DOI: 10.11817/j.ysxb.1004.0609.2021-37700

铝箔清洗线卷取过程横向起皱与屈曲

于海军1,何安瑞1,陈长科2,王修亮2,左小刚2

(1. 北京科技大学 高效轧制国家工程研究中心,北京 100083;

2. 新疆众和股份有限公司,乌鲁木齐 830013)

摘 要:铝箔在清洗线出口卷取过程中常出现明显的横向起皱现象,严重时导致铝箔横向屈曲并产生废料。为了掌握卷取过程铝箔横向起皱规律以及采用适当方法来改善卷取过程屈曲问题,根据清洗线出口卷取设备实际情况,采用ABAQUS有限元软件建立清洗线出口卷取过程动态仿真模型。针对当前存在的横向起皱和屈曲问题,利用该模型研究铝卷凸度、铝箔长宽比、铝箔厚度、卷取张力、铝箔屈服强度和铝箔初始板形缺陷对铝箔卷取过程横向起皱和屈曲的影响,得出各因素对铝箔横向起皱和屈曲的影响规律,预测铝箔发生屈曲的可能性。仿真得出的一系列结论为生产中卷取工艺的优化提供理论依据,可以更有效地控制铝箔横向起皱和屈曲现象,减少废料的产生。

关键词:铝箔;卷取;横向起皱;横向屈曲;有限元

文章编号:1004-0609(2021)-03-0546-10 中图分类号:TG339 文献标志码:A

引文格式:于海军, 何安瑞, 陈长科, 等. 铝箔清洗线卷取过程横向起皱与屈曲[J]. 中国有色金属学报, 2021, 31(3): 546-555. DOI: 10.11817/j.ysxb.1004.0609.2021-37700

YU Hai-jun, HE An-rui, CHEN Chang-ke, et al. Transverse wrinkling and buckling of aluminum foil in coiling process of cleaning line[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 546-555. DOI: 10.11817/j.ysxb.1004.0609.2021-37700

铝箔带材广泛应用于电子、包装、医药等领域,其主要生产工艺流程为热轧→冷轧→退火→箔轧→清洗→分卷→包装→交货,其中箔轧和清洗工序中最易出现板形质量问题。板形质量作为评价铝箔产品质量的重要指标之一,直接影响铝箔生产成品率和工厂效益。为提高铝箔板形质量,许多学者进行了深入研究。刘华等[1-3]研究了工作辊辊形、张力和轧制速度对箔轧过程铝箔带材板形的影响,开发和优化了有利于箔轧板形的工作辊辊形和轧制工艺。龚殿尧等[4]通过优化工作辊曲线半角角度,改善了箔轧过程中存在的二肋浪问题。王鹏等[5]通过对设备精度、坯料形状和冷轧工艺等影响铝箔板形的因素进行分析,提出了铝箔窝浪缺陷产生的原因及对策,提高了铝箔的平坦度。廖志宇等[6]对箔轧过程工艺影响因素进行分析,结合实际生产情况提出了工艺控制的重点在轧辊参数和轧制油的结论。LI等[7]开发了分段冷却智能控制技术,认为轧制油黏度和温度以及喷射速度和角度是改善板形的关键。王鹏飞等[8]和李志明等[9]则针对冷轧板形信号处理系统进行研究,通过提高轧制过程带材板形检测精度来提高板形控制精度。以上学者对铝箔板形问题的研究都集中在铝箔轧制过程,这与铝箔卷取过程中出现的横向起皱和屈曲缺陷截然不同。卷取过程中铝箔两端承受拉伸载荷,与薄板拉伸过程的横向起皱和屈曲现象相似,一些学者已对薄板拉伸过程中的屈曲现象进行了研究。FRIEDL等[10]和RAMMERSTORFER[11]研究了薄板在纵向张力作用下的横向应力和屈曲,并给出四边简支矩形薄板在张力作用下的临界屈曲拉伸应力计算方法。NAYYAR等[12-13]采用数值方法对薄聚乙烯膜在两端固支并承受单轴拉伸载荷时的屈曲进行了求解,并通过实验进行了验证,实验中横向起皱高度随着横向压应力的增大而增大。SIPOS等[14]对正交各向异性薄膜进行研究,发现当拉伸载荷逐渐增大时,薄膜横向起皱改善并最终消失。以上国外学者对拉伸载荷下薄板和薄膜横向起皱的研究均建立在静态拉伸基础上,而铝箔卷取过程为动态过程,影响铝箔横向起皱和屈曲的因素多且复杂,当前尚未见到相关研究成果。

铝箔清洗线卷取过程横向起皱和屈曲研究的最终目的是改善卷取过程铝箔板形,以减少铝箔屈曲导致的废料量,提高效益。因此,本文采用ABAQUS有限元软件,根据生产设备实际情况建立铝箔动态卷取模型,对影响清洗线卷取过程中铝箔横向起皱和屈曲的各因素进行仿真研究,并在此基础上提出相应的改善铝箔横向起皱和屈曲的控制策略。

1 板形问题分析

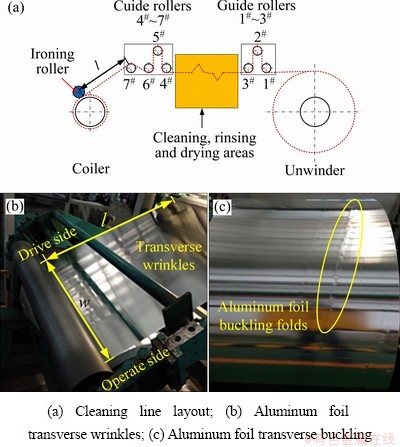

为去除箔轧后铝箔表面粘附的轧制油和铝屑,需对铝箔带材进行清洗处理。铝箔带材的清洗在清洗线完成,清洗线布置、卷取过程铝箔横向起皱及屈曲缺陷情况如图1所示。

图1(a)中虚线圆和虚线线条所示分别为铝箔卷和铝箔带材,清洗过程中铝箔卷从右侧放卷,经入口导向辊进入清洗、漂洗和烘干区域,然后通过出口导向辊被卷取在卷筒上。卷取过程中铝箔带材出现明显横向起皱现象,卷径较小时横向起皱较严重,随着生产的进行卷径逐渐增大,横向起皱有所好转,但依旧存在横向起皱现象,铝箔横向起皱情况如图1(b)所示。横向起皱严重时铝箔横向屈曲形成褶皱,产生图1(c)所示板形缺陷。该缺陷直接影响铝箔板形质量并影响后续生产,此时必须停机对铝箔卷进行分卷,降低了生产效率并产生废料,影响铝箔总成品率。

生产中影响铝箔横向起皱和屈曲的因素较多,去除人为可控因素如卷取开始时的打底质量外,主要的影响因素包括铝卷凸度、铝箔长宽比(图1(a) 中导向辊7#与熨平辊之间铝箔带材的纵向长度l和图1(b)中铝箔横向宽度w的比值)、铝箔厚度、卷取张力、铝箔屈服强度和铝箔带材初始板形缺陷。为分析各因素对铝箔卷取过程横向起皱和屈曲的影响,建立卷取过程有限元动态仿真模型,根据实际生产工况进行仿真分析,为改善清洗线铝箔卷取过程板形缺陷提供理论依据。

图1 铝箔清洗线与出口缺陷图

Fig. 1 Cleaning line layout and aluminum foil flatness defect

2 有限元仿真模型

2.1 模型设置

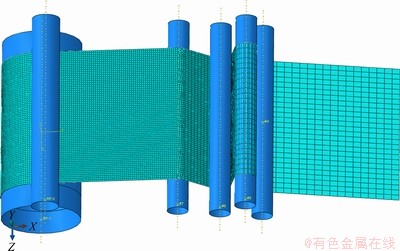

采用ABAQUS有限元软件建立卷取过程动态仿真模型,选择动态显式算法求解。相比卷筒、熨平辊和导向辊,铝箔刚度极小,因此模型中卷筒、熨平辊和导向辊均为刚体。铝箔为弹塑性材料,其弹性模量E为70 GPa,泊松比 为0.32。铝箔网格采用SR4薄壳单元,单元的长度和宽度均为15 mm。仿真过程由两个分析步组成,在Step1中,铝箔入口端施加均布张力,使铝箔和卷筒建立稳定接触关系;在Step2中,保持入口端张力不变,卷筒旋转360°,观察铝箔在各因素影响下的横向起皱和屈曲情况。测量现场生产设备,得到模型几何参数,如表1所列。图2所示为铝箔清洗线出口卷取过程有限元仿真模型。

为0.32。铝箔网格采用SR4薄壳单元,单元的长度和宽度均为15 mm。仿真过程由两个分析步组成,在Step1中,铝箔入口端施加均布张力,使铝箔和卷筒建立稳定接触关系;在Step2中,保持入口端张力不变,卷筒旋转360°,观察铝箔在各因素影响下的横向起皱和屈曲情况。测量现场生产设备,得到模型几何参数,如表1所列。图2所示为铝箔清洗线出口卷取过程有限元仿真模型。

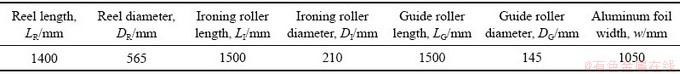

表1 模型几何参数

Table 1 Geometric parameters of model

图2 有限元模型

Fig. 2 Finite element model

2.2 仿真工况设置

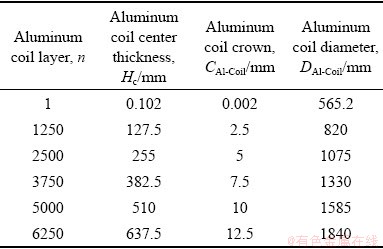

采用称重法[15]测量多卷同一厚度规格铝箔的单层厚度,铝箔中心厚度均值hc为102 μm,铝箔平均凸度CAl为2 μm。卷取过程中,存在凸度的单层铝箔逐层叠加,在不考虑铝箔带材存在微边浪和卷取松卷的情况时,铝卷厚度和凸度都将逐渐增大,此时单层铝箔的厚度和凸度与铝卷的厚度和凸度满足式(1)所示关系,铝卷直径与铝卷中心厚度关系如式(2)所示。由于单层铝箔中心厚度hc和单层铝箔凸度CAl已知,不同铝卷层数对应的铝卷中心厚度、铝卷凸度和铝卷直径如表2所示:

(1)

(1)

(2)

(2)

式中:Hc为铝卷中心厚度,mm;CAl-Coil为铝卷凸度,mm;DAl-Coil为铝卷直径,mm;DR为卷筒直径,mm。

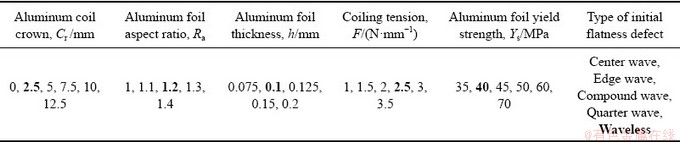

随着卷径的增大,铝箔长宽比将不断减小,根据清洗线出口设备几何位置计算得到铝箔长宽比最大约为1.4,最小约为1;铝箔厚度因铝箔规格有所不同,最小厚度0.075 mm,最大厚度0.2 mm;单位卷取张力一般为2.5 N/mm;同时,考虑铝箔可能存在初始板形缺陷,设置如表3所示仿真工况。其中,加粗标记的参数为生产中常见参数,在研究某一参数对铝箔横向起皱和屈曲的影响时,其余参数取加粗标记的参数值。

表2 铝卷凸度与铝卷直径对应关系

Table 2 Relationship between crown and diameter of aluminum coil

3 结果与分析

3.1 铝箔面内应力与面外位移分布

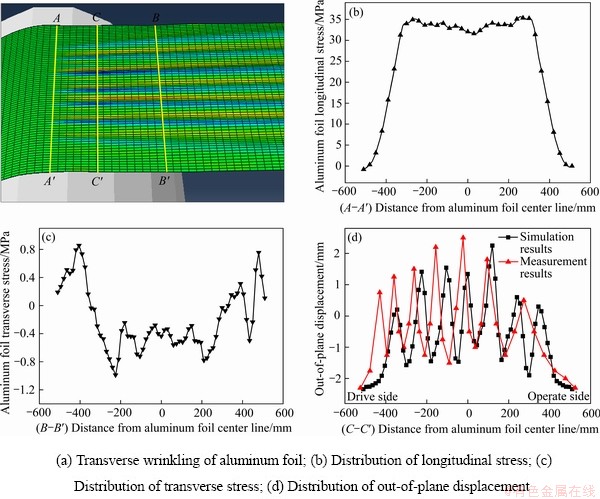

以表3中加粗的参数值为研究对象,仿真得到此工况下铝箔横向起皱情况,如图3(a)所示。截面A-A′为铝箔与卷筒相切处,取此截面处铝箔纵向应力来考察卷取张力横向分布情况,如图3(b)所示。截面B-B′位于卷取入口,与A-A′相距15个单元的长度,距离为225 mm,取此截面处铝箔横向压应力值来考察铝箔横向压应力分布情况,如图3(c)所示。截面C-C′与截面A-A′相距6个单元的长度,距离为90 mm,此截面为铝箔严重起皱区域,取此截面面外位移来考察铝箔起皱严重程度。为验证模型计算精度,对生产过程中截面C-C′处的铝箔起皱情况进行停机测量,铝箔面外位移测量结果和有限元仿真结果如图3(d)所示。

对比图3(a)和图1(b)可知,模型仿真和生产过程的起皱条纹分布情况一致,均为7个起皱条纹。

由图3(b)和图3(c)可知,铝卷凸度会导致卷取张力沿铝箔宽度方向分布不均,不均匀的卷取张力会诱导铝箔面内产生的横向压应力,进而导致铝箔产生横向起皱现象[16]。由图3(d)可知,模型计算结果与生产实测结果具有相同的分布规律且铝箔面外位移值相差不大,说明有限元模型具有较高的精度,可以用于对生产工况进行仿真分析。

表3 模型仿真工况

Table 3 Simulation condition of model

图3 有限元仿真结果

Fig. 3 Finite element simulation result

3.2 铝箔横向起皱和屈曲评价标准

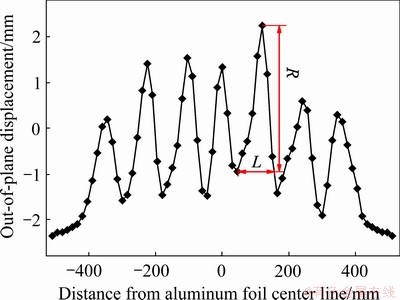

铝箔在清洗线出口的卷取过程存在明显的横向起皱现象,要研究各因素对卷取过程横向起皱的影响,需要给出横向起皱严重程度的评价标准。刘艳红[17]和叶玉娟等[18-19]在研究连续退火生产线带钢屈曲问题时,采用横向弯曲曲率SK来评价带钢可能发生横向屈曲的严重程度,有限元和试验研究表明,SK增大时,带钢塑性应变增大,更容易产生屈曲问题。但考虑到铝箔的SK值无法直接测量,现场多采用翘曲度λ来研究铝箔横向起皱情况[20]。为便于分析判断和现场应用,本文采用翘曲度λ来评价卷取过程铝箔带材横向起皱严重程度,翘曲度λ值越大,铝箔横向起皱越严重,超过某一临界值后,铝箔将发生横向屈曲。为得到λ最值,须首先提取经过SK最大值的横截面(见图3(d)中的C-C′截面)上节点的铝箔面外位移,然后根据图4和式(3)计算λ值。

图4 翘曲度表示方法示意图

Fig. 4 Diagram of waviness

(3)

(3)

式中:R为波高,mm;L为波长,mm;λ为翘曲度。

3.3 生产因素对无浪形铝箔横向起皱和屈曲的影响

铝箔清洗线出口卷取过程为动态过程,影响铝箔横向起皱的因素较多,分析生产过程可知,当铝箔无初始浪形缺陷时,卷取过程铝箔横向起皱和屈曲的主要影响因素为铝卷凸度、铝箔长宽比、铝箔厚度、卷取张力和铝箔屈服强度。

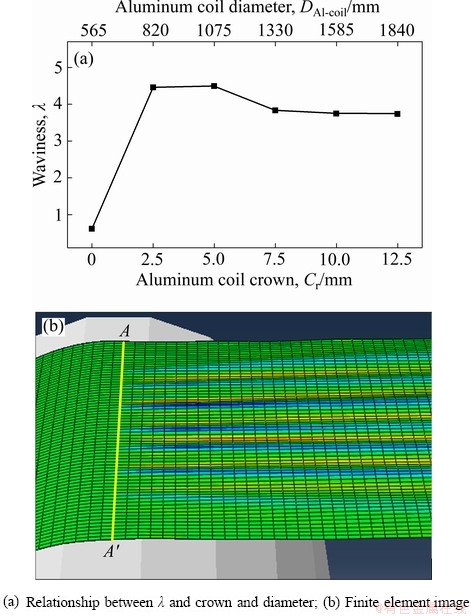

3.3.1 铝卷凸度对横向起皱和屈曲的影响

不考虑铝卷层间空隙及铝箔边部细小波浪的影响,随着卷取的进行,铝卷直径和凸度都逐渐增大。因此,仿真模型中同时考虑铝卷凸度和铝卷直径的变化,研究了不同铝卷凸度及其对应铝卷直径时铝箔横向起皱的情况。保持其余参数不变,得到铝箔翘曲度λ与铝卷凸度和铝卷直径的关系曲线,如图5(a)所示。由图5(a)可知,铝箔翘曲度λ随铝卷凸度增大先增大后减小,铝卷凸度大于7.5 mm后,翘曲度值基本保持不变,说明铝箔横向起皱在初始卷取时较严重,随着卷取的进行,横向起皱将逐渐改善,与现场生产情况一致。铝卷凸度为2.5 mm时,铝箔起皱情况如图5(b)所示,铝箔起皱区域在截面A-A′右侧,说明起皱区域没有卷入铝卷,不会引起铝箔横向屈曲缺陷。

图5 铝卷凸度和直径对翘曲度λ和板形的影响

Fig. 5 Effect of crown and diameter on λ and flatness

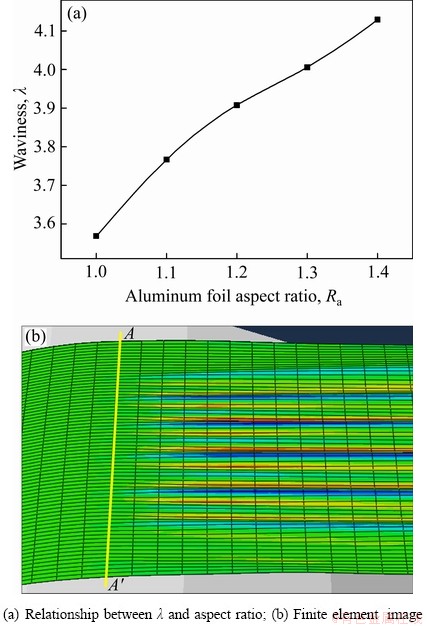

3.3.2 铝箔长宽比对横向起皱和屈曲的影响

随着卷取的进行,铝卷直径不断增大,铝箔长宽比将不断减小。保持其余参数不变,仿真计算得到翘曲度λ与铝箔长宽比的关系曲线,如图6(a)所示。随铝箔长宽比的增加,λ逐渐增大,即随着卷取的进行,铝箔长宽比不断减小,铝箔横向起皱情况将逐渐好转,与现场生产中观察所见一致。铝箔长宽比为1.4时翘曲度值最大,其对应的铝箔起皱情况如图6(b)所示,铝箔起皱区域未越过截面A-A′,铝箔未产生横向屈曲缺陷。

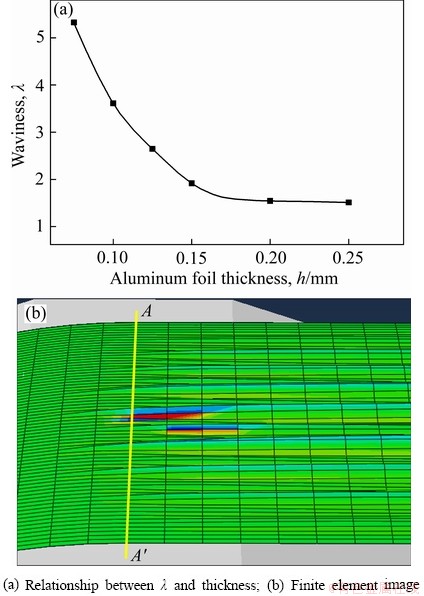

3.3.3 铝箔厚度对横向起皱和屈曲的影响

生产中铝箔厚度规格不尽相同,为研究铝箔横向起皱和厚度的关系,给出铝箔厚度与λ的关系曲线,如图7(a)所示。随着铝箔厚度增大,λ值减小,说明横向起皱在极薄铝箔卷取过程中更易出现,较厚铝箔卷取过程中横向起皱较小,一般不会导致屈曲问题。铝箔厚度为0.075 mm时,翘曲度值较大,其横向屈曲情况如图7(b)所示,起皱区域进入截面A-A′左侧,铝箔横向起皱较严重,容易出现横向屈曲,清洗中应格外注意。

图6 铝箔长宽比对翘曲度λ和板形的影响

Fig. 6 Effect of aspect ratio on λ and flatness

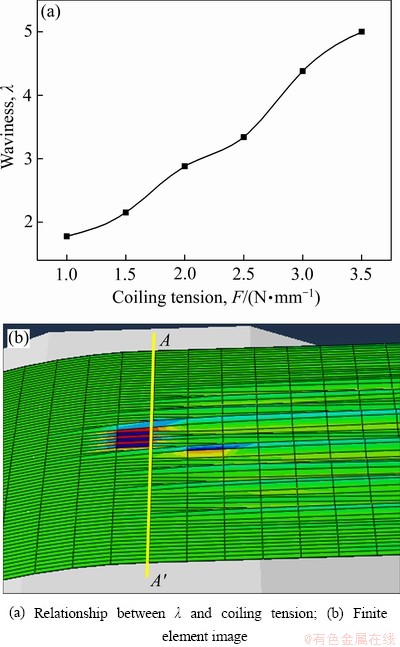

3.3.4 卷取张力对横向起皱和屈曲的影响

卷取张力是卷取过程的重要工艺参数,研究不同卷取张力对横向起皱的影响可以通过优化卷取张力来改善铝箔横向起皱,图8(a)所示为卷取张力与翘曲度λ的关系曲线。由图8(a)可知,λ随卷取张力加大而增大,即铝箔横向起皱将随着卷取张力的增大而加重。卷取张力为2.5 N/mm时,铝箔起皱情况如图8(b)所示,起皱区域超过截面A-A′,容易导致铝箔产生横向屈曲缺陷。因此,在保证不出现松卷缺陷的情况下,可通过适当减小卷取张力来改善卷取过程横向起皱和屈曲问题。

图7 铝箔厚度对翘曲度λ和板形的影响

Fig. 7 Effect of thickness on λ and flatness

图8 卷取张力对翘曲度λ和板形的影响

Fig. 8 Effect of coiling tension on λ and flatness

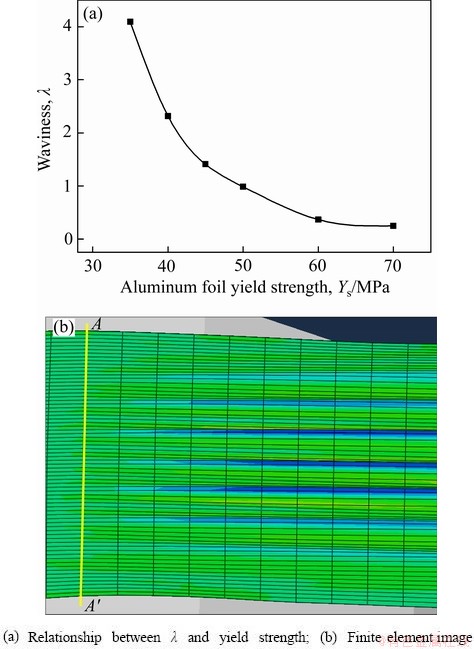

3.3.5 铝箔屈服强度对横向起皱和屈曲的影响

不同型号铝箔屈服强度会有所不同,为研究铝箔屈服强度对横向起皱的影响,给出铝箔屈服强度与翘曲度λ的关系曲线,如图9(a)所示。随着铝箔屈服强度增大,λ值减小,说明屈服强度较小的铝箔在卷取时更容易出现横向起皱缺陷。铝箔屈服强度为35 MPa时,翘曲度值最大,其对应的铝箔起皱情况如图9(b)所示,起皱区域未达到截面A-A′,铝箔不会产生横向屈曲缺陷,随着铝箔屈服强度的增大,铝箔起皱将得到改善。

图9 铝箔屈服强度对翘曲度λ和板形的影响

Fig. 9 Effect of yield strength on λ and flatness

根据上述有限元仿真结果可知,无初始浪形缺陷的铝箔带材在卷取过程中一般仅存在横向起皱缺陷,当铝箔厚度为0.075 mm或卷取张力为3.5 N/mm时,铝箔横向起皱将发展为横向屈曲,产生废料。由于铝箔起皱缺陷随铝箔长宽比和卷取张力的减小而降低,针对较薄无浪形铝箔带材,可采用减小铝箔长宽比和适当减小卷取张力的措施来改善卷取过程横向屈曲缺陷。铝箔起皱缺陷随铝箔屈服强度的增大而降低,对屈服强度小于35 MPa的铝箔带材的清洗过程需要格外注意。

3.4 铝箔初始板形缺陷对横向起皱和屈曲的影响

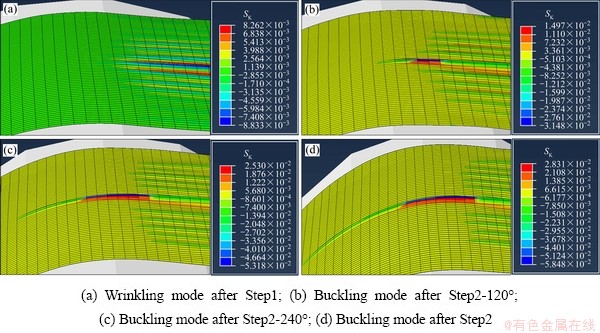

3.4.1 卷取过程铝箔横向屈曲演变

由于铝箔具有极大的宽厚比,在轧制过程中容易出现一定板形缺陷,对轧后铝箔进行清洗时,不同初始板形缺陷将对铝箔卷取过程的横向起皱和屈曲产生不同影响。为研究具有初始浪形缺陷的铝箔在卷取过程中的横向起皱和屈曲过程,根据现场浪形情况,对浪高为3 mm,波长为200 mm,波宽为500 mm的中浪初始板形缺陷的铝箔的卷取过程进行研究。图10所示为铝箔在卷取过程中横向起皱和屈曲的演变情况。图10(a)所示为Step1结束后,铝箔和铝卷建立稳定接触后的横向起皱情况,此时铝箔仅发生横向起皱,尚未产生横向屈曲。图10(b)所示为Step2卷筒旋转120°后的铝箔屈曲模态,此时横向弯曲曲率SK为0.0315 mm-1,铝箔已经出现屈曲。随着卷取的进行,横向弯曲曲率增大,铝箔横向屈曲进一步发展,其屈曲模态如图10(c)和10(d)所示。由此可知,在张力作用下时铝箔仅产生起皱缺陷,随着卷取的进行,起皱区域将进入铝卷造成横向屈曲缺陷。

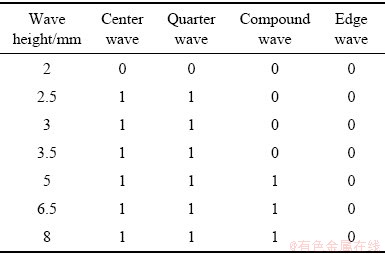

3.4.2 初始板形缺陷对铝箔横向起皱和屈曲的影响

图10所示为具有中浪初始板形缺陷的铝箔的横向屈曲演变过程,为研究不同初始板形缺陷对铝箔横向起皱和屈曲的影响,对具有不同高度的四种初始板形缺陷的铝箔卷取过程进行研究,观察Step2结束后的铝箔屈曲情况,用“1”表示铝箔出现横向屈曲缺陷,“0”表示铝箔仅存在横向起皱而未产生横向屈曲缺陷,各工况下铝箔屈曲情况如表4所列。

由表4可知,浪高对不同初始板形缺陷铝箔的横向屈曲影响不同。浪高超过2.5 mm时,具有中浪和四分浪板形缺陷的铝箔开始出现横向屈曲;浪高超过5 mm时,具有边中复合浪板形缺陷的铝箔开始出现横向屈曲;对于具有双边浪板形缺陷的铝箔,在不同浪高板形缺陷下铝箔均未出现横向屈曲。因此,为了避免卷取过程中铝箔出现横向屈曲问题,生产过程中应采用微边浪板形控制策略,并严格控制其他类型板形缺陷的浪形高度。

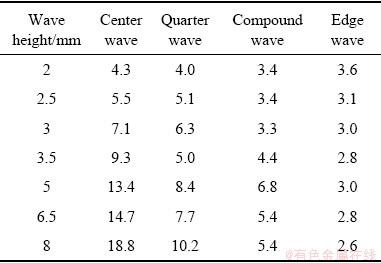

提取各工况下截面C-C′处铝箔面外位移分布曲线并计算得到各工况下翘曲度λ值,如表5所列。

图10 铝箔屈曲演变过程

Fig. 10 Buckling evolution of aluminum foil

表4 不同板形缺陷的铝箔屈曲情况

Table 4 Buckling of aluminum foil with different initial flatness defects

表5 不同板形缺陷时铝箔翘曲度λ

Table 5 Value of λ with different initial flatness defects

由表5可知,初始板形缺陷分别为中浪、四分浪、边中复合浪和双边浪时,λ逐渐减小,横向起皱逐渐改善。结合表4可知,当翘曲度λ大于5时,铝箔开始产生横向屈曲缺陷,生产中可通过测量翘曲度值来预测卷取过程中铝箔可能出现的横向屈曲。同时,为改善卷取过程的横向起皱并减少轧制过程中断带事故的发生,在箔轧工序中可采用微双边浪轧制的控制策略,避免中浪、复合浪和四分浪等板形缺陷的产生。

4 结论

1) 清洗线出口铝箔卷取过程中,铝卷凸度造成卷取张力分布不均,诱导产生横向压应力,导致铝箔产生横向起皱,起皱区域卷入铝卷后便产生横向屈曲缺陷。

2) 对于无初始浪形缺陷的铝箔,随着卷取的进行,铝卷凸度增大的同时,铝卷直径不断增大,铝箔长宽比减小,两因素共同作用下,翘曲度值逐渐减小,铝箔起皱情况逐渐改善,与现场生产中观察到的情况一致;铝箔厚度和屈服强度增大,翘曲度减小,铝箔横向起皱改善;卷取张力增大,翘曲度增大,铝箔横向起皱加重。其中,单位卷取张力超过3 N/mm,铝箔厚度小于0.1 mm,铝箔屈服强度小于35 MPa时,铝箔横向起皱较为严重,容易出现横向屈曲缺陷,应特别注意。

3) 对于存在初始板形缺陷的铝箔,浪高对不同初始板形缺陷类型的铝箔的横向屈曲影响不同,中浪和四分浪受浪高影响最严重;翘曲度λ值超过5时,铝箔在卷取过程中将出现横向屈曲缺陷;相比中浪、复合浪和四分浪,具有双边浪初始板形缺陷的铝箔不易出现横向屈曲,在箔轧工序采用微边浪板形控制策略,有助于卷取过程横向屈曲板形缺陷的改善。

REFERENCES

[1] 刘 华, 吴 斌, 何安瑞, 等. 工作辊辊形对铝箔板形影响的有限元分析[J]. 北京科技大学学报, 2005, 27(1): 90-93.

LIU Hua, WU Bin, He An-rui, et al. Finite element analysis of work roll contour influence on aluminum foil profile[J]. Journal University Science Technology Beijing, 2005, 27(1): 90-93.

[2] 刘 华, 杨 荃, 何安瑞. 张力对大宽厚比铝箔板形的影响[J]. 塑性工程学报, 2005, 12(4): 62-65.

LIU Hua, YANG Quan, He An-rui. Influence of tension on aluminum foil profile under large width to thickness ratio[J]. Journal of Plasticity Engineering, 2005, 12(4): 62-65.

[3] 刘 华, 杨 荃, 何安瑞. 速度对极薄铝箔轧制的影响[J]. 塑性工程学报, 2007, 14(1): 76-79.

LIU Hua, YANG Quan, He An-rui. Influence of speed on ultra thin aluminum foil rolling[J]. Journal of Plasticity Engineering, 2007, 14(1): 76-79.

[4] 龚殿尧, 徐建忠, 邸洪双, 等. 四重铝箔轧机工作辊辊形曲线的优化[J]. 东北大学学报(自然科学版), 2013, 34(7): 952-955.

GONG Dian-yao, XU Jian-zhong, DI Hong-shuang, et al. Optimization of working roll curve of four-high aluminum foil rolling mill[J]. Journal of Northeastern University (Natural Science), 2013, 34(7): 952-955.

[5] 王 鹏, 徐静霞. 铝箔板形窝浪缺陷产生原因及对策[J]. 轻合金加工技术, 2013, 41(12): 27-32.

WANG Peng, XU Jing-xia. Reasons and measures for aluminum foil nest waves[J]. Light Alloy Fabrication Technology, 2013, 41(12): 27-32.

[6] 廖志宇, 杨松涛. 铝箔轧制工艺影响因素的分析与探讨[J]. 有色金属加工, 2014, 43(1): 21-24.

LIAO Zhi-yu, YANG Song-tao. Analysis and discussion on effect factors of aluminum foil rolling process[J]. Nonferrous Metals Processing, 2014, 43(1): 21-24.

[7] LI Mou-wei, LIU Hong-fei, WANG Xiang-li, et al. Key techniques of automatic gauge control and profile control for aluminium strip and foil[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): 1595-1599.

[8] 王鹏飞, 张智杰, 李 旭, 等. 冷轧带材板形在线云图监控系统研究与应用[J]. 中国有色金属学报, 2019, 29(12): 2775-2784.

WANG Peng-fei, ZHANG Zhi-jie, LI Xu, et al. Research and application of online sonogram monitoring system for cold rolled strip flatness[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(12): 2775-2784.

[9] 李志明, 彭 艳, 于丙强, 等. 一种板形信号处理系统研究[J]. 中南大学学报(自然科学版), 2012, 43(4): 1299-1308.

LI Zhi ming, PENG Yan, YU Bing qiang, et al. Research on a shape signal processing system[J]. Journal of Central South University (Science and Technology), 2012, 43(4): 1299-1308.

[10] FRIEDL N, RAMMERSTORFER F G, FISCHER F D. Buckling of stretched strips[J]. Computers and Structures, 2000, 78: 185-190.

[11] RAMMERSTORFER F G. Buckling of elastic structures under tensile loads[J]. Acta Mechanica, 2018, 229: 881-900.

[12] NAYYAR V, CHANDAR K R, HUANG R. Stretch-induced stress patterns and wrinkles in hyperelastic thin sheets[J]. International Journal Soilds Structure, 2011, 48: 3471-3483.

[13] NAYYAR V, CHANDAR K R, HUANG R. Stretch-induced wrinkling of polyethylene thin sheets: Experiments and modeling[J]. International Journal Soilds Structure, 2014, 51: 1847-1858.

[14] SIPOS A A, FEHER E. Disappearance of stretch-induced wrinkles of thin sheets: A study of orthotropic films[J]. International Journal Soilds Structure, 2016, 97/98: 275-283.

[15] 朱小平, 杜 华, 王蔚晨, 等. 自支撑金属薄膜厚度称重法溯源技术的研究[J]. 计量学报, 2014, 35(6A): 31-33.

ZHU Xiao-ping, DU Hua, WANG Wei-chen, et al. Study on the weighing tracing method of thickness for the self-supporting metal foil[J]. Acta Metrologica Sinica, 2014, 35(6A): 31-33.

[16] SEGEDIN R H, COLLINS I F, SEGEDIN C M. The Elastic wrinkling of rectangular sheets[J]. International Journal Mechanical Science, 1988, 30(10):719-732.

[17] 刘艳红. 连续退火生产线带钢稳定通板技术研究[D]. 上海: 上海交通大学, 2010: 66-68.

LIU Yan-hong. Research on stable travelling technology of strip in continuous annealing production line[D]. Shanghai: Shanghai Jiao Tong University, 2010: 66-68.

[18] 叶玉娟, 周旭东, 李 俊, 等. 连续退火炉内带钢的张力分布及瓢曲分析[J]. 锻压技术, 2010, 35(3): 131-134.

YE Yu-juan, ZHOU Xu-dong, LI Jun, et al. Analysis of strip buckling and tension distribution in continuous annealing furnace[J]. Forging and Stamping Technology, 2010, 35(3): 131-134.

[19] 叶玉娟. 带钢连续退火瓢曲现象的研究[D]. 洛阳: 河南科技大学, 2009: 30-47.

YE Yu-juan. Research on strip wrinkling during continuous annealing process[D]. Luoyang: Henan University of Science and Technology, 2009: 30-47.

[20] 于丙强, 杨利坡, 高 朋. 冷轧带钢板形测量方法对比分析[J]. 钢铁研究学报, 2014, 26(5): 36-41.

YU Bing-qiang, YANG Li-po, GAO Peng. Comparison of shape measurement methods of cold rolling strip[J]. Journal of Iron and Steel Research, 2014, 26(5): 36-41.

Transverse wrinkling and buckling of aluminum foil in coiling process of cleaning line

YU Hai-jun1, HE An-rui1, CHEN Chang-ke2, WANG Xiu-liang2, ZUO Xiao-gang2

(1. National Engineering Research Center for Advanced Rolling Technology, University of Science and Technology Beijing, Beijing 100083, China;

2. Xinjiang Zhonghe Co., Ltd., Urumchi 830013, China)

Abstract: There are obvious transverse wrinkles in the aluminum foil coiling process at the exit of the cleaning line, which in serious cases causes transverse buckling flatness defect and a waste of aluminum foil. In order to grasp the wrinkling law of aluminum foil in the coiling process, and improve the aluminum foil flatness by taking appropriate measures, a dynamic simulation model was established based on the exit actual coiling equipment conditions of the cleaning line by the ABAQUS finite element software. Aiming at the current problems, the model was used to study the effects of aluminum coil crown, aluminum foil aspect ratio, aluminum foil thickness, coiling tension, aluminum foil yield strength and initial flatness defects on the aluminum foil transverse wrinkling and buckling in the coiling process. The influences of various factors on the transverse wrinkling and buckling of aluminum foil were obtained, and the prediction of the transverse buckling becomes possible. A series of conclusions obtained by the simulation provide a theoretical basis for the optimization of the coiling process in actual production, which can more effectively improve the aluminum foil flatness in the coiling process of the cleaning line and reduce the generation of waste.

Key words: aluminum foil; coiling; transverse wrinkling; transverse buckling; finite element

Foundation item: Projects(51674028) supported by the National Natural Science Foundation of China; Project (GKAA17202008) supported by the Guangxi Special Funding Program for Innovation-Driven Development, China

Received date: 2019-12-02; Accepted date: 2020-09-17

Corresponding author: HE An-rui; Tel: +86-10-62332598; E-mail: harui@ustb.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51674028);广西创新驱动发展专项资金项目(桂科AA17202008)

收稿日期:2019-12-02;修订日期:2020-09-17

通信作者:何安瑞,教授,博士;电话:010-62332598;E-mail:harui@ustb.edu.cn