DOI: 10.11817/j.issn.1672-7207.2017.03.007

基于响应面法的7050铝合金筋板类锻件热模锻成形工艺优化

吴道祥1, 2,周杰1, 2,马鹏程1, 2,赵天生1, 2

(1. 重庆大学 材料科学与工程学院,重庆,400044;

2. 重庆大学 材料成形研究所,重庆,400044)

摘要:针对某铝合金航空锻件热锻成形中出现的充填不满、流线穿流、变形不均匀等缺陷问题,以x1(坯料高宽比)、x2(坯料温度)、x3(成形速度)、x4(摩擦因数)为优化变量,采用响应面法结合有限元数值模拟对锻件成形多目标工艺参数优化进行研究。根据试验设计结果分别建立3个目标函数的二阶分析模型,得到的回归模型预测精度较高,能较好地描述3个目标函数关于设计变量的响应。通过分析建立的响应面3D和2D优化图,采用MATLAB软件对试验参数进行进一步的优化。研究结果表明:锻件成形最优工艺参数如下:x1为1.3、x2为450 ℃、x3为6 mm/s、x4为0.3。将优化后的最优工艺参数应用到后续的实际生产验证,锻件成形缺陷得到有效消除,证明该优化方法有效。

关键词:多目标优化;响应面法;筋板类锻件;热模锻;数值模拟

中图分类号:TG316 文献标志码:A 文章编号:1672-7207(2017)03-0601-07

Optimization of hot die forging process parameters of 7050 aluminum alloy rib-web type components based on response surface method

WU Daoxiang1, 2, ZHOU Jie1, 2, MA Pengcheng1, 2, ZHAO Tiansheng1, 2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Institute of Materials Forming, Chongqing University, Chongqing 400044, China)

Abstract: Due to the defects such as under-filling, partial draining and uneven deformation appearing in precision forming process of aluminum alloy aviation components, the height-width ratio of the billet (x1), billet temperature (x2), punch velocity (x3) and friction coefficient (x4) were selected to the optimization variables. Multi-objective optimization of hot die forging process parameters were studied using the response surface method (RSM) combined with finite element method (FEM). Second-order analysis models were established to describe the response of the three functions about optimization objectives and the results illustrated that the regression models were fine in prediction accuracy. By analyzing the 3D and 2D optimization graphs, the software of MATLAB was used to further optimized experiment parameters. The results show that the optimal process parameters are as follows: x1 is 1.3, x2 is 450 ℃, x3 is 6 mm/s and x4 is 0.3. Through the next actual production verification, the optimal process parameters optimized can effectively eliminate the dissatisfaction of the components.

Key words: multi-objective optimization; response surface method; rib-web components; hot die forging; finite element method

铝合金构件被广泛应用于航天、航空等领域,为了满足现代装配轻量化的要求,这类构件通常被设计成高筋、薄腹板以及带有纵、横内筋的结构[1-2]。在成形的过程中,这种结构的锻件由于工艺参数的设置欠佳,会造成各种成形缺陷,如填充不满、流线穿流、组织晶粒粗大且分布不均等质量问题[3-5]。目前学者们利用有限元仿真软件在筋板类锻件热模锻成形方面展开了大量的研究工作。PARK等[6]采用有限元模拟软件对筋板类锻件模锻成形过程进行模拟实验,通过对不同形状坯料填充型腔的方式、金属流动场、等效应变场等进行分析,得出最优的预制坯形状及工艺组合。SHAN等[7]采用局部加载的方法对筋板类锻件等温模锻成形进行有限元模拟分析,通过控制锻件成形时金属的流动方向与距离,改善了锻件的充填情况,避免出现充不满、折叠等缺陷。ZHANG等[8]采用实验与数值模拟相结合的方法,研究了某7075铝合金盘类锻件等温精密成形过程组织流线分布情况及演变方式。孙志超等[9]基于DEFORM-3D有限元模拟软件对TA15钛合金复杂构件预锻初始毛坯形状进行优化,避免了锻件组织流线穿流、锻件表面折叠等缺陷的发生,获得了填充性能良好、内部组织均匀细小的预锻件。这些研究都从单因素单目标来分析锻件成形过程。而对于薄腹板并带有纵横内筋结构的铝合金锻件,成形过程中不同锻造缺陷之间存在着耦合变量,基于某一性能的优化往往会导致另一性能的降低。因此,基于某一性能或多性能的多目标优化方法,应考虑各目标之间的耦合关系[10]。本文作者针对某锻造厂生产的某铝合金航空锻件热锻成形中出现的充填不满、流线穿流、变形不均匀的问题,提出数值模拟法结合响应面法(response surface method, RSM)的优化方法。该方法是一种能够同时确保锻件充填饱满、锻件不出现穿流缺陷以及锻件组织变形均匀的协同优化方法,是一种典型的多学科设计方法[11-12],可以把锻件充填性能、组织流线、成形均匀性等各个指标进行多目标的平衡和优化。

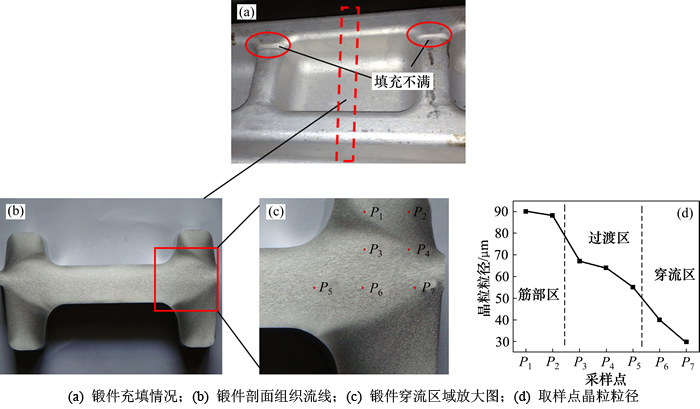

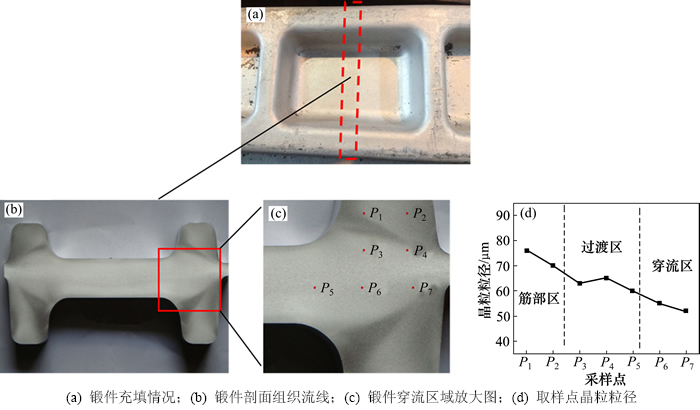

1 锻件成形缺陷

锻造试验在某铝加工厂300 MN水压机上进行,坯料材料为7050铝合金,锻件成形工艺的步骤为自由锻制坯—预锻—终锻。坯料初始温度为450 ℃,模具预热温度为350 ℃,液压机工作速度为8 mm/s,保压时间5 min。锻造后,对锻件进行T6热处理,热处理完后锻件局部示意图如图1所示。从图1(a)可知:在锻件中间加强筋部位出现充填不满缺陷。沿锻件筋板处将锻件分成两半,对锻件剖面进行打磨,用NaOH溶液及HNO3溶液进行碱蚀、酸洗得到如图1(b)所示锻件流线,图1(c)所示为剖面局部示意图。结合图1(b)和图1(c)可知:锻件在H形筋的根部圆角与腹板间形成了穿出流线,沿水平方向流向飞边槽的金属切断原有金属流线,造成穿流缺陷。在锻件剖面不同 位置选择7个采样点,取金相试样进行粗磨、抛光,用配方比(体积比)为V(HF):V(HCl):V(HNO3):V(H2O)=1:1.5:2.5:95侵蚀剂侵蚀后,在金相显微镜下观察试样晶粒粒径,各取样点试样晶粒粒径如图1(d)所示。从图1(d)可知:锻件剖面不同位置晶粒粒径差距较大,位于锻件筋部的P1和P2点晶粒粒径在90 μm左右;锻件筋板与腹板过渡区的P3和P4点晶粒粒径在65 μm左右,P5点晶粒粒径约为55 μm;在穿流区域,P6点晶粒粒径达到40 μm, P7点部位晶粒粒径最小,达到30 μm。铝合金在热锻条件下通常通过发生动态再结晶来细化晶粒[13],而动态再结晶又与坯料的变形程度密切相关[14],坯料变形时储存的变形能达到一定临界值,就会发生动态再结晶,在原晶粒的晶界开始形成新的晶粒,使坯料晶粒得到细化[15]。因此,由以上分析可知,锻件剖面金属变形不均匀。

图1 热模锻后锻件示意图

Fig. 1 Typical local schematic diagrams of component after hot forging

2 基于响应面法的试验设计

2.1 目标函数设计

根据锻件成形过程中出现的充填不满、流线穿流、变形不均匀等成形缺陷,选取锻件充填性能、组织流线、成形均匀性3个指标作为优化目标。将锻件剖面上实际锻件与理想锻件间的面积差异作为衡量锻件填充性能的评价指标,其目标函数如下:

(1)

(1)

式中:η为锻件充填性能目标函数;N为单元总数;Ai为锻件剖面第i个单元格中实际锻件与理想锻件不重合区域的面积。

将成形结束时腹板处金属流向模具飞边的平均速度作为评价锻件纤维折断(即流线穿流)的评价指标,目标函数如下:

(2)

(2)

式中:γ为锻件组织流线目标函数;vi为锻件剖面腹板处第i个单元格中金属流向飞边的速度。

将锻件剖面任意区域应变与整体平均应变之间的差值的平方和作为评价锻件成形均匀性的评价指标,目标函数如下:

(3)

(3)

式中:ξ为锻件成形均匀性目标函数;εi为锻件剖面第i个单元格内金属等效应变;εavg为锻件剖面平均等效应变。

2.2 试验设计

响应面法的使用必须先确定合理的变量因素以及相应的水平参数[16]。由文献[17-18]可知:铝合金筋板类锻件在成形过程中出现的各种缺陷与坯料形状尺寸、模锻时坯料初始温度、压机工作速度以及成形时模具内壁的润滑情况等密切相关。因此,选取坯料高宽比、坯料温度、成形速度以及摩擦因数作为本试验变量因素。为了后续实验设计方便,将坯料高宽比、坯料温度、成形速度以及摩擦因数分别记为x1,x2,x3和x4。

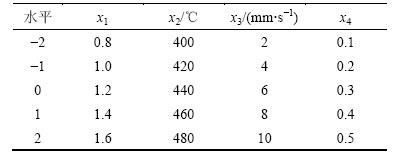

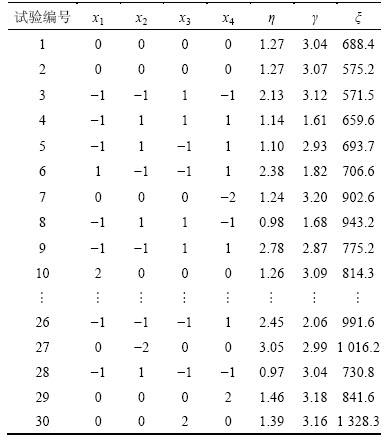

文中有优化变量4个,优化目标3个,因此该试验二阶响应面模型的回归系数共有15个。为了得到合理的回归方程,取每个因子水平数为5,但这要求试验次数比较多,实现比较困难。中心复合试验设计(CCD)就是为了解决这一矛盾而提出的一种设计试验的方法[19]。应用四因子(x1,x2,x3,x4)、五水平(-2,-1,0,1,2)的中心复合设计(CCD)进行试验设计,因子水平如表1所示。试验方案及部分试验结果如表2所示。

表1 因素水平的中心复合设计

Table 1 Central composite design of factor levels

表2 试验方案及部分试验结果

Table 2 Test program and part of results

2.3 响应面模型

采用二阶模型建立3个目标响应η,γ,ξ关于设计变量x1,x2,x3,x4的预测模型。对于四因素试验,多项式模型表示如下:

(4)

(4)

采用式(4),应用最小二乘法对表2的数据进行回归分析,得到关于3个目标响应函数如下:

(5)

(5)

(6)

(6)

(7)

(7)

为了验证所建的响应面模型是否能真正反映响应面与设计因素间的统计规律,对式(5)~(7)进行方差分析。方差分析结果如表3~5所示。

表3充填性能η方差分析

Table 3 Variance analysis of η

表4 组织流线γ方差分析

Table 4 Variance analysis of γ

表5 成形均匀性ξ方差分析

Table 5 Variance analysis of ξ

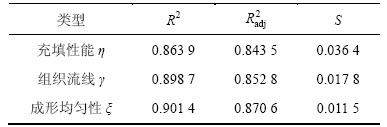

由表3~5可知:3个模型的F值分别为3.47,3.56和5.75,以及相应的P值依次为0.001 4,0.001 0和0.000 6,皆小于0.05(α=0.05),这说明3种模型是显著的。除F检验之外,可通过S,R2和R2adj来进一步检验预测模型的可靠性,通常R2和R2adj越大,S越小,回归模型的拟合程度越好。确定系数分析如表6所示。从表6可知:3个模型相关系数R2分别为86.39%,89.87%和90.14%,说明模型的预测精度较好。综上所述3个预测模型能较好地描述所提出的3个目标函数η,γ,ξ关于设计变量x1,x2,x3,x4的响应,并有很好的精度,可以用于后续工艺优化。

表6 确定系数分析

Table 6 Determine coefficient analysis

3 试验方案优化与验证

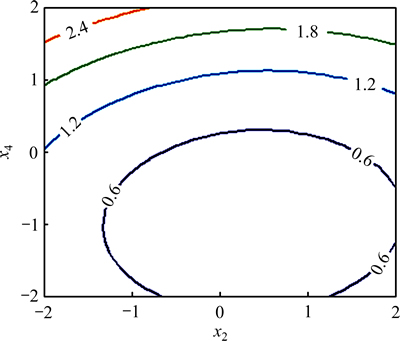

从各个模型的方差分析结果可以找出对各个目标函数影响最显著的变量因素。其中,对充填性能η影响最为显著的因素为x2(坯料温度)和x4(摩擦因数);对组织流线γ影响最为显著的因素为x1(坯料高宽比)和x3(成形速度);对成形均匀性ξ影响最为显著的因素为x1(坯料高宽比)和x4(摩擦因数)。为了进一步分析各个变量因素对3个响应优化量的影响,现选取影响各个响应优化量最显著的因素来分析。图2和图3所示分别为在x1=0,x3=0时响应目标函数η关于变量x2和x4的等值线图以及x2=0,x4=0时响应目标函数γ关于变量x1和x3的等值线图。

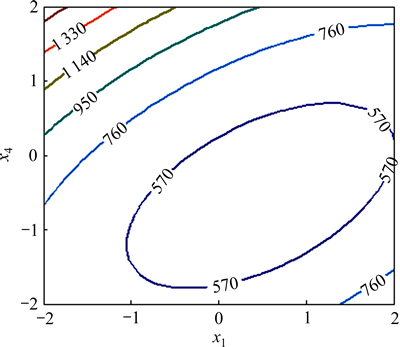

从图2可以看出:当变量x1=0,x3=0时,充填性能η的响应值随着变量x4增加而增加。对变量x2,随着变量x2的增加,充填性能η的响应值降低,但是当变量x2>1后,响应值随着变量x2的增加而增加。当-1<x2<2,x4<0时,响应值可降至0.6左右。从图3可以看出:当变量x2=0,x4=0时,组织流线γ的响应值随变量x1,x3的变化情况,随着变量x1的增加,目标γ的响应值降低,但是当变量x1>1后,目标响应值又开始增加。对于变量x3,在x1<0时,目标响应值随着变量x3的增加而减小;在x1>0时,目标响应值随着变量x3的增加而增加。当-1<x1<1,-1<x3<1时,响应值可将至1.6左右。图4所示为x2=0,x3=0时响应目标函数ξ关于变量x1和x4的三维曲面图和等值线图。从图4可知:成形均匀性ξ的响应值随着变量x1的增加而降低,随着变量x4的增加,目标响应值也增加。当x1>-1,x4<0时,响应值可降至570左右。通过建立的响应面模型,使用MATLAB软件求出可行设计空间中目标函数最优解及对应的工艺参数组合:x1(坯料高宽比)为1.3、x2(坯料温度)为450 ℃、x3(成形速度)为6 mm/s、x4(摩擦因数)为0.3。

图2 x1=0,x3=0时目标函数η关于变量x2和x4的等值线图

Fig. 2 Contour map of response value of η when x1=0, x3=0

图3 x2=0,x4=0时目标函数γ关于变量x1和x3的等值线图

Fig. 3 Contour map of response value of γ when x2=0, x4=0

图4 x2=0,x3=0时目标函数ξ关于变量x1和x4的等值线图

Fig. 4 Contour map of response value of ξ when x2=0, x3=0

图5 优化工艺后模锻件示意图

Fig. 5 Typical local schematic diagrams of component after optimization

图5所示为将优化后的工艺参数应用到实际生产后得到的模锻件。从图5(a)可知:优化工艺后得到的模锻件基本填充完整,没有出现充填不满现象。将优化后的锻件沿筋板处分成两半,对锻件剖面进行打磨、碱蚀、酸洗后得到图5(b)和图5(c)所示锻件流线,相比于初始工艺,优化工艺后得到的模锻件截面金属流线与锻件表面夹角较小,金属沿水平方向快速流动形成的锻件腹板与筋条区域穿流缺陷得到一定程度的缓解,流线形态优于初始模锻工艺下的锻件流线形态。另外,从图5(d)可知:优化工艺后的锻件剖面取样点晶粒粒径最大值为76 μm,最小值为52 μm,整体晶粒粒径在60 μm左右,不同位置取样点晶粒粒径差异较初始工艺小,锻件金属变形较初始工艺更为均匀。综上所述,基于响应面法得到的7050铝合金筋板类锻件热模锻成形工艺参数能有效提高锻件在成形时的充填性能,改善锻件截面金属流线形态,提高锻件成形后的组织均匀性。

4 结论

1) 基于响应面法(RSM),分别建立了3个目标响应充填性能η、组织流线γ、成形均匀性ξ关于设计变量x1(坯料高宽比)、x2(坯料温度) 、x3(成形速度)、x4(摩擦因数)的二阶响应模型,得到的回归模型拟合度分别为86.39%,89.87%和90.14%,预测精度较好,能较好地描述3个目标函数关于设计变量的响应。

2) 通过对建立的响应面模型进行方差分析,综合响应面优化图,对充填性能η影响最为显著的因素为x2和x4,当-1<x2<2,x4<0时,响应值可降至0.6左右;对组织流线γ影响最为显著的因素为x1和x3,当-1<x1<1,-1<x3<1时,响应值可将至1.6左右;对成形均匀性ξ影响最为显著的因素为x1和x4,当x1>-1,x4<0时,响应值可降至570左右。

3) 运用MATLAB软件对试验参数进一步进行优化,得到锻件成形最优工艺参数:x1为1.3,x2为450 ℃,x3为6 mm/s,x4为0.3。将优化后的工艺参数应用到实际生产,锻件成形充填不满的现象得到有效的消除,穿流缺陷得到有效的控制,锻件金属变形较初始工艺更为均匀。

参考文献:

[1] BIROL Y. Effect of extrusion press exit temperature and chromium on grain structure of EN AW 6082 alloy forgings[J]. Materials Science and Technology, 2015, 31(2): 207-211.

[2] ZHANG Yanqiu, JIANG Shuyong, ZHAO Yanan, et al. Isothermal precision forging of complex-shape rotating disk of aluminum alloy based on processing map and digitized technology[J]. Materials Science and Engineering A, 2013, 580(10): 294-304.

[3] ZHANG Yanqiu, JIANG Shuyong, ZHAO Yanan, et al. Isothermal precision forging of aluminum alloy ring seats with different preforms using FEM and experimental investigation[J]. International Journal of Advanced Manufacturing Technology, 2014, 72: 693-1703.

[4] KHALIPOURAZARY S, ADVAND A, AZDAST T, et al. Design and manufacturing of a straight bevel gear in hot precision forging process using finite volume method and CAD/CAE technology[J]. International Journal of Advanced Manufacturing Technology, 2011, 56: 87-95.

[5] 张玉勋, 易幼平, 李云. 铝合金机轮轮毂锻造流线仿真与实验研究[J]. 中南大学学报(自然科学版), 2011, 42(7): 1967-1972.

ZHANG Yuxun, YI Youping, LI Yun. Simulation and experiment research on forging flow lines for aluminum alloy wheel-hub[J]. Journal of Central South University (Science and Technology), 2011, 42(7): 1967-1972.

[6] PARK J J, HWANG H S. Preform design for precision forging of an asymmetric rib-web type component[J]. Journal of Materials Processing Technology, 2007, 187/188: 595-599.

[7] SHAN Debin, XU Wenchen, SI Changhao. Research on local loading method for an aluminum-alloy hatch with cross ribs and thin webs[J]. Journal of Materials Processing Technology, 2007, 187: 480-485.

[8] ZHANG Yanqiu, SHAN Debin. Flow lines control of disk structure with complex shape in isothermal precision forging[J]. Journal of Materials Processing Technology, 2009, 209(2): 745-753.

[9] 孙志超, 杨合, 李志燕. TA15合金H型构件等温局部加载成形工艺研究[J]. 稀有金属材料与工程, 2009, 38(11): 1904-1909.

SUN Zhichao, YANG He, LI Zhiyan. H-shaped component isothermal local loading forming of TA15 titanium alloy[J]. Rare Metal Materials and Engineering, 2009, 38(11): 1904-1909.

[10] 刘士士, 谷正气, 伍文广. 基于响应面方法的车辆多目标协同优化[J]. 中南大学学报(自然科学版), 2012, 43(7): 2586-2592.

LIU Shishi, GU Zhengqi, WU Wenguang. Multi-objective collaborative optimization of vehicle based on response surface methodology[J]. Journal of Central South University (Science and Technology), 2012, 43(7): 2587-2592.

[11] ZHAO Weitao, QIU Zhiping. An efficient response surface method and its application to structural reliability and reliability-based optimization[J]. Finite Elements in Analysis and Design, 2013, 67: 34-42.

[12] 夏玉峰, 杨显红, 郑晓凯, 等. 基于响应面法的钩尾框渐进热弯曲工艺多目标优化[J]. 中南大学学报(自然科学版), 2014, 45(9): 2977-2984.

XIA Yufeng, YANG Xianhong, ZHENG Xiaokai, et al. Multi-object optimization of incremental hot bending process of hook tail frame based on RSM[J]. Journal of Central South University (Science and Technology), 2014, 45(9): 2977-2984.

[13] 易幼平, 刘超, 黄始全. 基于DEFORM-3D的7050铝合金动态再结晶元胞自动机模拟[J]. 中南大学学报(自然科学版), 2010, 41(5): 1814-1820.

YI Youping, LIU Chao, HUANG Shiquan. Simulation of dynamic recrystallization for 7050 aluminium alloy on platform of DEFORM-3D using cellular automaton[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1814-1820.

[14] YI Youping, FU Xin, CUI Jindong, et al. Prediction of grain size for large-sized aluminium alloy 7050 forging during hot forming[J]. Journal of Central South University of Technology, 2008, 15(1): 1-5.

[15] FAN X G, YANG H, SUN Z C, et al. Effect of deformation in homogeneity on the microstructure and mechanical properties of large-scale rib–web component of titanium alloy under local loading forming[J]. Materials Science and Engineering A, 2010, 527(21): 5391-5399.

[16] PALANIVEL R, MATHEWS P K. Prediction and optimization of process parameter of friction stir welded AA5083-H111 aluminum alloy using response surface methodology[J]. Journal of Central South University, 2012, 19(1): 1-8.

[17] 王梦寒, 徐志敏, 吴道祥. 基于正交实验的H 型截面铝合金锻件多目标成形优化[J]. 热加工工艺, 2012, 41(3): 61-63.

WANG Menghan, XU Zhimin, WU Daoxiang. Optimization of forming process for the aluminum H-shape forging multi-objective based on orthogonal experiment[J]. Hot Working Technology, 2012, 41(3): 61-63.

[18] 徐志敏. 7050铝合金H型截面锻件成形工艺设计优化与微观组织控制[D]. 重庆: 重庆大学材料科学与工程学院, 2012: 1-67.

XU Zhimin. Process design optimization & microstructure control on properties of H-section 7050 Al alloy forging[D]. Chongqing: Chongqing University. College of Materials Science and Engineering, 2012: 1-67.

[19] MOHAMED M N, AMGAD A A, HAMDANI S. Optimization of reaction parameters of radiation induced grafting of 1-vinylimidazole onto poly (ethylene-co-tetraflouroethene) using response surface method[J]. Radiation Physics and Chemistry, 2011, 80(11): 1222-1227.

(编辑 赵俊)

收稿日期:2016-04-20;修回日期:2016-06-16

基金项目(Foundation item):国家自然科学基金资助项目(51275543);中国科技部重大专项项目(2012ZX04010-081);重庆市科委应用开发(重大)项目(cstc2014yykfC70003) (Project(51275543) supported by the National Natural Science Foundation of China; Project(2012ZX04010-081) supported by the Special Funds for Major Projects of China’s Ministry of Science & Technology; Project(cstc2014yykfC70003) supported by the Chongqing Science & Technology Application Development Program)

通信作者:吴道祥,博士,从事铝合金锻件成形工艺研究;E-mail: 20100902091@cqu.edu.cn