Effects of heat treatment on microstructure and mechanical properties of ZK60 Mg alloy

来源期刊:中国有色金属学报(英文版)2011年第4期

论文作者:陈先华 黄小旺 潘复生 汤爱涛 王敬丰 张丁非

文章页码:754 - 760

关键词:镁合金;热处理;析出;强度;塑性

Key words:Mg alloy; heat treatment; precipitate; strength; ductility

摘 要:研究固溶和时效热处理工艺对铸态ZK60镁合金显微组织与力学性能的影响。结果表明,当固溶处理条件为400 °C下保温10 h、时效处理温度为150 °C时,ZK60合金中析出相随时效时间的延长而增加,直至30 h。当时效温度升至200 °C时,析出相体积分数在时效时间为15~20 h时达到最大值。室温拉伸实验表明,高密度第二相析出物有利于提高合金的强度和塑性。优化的热处理工艺条件为400 °C固溶10 h随后于150 °C时效30 h,得到的镁合金兼具有高的强度与塑性综合性能。

Abstract: The microstructure and mechanical properties of ZK60 Mg alloy were investigated under different solution treatments and artificial aging conditions. When as-cast ZK60 alloy was solution treated at 400 °C for 10 h and artificially aged at 150 °C, the volume fraction of precipitates increased with the aging time up to 30 h. When the as-cast ZK60 alloy was solution treated at 400 °C for 10 h and artificially aged at 200 °C for 15-20 h, the volume fraction of precipitates reached a peak value. Tensile test at room temperature showed that a high density of the second phase precipitates was beneficial to improving the strength and elongation. Solution treatment at 400 °C for 10 h and artificial aging at 150 °C for 30 h is considered the optimum heat treatment condition to obtain a good combination of strength and ductility.

CHEN Xian-hua1, 2, HUANG Xiao-wang1, PAN Fu-sheng1, 2, TANG Ai-tao1, 2, WANG Jing-feng1, 2, ZHANG Ding-fei1, 2

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China

Received 23 September 2010; accepted 25 December 2010

Abstract: The microstructure and mechanical properties of ZK60 Mg alloy were investigated under different solution treatments and artificial aging conditions. When as-cast ZK60 alloy was solution treated at 400 °C for 10 h and artificially aged at 150 °C, the volume fraction of precipitates increased with the aging time up to 30 h. When the as-cast ZK60 alloy was solution treated at 400 °C for 10 h and artificially aged at 200 °C for 15-20 h, the volume fraction of precipitates reached a peak value. Tensile test at room temperature showed that a high density of the second phase precipitates was beneficial to improving the strength and elongation. Solution treatment at 400 °C for 10 h and artificial aging at 150 °C for 30 h is considered the optimum heat treatment condition to obtain a good combination of strength and ductility.

Key words: Mg alloy; heat treatment; precipitate; strength; ductility

1 Introduction

There has been a renaissance in magnesium alloy research in the last few years driven by increasing global awareness of the link between energy usage and climate change[1]. Magnesium alloys are potentially suitable candidates for replacing heavier materials in some automobile and aerospace parts[2-4]. The mechanical limitations of Mg alloys reside basically in their limited strength, plasticity and formability[5-6]. In order to improve the mechanical properties, some investigations focused on optimizing heat treatment processing routes[7-9].

In general, solution treatment and/or aging process is employed to enhance the mechanical properties of Mg alloys[8]. Solution treatment causes the precipitates dissolving into the Mg matrix and forms supersaturated solid solution during quenching. The aging process results in the transformation of supersaturated solid solution to fine precipitates. The precipitation of the second phases is dependent on aging temperature, time and chemical composition of the alloys. Among these variables, the temperature and time are controlled to elucidate the heat treatment process. Moreover, the aging time for these alloys must be carefully chosen to allow sufficient precipitation of the second phases. Depending upon their volume fraction and morphology, the second phase constituents strengthen and embrittle the matrix to varying degree.

ZK60 Mg alloy is one of the most typical high-strength wrought Mg alloys. Considerable attention was concentrated lately on the study of the influence of heat treatment on the mechanical properties of ZK60 alloy subjected to plastic deformation, including extrusion, rolling, forging and so on[10-12]. However, quite limited studies reported on the heat treatment procedures of as-cast ZK60 alloy[13]. In the present work, the effects of solution treatment and artificial aging on the microstructure and mechanical properties of ZK60 alloy in cast state are examined. This study also aims to determine the structure transformation of ZK60 alloy after various heat treatments, and hence optimize the heat treatment parameters.

2 Experimental

Alloy ingots of ZK60 were prepared from high purity Mg (99.98%), Zn (99.99%) and Mg-27.85Zr (mass fraction, %) master alloy in an electric resistance furnace. When the temperature reached 780 °C, molten alloy was stirred for 8 min and subsequently held for 30 and 45 min, respectively. Then semi-continuous casting was used to prepare cylinder ingots of ZK60 magnesium alloy with a diameter of 90 mm. The actual chemical composition of the alloy is listed in Table 1. The ingots were solution treated at 400 °C for 10 h and subsequently water quenched. Artificial aging treatment was then performed at 150 and 200 °C for 5 , 10 , 15 , 20 , 25 and 30 h, respectively.

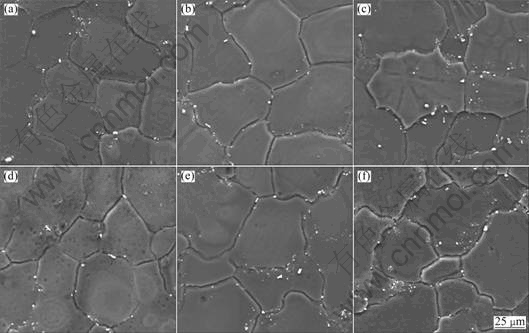

Table 1 Chemical composition of ZK60 alloy (mass fraction, %)

The microstructural characterization was performed by using optical microscopy (OM) and scanning electron microscopy (SEM, TESCAN VEGA Ⅱ LMU) with an accelerating voltage of 20 kV and conventional filament source. Specimens for OM and SEM observations were mechanically polished and chemically etched in a solution of 1.5 g picric acid + 25 mL ethanol + 5 mL acetic acid + 10 mL water. Phase analyses were performed with a Rigaku D/MAX-2500PC X-ray diffractometer (XRD).

The mechanical properties of the as-cast and heat-treated ZK60 alloys were measured by tensile testing and microhardness measurement at room temperature. Tensile specimens with size of d 5 mm × 50 mm were prepared through machining the alloy rods. Tensile tests were carried out on a CMT5105 material test machine at a constant strain rate of 10-3 s-1. The reported Vickers hardness (HV) represented the average value of ten separate measurements taken at randomly selected points under a load of 0.49 N for 10 s.

3 Results and discussion

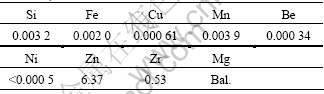

The typical microstructure of as-cast alloy is presented in Fig.1. The OM image (Fig.1(a)) shows the bright contrast of α-Mg matrix and the dark contrast of the second phase. The eutectic is a mixture of Mg-Zn phase and supersaturated solid solution. Fig.1(b) shows the fine structure of Mg-Zn phase.

Fig.1 OM (a) and SEM (b) images of as-cast ZK60 alloy

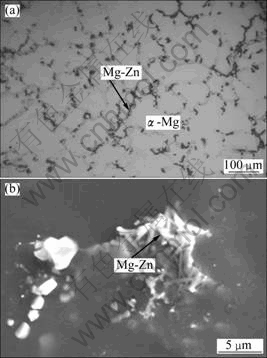

The as-cast ZK60 alloy was held at 400 °C for 10 h, which could significantly reduce the volume fraction of the second Mg-Zn phase, resulting in a relatively high Zn solid solution concentration. As shown in Fig.2(a), it is clear that solution treatment also induces an obvious grain growth in ZK60 alloy. The mean grain size is almost doubled after solution treatment. Figures 2(b) and (c) show the optical microstructures of ZK60 alloy specimens subjected to solution treatment followed by aging at 150 °C for 15 h and 200 °C for 15 h, respectively. The sequential artificial aging treatment did not change much the grain size and distribution, while the precipitation of the second phase occurred inside the grains.

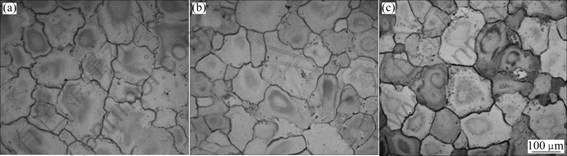

SEM observation at higher magnification in Fig.3 clearly shows these precipitates in the specimens after artificial aging at 150 and 200 °C for different time. Most of the precipitates with a size of less than 1 ?m are very fine. It is found that the distribution of the precipitates is not homogeneous in the grains, and more precipitate particles are presented in the vicinity of grain boundaries. This may be attributed to that the grain boundary region can act as effective nucleation sites for precipitating of the second phase, since the grain boundaries possess high excess energy and the impurities tend to exist in the region. The volume fraction of precipitates varies with aging time at any temperature. From Figs.3(a-c), it can be seen that aging treatment at 200 °C for 15 h leads to a higher density of precipitates compared with that aging for 5 and 20 h. For aging at 200 °C, the precipitate particles increase gradually with holding time as shown in Figs.3(d-f).

Fig.2 Optical images of ZK60 alloy in varying heat treatment conditions: (a) Solution treated; (b) Solution treated, and aged at 150 °C for 15 h; (c) Solution treated, and aged at 200 °C for 15 h

Fig.3 SEM images of alloy after solution treatment followed by different aging parameters: (a) 150 °C, 10 h; (b) 150 °C, 15 h; (c) 150 °C, 30 h; (d) 200 °C, 5 h; (e) 200 °C, 15 h; (f) 200 °C, 20 h

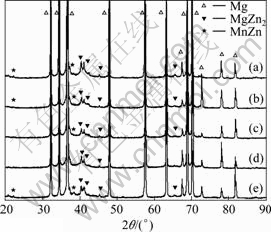

In order to identify the second phase precipitates in ZK60 alloy, XRD analysis was carried out on the specimens. The XRD patterns of as-cast, solution treated and solution treated plus aged at 150 °C are illustrated in Fig.4, which indicates that the precipitates of the alloys at various heat-treatment states mainly consist of MgZn2 and MgZn phases. From the intensity of diffraction peaks, it is concluded that the solution treatment gives rise to an obvious decrease in the volume fraction of the second phase, while lots of MgZn2 and MgZn phases precipitate again during the subsequent aging, especially during the aging treatment at 150 °C for 30 h. This is consistent with the result from OM and SEM observations.

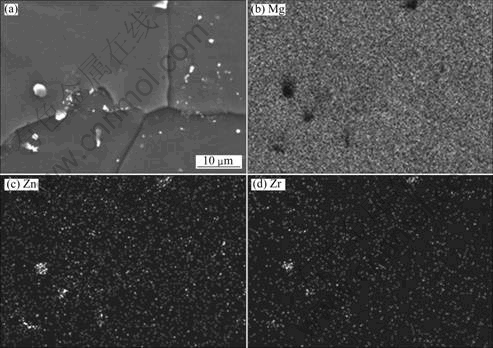

Typical EDS mapping of the precipitate particles in the alloy after solution treatment and aging at 150 °C for 30 h is shown in Fig.5. It is noted that many precipitates are found in the Mg and Zn EDS maps, which is in agreement with the XRD analysis. However, Zr element is found in some second phase particles, which may be attributed to the following two reasons: 1) Zr-rich particles can act as the nucleation sites during Mg solidification by the peritectic reaction[14-15]; 2) Zn2Zr3 phase is presented in the grains[15]. It is possible that XRD analysis is not able to identify the Zr and Zn2Zr3 phases due to the low concentration of Zr.

Fig.4 XRD patterns of alloy in various heat treatment states: (a) solution treated, aged at 150 °C for 30 h; (b) Solution treated, aged at 150 °C for 15 h; (c) Solution treated, aged at 150 °C for 10 h; (d) Solution treated; (e) As cast

Fig.5 EDS mapping analysis of ZK60 alloy subjected to solution treatment and aging at 150 °C for 30 h: (a) SEM image; (b-d) Distribution of Mg, Zn and Zr

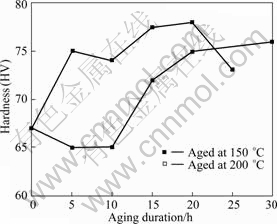

Figure 6 shows the aging hardening curves of ZK60 specimens at constant aging temperatures of 150 and 200 °C for different time, respectively. The specimens for aging treatment were solution treated at 400 °C for 10 h and obtained a microhardness of HV 67. The hardness increased to the peak value of HV 79 after aging at 200 °C for 15-20 h, then tended to decrease. The variation tendency of hardness value with aging time at 150 °C is different from that at 200 °C. For the specimen subjected to artificial aging at 150 °C, no peak value was found and the hardness was enhanced with the increase of holding time, when the aging time is up to 30 h, the hardness is about HV 77.

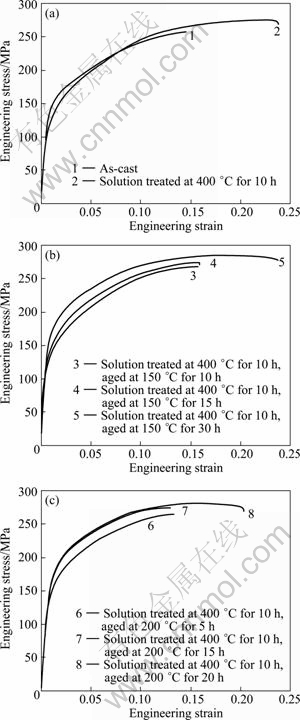

According to the aging curves, uniaxial tensile testing was performed on seven ZK60 specimens in different heat-treatment states. The obtained tensile engineering stress—strain curves are shown in Fig.7. All the stress—strain curves can be divided into three regions. Region I corresponds to the elastic deformation. In region II, obvious strain hardening is present and the plastic deformation is uniform across the gauge length. In region III, localized necking occurs and the stress decreases gradually.

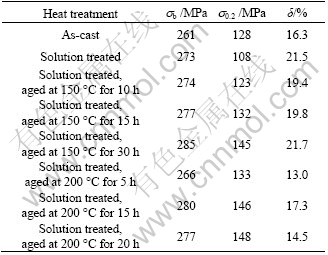

Fig.6 Aging hardening curves of alloy under different aging conditions

A quantitative summary of the tensile results for each sample, including ultimate tensile strength (sb), yield strength (s0.2) as well as elongation-to-failure (δ), is listed in Table 2. Table 2 shows the effect of heat treatment condition on the tensile properties of as-cast ZK60 Mg alloy. The as-cast alloy was solution treated at 400 °C for 10 h, and then artificially aged at varying temperature and time conditions. Solution treated alloys exhibit a decreased yield strength and increased tensile elongation compared with the as-cast ZK60 specimens. After subsequent aging treatment at 150 °C for 10 h, the specimen possesses higher strength and lower tensile elongation in comparison with the solution treated one. It is interesting to note that both the strength and elongation increase with increasing aging time. After aging treatment at 150 °C for 30 h, sb and s0.2 are up to 285 and 145 MPa, respectively, which are obviously higher than those of as-cast and solution treated samples. In addition, the elongation of the specimen under this condition under 21.7%, which is comparable to that of the solution treated one and greater than that of the as-cast one. For aging treatment at 200 °C, the tensile strength and elongation reach peak values with the aging time of 15 h, and then exhibit a decrease with increasing aging time.

Table 2 Tensile properties of ZK60 alloy in different heat treatment states

The strength of Mg alloys is generally influenced by the contributions from intrinsic lattice, grain boundaries, solid solution, second phases and dislocations[16-17]. A possible expression of the yield strength of as-cast specimen can be approximated linearly as[6]:

![]() (1)

(1)

where σ0 is the intrinsic lattice resistance to basal slip; σnss is the contribution of non-uniform solid solution which is associated mostly with effects of Zn and Zr; σgb=Mksd-1/2 is the grain boundary contribution through the Hall-Petch relation, in which d is the grain size, M is

the Taylor factor for basal ship, ![]() ,

, ![]() is related to more difficult prismatic slip in a single

is related to more difficult prismatic slip in a single

crystal for Mg based alloys and C* is a constant; σdisp=KVε is the dispersion strengthening due to the second phase, where K is a constant, V is the volume fraction of Mg-Zn phases and ε is the applied strain.

The microstructure of the solution treated specimen is more simple compared to that of the as-cast specimen. The yield strength of the solution treated specimen in that case can be expressed as[6]:

![]() (2)

(2)

where σuss is the contribution of uniform solid solution.

Fig.7 Tensile engineering stress—strain curves of alloy in different heat treatment states

The microstructure change induced by artificial aging is mainly the precipitation of Mg-Zn phases. The yield strength of the specimens subjected to solution treatment plus aging can be written as:

![]() (3)

(3)

where σprec=KVε is the precipitation strengthening due to the second phase, where K is a constant, V is the volume fraction of Mg-Zn precipitates and ε is the applied strain.

Solution treatment increases the grain size greatly, which results in the fact that the contribution of σgb to the strength of solutionized specimen is significantly weaker compared to that of as-cast specimen. At the same time, the contribution of σprec to the strength is almost negligible for the solutionized specimen. Therefore, it is reasonable that the yield strength of the solution treated specimen is comparatively lower than that of the as-cast specimen.

Numerous MgZn and MgZn2 precipitates form when the specimens are subjected to the treatment of solution treatment plus aging. Additionally, the grains grow quite slightly during aging treatment. The combined contribution of σgb and σprec to the yield strength of aged specimens is stronger compared to the contribution of σgb to the strength of the solutionized specimen, which is responsible for the fact that the yield strength of aged specimen is higher than that of solution treated specimen. According to the SEM observations, the volume fraction of precipitates increases with the holding time increasing for these specimens aged at 150 °C. Consequently, the yield strength is the highest when the aging time is 30 h. For the specimens aged at 200 °C, the highest volume fraction of precipitates and yield strength are obtained when the aging time is 15-20 h.

After solution treatment and aging at 150 °C for 30 h, the specimen exhibits the highest tensile strength and elongation among these experimental specimens. This indicates that the precipitation of the second phase is beneficial to the enhancement of both strength and ductility, which is different from some results reported in Refs.[10-11]. It is considered that the formation of some second phase compounds containing impurities (such as Mg2Si and Mg2Ni) during aging could purify the Mg matrix, which might improve the plasticity of the alloy. Further systematic investigation is needed to explain the phenomenon.

4 Conclusions

1) When the as-cast ZK60 alloy is subjected to solution treatment at 400 °C for 10 h and artificial aging treatment at 150 °C for different times, the volume fraction of precipitates increases with the aging time up to 30 h.

2) When the as-cast ZK60 alloy is subjected to solution treatment at 400 °C for 10 h and artificial aging treatment at 200 °C, the volume fraction of precipitates reaches the peak value with aging time of 15-20 h.

3) Solution treatment at 400 °C for 10 h plus artificial aging at 150 °C for 30 h can be considered the optimum heat treatment. A good combination of tensile strength and ductility is achieved under this treatment condition.

References

[1] BOHLEN J, LETZIG D, KAINER K U. New perspectives for wrought magnesium alloys [J]. Materials Science Forum, 2007, 546-549: 1-10.

[2] MORDIKE B L, EBERT T. Magnesium: properties—Applications—potential [J]. Materials Science and Engineering A, 2001, 302(5): 37-45.

[3] KAINER K U, von BUCH F. Magnesium alloys and technologies [M]. Weinheim: WILEY-VCH Verlag GmbH, 2003: 1-3.

[4] SUZUKI A, SADDOCK N D, JONES J W, POLLOCK T M. Solidification paths and eutectic intermetallic phases in Mg-Al-Ca ternary alloys [J].Acta Materialia, 2005, 53(9): 2823-2834.

[5] del VALLE J A, CARRENO F, RUANO O A. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling [J]. Acta Materialia, 2006, 54: 4247-4259.

[6] YAKUBTSOV I A, DIAKA B J, SAGER C A, BHATTACHARYA B, MACDONALD W D, NIEWCZAS M. Effects of heat treatment on microstructure and tensile deformation of Mg AZ80 alloy at room temperature [J]. Materials Science and Engineering A, 2008, 496: 247-255.

[7] BEER A G, BARNETT M R. Microstructure evolution in hot worked and annealed magnesium alloy AZ31 [J]. Materials Science and Engineering A, 2008, 485: 318-324.

[8] BALASUBRAMANI N, PILLAI U T S, PAI B C. Optimization of heat treatment parameters in ZA84 magnesium alloy [J]. Journal of Alloys and Compounds, 2008, 457: 118-123.

[9] XU D K, LIU L, XU Y B, HAN E H. The effect of precipitates on the mechanical properties of ZK60-Y alloy [J]. Materials Science and Engineering A, 2006, 420: 322-332.

[10] CHEN H M, YU H S, KANG S B, CHO J, MIN G H. Optimization of annealing treatment parameters in a twin roll cast and warm rolled ZK60 alloy sheet [J]. Materials Science and Engineering A, 2010, 527: 1236-1242.

[11] CHEN H M, KANG S B, YU H S, CHO J, KIN H W, MIN G H. Effect of heat treatment on microstructure and mechanical properties of twin roll cast and sequential warm rolled ZK60 alloy sheets [J]. Journal of Alloys and Compounds, 2009, 476: 324-328.

[12] YU Kun, LI Wen-xian, WANG Ri-chu. Effects of heat treatment on microstructures and mechanical properties of ZK60 magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 188-192. (in Chinese)

[13] YUAN Wu-hua, ZHANG Zhao-chun, GUO Qiang, XIA Wei-jun, JI Zhe, CHEN Zhen-hua. Influence of solution treatment on structures and properties of ZK60 alloy [J]. Heat Working Technology, 2006, 35(2): 22-24. (in Chinese)

[14] ROBERTS C S. Magnesium and its alloys [M]. New York: Wiley & Sons, 1960: 206-207.

[15] SHAHZAD M, WAGNER L. Microstructure development during extrusion in a wrought Mg-Zn-Z0r alloy [J]. Scripta Materialia, 2009, 60: 536-538.

[16] MEYERS M A, CHAWLA K K. Mechanical behavior of materials [M]. New Jersey: Prentice Hall, Inc, 1999: 375.

[17] COURTNEY T H. Mechanical behavior of materials [M]. Michigan: McGraw-Hill Companies, Inc, 2000: 181-182.

陈先华1, 2, 黄小旺1, 潘复生1, 2, 汤爱涛1, 2, 王敬丰1, 2, 张丁非1, 2

1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044

摘 要:研究固溶和时效热处理工艺对铸态ZK60镁合金显微组织与力学性能的影响。结果表明,当固溶处理条件为400 °C下保温10 h、时效处理温度为150 °C时,ZK60合金中析出相随时效时间的延长而增加,直至30 h。当时效温度升至200 °C时,析出相体积分数在时效时间为15~20 h时达到最大值。室温拉伸实验表明,高密度第二相析出物有利于提高合金的强度和塑性。优化的热处理工艺条件为400 °C固溶10 h随后于150 °C时效30 h,得到的镁合金兼具有高的强度与塑性综合性能。

关键词:镁合金;热处理;析出;强度;塑性

(Edited by FANG Jing-hua)

Foundation item: Project (2009BB4215) supported by the Natural Science Foundation Project of CQ CSTC, China; Project (20090191120013) supported by the PhD Programs Foundation of Ministry of Education of China; Project (50725413) supported by the National Natural Science Foundation of China; Project (2007CB613704) supported by the National Basic Research Program of China; Project (CDJZR10 13 00 01) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: CHEN Xian-hua; Tel: +86-23-65102821; E-mail: xhchen@cqu.edu.cn

DOI: 10.1016/S1003-6326(11)60776-0