文章编号:1004-0609(2008)08-1407-07

基于Murty准则粗片层TC11合金两相区的热态变形行为

李 鑫1, 2,鲁世强1,王克鲁1,丁林海1,李臻熙3,曹春晓3

(1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 南京航空航天大学 材料科学与技术学院,南京 210016;

3. 北京航空材料研究院,北京100095)

摘 要:利用基于Murty准则的加工图技术研究具有粗片层α的TC11合金在α+β两相区的热态变形行为。结果表明,基于Murty准则的加工图技术能较好地预测流动失稳区域和反映耗散能量的变形机制和微观组织。通过加工图分析和微观组织观察得到,流动失稳区域为750~880 ℃、0.007~10.0 /s和880~950 ℃、0.2~10.0 /s,流动失稳现象为宏观剪切裂纹、绝热剪切带和原始β晶界孔洞;较佳的加工区域为770~900 ℃、0.001~0.005 /s和900~950 ℃、0.001~0.03 /s,这两个区域分别是α片层球化机制起作用和α片层球化以及α+β→β相变两种机制同时起作用的区域。锻造时可根据锻件的需要来决定α相的含量,在850~950 ℃之间选取最佳变形温度,最佳应变速率为0.001 /s。

关键词:TC11合金;Murty准则;加工图;热变形;变形机制;流动失稳

中图分类号:TG 146.2; TG 316 文献标识码:A

Hot deformation behavior of TC11 alloy with thick lamellar microstructure in two phase field based on Murty criterion

LI Xin1, 2, LU Shi-qiang1, WANG Ke-lu1, DING Lin-hai1, LI Zhen-xi3, CAO Chun-xiao3

(1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. Institute of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The hot deformation behavior of TC11 alloy with thick lamellar α was investigated by the approach of processing map based on Murty criterion. The results show that the approach of processing map based on Murty criterion can predict flow instability zones and exhibit deformation mechanisms and microstructures dissipating energy well. By analyzing the processing map and observing microstructures, the flow instability zones are in the ranges of 750?880 ℃, 0.007?10.0 /s and 880?950 ℃, 0.2?10.0 /s, and the manifestations of flow instability are macro cracking, adiabatic shear bands and prior β boundary cavities. The preferable ranges for hot working are in the ranges of 770?900 ℃, 0.001?0.005 /s and 900?950 ℃, 0.001?0.03 /s. In this two ranges, the globularization of lamellar α operates and globularization of lamellar α along with α+β→β phase transformation operates, respectively. For forging of TC11 alloy, the optimum temperature can be selected between 850 ℃ and 950 ℃ in light of the need of α phase content, and the optimum stain rate is 0.001 /s.

Key words: TC11 alloy; Murty criterion; processing map; hot deformation; deformation mechanism; flow instability

TC11合金是一种综合性能良好的马氏体α+β型热强钛合金,其微观组织对变形热力参数(变形温度、应变速率等)比较敏感,在生产中不易获得组织和性能稳定一致的工件,且容易产生各种宏观和微观缺陷,从而会影响到材料的加工性能和工件的力学性能。本研究拟以具有粗片层α相的TC11合金在α+β两相区热态压缩实验结果为基础,通过建立和分析加工图并辅以微观组织观察来研究变形缺陷、微观组织以及变形机制与变形热力参数之间的关系,这对合理制定和优化粗片层组织TC11合金两相区的锻造工艺具有一定的指导意义。

加工图是根据国外学者PRASAD等[1?2]发展的动态材料模型理论建立的,目前是一种用于金属热变形工艺设计和优化的强有力工具。在国内,鲁世强和李鑫等[3?5]对动态材料模型及其加工图技术的理论基础进行了综述,并对确定加工图中稳定变形区和失稳变形区的各种准则的推导过程进行了较详细的介绍,从理论角度比较和分析了各种准则的适用范围,在此基础上利用加工图技术对具有等轴组织的TC11合金在近β相区和β单相区的热态变形行为进行了研究,并优化出其高温变形参数。李淼泉等[6?7]研究了TC6和TA15两种钛合金的热变形行为,并利用加工图获悉了这两种钛合金在热变形时容易产生变形缺陷的流变失稳区域和最佳的变形工艺参数。这些研究对制定钛合金和其他合金的热加工工艺具有较好的指导作用。

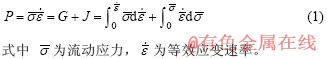

根据动态材料模型理论,热变形过程中的材料可以看作一个封闭系统,其吸收外部的机械功率(P)可以通过转变为粘塑性热和用于微观组织变化而耗散,对应于这两部分的功率分别称为功率耗散量(G)和功率耗散协量(J),即[2]

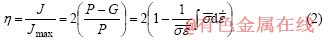

对于理想的线性耗散来说,J具有最大值Jmax = P/2。定义功率耗散效率:

η为无量纲参数,它随变形温度和应变速率的变化便形成了呈现不同区域的功率耗散图,功率耗散图中的这些区域往往和某些特定的微观变形机制相联系。一般说来,η值较高的区域往往对应着最佳的加工性能区,有时楔形裂纹出现的区域也具有较高的η值,因此分析加工图时需要进一步的微观组织来佐证[8]。

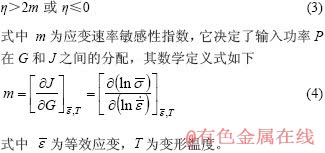

按照应用于大塑性流动连续介质力学的不可逆热力学极值原理,当dD/d <D/

<D/ 时,材料在热变形时会出现流动失稳。式中D为给定温度下表征材料本征行为的耗散函数[2]。MURTY等[9]认为功率耗散协量J与冶金过程的微观组织变化有关,因此用J代替耗散函数D,从而导出Murty流动失稳准则

时,材料在热变形时会出现流动失稳。式中D为给定温度下表征材料本征行为的耗散函数[2]。MURTY等[9]认为功率耗散协量J与冶金过程的微观组织变化有关,因此用J代替耗散函数D,从而导出Murty流动失稳准则

式(3)随应变速率和变形温度的变化形成了失稳图,叠加在功率耗散图上便构成了加工图。

1 实验

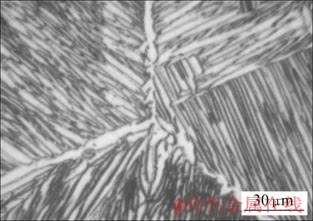

实验材料为在1 040 ℃保温30 min随炉冷却的TC11合金,(α+β)/β相变点为1 008 ℃,微观组织为粗片层α组织,如图1所示。从图1可以看出,原始β晶粒较为粗大,β晶界清晰完整,由一层厚度约为4 μm的α层勾画出,晶内α片层的厚度约为2.4 μm。热压缩实验在THERMECMASTOR-Z型热加工模拟试验机上进行,压缩试样为两端面加工有0.2 mm深凹槽的d 8 mm×12 mm的圆柱体。热压缩时,两端面的凹槽充填特供的高温润滑用玻璃粉,以减小试样与垫块之间的摩擦。实验采用的应变速率为0.001、0.01、0.1、1.0和10.0 /s,变形温度为750、800、850、900和950 ℃,共计25个变形规范。所有试样的高度压缩率均为50%。实验过程中,配有微机处理系统的试验机自动采集有关数据,并进行修正和计算,最后以表格形式输出载荷、行程、真应力和真应变等数据。

图1 TC11合金的显微组织

Fig.1 Microstructure of TC11 alloy

试样采用真空感应加热,压缩过程中由焊接在试样侧表面中部的热电偶实时测量温度,通过闭环温控系统实现控温精度为±1 ℃。为了保留高温变形组织,试样变形后立即喷氦气冷却。变形试样沿平行于压缩轴线方向对半剖开,取其中一半按标准金相试样制备步骤制样,用体积比为1?3?6的HF+HNO3+H2O的腐蚀液进行腐蚀,利用XJP?6A型金相显微镜进行微观组织观察。

2 实验结果

2.1 试样外观

试样变形后,其外观出现一定的变化。当温度较低、应变速率较高时,试样宏观上出现了剪切现象,有的甚至出现了宏观裂纹。随着温度的升高和应变速率的降低,试样的剪切程度逐渐减弱。

2.2 加工图

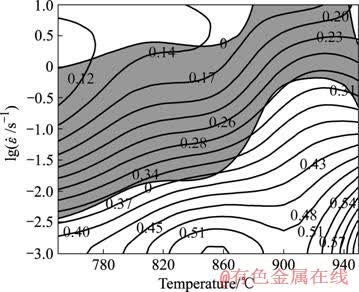

在利用热压缩实验数据绘制加工图时,为了获取更多的流动应力数据和减小计算误差,先采用3次样条插值函数对流动应力进行插值,然后利用最小二乘法对插值后的流动应力进行拟和,用式(2)和(4)计算出不同温度和不同应变速率下的η值和m值,用式(3)确定流动失稳区域,从而绘制出粗片层TC11合金在不同真应变下的加工图。图2所示为真应变0.3时的加工图,其他真应变下的加工图与图2相似。图2中的曲线为耗散效率η的等值线,其上的数字为对应等值线的η值,阴影部分为流动失稳区域。

从图2可以看出,加工图上显示出两个主要的峰值η区域,这两个峰值η区域的温度范围分别大致为770~900 ℃和900~950 ℃,应变速率范围分别大致为0.001~0.005 /s和0.001~0.03 /s,这两个峰值η区域的η最大值出现的温度分别为850 ℃和950 ℃,对应的应变速率均为0.001 /s。另外,从图2还可以看出,失稳区域出现在较高的应变速率范围,大致为750~880 ℃、0.007~10.0 /s和880~950 ℃、0.2~10.0 /s,随温度的降低,失稳区域逐渐向低应变速率范围扩展。

图2 真应变为0.3时TC11合金的加工图

Fig.2 Processing map for TC11 alloy at strain of 0.3 (Numbers in isograms are values of efficiency of power dissipation η and shadow is instability zone).

3 分析和讨论

3.1 流动失稳现象

3.1.1 宏观裂纹

图3所示为在变形条件为800 ℃、10.0 /s时压缩试样的宏观照片,这个变形条件位于加工图中的左上角被失稳区包围的一小块稳定区域内。从图3可以清晰地观察到试样表面与压缩轴线接近成45?角的宏观剪切裂纹。在此小区域内变形时,由于温度低,应变速率高,变形热效应大,而钛合金的导热性较差,造成大量塑性功所转变成的热来不及向周围较冷的部分传递,致使局部温度升高。由于试样压缩时在与压缩轴线成45?角的方向对变形最有利,因而此局部区域的温度高、流动应力小,变形主要集中在此局部区域,变形非常不均匀,导致宏观剪切裂纹的产生。

图3 在800 ℃、10.0 /s压缩时试样的宏观裂纹

Fig.3 Macro picture of TC11 specimen compressed at 800 ℃ and 10.0 /s exhibiting cracking (Compression axis is vertical).

宏观剪切裂纹主要与试样的几何形状(决定传热)和应力状态(决定最大切应力平面)及转化为热的功率耗散量G有关[10],而Murty准则是与通过组织演变的耗散协量J有关,不能预测到这种宏观绝热剪切裂纹的产生。因此,这个较小的区域是非常有害的变形热力参数区域。

3.1.2 绝热剪切带

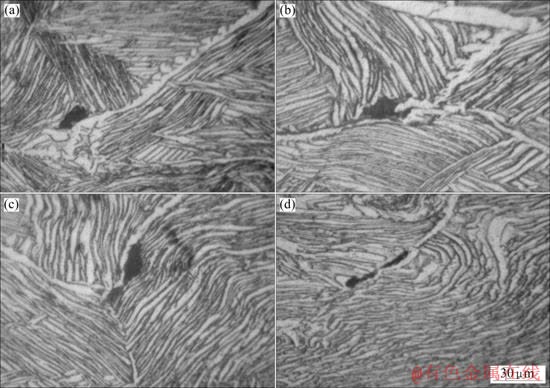

图4所示为在失稳区内较高应变速率范围(应变速率大于0.01 /s)压缩试样的微观组织。从图4可以明显地观察到绝热剪切带,这些绝热剪切带与压缩轴线接近成45?角,贯穿变形试样。绝热剪切带是由于绝热效应和TC11合金较低的热导率导致局部不均匀变形引起的,属于不均匀变形带,但没有引起宏观的剪切裂纹。从图4可以看出,绝热剪切带的宽度随温度的升高和应变速率的降低而增加,而变形的剧烈程度则随温度的升高和应变速率的降低而减弱。MEYERS等[11]研究了Ti, Ta, Ti-6Al-4V和不锈钢等金属材料内部的绝热剪切带的产生和扩展,指出当材料在较高的应变速率下进行塑性变形时,绝热剪切带以类似于位错的方式成为塑性变形的主要载体。文献[12]指出,在绝热剪切带内的热软化区域容易出现空穴形核、长大和连接,易导致裂纹的产生。绝热剪切带的产生会使得材料性能非常不均匀和性能下降,因此,应该避免出现。

图4 在不同变形条件下压缩时试样内部的绝热剪切带

Fig.4 Microstructures exhibiting adiabatic shear bands (Compression axis is vertical in all micrographs) for TC11 specimens compressed under different conditions: (a) 750 ℃, 1.0 /s; (b) 750 ℃, 0.1 /s; (c) 800 ℃, 1.0 /s; (d) 800 ℃, 0.1 /s; (e) 850 ℃, 1.0 /s; (f) 900 ℃, 10.0 /s

3.1.3 原始β晶界孔洞

图5所示为在失稳区内的较低温度和较低应变速率范围(温度小于900 ℃,应变速率小于1.0 /s)压缩 试样小变形区的微观组织。从图5可以看出,在原始β晶界上有孔洞的产生。XUN等[13]研究了Al-Li 合金超塑性变形时晶界孔洞的形核机制,认为孔洞的产生与大角度晶界滑移有关,并认为晶界的滑移过程会导致三叉晶界区域或沿晶界凸起区域的晶格错配和应力集中,进一步的变形需要应力集中被释放,否则,孔洞便会在这些地方形核。SEMIATIN等[14]对具有魏氏组织的Ti-6Al-4V钛合金拉伸过程中出现的孔洞现象进行了研究发现,在低温(小于900 ℃)时孔洞主要出现在原始的β晶界或三叉晶界。魏氏组织通常由α+β片丛、晶界α层和二者之间的一层较薄的β层组成,β层由于具有bcc结构在三者当中是软体相,SEMIATIN认为,孔洞主要是晶界上较薄的β层内的应力集中造成的,且出现在这层较薄的β层内。XUN和SEMIATIN均发现,孔洞的长度方向接近垂直于拉伸轴线的方向。

图5 在不同变形条件下压缩时试样小变形区的原始β晶界孔洞

Fig.5 Microstructures exhibiting cavities at prior β boundaries (Compression axis is vertical in all micrographs) for TC11 specimens compressed under different conditions: (a) 750 ℃, 0.01 /s; (b) 800 ℃, 0.1 /s; (c) 800 ℃, 0.01 /s; (d) 850 ℃, 0.01 /s

在本研究中,孔洞主要出现在压缩试样的小变形区,并且从图5可以看出,出现孔洞的原始β晶界与压缩轴线接近成45?角,孔洞的形状随着温度的升高和应变速率的降低逐渐变长、变窄。因此,可以认为在热压缩过程中,与压缩轴线接近成45?角的原始β晶界在切应力的作用下将会滑动,从而会在三叉晶界或晶界上产生应力集中,并且小变形区在环向上受到拉应力的作用,如果晶界β层的软化速率和原子扩散速率大于晶界β层内的应力积累速率,应力集中将被释放,否则孔洞将会在β层内形核,并扩展形成较大的孔洞。由于β相的软化(通过动态回复等)是一个热激活过程,且原子的扩散需要一定的时间,因此,温度和应变速率会对晶界β层的松弛机制有较强的影响,因而限制原始β晶界孔洞的形核条件是由促使晶界β层软化速率和原子扩散速率充分进行的温度和应变速率共同决定的。

3.2 稳定区域的变形机制

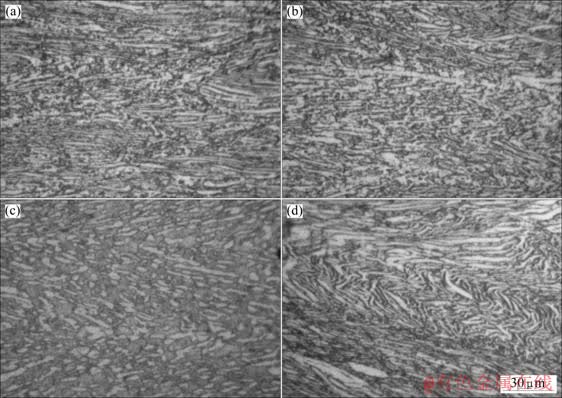

图6所示为稳定区域内不同变形条件下压缩试样的微观组织。其中图6(a)和(c)所示分别为第一个和第二个峰值η区域内的微观组织,图6(b)和(d)所示为两个峰值η区域之间的微观组织。

图6 稳定区内不同变形条件下压缩时试样的微观组织

Fig.6 Microstructures exhibiting globularization and kinking of lamellar α (Compression axis is vertical in all micrographs) for TC11 specimens compressed under different conditions: (a) 850 ℃, 0.001 /s; (b) 900 ℃, 0.001 /s; (c) 950 ℃, 0.001 /s; (d) 900 ℃, 0.01 /s

一般说来,不同的峰值η区域会有不同的微观机制在起作用。从图6可以看出,变形条件为850 ℃、0.001 /s(图6(a)),900 ℃、0.001 /s(图6(b))和950 ℃、0.001 /s(图6(c))时,均有较多的α片层球化,且球化比例随着温度的升高而增加,在900 ℃、0.01 /s(图6(d))时,α片层的球化较少,并且有扭曲的α片层。从α相含量来看,在应变速率为0.001 /s时,当温度从850 ℃升高到900 ℃时,α相含量变化不大;而当温度从900 ℃升高到950 ℃时,α相含量明显减少。因此,第一个峰值η区域为α片层的球化区域,在这个区域内,耗散的功率主要用于α片层的球化;第二个峰值η区域为α片层的球化和α+β→β相变这两种微观机制同时起作用的区域,当这两种微观机制所耗散的功率相同时,用于组织演变的功率耗散协量J达到最大值,此时η也达到最大值[1];在这两个峰值η区域之间是过渡区域。

SESHACHARYULU等[15]研究了片层组织Ti-6Al-4V钛合金的球化过程,认为变形过程中在α片层内部会形成分布着异号位错的剪切带,异号位错通过滑移和交滑移相抵消,只留下同号的位错沿剪切带形成新的界面,然后新的界面通过扩散迁移完成α片层的球化。WEISS等[16]则认为α片层的断开有两种方式:一种是在热变形过程中,形成穿过片层α的低角度和高角度界面,角度取向差从较小的度数增加到大约30?,β相沿着这些界面渗入α片层,如果α片层的厚度小于β相渗入距离的2倍,α片层就会断开。α片层断开的另外一种方式就是在热变形过程中α片层发生了局部剪切和转动,穿越剪切带的取向差可达到20?,β相可能沿着剪切带渗入α片层,从而部分或全部地将α片层断开。

按照SESHACHARYULU和WEISS的球化观点,球化的α相尺寸应该和α片层的厚度相近,但从图6可以看出,球化的α相尺寸中既有与α片层厚度相近的,也有小于α片层厚度的,这说明α片层的球化方式除了α片层的断开,还可能有动态再结晶或其他的方式。另外,从图6还可以观察到少量尺寸较大的球化α相,这可能是因为应变速率较低,球化的α相出现了聚集长大。由于α片层的球化是与扩散相联系的过程,因此,应变速率越低,温度越高,原子扩散越充分,球化比例越高。

3.3 锻造工艺设计

通过加工图分析和微观组织观察,流动失稳区域为750~880 ℃、0.007~10.0 /s和880~950 ℃、0.2~10.0 /s,变形缺陷为宏观剪切裂纹、绝热剪切带和原始β晶界孔洞,这个区域在热变形时尽量避开;较佳加工区域为770 ~900 ℃、0.001~0.005 /s和900~950 ℃、0.001~0.03 /s,这两个区域分别为α片层球化机制起作用和α片层球化以及α+β→β相变这两种机制同时起作用的区域。另外,由于 最大值在两个较佳区域中出现的参数分别为850 ℃、0.001 /s和950 ℃、0.001 /s,因此,在实际制定锻造加工工艺时,可以根据所需锻件的性能来决定锻件中α相的含量,进而在850~950 ℃之间来选取最佳的变形温度,最佳应变速率为0.001 /s。

最大值在两个较佳区域中出现的参数分别为850 ℃、0.001 /s和950 ℃、0.001 /s,因此,在实际制定锻造加工工艺时,可以根据所需锻件的性能来决定锻件中α相的含量,进而在850~950 ℃之间来选取最佳的变形温度,最佳应变速率为0.001 /s。

4 结论

1) 通过加工图分析和宏观以及微观组织观察可知,流动失稳区域为750~880 ℃、0.007~10.0 /s和880~950℃、0.2~10.0 /s,流动失稳现象为宏观剪切裂纹、绝热剪切带和原始β晶界孔洞。

2) 通过加工图分析和微观组织观察可知,较佳加工区域为770~900 ℃、0.001~0.005 /s和900~950 ℃、0.001~0.03 /s,这两个区域分别是α片层球化机制起作用和α片层球化以及α+β→β相变两种机制同时起作用的区域。

3) 通过微观组织观察可知,在较佳的加工区域内,α片层的球化比例随着温度的升高而增加,而α相的含量随温度的升高而减少,实际锻造时根据所需锻件的性能来决定锻件中α相的含量,在850~950℃之间选取最佳变形温度,最佳应变速率为0.001 /s。

REFERENCES

[1] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883?1892.

[2] PRASAD Y V R K, SESHACHARYULU T. Modeling of hot deformation for microstructural control[J]. International Materials Reviews, 1998, 43(6): 243?258.

[3] 鲁世强, 李 鑫, 王克鲁, 董显娟, 李臻熙, 曹春晓. 基于动态材料模型的材料热加工工艺优化方法[J]. 中国有色金属学报, 2007, 17(6): 890?896.

LU Shi-qiang, LI Xin, WANG Ke-lu, DONG Xian-juan, LI Zhen-xi, CAO Chun-xiao. Optimizing approach of materials hot working processes based on dynamic material model[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 890?896.

[4] 鲁世强, 李 鑫, 王克鲁, 董显娟, 李臻熙, 曹春晓. 用于控制材料热加工组织与性能的动态材料模型理论及其应用[J]. 机械工程学报, 2007, 43(8): 77?85.

LU Shi-qiang, LI Xin, WANG Ke-lu, DONG Xian-juan, LI Zhen-xi, CAO Chun-xiao. Dynamic materials model theory and its application for controlling microstructures and properties of hot worked materials[J]. Chinese Journal of Mechanical Engineering, 2007, 43(8): 77?85.

[5] 李 鑫, 鲁世强, 王克鲁, 赵为纲, 李臻熙, 曹春晓. 应用Murty准则优化TC11钛合金高温变形参数[J]. 金属学报, 2007, 43(12): 1268?1274.

LI Xin, LU Shi-qiang, WANG Ke-lu, ZHAO Wei-gang, LI Zhen-xi, CAO Chun-xiao. Optimization of high temperature deformation parameters of titanium alloy TC11 by using Murty criterion[J]. Acta Metallurgica Sinica, 2007, 43(12): 1268?1274.

[6] LI Xiao-li, LI Miao-quan, ZHU Da-song, XIONG Ai-ming. Deformation behavior of TC6 alloy in isothermal forging[J]. Journal of Materials Engineering and Performance, 2005, 14(5): 671?676.

[7] 李淼泉, 李晓丽, 龙 丽, 许广兴, 于 浩, 迟彩楼, 温国华. TA15合金的热变形行为及加工图[J]. 稀有金属材料与工程, 2006, 35(9): 1354?1358.

LI Miao-quan, LI Xiao-li, LONG Li, XU Guang-xing, YU Hao, CHI Cai-lou, WEN Guo-hua. Deformation behavior and processing map of high temperature deformation of TA15 alloy[J]. Rare Metal Materials and Engineering, 2006, 35(9): 1354?1358.

[8] 黄光胜, 汪凌云, 陈 华, 黄光杰, 张所全. 2618铝合金的热变形和加工图[J]. 中国有色金属学报, 2005, 15(5): 763?767.

HUANG Guang-sheng, WANG Ling-yun, CHEN Hua, HUANG Guang-jie, ZHANG Suo-quan. Hot deformation and processing maps of 2618 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 763?767.

[9] MURTY S V S N, RAO B N, KASHYAP B P. Instability criteria for hot deformation of materials[J]. International Materials Reviews, 2000, 45(1): 15?26.

[10] VENUGOPAL V, MANNAN S L, PRASAD Y V R K. Optimization of cold and warm workability in stainless steel type AISI 316L using instability maps[J]. Journal of Nuclear Materials, 1995, 227: 1?10.

[11] MEYERS M A, NESTERENKO V F, LASALVIA J C, XUE Q. Shear localization in dynamic deformation of materials: microstructural evolution and self-organization[J]. Mater Sci Eng A, 2001, 317: 204?225.

[12] XUE Q, MEYERS M A, NESTERENKO V F. Self-organization of shear bands in titanium and Ti-6Al-4V alloy[J]. Acta Materialia, 2002, 50: 575?596.

[13] XUN Y, TAN M J, LIEW K M. EBSD characterization of cavitation during superplastic deformation of Al-Li alloy[J]. Journal of Materials Processing Technology, 2005, 162/163: 429?434.

[14] SEMIATIN S L, SEETHARAMAN V, GHOSH A K, SHELL E B, SIMON M P, FAGIN P N. Cavitation during hot tension testing of Ti-6Al-4V[J]. Mater Sci Eng A, 1998, 256: 92?110.

[15] SESHACHARYULU S, MEDEIROS S C, MORGAN J T, MALAS J C, FRAZIER W G, PRASAD Y V R K. Hot deformation mechanisms in ELI grade Ti-6AI-4V[J]. Scripta Materialia, 1999, 41(3): 283?288.

[16] WEISS I, FROES F H, EYLON D, WELSCH G E. Modification of alpha morphology in Ti-6AI-4V by thermomechanical processing[J]. Metallurgical Transactions A, 1986, 17: 1935?1947.

基金项目:江西省自然科学基金资助项目(2007GQC1575);江西省教育厅科技资助项目(GJJ08203)

收稿日期:2007-11-21;修订日期:2008-04-16

通讯作者:李 鑫,讲师,博士研究生;电话:13879123507;E-mail: lixin572@163.com

(编辑 陈爱华)