文章编号:1004-0609(2015)10-2632-10

微量元素含量对Al-Zn-Mg合金组织与性能的影响

付 高1, 2,邓运来1, 2,王亚风1, 2,戴青松1, 2,张新明1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 材料科学与工程学院 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:通过光学显微镜、扫描电镜、透射电镜、强度实验、冲击韧度实验、应力腐蚀实验、剥落腐蚀实验及极化曲线测试,研究不同微量元素(Cr、Mn、Ti、Zr、Cu)含量添加对Al-Zn-Mg铝合金组织、力学性能与腐蚀性能的影响。结果表明:较多的微量元素使得合金内部第二相析出密度变大,对亚晶界/晶界的迁移起阻碍作用而未诱发粒子形核,提升合金抑制再结晶的能力,从而保持细小晶粒及亚晶组织,合金的抗拉强度提升69 MPa,应力腐蚀开裂延迟了108 h。但同时微量元素使得AlFeMnCu等粗大的第二相增多,使自腐蚀电位正移、腐蚀电流密度变小,而塑性、韧性及耐剥落腐蚀性能均有所下降。

关键词:Al-Zn-Mg铝合金;微量元素;力学性能;腐蚀性能;电化学性能

中图分类号:TG146 文献标志码:A

Effects of microelement content on microstructure and properties of Al-Zn-Mg aluminium alloy

FU Gao1, 2, DENG Yun-lai1, 2, WANG Ya-feng1, 2, DAI Qing-song1, 2, ZHANG Xin-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

School of Material Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of different microelement (Cr, Mn, Ti, Zr, Cu) contents on the microstructure, mechanical properties and corrosion properties of Al-Zn-Mg aluminium alloys were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy, tensile test, impact properties test, stress corrosion and polarization curve measurement.The results show that a little more microelement added to the Al-Zn-Mg aluminium alloys effectively delays the mergence and growth of the sub-grain during the recovery process, inhibits the recrystallization capability of Al matrix, and significantly enhances the mechanical properties and resistance to stress corrosion increasing the tensile strength by 69MPa and postpones the moment of stress corrosion cracking for 108 h. However, the present of more trace elements makes wider distribution of the slightly larger size AlFeMnCu phase generate inside the alloy, makes the matrix as the anode form a microcell, and the surface pitting, plasticity, toughness and corrosion resistance decrease.

Key words: Al-Zn-Mg aluminium alloy; microelement; mechanical property; corrosion property; electrochemical performance

Al-Zn-Mg合金(7xxx系)强度较高,韧性和疲劳性能较好,且因其热变形优良,热裂倾向小而具备较好的焊接性能,特别适合于制造需要焊接的高性能结构,如高速列车的车厢主承力件等[1-2]。近年来,添加不同微量元素对铝合金进行微合金化,是现阶段高强铝合金研究、开发的一个热点[3-5]。微合金化元素(Cr、Mn、Ti、Zr)可细化合金铸锭组织,降低再结晶程度,提升材料强度、耐蚀性、及改善加工性。其中Cr元素对提高7xxx系铝合金的抗应力腐蚀性能效果最为显著[6]。Cu作为主要的合金添加元素引起大量学者的关注,一般认为Cu原子可溶入η′及η相中,使晶内与晶界的电位差降低,从而提高材料的抗应力腐蚀开裂性能。SARKAR等[7]在Al-6Zn-2Mg-(0.01-2.1)Cu合金的研究中发现Cu元素能提高强化相的体积分数,从而提高合金强度,而且适量Cu元素能提高析出相与基体的共格程度。

日本研发的Al-Zn-Mg系铝合金,已经广泛应用于高速铁路机车与大型建筑物承重构件等方面,然而其具体的加工细节并未公开报道。我国正处高铁大发展时期,对高综合性能的轨道交通铝材有着迫切的需求,近些年来, Al-Zn-Mg合金材料与工艺研究也引起我国相关部门的关注。如材料热处理制度与强韧、耐蚀与疲劳性能的影响[8-9],以及焊接接头性能等[2, 10-11],而关于微合金化对该合金性能的影响及其机理研究鲜有报道。微合金化往往对合金的最终组织及性能有重大影响,因此,得到合适的微量元素配比十分重要。本文作者研究微量元素含量(Cr、Mn、Ti、Zr、Cu)高、低两种情况对Al-Zn-Mg系再结晶程度、强度、抗应力腐蚀性能、耐剥落蚀性能及电化学性能的影响,期望能对Al-Zn-Mg合金的成分与组织模式优化及加工工艺改进提供参考。

1 实验

本研究中用到的两种成分Al-Zn-Mg合金,设计成主合金元素Zn、Mg,以及杂质元素Fe、Si含量相同,而微量元素Cr、Mn、Ti、Zr、Cu的含量分成高(用合金A表示)、低(用合金B表示)两个水平,均采用中间合金方式加入合金中。原料备好采用电阻炉熔炼合金,在水冷铁模内浇铸成铸锭,随炉浇铸的成分试样测试的实际成分如表1所列。

两种试验合金铸锭经过均匀化和车皮处理后进行轧制。初轧温度为430 ℃,将板材轧制至20 mm厚。合金轧制后固溶,固溶温度为470 ℃,固溶时间为1 h。固溶后在1 h内进行变形量为2%的预拉伸,然后停放使之进行自然时效,停放60 d后开展实验。

实验的力学及腐蚀性能试样均测试其轧向性能[12],拉伸试验和冲击韧度厚度均为10 mm。在CSS-44100型电子万能试验机上进行常温拉伸试验,实验速率2 mm/min。冲击韧性测试在摆锤式冲击试验机上进行,冲击韧度取值为冲击吸收功/试样横截面积。C环应力腐蚀实验遵照国家标准GB/T 15970.5-1998进行,采用经校准的弹簧加载,之后在3.5%NaCl溶液中室温腐蚀,每隔12 h观察试样并拍照记录。从板材中切取拉伸试样进行剥落腐蚀实验,经打磨和表面处理后,用清水冲洗干净并吹干。在试样中间留出标距为70 mm的区域,其余部分用松香封住。剥落腐蚀液为:234 g NaCl+50 g KNO3+6.3 mL HNO3加蒸馏水稀释至l L,容面比为15 mL/cm2,试验在(25±3) ℃的恒温水浴箱中进行。在Im6e型电化学工作站进行Tafel曲线测试,溶液体系为3.5%NaCl溶液。

样品经机械抛光后,分别用Graff Sargent试剂腐蚀和氟硼酸水溶液电解抛光覆膜,前者在光学金相显微镜下观察合金组织,后者置于偏振光下观察合金组织。在FEI-Sirion200型场发射扫描电子显微镜下进行试样的扫描电镜观察。在Tecnai G220型透射电镜下进行两种Al-Zn-Mg铝合金的组织观察,将样品减薄至80 μm左右并冲成直径为3 mm的小圆片,之后进行双喷减薄,选择的双喷温度为-25 ℃、双喷腐蚀液为30%HNO3+70%CH3OH。

2 实验结果

2.1 Al-Zn-Mg合金的显微组织

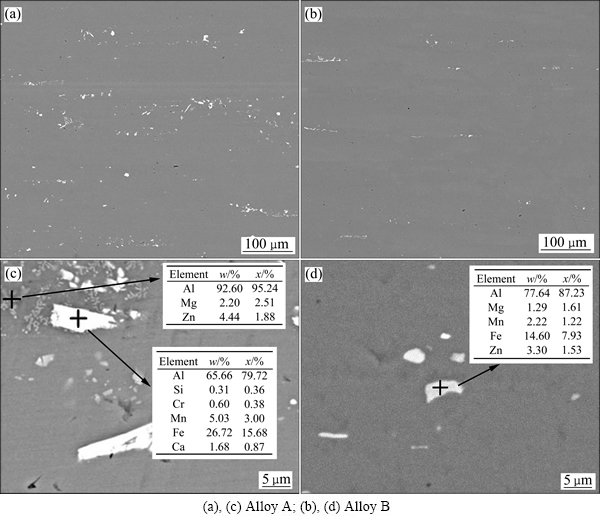

表1 试验用Al-Zn-Mg铝合金的化学成分

Table 1 Chemical composition of investigated Al-Zn-Mg alloys

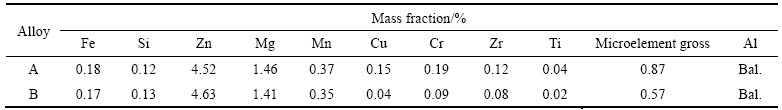

图1 Al-Zn-Mg合金金相照片

Fig. 1 Optical micrographs of Al-Zn-Mg alloys

图1所示为实验合金的自然时效态光学显微组织。从图1中可以看出,两种合金为明显的轧制组织,晶粒呈现纤维状。从图1(a)和(c)可观察到合金A晶粒细小且保持扁平的纤维状组织,而从图1(b)和(d)可到看到,合金B已发生局部再结晶,亚晶粒合并长大的现象较为明显。这表明较多微量元素的添加能提升合金抑制再结晶性的能力,使得合金经较高温度处理后仍能保持细小的亚晶组织。

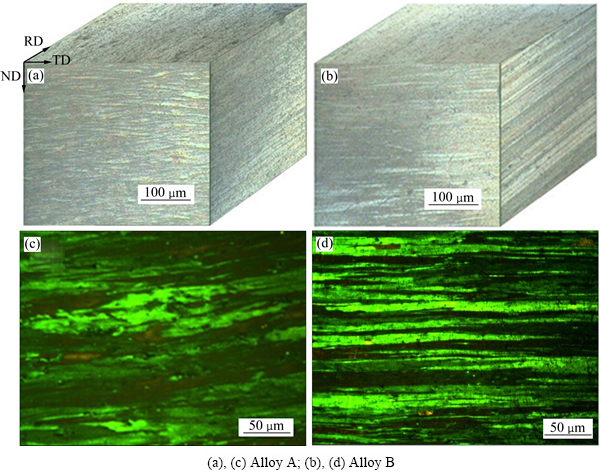

图2所示为两种Al-Zn-Mg合金的TEM明场像及斑点衍射图谱(SAED)。由SAED谱可知两种合金中析出相的种类相同,均存在GP区、η′相及Al3Zr、Al3Cr等。由图2(a)和(b)可知,合金A晶界不连续,晶界及靠近晶界处有较多尺寸为50~200 nm的深色第二相粒子,在合金B中也存在该类粒子,但其颜色较浅,数量很少且在晶界上几乎无分布,而且其晶界很干净。文献[13]证实这些是含Cr的E相(Al18Cr2Mg3),并能在粒子周围形成无析出区,这些粒子对提高合金的强度有很大贡献。

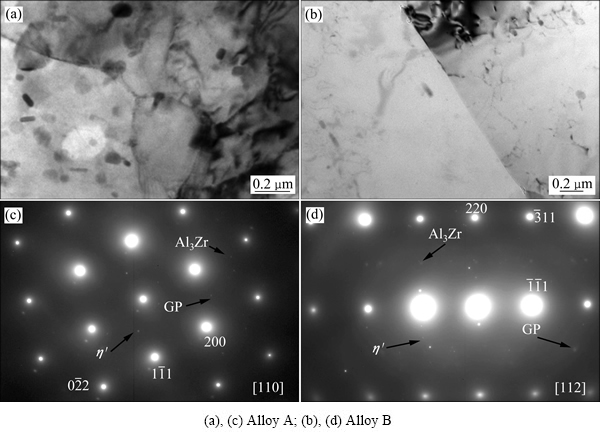

图3所示为两种合金的第二相SEM像及EDS谱分析结果。由图3可知,两种合金的第二相均大致沿轧向呈现链状分布,这些第二相主要有长条状、块状和点状相。对比图3(a)和(b)可知,合金A中第二相的尺寸明显要大,数量也更多。对第二相粒子进行EDS分析,从图3(c)和(d)可发现,两种合金中均主要为AlFeMnCu相和Zn2Mg相的聚合体。说明所添加的微量元素能结合合金中其它元素形成几种金属间化合物的聚合体,而且使得第二相的尺寸及密度均变大。这些第二相粒子硬度大且脆性高,能提高合金强度,但会对韧性、塑性和耐剥落腐蚀性能产生不良影响。

2.2 力学性能实验

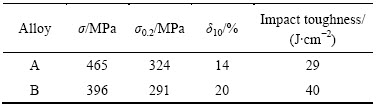

表2所示为Al-Zn-Mg合金的拉伸性能与冲击韧度。由表2可知,在Al-Zn-Mg铝合金中添加较多微量元素使得合金的屈服强度和抗拉强度分别提高了33 MPa、69 MPa,而伸长率下降了6%,冲击韧度下降了11 J/cm2。

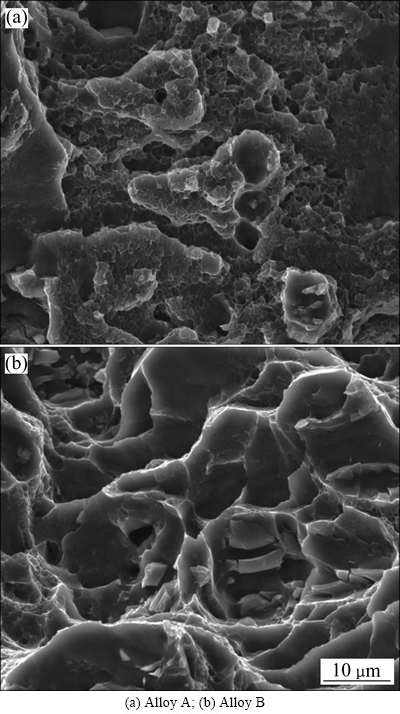

图4所示为Al-Zn-Mg合金的拉伸断口形貌。由图4(a)可以观察到合金A拉伸断口呈碎片状解理开裂,撕裂棱粗大,韧窝数量较少,但其尺寸大小及分布不均匀且深度浅。而合金B为典型的第二相引发的穿晶韧性断裂,这些韧窝的排列没有明显的方向性而分布较为均匀,平均直径大概在10 μm左右,且较深。

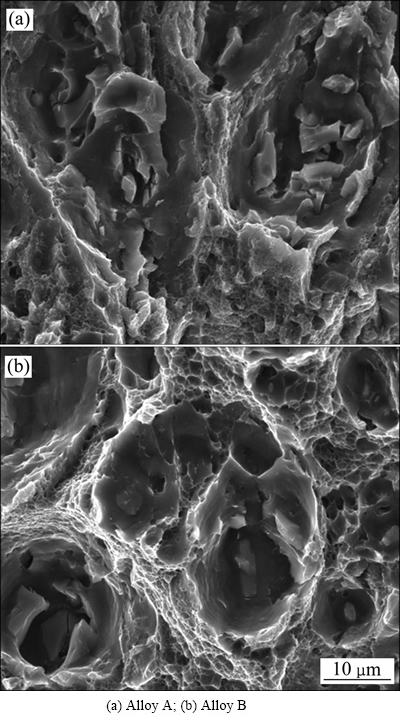

图5所示为Al-Zn-Mg合金的冲击韧度断口SEM像。可知两种合金A、B的冲击韧度断口均可观察到韧窝周围及底部有许多第二相,由此可知,两种合金在摆锤实验中的断裂方式主要是由粗大第二相引发的韧窝开裂。比较图5(a)和(b)可知,合金A的韧窝中有撕裂时残存的条状物比合金B的多,而合金B的韧窝比合金A的深,韧窝里又有小韧窝,是韧性好的典型表现。合金A大韧窝的周围有许多细小碎片状结构,这些碎片呈一定台阶状;而合金B的大韧窝里面和周围有许多小韧窝的分布,这些小韧窝的存在进一步提升了合金的冲击韧性。

图2 Al-Zn-Mg合金的TEM像和SAED谱

Fig. 2 TEM images((a), (b)) and SAED patterns((c), (d)) of Al-Zn-Mg alloys

图3 Al-Zn-Mg合金的SEM像和EDS分析

Fig. 3 SEM images((a), (b)) and EDS analysis((c), (d)) of Al-Zn-Mg alloys

表2 Al-Zn-Mg合金的拉伸性能和冲击韧度

Table 2 Tensile properties and impact toughness of Al-Zn-Mg alloys

图4 Al-Zn-Mg合金拉伸断口SEM像

Fig. 4 Tensile fractural SEM images of Al-Zn-Mg alloys

2.3 C环应力腐蚀试验

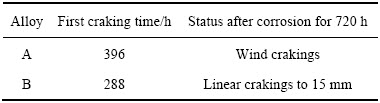

表3所列为C环腐蚀试验结果。由表3可知,合金A的开裂时间比合金B的晚108 h,且两者裂纹形貌不同,合金A呈蜿蜒状,而合金B裂纹呈直线发展,最长为15 mm。

图5 Al-Zn-Mg合金冲击韧度断口SEM像

Fig. 5 Impact toughness fractural SEM images of Al-Zn-Mg alloys

表3 恒应变C环腐蚀实验结果

Table 3 Corrosion experiment results of C-rings

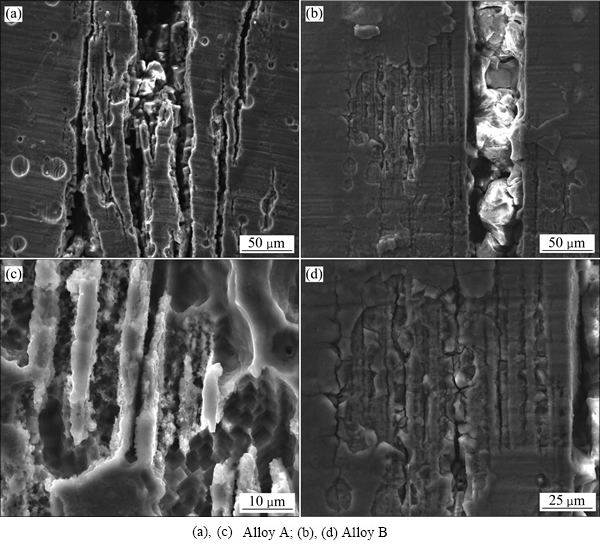

图6所示为C环应力腐蚀表面SEM像。由图6(a)和(b)可看出,两种合金均有明显的应力腐蚀裂纹,裂纹最大宽度均为70 μm左右。其中合金A的裂纹条数多,呈枝条状发展,可以发现明显的裂纹尖端和二次裂纹;合金B的裂纹基本都呈直线型,裂纹长度贯穿整个试样,未发现二次裂纹。在两种合金应力腐蚀裂纹周围都有可以观察到点蚀。图6(c)和(d)所示分别为合金A、B点蚀严重区域高倍SEM像。合金A的蚀坑深度大,蚀坑内部呈沟槽状,蚀坑间还有剩余的白色条状物相连接,这些条状物为第二相,作为阴极与基体形成微电池,而使基体腐蚀而剥落,这种现象称之为沟状溶解(Enching process)[14];而合金B主裂纹周围的合金受腐蚀而出现层状剥落,裂纹左侧剥落区域尺寸约为100 μm×100 μm。合金B的抗应力腐蚀性能比合金A的要差,而表面蚀坑较少,且蚀坑半径较小深度较浅。从图6中并不能看出应力腐蚀性能的明显差异。

图6 C环应力腐蚀表面SEM像

Fig.6 Low magnification((a), (b)) and high magnification((c), (d)) surface SEM images of C-rings after stress corrosion

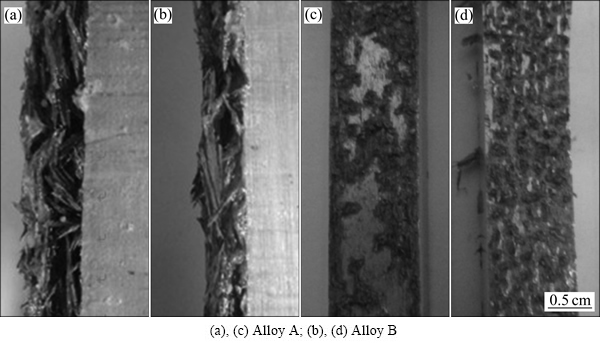

2.4 剥落腐蚀实验

合金开始放入腐蚀液即产生大量气泡,腐蚀7 h后,表面开始变色;腐蚀8 h时,表面即开始轻微爆皮;腐蚀24 h时,表面基本被黑色的腐蚀产物所覆盖,一些腐蚀产物已经溶解并沉入容器底部;腐蚀到48 h时,样品表面腐蚀产物层厚度增加。图7所示为样品去除腐蚀产物前后的腐蚀形貌,由图7(a)和(b)可知,合金A的腐蚀产物厚度约为9.5 mm,合金B的约为5 mm,可知合金A腐蚀更加深入到组织内部。由图7(c)和(d)可知,合金A由于剥落严重,已经露出大面积有光泽的新鲜表面(EB级),而合金B的腐蚀深度相对较浅(EA级),而腐蚀产物粘连较为严重。

合金经过48 h剥落腐蚀后进行常温拉伸测试,其结果如表4所列。由表4可知,合金A经过48 h剥落腐蚀后抗拉强度和屈服强度分别降至393和295 MPa,损失率分别为15%和9%;合金B分别降至354和278 MPa,损失率分别为10%和4.5%。合金A、B剥落腐蚀后伸长率损失分别为40%和50%。结果显示剥落腐蚀会恶化合金拉伸性能,尤其降低合金的塑性,而合金A的强度损失明显高于合金B的,塑性损失率略低于合金B的。

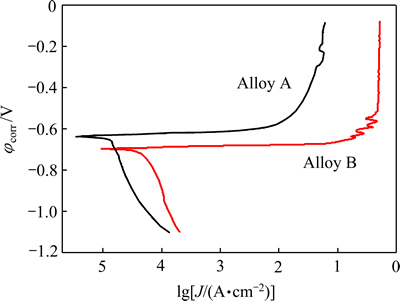

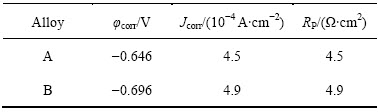

2.5 极化曲线实验

图8所示为Al-Zn-Mg合金的极化曲线。表5所列为Al-Zn-Mg合金的极化曲线腐蚀参数。从图8和表5可知,合金A的自腐蚀电位和电流分别为-0.64 V、4.5×10-4 A/cm2;合金B的自腐蚀电位为-0.7 V,腐蚀电流密度为4.9×10-4 A/cm2。虽然合金A的腐蚀电位高较合金B的、电流密度较合金B的小。而自腐蚀点位高的金属耐蚀性强,腐蚀电流密度跟腐蚀速率成正比,表明合金A的抗应力腐蚀性能更强,此结果反映的合金腐蚀倾向和合金的抗应力腐蚀性能吻合,而与表面点蚀情况相反。

图7 Al-Zn-Mg合金去除腐蚀产物前后的SEM像

Fig. 7 SEM images of Al-Zn-Mg alloy before((a), (b)) and after((c), (d)) exfoliation corrosion

表4 剥落腐蚀后Al-Zn-Mg合金拉伸性能

Table 4 Tensile performance of Al-Zn-Mg alloys after exfoliation corrosion

图8 Al-Zn-Mg合金极化曲线

Fig. 8 Polarization curves of Al-Zn-Mg alloys

表5 Al-Zn-Mg合金的极化曲线腐蚀参数

Table 5 Corrosion parameters of polarization curves of Al-Zn-Mg alloys

3 分析与讨论

从图1和2可以看出,较多Cr、Mn、Ti、Zr、Cu元素的添加使得Al-Zn-Mg合金保持了纤维状的变形组织,亚结构完整且亚晶尺寸较小;而没有添加的合金已发生明显的局部再结晶,部分亚晶界消失,小尺寸的亚晶粒合并成大晶粒。这是由于合金A在铸锭均匀化处理和后续的加工工序中会形成大量Al3Cr等铝基体与合金元素形成的第二相,稳定变形组织,使得亚晶界难以迁移,阻碍亚晶合并形成大角度晶粒。

铝合金的强度主要受晶内沉淀相、难溶硬脆第二相、晶粒尺寸及位错密度等因素的影响。结合图1~3的组织观察结果可推知,两种合金的强化机制是亚结构强化、弥散强化和脆性第二相强化的综合效果。合金A亚结构尺寸小、数量多,Cu的存在使得其在位错附近聚集,这种聚集不仅能钉扎位错,起到强化效果,还能阻碍晶界的迁移,阻止晶粒的长大。从理论上讲,大量亚晶界的存在有利于分散应力,有利于合金塑性,使得伸长率提高,但合金A中由于Cu元素容易在晶界偏析,容易结合其他元素形成大量尺寸较大的第二相。而韧窝往往沿着这些第二相粒子产生,合金在经受冲击载荷的作用下在第二相粒子处产生应力集中,第二相粒子开裂或与基体分离,形成微孔。这些微孔聚集长大,形成宏观裂纹,最终断裂。通常认为超过1 μm的第二相粒子会对合金的塑性和疲劳性能产生不良影响[15]。而合金B中的位错在晶界处塞积严重,造成应力集中,降低了晶内与晶界的强度差,且该合金中的难溶第二相粒子较少,故其塑性韧性较高。

一般而言,与粗大的再结晶晶粒相比,小角度晶界或亚晶界有着更强的抗应力腐蚀能力。7xxx系合金的应力腐蚀通常是从晶界拓展,因此,析出相在晶界的分布对合金的抗应力腐蚀性能产生重要影响。大多数学者认为,晶界不连续的析出相分布能切断阳极腐蚀通道,从而提高合金的抗应力腐蚀性能。从TEM像观察可知,合金A晶界处析出相尺寸较大,这种粗大不连续的析出相分布能够切断阳极腐蚀的通路,且较多微量元素的加入抑制了合金的再结晶,使得合金固溶淬火后仍能保持明显的变形组织,阻止了大角度晶界的形成,而小角度晶界的能量比大角度晶界的要低,析出相在晶界上的析出程度低于大角度晶界的,不易形成连续的析出相,有利于抗应力腐蚀的提高[16-17]。Cu元素的加入能降低基体与晶界处的电位差,使得腐蚀均匀进行。

点蚀的形成分为蚀孔的形核和发展两个阶段,即点蚀首先在金属表面的某些敏感处孕育形核,然后在化学或物理的作用下蚀孔不断向金属内部纵深发展。铝合金表面的缺陷、异质相颗粒等能充当这些敏感部位优先萌生点蚀的位置,此种观点已经成为共识。合金A中的异质相的密度比合金B的要大,使得其容易被侵蚀。这些颗粒在加工过程中会破坏表面氧化膜的连续性,在其附近是钝化膜破裂的优先位置[18]。致密的氧化膜保护金属不受腐蚀,而裂纹、缺陷多的疏松氧化膜反而能促进腐蚀的发展。图9所示为合金A表面点蚀机制简单示意图。由图9可知,第二相颗粒处的氧化膜更加容易被破坏,铝合金表面的金属间化合物颗粒由于和基体存在电位差而形成微电池发生电化学腐蚀,含Fe、Cu的第二相腐蚀电位比基体的要高,在这些第二相颗粒上发生的反应为:O2+2H2O+4e-→ 4OH-,使得这些相周围的合金基体逐渐溶解从而发生去合金化反应。这点从蚀坑的SEM像可以看出。且前者的蚀坑内部有腐蚀产物覆盖,使得局部电解液侵蚀条件得以维持,从而蚀坑进一步发展、连通。亚结构的高能状态也能促使合金点蚀的发生与发展,在C环试样SEM像中可以观察到冰糖状溶解,相比铝合金表面包含腐蚀电位差距更大的异质相颗粒,亚晶粒与晶粒的电位差别是微乎其微的,在3.5%NaCl溶液中不太容易形成溶解迅速的原电池,亚晶粒的溶解更多的可能是与溶液的化学溶解。

关于剥落腐蚀,目前被广泛接受的是ROBINSON等[19-20]认为,拉长的晶粒和晶界电偶腐蚀是其发生的两个必要条件。腐蚀发生后,晶界处的腐蚀产物比原来被腐蚀的基体体积要大,因而会对晶界产生一种额外的楔形应力,致使晶粒剥落并逐渐向内发展。合金A中的第二相平均尺寸及密度都比合金B的要大,而亚结构尺寸小且密度大。大量第二相的存在会与基体形成更多的微电池进行腐蚀,从而生成更多的腐蚀产物;KELLY等[21]发现腐蚀产物对晶界应力值越大,KISCC值越小,确认了剥落腐蚀的扩展其实是以应力辅助腐蚀的方式进行的。由此可知,剥落腐蚀跟晶粒的长宽比存在一定关联,长宽比大的合金晶粒剥落时所需要的应力会比长宽比小的合金的要小。如前所述,合金A腐蚀时由于腐蚀产物多,必然导致腐蚀产物所产生的应力要大,且该合金中保持了细长的纤维状组织,亚结构多,故腐蚀时腐蚀产物更容易将晶粒顶起并产生剥落。从而产生图7所示的基体呈大面积的剥落现象,从而合金A的剥落腐蚀性能要劣于合金B的。

图9 合金A表面点蚀过程示意图

Fig. 9 Schematic diagram surface pitting process of Alloy A

4 结论

1) 较多微量元素的加入能阻碍亚晶界向大角度再结晶晶界转变,从而降低Al-Zn-Mg铝合金板材的再结晶程度,整体而言使得合金A的综合性能高于合金B的。

2) 较多微量元素的加入能提高Al-Zn-Mg铝合金的力学性能,其中抗拉强度提高69 MPa,屈服强度提高33 MPa,由于合金内部产生较多粗大AlFeMnCu硬脆相,使得合金的塑性和韧性下降,其中伸长率降低6%,冲击韧度由40 J/cm2降至29 J/cm2,降幅为27.5%。

3) 较多微量元素尤其是Cr、Cu元素的添加使得合金A较合金B的抗应力腐蚀性能明显增强,在3.5%NaCl溶液中、加载90% σ0.2条件下,其开裂时间比含微量元素总量较少的合金B延迟108 h,且腐蚀电位升高,腐蚀电流密度减小,极化电阻增大,腐蚀的均匀性也更好;但是其表面耐蚀性有所下降,硬脆相作为阴极和基体形成微电池发生腐蚀及去合金化,点蚀密度比没有添加这两种元素合金的要高,点蚀的直径和深度也更大。

4) 较多微量元素的添加使得Al-Zn-Mg组织中粗大第二相增加,晶粒的长宽比变大,这些使得其剥落腐蚀敏感性增加。

REFERENCES

[1] DENG Bo, ZHONG Yi, QI Hua-rong, ZHANG Jia. Experiment on high speed reverse-extrusion of 7No1 aluminum alloy[J]. Yunnan Metallurgy, 2006, 35(4): 50-52.

[2] 张建波, 张永安, 何振波, 金龙兵, 朱宝宏, 李志辉. 自然时效对7N01铝合金组织和性能的影响[J]. 稀有金属, 2012, 36(2): 191-195.

ZHANG Jian-bo, ZHANG Yong-an, HE Zhen-bo, JIN Long-bing, LI Zhi-hui. Effects of natural age on microstructure and properties of 7N01 aluminium alloy[J]. Chinese Journal of Rare Metals, 2012, 36(2): 191-195.

[3] SINGH V, SATYA P K, GOKHALE A A. Effect of minor Sc additions on structure, age hardening and tensile properties of aluminium alloy AA8090 plate[J]. Scripta Materialia, 2004, 50(6): 903-908.

[4] SUH D W, LEE S Y, LEE K H, LIM S K, OH K H. Microstructural evolution of Al-Zn-Mg-Cu-(Sc) alloy during hot extrusion and heat treatments[J]. Journal of Materials Processing Technology, 2004, 155: 1330-1336.

[5] WU Yi-lei, LI Cheng-gong, FROES F S, ALVAREZ A. Microalloying of Sc, Ni, and Ce in an advanced Al-Zn-Mg-Cu alloy[J]. Metallurgical and Materials Transactions A, 1999, 30(4): 1017-1024.

[6] DADZIS K, EHRIG J, NIEMIETZ K,  TZOLD O, WUNDERWALD U, FRIEDRICH J. Model experiments and numerical simulations for directional solidification of multicrystalline silicon in a traveling magnetic field[J]. Journal of Crystal Growth, 2011, 333(1): 7-15.

TZOLD O, WUNDERWALD U, FRIEDRICH J. Model experiments and numerical simulations for directional solidification of multicrystalline silicon in a traveling magnetic field[J]. Journal of Crystal Growth, 2011, 333(1): 7-15.

[7] SARKAR B, MAREK M, STARKE E. The effect of copper content and heat treatment on the stress corrosion characteristics of Ai-6Zn-2Mg-XCu alloys[J]. Metallurgical Transactions A, 1981, 12(11): 1939-1943.

[8] LIU Xue-song, ZHANG Liang, WANG Lin-sen, WU Shuang-hui, FANG Hong-yuan. Fatigue behavior and life prediction of A7N01 aluminum alloy welded joint[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2930-2936.

[9] 闫德俊, 刘雪松, 方洪渊, 赵华生, 彭爱林, 杨建国, 张 健. 高速列车用高强铝合金焊接接头疲劳裂纹的扩展特性[J]. 中国有色金属学报, 2012, 22(12): 3313- 3319.

YAN De-jun, LIU Xue-song, FANG Hong-yuan, ZHAO Hua-sheng, PENG Ai-lin, YANG Jian-guo, ZHANG Jian. Fatigue crack propagation characteristics of high strength aluminum alloy welded joint used by high speed train[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3313-3319.

[10] 孟立春, 赵明书, 栾国红. 7N01-T4和7N01-T5铝合金焊接位置的选择对搅拌摩擦焊接头性能的影响[J]. 航空制造技术, 2011(1/2): 132-133, 138.

MENG Li-chun, ZHAO Ming-shu, LUAN Guo-hong. Effect of 7N01-T4 and 7N01-T5 aluminium position change on friction stir welding joint properties[J]. Aeronautical Manufacturing Technology, 2011(1/2): 132-133, 138.

[11] 宋 涛, 高家诚, 乔丽英, 高安江. 7N01铝合金120 ℃单级时效的组织和性能[J]. 材料热处理学报, 2011, 32(7): 104-109.

SONG Tao, GAO Jia-cheng, QIAO Li-ying, GAO An-jiang. Microstructure and properties of 7N01 aluminium alloy after single-aging at 120 ℃[J]. Transactions of Materials and Heat Treatment, 2011, 32(7): 104-109

[12] AMIN M A, KHALED K, FADL-ALLAH S A. Testing validity of the Tafel extrapolation method for monitoring corrosion of cold rolled steel in HCl solutions–experimental and theoretical studies[J]. Corrosion Science, 2010, 52(1): 140-151.

[13] WERT J A, PATON N, HAMILTON C, MAHONEY M. Grain refinement in 7075 aluminum by thermomechanical processing[J]. Metallurgical Transactions A, 1981, 12(7): 1267-1276.

[14] RYNDERS R M, PAIK C H, KE R, ALK R C. Use of in situ atomic force microscopy to image corrosion at inclusions[J]. Journal of the Electrochemical Society, 1994, 141(6): 1439-1445.

[15] SUN Dao-ming, JIANG Yi-ming, TANG Yu, XIANG Qiu-wei, ZHONG Cheng, LIAO Jia-xing, LI Jin. Pitting corrosion behavior of stainless steel in ultrasonic cell[J]. Electrochimica Acta, 2009, 54(5): 1558-1563.

[16] MUKHOPADHYAY A. Microstructure and properties of high strength aluminium alloys for structural applications[J]. Transactions of the Indian Institute of Metals, 2009, 62(2): 113-122.

[17] 陈学海, 陈康华, 梁信, 陈送义, 彭国胜. 热变形温度对7085铝合金组织和性能的影响[J]. 中国有色金属学报, 2011, 21(1): 88-94.

CHEN Xue-hai, CHEN Kang-hua, LIANG Xin, CHEN Song-yi, PENG Guo-sheng. Effects of hot deformation temperature on microstructure and properties of 7085 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 88-94.

[18] 李红英, 王长建, 曾再得. 微量元素对1050铝基PS版电蚀性能的影响[J]. 腐蚀与防护, 2007, 28(4): 194-197.

LI Hong-ying, WANG Chang-jian, ZENG Zai-de. Effects of microelements on electrolysis properties of 1050 aluminium substrate plate[J]. Corrosion and Protection, 2007, 28(4): 194-197.

[19] ROBINSON M. The role of wedging stresses in the exfoliation corrosion of high strength aluminium alloys[J]. Corrosion Science, 1983, 23(8): 887-899.

[20] ROBINSON M, JACKSON N. Exfoliation corrosion of high strength Al-Cu-Mg alloys: Effect of grain structure[J]. British Corrosion Journal, 1999, 34(1): 45-49.

[21] KELLY D, ROBINSON M. Influence of heat treatment and grain shape on exfoliation corrosion of Al-Li alloy 8090[J]. Corrosion, 1993, 49(10): 787-795.

(编辑 王 超)

基金项目:国家重点基础研究发展计划资助项目(2012CB619500);国家自然科学基金资助项目(51375503)

收稿日期:2015-01-15;修订日期:2015-05-07

通信作者:邓运来,教授,博士;电话:0731-88876913;E-mail: dengylcsu@126.com