3000 °C氧-乙炔重复烧蚀后4D-炭/炭复合材料的剩余强度和热物理性能

来源期刊:中国有色金属学报(英文版)2013年第6期

论文作者:Wajed ZAMAN 李克智 Sumeera IKRAM 李 伟

文章页码:1661 - 1667

关键词:炭/炭复合材料;烧蚀率;压缩强度;热物理性能

Key words:carbon/carbon composites; ablation rate; compressive strength; thermophysical properties

摘 要:主要研究炭/炭(C/C)复合材料在高温使用环境下的烧蚀、剩余强度以及热物理性能。实验采用四维C/C复合材料,在3000 °C下进行重复氧-乙炔烧蚀实验,每次烧蚀时间为30 s,烧蚀后快速冷却。结果表明:材料的烧蚀率与烧蚀时间呈线性关系;在总烧蚀时间相同的情况下,单步烧蚀比逐步烧蚀的烧蚀率高。经过最初几步烧蚀实验后,材料的烧蚀率保持恒定。试样烧蚀面的粗糙度对试样的烧蚀率有重要影响。随着烧蚀次数的增加,材料的压缩强度、热导率和热膨胀系数逐步降低,而比热容几乎保持不变。

Abstract: The performance of carbon-carbon (C/C) composite’s reusable parts regarding the extent of erosion, and residual mechanical and thermophysical properties in high temperature applications was studied. C/C composites were fabricated with four- directional preform architecture. The composites were repeatedly ablated using oxyacetylene flame of about 3000 °C for 30 s each time. The results show that the ablation rate of the composite is linearly proportional to the ablation time; a single step ablation shows a higher ablation rate as compared to the ablation carried out in steps, keeping the total ablation time the same. The surface roughness and exposure area of the specimen to the flame were found to significantly increase the ablation rate. The compressive strength, thermal conductivity and coefficient of thermal expansion (CTE) of the composite were found to decrease after every ablation test, whereas the specific heat capacity of the composite remained unchanged.

Trans. Nonferrous Met. Soc. China 23(2013) 1661-1667

Wajed ZAMAN1, Ke-zhi LI1, Sumeera IKRAM2, Wei LI1

1. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. Department of Chemistry, Quaid-i-Azam University, Islamabad 45320, Pakistan

Received 30 January 2013; accepted 6 May 2013

Abstract: The performance of carbon-carbon (C/C) composite’s reusable parts regarding the extent of erosion, and residual mechanical and thermophysical properties in high temperature applications was studied. C/C composites were fabricated with four- directional preform architecture. The composites were repeatedly ablated using oxyacetylene flame of about 3000 °C for 30 s each time. The results show that the ablation rate of the composite is linearly proportional to the ablation time; a single step ablation shows a higher ablation rate as compared to the ablation carried out in steps, keeping the total ablation time the same. The surface roughness and exposure area of the specimen to the flame were found to significantly increase the ablation rate. The compressive strength, thermal conductivity and coefficient of thermal expansion (CTE) of the composite were found to decrease after every ablation test, whereas the specific heat capacity of the composite remained unchanged.

Key words: carbon/carbon composites; ablation rate; compressive strength; thermophysical properties

1 Introduction

Carbon-carbon (C/C) composites offer a unique set of properties like low density, excellent anti-ablation performance, biomedical compatibility, thermal shock resistance and retaining mechanical properties at high temperatures. These characteristics make C/C composites an ideal candidate in the biomedical applications, aerospace and aeronautics for making exit cones, leading edges and reentry tips of space shuttles and ballistic missiles, nozzles of solid rocket motors (SRM) and air craft brake discs [1-4]. C/C composites fabricated with four-directional (4D) preform architecture are preferred for the thermal management systems including heat sinks and plasma facing components of fusion devices because of their inherent quasi isotropic properties, high thermal conductivity and better anti-ablation performance [5-7]. But owing to their proprietary nature, very less data have been published in the open literatures [8-10].

Ablation of C/C composites depends upon their density, porosity, fiber properties, preform architecture and microstructure of the carbon matrix [11-13]. Oxyacetylene flame ablation is the most widely used experimental method to study and simulate the ablation and erosion behaviour of C/C composites in various aerodynamic, aerothermal and thermomechanical conditions [14-16]. The temperature of the C/C composites in many of their aerospace and aeronautical applications reaches a very high temperature in seconds. Sudden heating and cooling of C/C composites, from a temperature of 2000-3000 K, can produce thermal shock and is prone to disturb their mechanical and thermophysical properties. The long term use of C/C composites parts in any of their critical applications will depend upon their ablation and erosion rate and their residual properties, most importantly the compressive strength, specific heat capacity, thermal conductivity and thermal expansion. Excellent thermophysical properties ensure the uniform ablation and right geometrical parameters of the structure, otherwise if they are damaged, for example in their applications in nozzles, leading ages and nosetips of space shuttle, it may generate control problems and can put the flight at risk. Nowadays, C/C composites brake discs have been used in all the military and passenger aircrafts for mass reduction and cost saving. During a braking action, a large amount of heat is produced due to the friction between the rotor and stator, and is absorbed by the C/C composite brake discs material. To meet the thermo- structural and tribological design requirements of the brake discs, C/C composites need to have low coefficient of thermal expansion (CTE), high thermal conductivity, high heat capacity and high strength. Keeping in view of the requirements of C/C composites in reusable parts at high temperature, it is important to investigate the effect of repeated use of C/C composites in critical high temperature applications on their intrinsic mechanical and thermophysical properties.

In the current work, 4D C/C composite was fabricated with liquid phase impregnation carbonization (LPIC) using coal tar pitch as a matrix [17]. Higher fiber volume fraction and density of the resulting C/C composites were achieved to exactly address the C/C composite materials used in their field applications. The material was ablated many times using oxyacetylene flame of 3000 °C, and their residual compressive and thermophysical properties were monitored and discussed with the help of microscopy. This study will be helpful for efforts to simulate the life and efficiency of C/C composites parts regarding the extent of their erosion and residual mechanical and thermophyscial properties in high temperature applications in their civil and military fields.

2 Experimental

2.1 Composites fabrication

Four-directional (4D) preforms were prepared from polyacrylonitrile-based carbon fibre (12k) using a pultrusion machine. The carbon fibers were arranged in three in-plane directions (xy-direction), that is, 0°, 60° and 120° with a periodic arrangement while the fourth direction was perpendicular in the z-direction, i.e., through-the-thickness (t-t-t). The final 4D preforms had a fibre volume fraction of ~40% and a bulk density of around 0.72 g/cm3.

The preform was densified by liquid phase impregnation carbonization (LPIC) using coal tar pitch. The preform was first densified to 1.0-1.3 g/cm3 using pressure impregnation technique. The green composite was then subjected to various cycles of vacuum impregnation followed by hot isostatic pressure impregnation carbonization (HIPIC) processes. High temperature treatment (HTT) of the composites was carried out at 2300 °C with controlled cooling. The HTT was carried out many times in the middle to open the pores for the next densification cycle. By this way graphitized C/C composites with high density and less porosity, required for excellent mechanical and ablation properties, were achieved. The detailed fabrication process of 4D C/C composite has been reported in our previous paper [17].

2.2 Characterisation

2.2.1 Density and porosity

The density of 4D C/C composites after final HTT was measured by the Archimedes water-immersion method at room temperature using Sartorius CP224S densitometer. The final density of the composite was found to be (1.85±0.01) g/cm3. The open porosity of the composites was determined using air displacement method by filling the pores with kerosene under vacuum. The final open porosity of the composite was (6.5±0.2)%.

2.2.2 X-ray diffraction analysis

X-ray diffraction analysis of the C/C composite was carried out using X’Pert Pro PANalytical model diffractometer. Silicon powder was introduced as a standard. The degree of graphitization after final HTT was found to be ~92 %.

2.3 Oxyacetylene ablation

For oxyacetylene ablation, the specimens with dimensions of d30 mm×10 mm were exposed vertically (perpendicular to the axis of the flame) to an oxyacetylene flame. The distance between the front surface of the specimen and nozzle tip was kept 10 mm. The oxygen to acetylene flow rate was 1.35, while the heat flux was measured as 3.9 MW/m2. The temperature of oxyacetylene flame reached the maximum value of around 3000 °C measured with optical pyrometer. The z-direction fibers were oriented parallel to the flame axis. The composites were ablated for 30, 60, 90 and 120 s in one step ablation. The tests were also performed for repeated-ablation. For that purpose, the ablation tests of the same sample were conducted many times, each time for 30 s and then samples were cooled down to room temperature before subjecting the sample to next ablation experiment. The linear erosion rate and mass ablation rate were calculated for each specimen by dividing either the specimen thickness or the mass change before and after the test by the ablation time.

2.4 Thermophysical analyses

Thermophysical analyses include thermal conductivity, specific heat capacity and coefficient of thermal expansion.

2.4.1 Thermal conductivity and specific heat capacity

Thermal conductivity and specific heat capacity of the composite material were measured in the t-t-t direction of the composite before and after repeated ablations (thermal shocks) from room temperature to 1000 °C. Thermal conductivity and specific heat capacity were measured with a Netzsch-LFA 457 MicroFlash instrument for the specimens with dimensions of d12.7 mm×4 mm.

2.4.2 Coefficient of thermal expansion

The coefficient of linear thermal expansion (CTE) of the material was measured in the in-plane directions of all the ablated and virgin composite samples with a Netzsch-DIL 402C TMA40 instrument in the temperature range of 25-1250 °C at heating rate of 5 °C/min. For CTE measurement rod-shaped specimens with dimensions of d6 mm × 25 mm were used.

2.5 Compressive analysis

For compressive analysis, the cylindrical samples of the composites before and after ablation with dimensions of d10 mm× 10 mm were measured using Instron-8872 instrument at a cross-head speed of 0.50 mm/s.

2.6 Microscopic examination

In order to characterize the texture and microstructure of C/C composites, both polarized light optical microscope (PLM) (Leica DMLP-S 1541537, type DMLM) and scanning electron microscope (SEM) (JEOL JSM-6700f) were used. The microstructures of the composites were investigated before and after ablation and compression tests at various magnifications.

3 Results and discussion

3.1 Microstructure of 4D C/C composite

Figure 1 shows the PLM micrographs of the 4D C/C composites. The matrix is highly anisotropic showing domain morphology. The carbon fibers within the carbon fiber bundles are well impregnated by the pitch matrix and there is a good bonding between the carbon fiber bundles and the carbon matrix. The micrographs show the presence of pores inside the carbon fiber bundles and the bulk matrix.

SEM image of the composite, as shown in Fig. 2, indicates the lamellar microstructure of the pitch based matrix. The carbon fibers have been completely wrapped by the thin graphitic sheets of the carbon matrix. The carbon matrix has an ordered structure oriented towards the axis of carbon fiber. The micrograph shows that the bonding between the individual carbon fibers and the matrix is not very strong. This kind of bonding is believed to protect the C/C composite from catastrophic failure under compressive and flexural loadings.

Fig. 1 PLM micrographs of 4D C/C composites showing fibers and anisotropic texture of matrix

Fig. 2 SEM image of 4D C/C composites showing carbon fibers embedded in carbon matrix

Fig. 3 Ablation and erosion rates of 4D C/C composite as function of ablation time

3.2 Oxyacetylene flame ablation of composite

Figure 3 shows the ablation and erosion rates of the C/C composites under oxyacetylene flame of 3000 °C as a function of ablation time. Ablation of materials involves thermomechanical denudation and thermo- chemical reactions. The ablation and erosion rates of the composites are found to increase with increasing the ablation time. The relationship of the erosion and ablation rate with respect to ablation time is almost linear. There is around two times increase in the ablation rate with the four times increase in the ablation time. The increase in ablation rate with increasing the ablation time is attributed to the thermochemical removal of the outer layer of the carbon fibers and the matrix around the carbon fibers which make the carbon fibers more susceptible to the oncoming flow of ablative gases. This phenomenon also causes the increase in the exposed surface area that escalates the ablation rate.

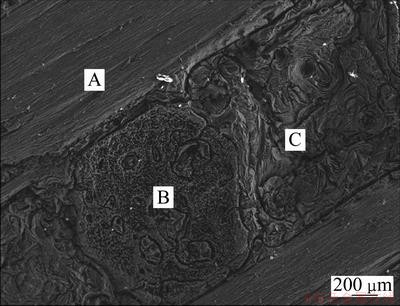

SEM image of the ablated C/C composites shows that the ablation rate in the carbon matrix region is higher than that in the fibre region as represented by the mark ‘C’ in Fig. 4. There is no marked difference in the ablation rate of the in-plane carbon fibers (horizentally oriented carbon fibers) and the transversely oriented carbon fibers marked as “A” and “B” respectively, in Fig. 4.

Fig. 4 SEM image showing horizentally (A) and transversely (B) oriented carbon fibers, and carbon matrix (C) after oxyacetlene flame ablation

Figure 5 shows the transversely and horizontally oriented carbon fibers after ablation for 60 s, respectively. The interface between the carbon matrix and the carbon fiber seems to be more susceptible to the oxyacetylene flame ablation. The loose interface leads to the exposure of the outer shell of the carbon fibers to the ablative gases. The outer layer of the carbon fiber is weaker to resist ablation than the core region because the outer layer has edged carbon atoms and more structural defects, which increases the fiber surface reactivity to ablative gases at high temperature. The transversely oriented carbon fibres thus become tapered as the ablation progresses. The tip of the fibers gets to sharpen with the ablation time increasing and is continuously removed by the incoming flame by block denudation, leaving behind the needles with the blunt tips. The rate of erosion, which is the measure of the thickness difference, remains almost constant after 90 s of ablation, while the ablation rate is constantly increasing, as shown in Fig. 3. This indicates that during long ablation time the oxyacetylene ablation affects more area on the composite surface.

Fig. 5 SEM images showing transversely (a) and horizentally (b) oriented carbon fibers after oxyacetlene ablation for 60 s

The ablation rate of the composite during repeated ablation experiment is shown in Fig. 6 as a function of ablation steps. The ablation rate of composite increases gradually in the beginning till four times of repeated ablation and then remains almost constant in the last six times of repeated ablation. Figure 7 shows the 4D C/C composite specimens ablated 4, 7 and 10 times, each time for 30 s. The oxyacetylene flame ablation produces a pit at the centre of the specimen at the target point. The area and depth of the pit are observed to increase with increasing the number of ablation steps, as shown by circles in Fig. 7.

Fig. 6 Variation in ablation rate of 4D C/C composite during repeated ablation

Fig. 7 Pictures of ablated 4D C/C composites after 30 s ablation under oxyacetylene flame of 3000 °C

3.3 Residual compressive properties after repeated exposure to oxyacetylene flame

Table 1 shows the compressive strength of the virgin 4D C/C composite material and the material after repeated exposure to oxyacetylene flame of 3000 °C, each time for 30 s. The standard deviation between the compressive strengths of many specimens tested in each case is very small, indicating the uniform density and uniform distribution of cracks and pores that are usually generated in a material during HIPIC and HTT process. After the first ablation, the compressive strength of the material falls down by around 10%. This can be attributed to the weakening of the interface, creation of new matrix cracks and the growth of pre-existing cracks by the rapid heating and cooling of the material. It is observed that the decrease in the compressive strength of the material becomes insignificant, as the number of heating and cooling cycles (ablation cycles) increases. The total decrease in the compressive strength of the material in 10 times is about 19.5%. It means that the major loss of compressive strength of the material takes place in the first time use of the C/C composite in the ablative environment.

Table 1 Compressive strength of 4D C/C composites before and after exposure to oxyacetylene flame of 3000 °C, repeatedly 1, 3, 7 and 10 times, each time for 30 s

3.4 Influence of repeated ablation on thermophysical properties

The thermal conductivity of the virgin, ablated and re-ablated C/C specimens are shown in Fig. 8, at various temperatures. The thermal conductivity of the composites decreases with increasing temperature in both the virgin specimen and the specimens after repeated ablation.

Fig. 8 Thermal conductivity of 4D C/C composites after repeated ablation as function of temperature

The results also show that the thermal conductivity of 4D C/C composites at any measured temperatures decreases after ablation. It can be attributed to the structural deformation and reaction of the composites with oxygen etc, during rapid heating and cooling that hinders the channels for the phonon transmission responsible for heat conduction. The specific heat capacity of the C/C composites increases with increasing temperature. Unlike thermal conductivity, the specific heat capacity of the material does not change significantly after ablation as shown in Fig. 9. The CTE behaviour of the 4D C/C composite with increasing temperature is the same as that reported in Ref. [17]. The material shows decrease in the CTE value with increasing their exposure frequency to the ablation environment, as shown in Fig. 10. There is a minor difference in CTE value at temperature below 150 °C; however, the difference in CTE value with ablation and reablation becomes more obvious beyond 150 °C.

Fig. 9 Variation in specific heat capacity of virgin and ablated 4D C/C composites as function of temperature

Fig. 10 CTE of virgin and ablated 4D C/C composites as function of temperature

4 Conclusions

4D C/C composites were fabricated using liquid phase impregnation carbonization with coal tar pitch as an impregnant. The composites were repeatedly ablated using oxy-acetylene flame of about 3000 °C each time for 30 s, and the residual compressive and thermo- physical properties of the composites were studied.

1) The erosion and ablation rate of the composite increase with the ablation time increasing, and the ablation rate is higher when the composite is ablated in one step as compared to that ablated in many steps.

2) The surface roughness and exposure area of the specimen to the flame significantly increase the ablation and erosion rate.

3) The compressive strength of the composite decreases significantly after the first ablation in oxyacetylene flame at 3000 °C; however, the decline in compressive strength becomes insignificant after repeated ablation.

4) The ablation has a pronounced effect on the thermal conductivity and coefficient of thermal expansion of 4D C/C composite, which are decreased linearly with ablation times, whereas the specific heat capacity of the composite remains unchanged after ablation.

References

[1] SAVAGE G. Carbon–carbon composites [M]. London: Chapman & Hall, 1993: 31-357.

[2] UCKLEY J D, EDIE D D. Carbon/carbon materials and composites [M]. New Jersey: Noyes Publications, 1993: 267-279.

[3] FITZER E. The future of carbon-carbon composites [J]. Carbon, 1987, 25: 163-190.

[4] ZHANG L L, LI H J, ZHANG S Y, LU J H, ZHANG Y L, ZHAO X N, GU C B, ZENG X R. Characterisation of wear particles from biomedical carbon/carbon composites with different preforms in hip joint simulator [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2562-2568.

[5] AUBARD X, CLUZEL C, GUITARD L, LADEVEZE P. Damage modeling of a 4D carbon/carbon composite for high temperature application [J]. Ceramic International, 2000, 26: 631-637.

[6] DAGLI L, REMOND Y. Identification of the non-linear behaviour a 4D carbon-carbon material designed for aeronautic application [J]. Applied Composite Materials, 2002, 9: 1-15.

[7] CHOURY J J. Carbon-carbon materials for nozzles of solid propellant rocket motors [R]. CA, USA: AIAA/SAE, 1976.

[8] BERDOYES M. Snecma propulsion solid advanced technology SRM nozzles. History and future [R]. CA, USA: AIAA, 2006.

[9] LEE Y J, JOO H J. Investigation on ablation behaviour of CFRC composites prepared at different pressure [J]. Composites Part A, 2004, 35: 1285-1290.

[10] BOURY D, MUNOZ M, ALBERT A, LASSALE S B. Ariane 5 SRM nozzle evolution [R]. Indianapolis, USA: AIAA/ASME/SAE/ASEE, 2002.

[11] CHO D, YOON B I. Microstructural interpretation of the effect of various matrices on the ablation properties of carbon fibre-reinforced composites [J]. Composites Science and Technology, 2001, 61: 271-280.

[12] YIN J, XIONG X, ZHANG H, HUANG B. Microstructure and ablation performances of dual-matrix carbon/carbon composites [J]. Carbon, 2006, 44: 1690-1694.

[13] PING L S, LI K Z, LI H J, YI Y L, YUAN Q L. Effect of HfC on the ablative and mechanical properties of C/C composites [J]. Materials Science and Engineering A, 2009, 517: 61-67.

[14] LI G D, XIONG X, HUANG K L. Ablation mechanism of TaC coating fabricated by chemical vapor deposition on carbon-carbon composites [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: s689-s695.

[15] SHEN X T, LI K Z, LI H J, FU Q G, LI S P, DENG F. The effect of zirconium carbide on ablation of carbon/carbon composites under an oxyacetylene flame [J]. Corrosion Science, 2011, 53: 105-112.

[16] SHEN X T, LI K Z, LI H J, DU H, CAO W, LAN F. Microstructure and ablation properties of zirconium carbide doped carbon/carbon composites [J]. Carbon, 2010, 48(2): 344-351.

[17] ZAMAN W, LI K Z, IKRAM S, LI W, ZHANG D S, GUO L J. Morphology, thermal response and anti-ablation performance of 3D-four directional pitch-based carbon/carbon composites [J]. Corrosion Science, 2012, 61: 134-142.

Wajed ZAMAN1,李克智1,Sumeera IKRAM2,李 伟1

1. 西北工业大学 材料学院,西安710072;

2. Department of Chemistry, Quaid-i-Azam University, Islamabad 45320, Pakistan

摘 要:主要研究炭/炭(C/C)复合材料在高温使用环境下的烧蚀、剩余强度以及热物理性能。实验采用四维C/C复合材料,在3000 °C下进行重复氧-乙炔烧蚀实验,每次烧蚀时间为30 s,烧蚀后快速冷却。结果表明:材料的烧蚀率与烧蚀时间呈线性关系;在总烧蚀时间相同的情况下,单步烧蚀比逐步烧蚀的烧蚀率高。经过最初几步烧蚀实验后,材料的烧蚀率保持恒定。试样烧蚀面的粗糙度对试样的烧蚀率有重要影响。随着烧蚀次数的增加,材料的压缩强度、热导率和热膨胀系数逐步降低,而比热容几乎保持不变。

关键词:炭/炭复合材料;烧蚀率;压缩强度;热物理性能

(Edited by Sai-qian YUAN)

Foundation item: Project (51221001) supported by the National Natural Science Foundation of china; Project (B08040) supported by the Introducing Talents of Discipline to Universities, China

Corresponding author: Ke-zhi LI; Tel: +86-29-88495764; E-mail: likezhi@nwpu.edu.cn

DOI: 10.1016/S1003-6326(13)62645-X