文章编号:1004-0609(2011)06-1491-05

添加剂皂化值对铝材轧制油工艺润滑性能的影响

孙建林,黄 瑛,熊孝经,么文静,武 迪

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:将皂化值不同的两种添加剂加入到基础油中配制成不同浓度的铝材轧制油,通过四球摩擦磨损试验考查添加剂的皂化值对轧制油摩擦学性能的影响,并通过四辊冷轧实验对轧制油轧制工艺润滑效果进行测试,结合退火清洁性实验对两种皂化值不同的添加剂进行综合评价。结果表明:皂化值较高的添加剂配制的轧制油表现出较好的抗磨减摩效果;随着添加剂含量的增加,极性分子在铝材表面的吸附量增大,轧制油的摩擦学性能增强,极压抗磨性能增强,且出现饱和吸附,添加剂皂化值越高,达到饱和吸附的速度越快;皂化值较高的添加剂对轧后铝材退火清洁性影响较小。

关键词:铝材轧制油;添加剂;皂化值;摩擦学性能;退火清洁性

中图分类号:TG339 文献标志码:A

Influence of additives with different saponification values on lubricative properties of aluminum rolling oils

SUN Jian-lin, HUANG Ying, XIONG Xiao-jing, YAO Wen-jing, WU Di

(School of Materials and Engineering, Unversity of Science and Technology Beijing, Beijing 100083, China)

Abstract: Two kinds of additives with different saponification values were added to aluminum rolling oils. The effect of additives saponification value on the tribological properties of different rolling oils were examined by four-ball friction and wear testing machine. And the lubrication effect of rolling oils was actually verified by cold rolling. Finally, the kinds of additives with different saponification values were synthetically evaluated combining with the experiments of annealing clean. The results indicate that the rolling oils confected with the additive with larger saponification value show a better anti-wear performance. With increasing the additive content, the polar molecule adsorption on the aluminum surface increases, so the anti-wear performance is enhanced, and there is a saturated adsorption. The greater the saponification value of the additive is, the faster speed the absorption saturation achieves. The effect of the large saponification value of additives on the aluminum annealing cleaning after rolling is small.

Key words: aluminum alloy oils; additive; saponification value; tribological properties; anneal cleaning

采用工艺润滑可以有效地降低铝板材轧制过程中的轧制压力,减小摩擦因数,改善轧件的表面质量[1-2]。轧制油通常由基础油和添加剂组成[3],其中基础油为主要组成部分。添加剂一般为受热挥发性好的高级脂肪酸、酯、醇,可以有效地吸附在铝材表面,形成承载力较强的化学吸附,为此轧制油中添加剂配方对轧制油质量水平及轧制工艺润滑效果起着决定性的作 用[4-5]。之前的研究中,较侧重各单体添加剂不同配比复合后的实践轧制润滑效果的比较,而忽略了评价润滑效果的有效理化指标[6-9]。本文作者研究发现,复合添加剂的皂化值高低是衡量其复合后润滑性能的重要指标,因此,选用两种不同理化性能的复合添加剂配制成轧制油,重点比较皂化值对添加剂性能的影响,对轧制油的摩擦学性能进行测试,并通过冷轧实验对润滑效果进行研究,这对根据实际的铝材轧制生产要求,选择合适理化性能的铝材轧制油提供了参考依据。

1 实验

1.1 基础油

实验用基础油如普通轻质矿物油,其理化性能主要参数如表1所列。

表1 实验用基础油的主要参数

Table 1 Major parameters of base oil used in experiments

1.2 添加剂

选用某铝材厂提供的两种皂化值不同的添加剂(ZX、ZD),其理化性能主要参数如表2和3所列。

对比两种添加剂的理化性能,其酸值和醇含量相等,即添加剂中有机酸和醇含量相等;皂化值是酸值和酯含量的总和,所选用的两种添加剂的酯含量差别较大。

将基础油和两种添加剂进行复配,形成添加剂浓度分别为5%、6%、7%和8%的轧制油,通过实验测定其在铝板材轧制润滑性能方面的区别。

表2 添加剂ZX的理化性能参数

Table 2 Major physical and chemical parameters of ZX additive

表3 添加剂ZD的理化性能参数

Table 3 Major physical and chemical parameters of ZD additive

1.3 四球机摩擦学性能实验

在MRS-10A四球摩擦磨损实验机上,采用GB/T 12583—1998国标实验测定轧制油的最大无卡咬负荷PB值,评价各轧制油的极压性能。在载荷为(196±5) N,转速为1 200 r/min下,进行60 min的摩擦磨损长磨试验,确定摩擦因数,以比较各轧制油的抗磨减摩性能。在轧制过程中油膜强度和摩擦因数不仅反映油品在一定工况下的承载能力和减摩防粘效果, 也反映了吸附膜的特性[10]。

本实验所用钢球为上海钢球厂生产的一级 GCr15标准钢球,直径为12.7 mm,硬度为 HRC 61~65。

1.4 铝板材冷轧实验

在d 95/200 mm×200 mm四辊冷轧实验轧机上测试最小可轧厚度,轧机功率35 kW,轧制速度为60 r/min。实验用带材为某铝材厂提供的厚度为2 mm的铝板。

1.5 退火实验

在退火时,铝箔试样表面滴上实验油样,称量后放在EXXON退火盒内,将退火盒放入退火炉内,设定退火温度为350 ℃,保温2 h后空冷。冷却后取出铝箔试样,称量后按EXXON方法进行评级和拍照。

2 结果与分析

2.1 不同皂化值添加剂轧制油的摩擦学性能分析

在MRS-10A四球摩擦磨损试验机上,不同添加剂的轧制油摩擦学性能测试结果如表4所列。

表4 不同轧制油摩擦学参数

Table 4 Tribological parameters of rolling oils with different additive contents

综合表4中的数据可以看出:1) 含有不同添加剂的轧制油在油膜强度(pB),摩擦因数(μ)及磨斑直径上均表现出较大差异。皂化值较高的添加剂配制的轧制油在油膜强度和摩擦因数方面的表现均优于皂化值较低的添加剂配制的轧制油。说明皂化值高有利于极性分子在轧件表面形成吸附膜,可以承受较大的轧件塑性变形抗力,保证较好的轧制润滑状态,以及良好的极压抗磨性能或抗磨减摩性能。2) 对于同一基础油和添加剂,随着添加剂含量的增加,极性分子在铝材表面吸附量增加,轧制油的摩擦学性能增强,极压抗磨性能增强,并出现饱和吸附,且添加剂皂化值越大,达到饱和吸附的速度越快。

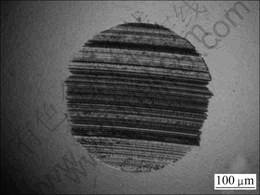

为了较直观地比较皂化值不同的两种添加剂的抗磨损性能,将其分别按5%(质量分数)的含量添加到基础油中,配制成为两种轧制油,在长磨实验后,拍摄金像照片如图1和2所示。

从图1和2中长磨实验后小钢球的磨斑直径、磨痕深浅、错乱程度可以清楚地显示:皂化值大的添加剂配制的轧制油抗磨减摩效果较优。

图1 5%ZD轧制油润滑下的钢球磨斑形貌

Fig.1 Wearing shape of steel ball with lubrication by 5%ZD

图2 5%ZX轧制油润滑下的钢球磨斑形貌

Fig.2 Wearing shape of steel ball with lubrication by 5%ZX

2.2 不同皂化值添加剂轧制油铝板带轧制实验

结合摩擦学实验,挑选抗磨减摩效果最好的添加剂含量为8%的两种轧制油,结合无润滑状态做对 比,在四辊冷轧实验轧机上对3种轧制状态进行最小可轧厚度测试,试验结果如图3所示。

图3 不同轧制状态对铝板轧制厚度的影响

Fig.3 Effect of different rolling states on thickness of rolling aluminum

从图3中可以看出,8%ZD轧制油的最小可轧厚度较小,根据Stone平均单位压力公式可以导出轧辊弹性压扁时的最小可轧厚度计算公式,即

(1)

(1)

式中: 为平均单位张力;E为轧辊弹性模量;μ为摩擦因数;D为轧辊直径;K为变形抗力。

为平均单位张力;E为轧辊弹性模量;μ为摩擦因数;D为轧辊直径;K为变形抗力。

从式(1)可以看出,摩擦因数、轧辊直径、轧辊弹性模量、张力和变形抗力都会影响最小可轧厚度,但在实验条件一定的条件下,最有效的措施是采用工艺润滑降低摩擦因数。结合图3可以看出,皂化值较大的添加剂ZD在减小摩擦因数方面上优于ZX。

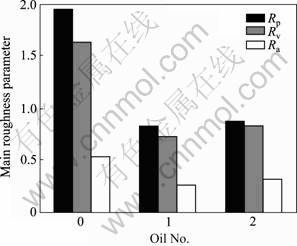

同时比较3种轧制状态下轧后铝材表面粗糙度,表征参数分别如下:中线平均值Ra,轮廓最大峰值Rp,轮廓最大谷深Rv。图4对比了采用3种轧制状态轧后铝材Ra、Rp及Rv的变化。将无润滑状态、8%ZD及8%ZX 3种轧制油分别编号为0、1、2。由图4可以看出:轧制油的Ra、Rp及Rv依次呈现下降趋势,其中采用8%ZD添加剂轧制后使得下降趋势和下降量最明显。

图4 轧后铝材粗糙度的主要数据指标

Fig.4 Main roughness parameters of aluminum after rolling

轧制润滑主要为边界润滑,两接触表面上的微凸体发生部分接触,变形区内压力一部分由流体承担,另一部分则由相接触的微凸体承担[11]。同时在边界润滑中,铝材轧制油中的添加剂能吸附或与金属表面反应,形成吸附膜或化学反应膜,以防止金属表面的剧烈磨损、擦伤甚至熔焊,起到极压润滑的作用[12-13]。ZD和ZX是复配型的添加剂,即含有酸、醇、酯3种极性分子,由于极性基团大小不一,分子极性强弱不一,吸附能大小不同,它们在铝材表面吸附时,可以形成致密的吸附膜。而ZD的皂化值较高,和ZX相比,3种极性分子不仅可以在金属表面聚合生成高分子聚合物膜,抑制金属表面的磨损,即添加剂在金属表面的微凸体上发生聚合反应,形成了较坚韧的聚合物膜,能减缓两表面微凸体的直接接触,抑制微凸体间的焊接现象。同时,由于较高的酯含量,可能有剩余的聚合物从微凸体上流下来,流到相邻的凹穴中,填补凹穴,使摩擦表面变得较平滑一些,进一步降低摩擦及磨损[14]。

2.3 退火清洁性分析

轧后铝材进行退火,一方面是为了改善铝材的性能,另一方面是为了清除轧后铝材表面残留的轧制 油。轧制工艺润滑是铝箔生产三大关键技术之一,但是轧制油,特别是轧制油中的添加剂在铝箔轧后退火时,容易在铝箔表面形成油斑影响产品表面质 量[15-17]。铝材轧制过程中,要求轧制油不仅具有较低的摩擦因数与轧制压力,同时在轧后退火时对铝板的表面油渍污染要小。一般是通过调整添加剂的类型与用量来兼顾上述两者要求[18-19],但同时也与轧制油的基础油有关[20]。

结合抗磨减摩实验,选择8%ZD和8%ZX两种轧制油进行退火实验。实验结果如图5所示。

图5 轧制油退火试验铝板表面照片

Fig.5 Photos of annealed aluminum surface: (a) 8%ZD; (b) 8%ZX

从图5可以看出,两种添加剂轧制油退火后的退火等级都是Ⅰ级。这是因为添加剂含量比较低时,轧制油中基础油含量为90%以上(占大多数),添加剂被稀释了,其退火清洁性差异未能充分显现出来。说明此时轧制油的退火性能仍表现为基础油的退火性能。从冷轧润滑效果方面看,皂化值较高的添加剂配制的轧制油,其摩擦因数低,抗磨减摩效果好。因此,综合考虑轧制润滑效果和退火清洁性的影响,在较低添加剂浓度的条件下,选择皂化值较高的添加剂。

3 结论

1) 对比两种皂化值不同的添加剂,皂化值较高的添加剂配制的轧制油与同质量分数、皂化值低的添加剂配制的轧制油相比,具有较好的抗磨减摩效果及较高的油膜承载能力。

2) 对同一基础油和添加剂,随着添加剂含量的增加,极性分子在铝材表面的吸附量增大,轧制油的摩擦学性能增强,极压抗磨性能增强,且出现饱和吸附,并且添加剂皂化值越大,达到饱和吸附的速度越快。

3) 含添加剂浓度较低的轧制油的退火性能仍表现为基础油的退火性能,此时,添加剂皂化值的大小对铝材轧后退火表面清洁性的影响较小。

REFERENCES

[1] SUN Jian-lin, WANG Lu, MA Yan-li, SHI Qing-bin, ZHANG Ai-hua, LI Jian. Surface quality of cold rolling aluminum strips under lubrication condition[J]. Journal of University of Science Technology Beijing, 2008, 15(3): 335-338.

[2] SUN Jian-lin, KANG Yong-lin, TIAN Guo-xiao. Lubrication in strip cold rolling process[J]. Journal of University of Science Technology Beijing, 2004, 11(4): 368-372.

[3] 孙建林. 轧制工艺润滑原理、技术与应用[M]. 北京: 冶金工业出版社, 2010.

SUN Jian-lin. Technology and application of rolling lubrication[M]. Beijing: Metallurgical Industry Press, 2010.

[4] 关云山, 石庆斌, 张爱华, 李 戬, 翟晓勋, 孙建林. 铝板带材轧制油复合添加剂的润滑效果研究[J]. 青海大学学报: 自然科学版, 2008, 26(6): 47-56.

GUAN Yun-shan, SHI Qing-bin, ZHANG Ai-hua, LI Jian, ZHAI Xiao-xun, SUN Jian-lin. Research on lubrication effect of composite additive in aluminum strip cold rolling[J]. Journal of Qinghai University: Natural Science, 2008, 26(6): 47-56.

[5] 孙建林, 马艳丽. 轧制过程工艺润滑技术的发展和应用[J]. 特殊钢, 2007, 28(3): 47-49.

SUN Jian-lin, MA Yan-li. Development and application of lubrication technology for rolling process[J]. Special Steel, 2007, 28(3): 47-49.

[6] 黄立宇, 王 飞. 冷轧铝板轧制油中复合添加剂的选用与实验研究[J]. 机械工程与自动化, 2007(3): 77-78.

HUANG Li-yu, WANG Fei. Selection and experimental research of compound additives in rolling oil during aluminum cold Rolling[J]. Mechanical Engineering & Automation , 2007(3): 77-78.

[7] 王 录, 孙建林, 王 雷, 史庆斌, 李 戬, 张爱华. 轧制油中添加剂对铝板冷轧过程及成品质量的影响[J]. 轻金属加工技术, 2008, 36(7): 23-25.

WANG Lu, SUN Jian-lin, WANG Lei, SHI Qing-bin, LI Jian, ZHANG Ai-hua. Effects of additives in rolling oil on cold rolling process and aluminium sheet quality[J]. Light Alloy Fabrication Technology, 2008, 36(7): 23-25.

[8] TREVERTON J A, BALL J, FAIRLIE M. The reaction of oxidised aluminum surface with lubrication additives and related compounds[J]. Applied Surface Science, 1991, 52(1/2): 107-124.

[9] JUNICHI S, TOSHIAKI W, SHIGEYUKI M. Adsorption characteristics and lubrication performance of coolant components in cold rolling of aluminum[J]. Tribology International, 2007, 40(5): 748-753.

[10] 毛大恒, 李 丽, 党志茂, 王和平, 李茂春. 提高1400轧机工艺润滑油性能的研究[J]. 中国有色金属学报, 1996, 6(2): 137-145.

MAO Da-heng, LI Li, DANG Zhi-mao, WANG He-ping, LI Mao-chun. Study on improving property of lubrication oil used in 1400 cold-rolling mill[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(2): 137-145.

[11] 孙建林, 康永林, 张新民. 混合润滑轧制入口膜厚模型[J]. 中国有色金属学报, 2001, 11(1): 18-21.

SUN Jian-lin, KANG Yong-lin, ZHANG Xin-min. Model for inlet film thickness in mixed-lubrication rolling[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 18-21.

[12] CHENG Lu, A Kiet-tieu, JIANG Zheng-yi. Modeling of the inlet zone in the mixed lubrication situation of cold strip rolling[J]. Journal of Materials Processing Technology, 2003, 140(1/3): 569-575.

[13] TASO Y H, SARGENT L B Jr. Friction and slip in cold rolling of metals[J]. ASLE Irans, 1978, 21(1): 20-24.

[14] YE Ji-ping, MAKOTO K, YOSHITERU Y. Evaluation of local mechanical properties in depth in MoDTC/ZDDP and ZDDP tribochemical reacted films using nanoindentation[J]. Tribology Letters, 2002, 13(1): 41-47.

[15] 孙建林, 孙艳伟, 马艳丽, 王 录, 张 军. 轧制油对铝箔退火表面质量的影响[J]. 北京科技大学学报, 2008, 30(2): 137-140.

SUN Jian-lin, SUN Yan-wei, MA Yan-li, WANG Lu, ZHANG Jun. Effect of rolling oil on the surface quality of annealed aluminum foils[J]. Journal of University of Science Technology Beijing, 2008, 30(2): 137-140.

[16] 徐 涛, 王 君. 铝及铝合金板带材表面油斑防控技术[J]. 机械工程师, 2007(4): 157-159.

XU Tao, WANG Jun. The controlling technology of oil stain on the surface of aluminum and the aluminum alloy[J]. Mechanical Engineer, 2007(4): 157-159.

[17] 周亚军, 毛大恒, 肖 刚, 李 丽. 绿色环保型的铝材轧制润滑添加剂的研制及其性能[J]. 中国有色金属学报, 2003, 13(4): 1036-1040.

ZHOU Ya-jun, MAO Da-heng, XIAO Gang, LI Li. Development of environmental friendly lubricant additives used in rolling aluminum and its properties[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 1036-1040.

[18] SUN J, ZHANG X. Influence of lubricating additives on surface quality for cold rolling aluminum strips[C]//STLE Annual Meeting. 52nd ed. Kansas, 1997: 5.

[19] TREVERTON J A, THOMAS M P. Surface contaminants on annealed aluminum foil and their effects on adhesion[J]. International Journal of Adhesion and Adhesives, 1989, 9(4): 211-218.

[20] 黄立宇, 王 飞. 冷轧铝板轧制油中基础油对轧制效果的影响[J]. 机械工程与自动化, 2008(2): 151-152.

HUANG Li-yu, WANG Fei. Influence of based oil in rolling oil on cold rolling of aluminum sheet[J]. Mechanical Engineering & Automation, 2008(2): 151-152.

(编辑 龙怀中)

基金项目:青海省科技攻关项目(2006-J-C29)

收稿日期:2010-04-26;修订日期:2010-08-26

通信作者:孙建林,教授,博士;电话:010-62333768;E-mail: sjl@ustb.edu.cn