面,同时,软基体还可以使硬相上的压力分布均匀[16]。C/C-Cu复合材料中存在着硬度不高的铜合金固溶体相,具有自润滑作用的炭纤维和炭基体相,少量硬质点TiC以及Cu和Ti的金属化合物相,使材料有很好的减摩耐磨性能。

由上述分析可知,在低载荷时,磨屑膜面积较大,摩屑膜的自润滑作用使摩擦因数较小,磨损也小;当载荷加大到80 N时,摩擦膜面积减小,炭纤维断裂增多,摩擦因数增大,同时,磨损也增大;载荷增大到100 N时,氧化膜增多,炭纤维的接触面积增加,断裂减少且形成较为光滑的摩擦表面,加上承受压力的硬质相陷入软基体中,使更多的硬颗粒承载而达到载荷均匀分布,所以,载荷为100 N时,摩擦因数和磨损量都降低。

2.2 不同对偶材料对滑动摩擦磨损性能的影响

图4所示为采用不同对偶材料时A2和A4试样的摩擦因数随时间的变化关系。从图4可以看出,采用硬度较高的40Cr钢做对偶件时,材料摩擦因数较高,且随着时间的增加,摩擦因数开始增幅较大而后逐渐趋于平缓;而采用硬度较低的紫铜和黄铜做对偶件时,摩擦因数较低,且随时间的变化较稳定;当紫铜为对偶件时,材料摩擦因数随时间的变化有时还出现下降的趋势,这可能与对偶件硬度低于材料的硬度有关。

(a) A2试样;(b) A4试样

1—40Cr;2—黄铜;3—紫铜

图4 采用不同对偶时试样摩擦因数随时间的变化曲线

Fig.4 Relationship between friction coefficient of different samples and time using different couple parts

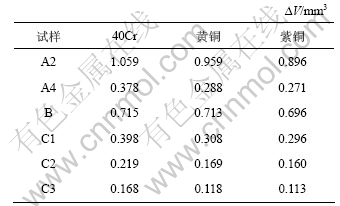

表3所示为复合材料采用不同对偶在50 N下摩擦10 h后材料的体积磨损量。在同样的载荷下,采用黄铜和紫铜对偶材料的体积磨损量比采用40Cr钢对偶的小;从表3可以看出,在其他条件一样的情况下,CVI坯体制备的材料的体积磨损量小于I/C坯体制备的材料的体积磨损量。坯体相同时,随着Ti含量的增加,复合材料组织中具有较高硬度化合物相的相对量增加,磨损量减小。

表3 50 N载荷下采用不同对偶件摩擦10 h后复合材料的体积磨损量

Table 3 Bulk wear loss of composites after wearing 10 h under load of 50 N using different couple parts

图5所示为50 N载荷下采用不同对偶摩擦10 h后复合材料的摩擦形貌。可以看出,当对偶件分别为采用紫铜、黄铜、40Cr时,随着对偶件硬度的提高,复合材料表面的摩擦磨损更为严重。采用紫铜对偶件摩擦后试样表面仅有轻微的滑痕,而采用40Cr钢对偶件摩擦后的试样表面有较深的磨损痕迹,且磨痕周围出现了变形,采用黄铜对偶件摩擦的试样表面磨损情况介于两者之间。

(a) 紫铜对偶;(b) 黄铜对偶;(c) 40Cr钢对偶

图5 采用不同对偶时A4试样的摩擦磨损形貌

Fig.5 Morphologies of A4 sample after wearing 10 h using different couple parts

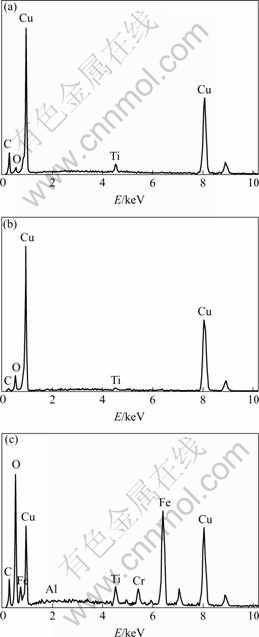

图6所示为A4试样采用不同对偶件产生的磨屑膜的能谱分析结果。可以看出,其磨屑膜以Cu为主,且有C的分布,形成了具有自润滑作用的表面膜。因此,材料摩擦因数较低,体积磨损量较少。从图6还可以看出,磨屑都含有O元素,但O含量与对偶件有关,采用40Cr钢对偶时,O含量较高;紫铜对偶时, O含量最低,说明40Cr钢对偶时,氧化磨损加大。

(a) 紫铜对偶;(b) 黄铜对偶;(c) 40Cr钢对偶

图6 采用不同对偶时50 N载荷时A4样品表面磨屑膜能谱分析

Fig.6 Energy spectrums of wear film of A4 sample under load of 50 N using different couple parts

对C/C-Cu复合材料采用不同对偶时,发现对偶本身的磨损都不是很大,对偶经过10 h摩擦后,只有微量的磨损,紫铜对偶的体积磨损量大于40Cr钢对偶的体积磨损量。

2.3 摩擦磨损机理

在摩擦起始阶段,摩擦表面微凸体互相嵌入,需发生较大的变形才能克服静摩擦力;由于跑合时表面微凸体断裂形成磨屑,若成膜不完整,则使得摩擦表面更粗糙,摩擦力上升;随摩擦时间增加,形成了较厚较完整的磨屑膜,导致摩擦力降低;C/C-Cu复合材料内各组分硬度不同,成膜能力有差异,随着载荷的改变,对偶的不同,磨屑膜的形成也不一样,这些因素的综合作用,使摩擦因数有所波动。

磨损的分类主要是:磨料磨损、粘着磨损、疲劳磨损和腐蚀磨损。C/C-Cu复合材料由于存在炭纤维和

基体炭,在摩擦过程中,不断有C供应,与金属颗粒混合在一起在摩擦表面形成具有自润滑作用的磨屑膜;炭纤维也和对偶摩擦面形成点接触,磨合一段时间后,复合材料的磨损表面主要承受载荷的是高强度纤维,而纤维本身的耐磨性较强,且其大部分表面又受到基体合金的保护而不易受到损伤,此时,纤维不易磨掉,由于C纤维在摩擦力的作用下变成微小的C颗粒,起到了一定的自润滑作用。C/C-Cu复合材料在低载荷时的磨损主要是磨料磨损,对摩擦表面产生犁削作用,沿滑动方向形成了不同程度的划痕(如图5所示)。在载荷作用下压入摩擦表面产生磨痕,在表面挤压出新的磨屑,这些磨屑逐渐形成磨屑膜。从图3可以看出,在磨屑膜上有对偶件的元素分布,同时对偶件上也有Cu和C等元素分布,因而摩擦磨损过程中产生了粘着磨损。从图6可以看到,在使用40Cr钢对偶和黄铜、紫铜对偶时都有氧存在,磨屑中也有氧成分,采用40Cr钢对偶时氧含量较高,氧化磨损更加严重些。在载荷加大的情况下,氧化磨损加剧。氧化磨损是化学氧化和机械磨损2种作用相继进行的过程,摩擦产生的温度升高,表面塑性变形促使空气中的氧扩散到变形层,而氧化扩散又增进塑性变形。可见,载荷较低时,C/C-Cu复合材料的磨损以磨料磨损为主,随着载荷的增高,粘着磨损和氧化磨损加剧,且采用不同对偶时,磨损的机制也有所不同。

3 结 论

a. 随着时间的延长,C/C-Cu复合材料摩擦因数趋于稳定;随着载荷的增加,摩擦因数和体积磨损量先增大后减小,80 N时达到最大值。

b. 采用硬度较高的40Cr钢为对偶件时,材料摩擦因数随着时间的延长而增加并趋于稳定;硬度低的黄铜和紫铜为对偶件时,摩擦因数随时间变化不大,甚至有下降趋势;与40Cr钢对偶时,材料的体积磨损量最大,而与紫铜对偶时的体积磨损量最小。

c. C/C-Cu复合材料的磨损机制主要为磨料磨损和粘着磨损。

参考文献:

[1] 陈文革, 沈宏芳, 胡 博. 制备工艺对Cu/C复合材料组织和性能的影响[J]. 电工材料, 2004(4): 3-6.

CHEN Wen-ge, SHEN Hong-fang, HU Bo. Influence of preparation process on structure and properties of Cu/ C sliding electrical contact materials[J]. Electrical Engineering Materials, 2004(4): 3-6

[2] 颜士钦, 凤 仪, 许少凡, 等. 炭纤维-石墨-银基复合材料电刷的应用研究[N]. 合肥工业大学学报: 自然科学版, 1996, 19(3): 19-25.

YAN Shi-qin, FENG Yi, XU Shao-fan, et al. Application study of carbon fiber-graphite-silver matrix composite electric brushes[J]. Journal of Hefei University of Techenology, 1996, 19(3): 19-25.

[3] 石振海, 徐向阳, 郭领军, 等. 炭/炭复合材料航空电刷的制备[J]. 炭素, 2004, 119(3): 3-6.

SHI Zhen-hai, XU Xiang-yang, GUO Ling-jun. Preparation of C/C composites aerial brush[J] . Carbon, 2004, 119(3): 3-6

[4] JIA Min-lin, CHEN-Chi M M A, WEN Chi-chang. Carbon/carbon composites derived from phenolic resin/silica hybrid creamers[J]. Journal of Materials Science, 2001, 36(17): 4259-4266.

[5] Toby J, Johnison D. Effects of fiber orientation on the tribology of a model carbon-carbon composites[J]. Wear, 2001, 249(8): 647-655.

[6] 李新春, 易茂中, 冯一雷, 等. C/C复合材料特性对其摩擦磨损性能的影响[J]. 新型炭材料, 2005, 20(2): 151-156.

LI Xin-chun, YI Mao-zhong, FENG Yi-lei. The effect of C/C composites characteristic on sliding friction and wear behavior[J]. New Carbon Materials, 2005, 20(2): 151-156.

[7] Wan Y Z, Wang Y L, Luo H L, et al. Effects of fiber volume fraction, hot pressing parameters and alloying elements on tensile strength of carbon fiber reinforced copper matrix composite prepared by continuous three-step electrodeposition[J]. Materials Science and Engineering A, 2000, 288(1): 26-33.

[8] Lin M H, Buchgraber W, Korb G, et al. Thermal cycling induced deformation and damage in carbon fiber reinforced copper composite[J]. Scripta Materialia, 2002, 46(2): 169-173.

[9] Jang Y, Kim S, Lee S, et al. Fabrication of carbon nano-sized fiber reinforced copper composite using liquid infiltration process[J]. Composites Science and Technology, 2005, 65(5): 781-784.

[10] 韩绍昌, 徐仲榆. 碳/铜复合材料研究进展[J]. 机械工程材料, 1999, 23(6): 6-9.

HAN Shao-chang, Xu Zhong-yu. Researching progress of C/Cu matrix composites[J]. Materials for Mechanical Engineering, 1999, 23(6): 6-9.

[11] Prakasan K, Seshan S. Wear resistance of cast Cu-based MMCs[J]. AFS Transactions, 2000, 108: 91-94.

[12] HE Da-hai, Manory R. A novel electrical contact material with improved self-lubrication for railway current collectors[J]. Wear, 2003, 249(7): 626-636.

[13] 邹柳娟, 范志强, 朱孝谦. 炭纤维增强铜基(碳/铜)复合材料的研究现状与展望[J]. 材料导报, 1998, 12(8): 56-59.

ZOU Liu-juan, FAN Zhi-qiang, ZHU Xiao-qian. Research status and outlook for carbon fiber reinforced copper(Cu) & plumbum(Pb) matrix composites[J]. Materials Review, 1998, 12(8): 56-59.

[14] Queipo P, Granda M, Ricardo S, et al. Preparation of pitch-based carbon–copper composites for electrical applications[J]. Fuel, 2004, 83(11/12): 1625-1634.

[15] 冉丽萍, 易茂中, 陈 斌. C/C坯体对RMI C/C-SiC复合材料组织的影响[J]. 中国有色金属学报, 2005, 23(8): 1208-1213.

RAN Li-ping, YI Mao-zhong, CHEN Bin. Influence of different C/C performs on microstructure of C/C-SiC composites fabricated by RMI[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1208-1213.

[16] 温诗铸. 摩擦学原理[M]. 北京: 清华大学出版社, 1990.

WEN Shi-zhu. Tribological principle[M]. Beijing: Tsinghua University Press, 1990.

收稿日期:2006-12-26

基金项目:国家重点基础研究发展计划资助项目(973计划) (2006CB600906)

作者简介:冉丽萍(1963-), 女, 副教授, 从事炭/炭复合材料和材料表面工程方面的研究

通讯作者:易茂中, 男, 博士, 教授, 博导;电话:0731-8830894; E-mail: yimaozhong@126.com