Effect of arc-ultrasound on microstructures and mechanical properties of plasma arc welded joints of SiCp/Al MMCs

来源期刊:中国有色金属学报(英文版)2011年第2期

论文作者:雷玉成 王志伟 陈希章

文章页码:272 - 277

关键词:SiCp/Al 基复合材料;电弧超声;等离子弧焊接;组织与性能

Key words:SiCp/Al MMCs; arc-ultrasound; plasma arc welding; microstructure and property

摘 要:通过外加激励源方式对等离子电弧进行高频调制从而激发出电弧超声,以Ti丝作为填充材料,以氮氩混合气体作为离子气,在不同激励频率下对SiCp/6061Al复合材料进行电弧超声等离子弧原位合金化焊接。结果表明:在施加电弧超声后,焊缝组织中TiC、TiN等新生颗粒明显得到细化,分布较为均匀;粗大Al3Ti相得到细化且数量减少;在50 kHz时焊缝组织最优。拉伸试验结果表明:在施加50 kHz超声时拉伸强度最大为225 MPa,比未施加超声时的203 MPa增加了7%左右。

Abstract: The effect of arc-ultrasound on microstructures and mechanical properties of SiCp/6061Al MMCs joints produced by arc-ultrasound plasma arc “in-situ” alloy-welding with different excitation frequencies was investigated, in which argon-nitrogen mixture was used as plasma gas, Ti wire as filler and the arc-ultrasound was produced by modulating the plasma arc with high frequency. The results show that arc-ultrasound could refine the new reinforced composites such as TiC, TiN significantly, and improve their distribution greatly. And new phase Al3Ti becomes finer and less. The test results of mechanical properties indicate that the maximum tensile strength of welded joints is gained when the excitation frequency is 50 kHz, and the maximum is 225 MPa, raising by about 7% compared with conventional plasma arc welding (PAW) (203 MPa).

LEI Yu-cheng1, 2, WANG Zhi-wei1, 2, CHEN Xi-zhang1, 2

1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. State Key Laboratory of Advanced Welding Production Technology,

Harbin Institute of Technology, Harbin 150000, China

Received 22 February 2010; accepted 6 July 2010

Abstract: The effect of arc-ultrasound on microstructures and mechanical properties of SiCp/6061Al MMCs joints produced by arc-ultrasound plasma arc “in-situ” alloy-welding with different excitation frequencies was investigated, in which argon-nitrogen mixture was used as plasma gas, Ti wire as filler and the arc-ultrasound was produced by modulating the plasma arc with high frequency. The results show that arc-ultrasound could refine the new reinforced composites such as TiC, TiN significantly, and improve their distribution greatly. And new phase Al3Ti becomes finer and less. The test results of mechanical properties indicate that the maximum tensile strength of welded joints is gained when the excitation frequency is 50 kHz, and the maximum is 225 MPa, raising by about 7% compared with conventional plasma arc welding (PAW) (203 MPa).

Key words: SiCp/Al MMCs; arc-ultrasound; plasma arc welding; microstructure and property

1 Introduction

At present, aluminum metal matrix composites(Al MMCs) are applied in aerospace, spaceflight, auto manufacturing, optical instrument and sports goods industry due to their excellent combination properties of high specific strength, high specific stiffness, high elastic modulus, good wear-resistance and high temperature resistance[1-2]. In order to industrialize the welding of aluminum metal matrix composites,we should not only prevent the formation of harmful phase Al4C3 during the welding of SiCp/Al MMCs,but also solve the problem how to avoid the weld defects which would lead to low strength of welded joints, such as large grains, pores and particles segregation[3-5].

Importing ultrasound into the molten pool is one of the effective ways to refine the weld structure and improve the joints strength[6-7]. But the common launch methods with piezoelectric crystals and with magnetostrictive transducer as ultrasound source are difficult to be actually applied during the welding process[8]. Arc-ultrasound proposed by WU et al[9-10] produced by emitting the arc with high-frequency has solved the problem successfully. WU et al[11-13] reported that with 50 kHz arc-ultrasound, the impact toughness has increased by about 50% in SAW weld zone of 09MnNiDR, and increased by about 80% in heat-affected zone; ZHOU et al[14-15] proposed that with 50 kHz arc-ultrasound, the cylindrical crystals were changed completely to isometric crystals in TIG weld zone of TC4, thereby the mechanical properties of welded joints were improved evidently. Based on this, we innovate a new welding method on Al MMCs-arc- ultrasound plasma arc “in-situ” alloy-welding, modulating the plasma arc using ultrasonic frequency pulses, which makes the arc “as the welding heat source, at the same time as a adjustable ultrasound emission source”. Ultrasound vibration is imposed on welding pool, which directly could refine weld, improve the distribution of particles and enhance the mechanical properties evidently[16].

2 Experimental

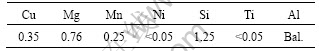

The morphology of SiCp/6061Al MMCs containing 10% (volume fraction) SiC particle (particle size 6 μm) made by the method of extrusion and foundry is shown in Fig.1. The maximum tensile strength of the base metal was 320 MPa in the state of annealing. It can be seen from Fig.1 that the distribution of reinforcement particles is uneven because of the limitation of making methods, the chemical compositions of the matrix for experimental materials are listed in Table 1. And the filler material is titanium alloy wire with content of titanium more than 99.5%, and is filled it by manual way during welding process.

Fig.1 Microstructure of SiCp/6061Al MMCs

Tabe1 Chemical compositions of aluminum alloy (mass fraction, %)

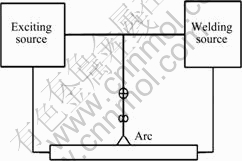

In the experiment, arc-ultrasound was emitted by modulating the plasma arc using self-made ultrasonic frequency pulse power, the excitation frequency range was 25-80 kHz, and the excitation current was 0-20 A. During the welding, excitation frequencies of 30, 50, 70 kHz and excitation current of 20 A were selected. The coupling mode between exciting source and welding source was parallel connection (see Fig.2).

Fig.2 Power source coupling mode (parallel connection)

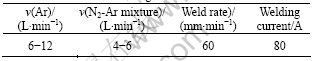

Rectangular specimens, with 80 mm in length, 20 mm in width, 4 mm in thickness, 35°groove and 1 mm root face, were cut from long bars of SiCp/6061Al MMCs, burnished using 150# SiC sand paper, and cleaned using acetone before welding. The butt weld gap was 0-2 mm. Then specimens were joined by arc-ultrasound plasma arc welding with plasma gas of argon and nitrogen using the plasma arc welding torch of Hpt-180 type. Table 2 describes the welding parameters.

Table 2 Parameters of welding

Transverse metallographic sections of the welds perpendicular to the welding direction were prepared using standard metallographic procedures and etched in Keller’s reagent. Microstructure of the weld was characterized by an optical microscope and scanning electron microscope (SEM). Phase analysis was carried out by X-ray diffraction and energy dispersive spectroscopy. The diffraction angle was changed from 20° to 80° (2θ) at an angular velocity of 8 (°)/min.

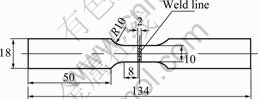

The tensile strength of the welded joints was measured with electronic universal testing machine made by Instron Company in American. The cross-head velocity was 0.5 mm/min, and the shape and size of tensile specimen are shown in Fig.3.

Fig.3 Shape of specimen for tensile test (Unit: mm)

3 Results and discussion

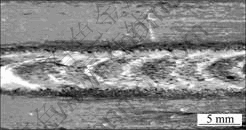

Fig.4 shows the macro morphology of welded joint by plasma arc “in-situ” alloy-welding with Ti wire as filler on SiCp/6061Al MMCs. We can see that the weld surface is good, no other obvious defects are observed except a little of gas pores near the surface of weld junction, which one of the major defects, and is affected by the performance of weld.

Fig.4 Macro morphology of welded joint with Ti wire as filler

3.1 Microstructure

Fig.5 shows the XRD pattern of welded joint by plasma arc “in-situ” alloy-welding with Ti wire as filler on SiCp/6061Al MMCs. In the weld there are some formations of new reinforcement phases such as Al3Ti, TiN, TiC and AlN, but no formation of Al4C3 phase.

Fig.5 XRD pattern of welded joint

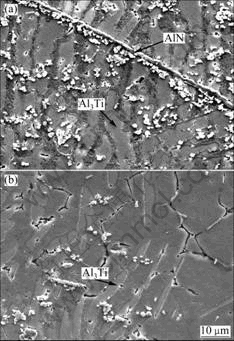

The SEM images of welded joint by plasma arc “in-situ” alloy-welding with Ti wire as filler on SiCp/6061Al MMCs are shown in Fig.6. During the welding, SiC reinforcement particles in the weld are dissolved completely, plenty of slender needle-like phases and bulky phases(grain size is 20-40 μm) are produced in the following solidification process, which are identified to be AlN and Al3Ti according to results of XRD (see Fig.5). Because Al in the molten pool reacts with abundant Ti according to reaction formula 3Al+Ti→Al3Ti, and due to high temperature and high concentration of Ti atoms in the molten pool, dispersion capacity of active Ti atom is so strong and beneficial to the preferred orientation growth of A13Ti phase, which leads to bulky and massive A13Ti. A13Ti has poor ductility at low temperatures, so it should be refined as much as possible[17]. Some bulky Al3Ti phases and little reinforcement particles are observed in the bond area. And because of the poor fluidity of molten pool, weld metal near bond area is not enough and leads to poor adhesive strength between some grains, which debases the mechanical properties of joint (see Fig.6(b)).

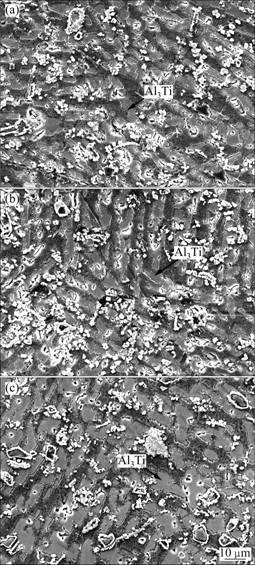

The SEM images of welded joints by plasma arc welding with 30, 50 and 70 kHz arc-ultrasound on SiCp/6061Al MMCs are shown in Fig.7. By comparing with the grain of 20-40 μm in Fig.6(without arc- ultrasound), bulky A13Ti phases are obviously refined, and are refined to 10-20 μm in Fig.7(a)(with 30 kHz arc-ultrasound) and about 5-10 μm in Fig.7(b) (with 50 kHz arc-ultrasound). In the weld zone, new reinforcement particles increase, especially with 50 kHz arc-ultrasound, the particles increase more obviously and

Fig.6 SEM images of welded joint with conventional PAW: (a) Weld-metal zone; (b) Bond zone

distribute more evenly. This is because the improvement of liquidity of molten pool caused by high-frequency vibration makes filler materials Ti react completely with N which is ionized from plasma gas and with C decomposed from SiC particles. Consequently, the new TiC and TiN particles become more and A13Ti particles become less because of consumption of abundant Ti in reactions of Ti+N→TiN and Ti+C→TiC. The sharp shock waves generate due to instantaneous collapse of plenty of cavitation bubbles and break up the growing crystal grains to prevent the grains from growth; simultaneously, crystal chunks are taken into the non-coagulation zone in the molten pool as crystal nucleus, which consequently makes weld structure finer and particles more even in distribution and more in number. In addition, the waves also shock the new particles strongly, and spread them out in molten pool very quickly and prevent particles from segregation at high temperatures. Simultaneously, deaeration and deslagging effects of ultrasound reduce gases and impurities in the melten pool, and improve the mechanical properties of material[18-21].

From Figs.7(a)-(c), we can conclude that weld microstructures with different arc-ultrasound frequencies are different. Compared with microstructures with 30 kHz and 50 kHz arc-ultrasound, Al3Ti phase with 70 kHz arc-ultrasound becomes bulky and new particles such as TiC, TiN and AlN become less. This is because with the increase of frequency, cavitation effect of ultrasound

Fig.7 SEM images of welded joints with arc-ultrasound: (a) 30 kHz; (b) 50 kHz; (c) 70 kHz

becomes weak, that is, with the increase of frequency, sonic expansion time becomes few, resulting in that cavitation nucleus has not enough time to grow to a certain state under which cavitation bubble will crash[22]. So cavitation is not fully.

Fig.8 shows the SEM image of the bond area of welded joint by plasma arc “in-situ” alloy-welding with 50 kHz arc-ultrasound on SiCp/6061Al MMCs. It can be seen that no Al3Ti phase and very little particles are observed because high-frequency vibration of ultrasound makes Ti react completely in the weld central zone, causing lack of alloying elements in the bond zone.

3.2 Microhardness

Due to welding thermal cycle,different positions have different intensities, so the hardness distribution of welded joints is uneven. Therefore, we accorded to

Fig.8 SEM image of bond zone with 50 kHz arc-ultrasound

the order, weld metal-fusion zone-heat-affected zone- base material, to dot to measure hardness. The average interval between two adjacent dots was 0.25 mm; each dot was measured three times to seek its average. Fig.9 shows the hardness curves of weld joints. From Fig.9 we can see that the weld metal hardness of welded joints with arc-ultrasound has a certain lower margin. This is mainly because arc-ultrasound has refined the new phases, and high-frequency vibration has avoided the segregation of particles and made them distribute even. Commonly, the higher the hardness of metals is, the worse the plasticity is. So we can conclude that arc-ultrasound can improve the plasticity of welded joints.

Fig.9 Hardness of welded joints with arc-ultrasound

3.3 Tensile test

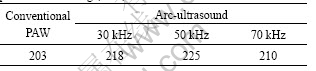

Tensile tests were carried out on welded joints with different arc-ultrasound frequencies, and the results are listed in Table 3. It can be seen from Table 3 that the maximum of tensile strength of weld joints is 225 MPa(with 50 kHz arc-ultrasound), compared with the maximum (203 MPa) of conventional PAW, raising by about 7%.

Table 3 Tensile properties of joints of SiCp/6061Al MMCs in plasma arc welding (MPa)

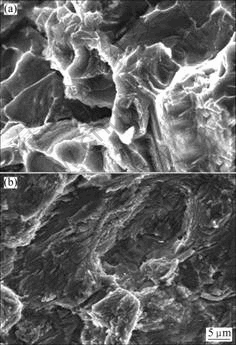

Fig.10 shows the fractographs of welded joints. It can be observed in Fig.10(a) that the joint fracture without arc-ultrasound is evidently brittle rupture, and dimples are few and shallow. Analysis linked with microstructure of welded joint(Fig.6), we believe that the slender needle-like AlN phase and particles segregation(TiC, TiN) have hindered the movements of dislocations greatly, therefore increased the dislocation density significantly, which would debase the capacity of plastic deformation. Otherwise, bulky and massive Al3Ti phase throughout the whole of crystal grain has destroyed the continuity of Al matrix greatly and reduced its plasticity and strength. From the fracture of welded joint with 50 kHz arc-ultrasound, we can observe a large number of micro-tear marks, which show certain toughness characteristics (see Fig.10(b)). This is because arc-ultrasound makes the new A13Ti phase finer and less, and the new particles (TiN, TiC) more homogeneous; and makes the hindrance of particles to dislocation movement weaken greatly, therefore improves the plasticity of welded joints. Otherwise, local instantaneous high temperature and high pressure[23-24] produced by the collapse of plenty of cavitation bubbles

Fig.10 Fractographs of welded joints: (a) Without arc- ultrasonic; (b) With 50 kHz arc-ultrasound

bring down the surface tension of liquid, improve the wetting property between particles and solution, and make particles be caught by metallic solution more easily, therefore enhance the interfacial bonding strength between particles and Al matrix. Simultaneously arc-ultrasound clears the gases and impurities mixed in the weld metal, consequently improves materials properties. And the penetration ratio increasing is the one of major factors, which improves the mechanical properties of joints effectively. With the arc-ultrasound, the fluidity of molten pool and the penetration ratio increase from 20% to 35%, improving the mechanical properties of joint.

4 Conclusions

1) The SEM images of welded joints by plasma arc “in-situ” alloy-welding on SiCp/6061Al MMCs with argon-nitrogen mixture as plasma gases and Ti wire as filler show that the needle-like harmful Al4C3 phases are completely prevented,but some welding defects still limit the properties of welded joints, such as bulky Al3Ti phase, slender needle-like AlN phase and particles segregation.

2) The structures of welded joints by plasma arc welding with arc-ultrasound are refined apparently, Al3Ti phase becomes finer and less, the new particles (TiC, TiN) become smaller and more even in the matrix. Tensile results show that the welded joints with 50 kHz arc-ultrasound is optimal, and the maximum is 225 MPa, about 70% of that of base metal, raising by about 7% compared with conventional PAW.

References

[1] FAN Jian-zhong, SANG Ji-mei, SHI Li-kai. Fabrication, application and development of particle reinforced aluminium matrix composites [J]. Materials Review, 2001, 15(10): 49-55. (in Chinese)

[2] ALLSION J E, COLE G S. Metal-matrix composites in the automotive industry [J]. Opportunites and Challenges, 1993, 45(1): 19-25.

[3] LIU Li-ming, ZHU Mei-li, XU Wei-ping, NIU Ji-tai. Laser welding mechanism and parameters of aluminum matrix composite SiCw/6061Al [J]. Transactions of the China Welding Institution, 2001, 22(4): 13-16. (in Chinese)

[4] NIU Ji-tai, ZHANG De-ku, JI Guo-juan. Effect of pulse parameters on microstructure of joint in laser beam welding for SiCp/6063 composite [J]. Transactions of Nonferrous Metals Society of China, 2003, 13(2): 289-293.

[5] LEI Yu-cheng, ZHANG Zhen, NIE Jia-jun, CHEN Xi-zhang. Effect of Ti-Al on microstructures and mechanical properties of SiCp/AlMMCs [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(11): 809-813.

[6] JIROMARU T, KAZUAKI H, ATSUSHI H, RYOICHI K, HISANORI M, KAORU M, TETSUGI U. Ultrasonic butt welding of aluminum, aluminum alloy and stainless steel plate specimens [J]. Ultrasonics, 2002, 40(1-8): 371-374.

[7] DU Jing-lei, LI Lu-Ming, ZHANG Yan-jun, WU Min-sheng. Influence on grain refinement of arc-ultrasound in welding process [J]. Electric Welding Machine, 2002, 32(3): 6-8. (in Chinese)

[8] DOBATKIN V I, ESKIN G I. The effect of high-intensity ultrasound on the phase interface In materials [M]. Moscow: Nauka, 1986.

[9] WU Min-sheng, DUAN Xiang-yang, LI Lu-ming, SUN Di-qing. Study of arc-ultrasonic excitation and its characteristics [J]. Journal of Tsinghua University: Science and Technology, 1999, 39(6): 110-112. (in Chinese)

[10] WU Min-sheng, ZHANG Chun-lei, DUAN Xiang-yang. Frequent characteristic and resonant mechanism of arc-excited ultrasonic [J]. Journal of Tsinghua University: Science and Technology, 1999, 39(11): 97-99. (in Chinese)

[11] WU Min-sheng, ZHANG Yan-jun, LI Lu-ming, HAO Hong-wei. Arc-excited ultrasonic welding to improve the quality of 09MnNiDR joints [J]. Journal of Tsinghua University: Science and Technology, 2006, 46(2): 161-164. (in Chinese)

[12] ZHANG Yan-jun, LI Lu-ming, WU Min-sheng. Effect of arc-excited ultrasonic on the quality of the 09MnNiDR steel's joint [J]. Journal of Fuzhou University: Natural Science Edition, 2006, 34(4): 533-538. (in Chinese)

[13] YANG Bo-yu, HAO Hong-wei, LI Lu-ming, WU Min-sheng, WANG Sheng. Study on arc-ultrasonic SAW improving structure and property of 09MnNiDR welding joint [J]. Hot Working Technology, 2006, 35(7): 1-3.

[14] ZHOU Rong-lin, GUO De-lun, LI Cong-qing, SUN Cong-chun, ZHANG Yan-jun. Arc-ultrasonic tungsten inert-gar arc welding of TC4 Ti alloy [J]. Transactions of the China Welding Institution, 2004, 25(6): 97-98.

[15] ZHANG Yan-jun, ZHOU Rong-lin, WU Min-sheng. Improving quality of Ti6Al4V welding joint by arc-excited ultrasonic treatment [J]. Electric Welding Machine, 2005, 35(9): 27-29.

[16] LI Xiao-chun, YANG Yong, CHENG Xu-dong. Journal search on ultrasonic-assisted fabrication of metal matrix nanocomposites [J]. Journal of Materials Science, 2004, 39: 3211-3212.

[17] ZHAO Yu-hou, YAN Wen, ZHOU Jing-en. Influence of Si and Mg on shape of Al3Ti reinforcing phase in “in-situ” Al-based composite [J]. Ordnance Materials Science and Engineering, 2001, 24(2): 34-37. (in Chinese)

[18] FENG Ruo, LI Hua-mao. Sonochemistry and its application [M]. Hefei: Anhui Science and Technology Press, 1990 (in Chinese).

[19] ABRAMOV O V. Ultrasound in liquid and solid metals [M]. Boca Raton, Fla: CRC Press, 1994.

[20] PUSKAR A. The use of high-intensity ultrasonic [M]. Amsterdam: Elsevier Materials Science Monographs, 1982: 302.

[21] ESKIN G I, ESKIN D G. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic cavitations [J]. Ultrasonic’s Sonchemistry, 2003, 10(4-5): 297-301.

[22] WANG Ping-hui. A study and analysis on influencing factor of the ultrasonic cavitation [J]. Journal of Hebei Institute of Technology, 2003, 25(4): 154-161. (in Chinese)

[23] DING Jia-shan, ZHAO Yu-tao, ZHANG Song-li. Synthesized (Al2O3+Al3Zr)p/A356 composites via in-situ ultrasonic-chemistry reaction [J]. Foundry, 2008, 57(4): 354-358. (in Chinese)

[24] ESKIN G I. Cavitation mechanism of ultrasonic melt degassing [J]. Ultrasonics Sonochemistry, 1995, 10(2): 137-141.

雷玉成1, 2, 王志伟1, 2, 陈希章1, 2

1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 哈尔滨工业大学 现代焊接生产技术国家重点实验室, 哈尔滨 150000

摘 要:通过外加激励源方式对等离子电弧进行高频调制从而激发出电弧超声,以Ti丝作为填充材料,以氮氩混合气体作为离子气,在不同激励频率下对SiCp/6061Al复合材料进行电弧超声等离子弧原位合金化焊接。结果表明:在施加电弧超声后,焊缝组织中TiC、TiN等新生颗粒明显得到细化,分布较为均匀;粗大Al3Ti相得到细化且数量减少;在50 kHz时焊缝组织最优。拉伸试验结果表明:在施加50 kHz超声时拉伸强度最大为225 MPa,比未施加超声时的203 MPa增加了7%左右。

关键词:SiCp/Al 基复合材料;电弧超声;等离子弧焊接;组织与性能

(Edited by LI Xiang-qun)

Foundation item: Project (09003)supported by the Open Research Fund of State Key Laboratory of Advanced Welding Production Technology, Harbin Institute of Technology, China; Project (JSAWT-07-04 ) supported by Provincial Key Research Fund of Advanced Welding Technology, Jiangsu University of Science and Technology, China

Corresponding author: LEI Yu-cheng; Tel: +86-13951282282; Fax: +86-511-88791357; E-mail: yclei@ujs.edu.cn

DOI: 10.1016/S1003-6326(11)60709-7