电子封装用Al-50%SiC复合材料的组织和性能

来源期刊:中国有色金属学报(英文版)2016年第10期

论文作者:滕飞 余琨 罗杰 房宏杰 史春丽 戴翌龙 熊汉青

文章页码:2647 - 2652

关键词:Al-50%SiC复合材料;粉末冶金;热性能;抗弯强度;电子封装材料

Key words:Al-50%SiC composites; powder metallurgy; thermal properties; flexural strength; electronic packaging material

摘 要:采用粉末冶金法制备体积分数为50%、不同SiC颗粒尺寸(平均尺寸为23、38和75 μm)的Al/SiC复合材料。研究SiC颗粒尺寸和退火对Al/SiC复合材料组织和性能的影响。结果表明,在所得复合材料中,SiC颗粒均匀分布在铝基体中。粗SiC颗粒能提高材料的热膨胀系数和热导率,细SiC颗粒降低材料的热膨胀系数和提高抗弯强度。经过400 °C、6 h退火后,SiC颗粒的尺寸和形态没有发生变化,但材料的热膨胀系数和抗弯强度降低,热导率增大。退火后,SiC颗粒尺寸为75 μm复合材料的热导率为156 W/(m·K),热膨胀系数为11.6×10-6 K-1, 抗弯强度为229 MPa。

Abstract: Al-50%SiC (volume fraction) composites containing different sizes of SiC particles (average sizes of 23, 38 and 75 μm) were prepared by powder metallurgy. The influences of SiC particle sizes and annealing on the properties of the composites were investigated. The results show that SiC particles are distributed uniformly in the Al matrix. The coarse SiC particles result in higher coefficient of thermal expansion (CTE) and higher thermal conductivity (TC), while fine SiC particles decrease CTE and improve flexural strength of the composites. The morphology and size of SiC particles in the composite are not influenced by the annealing treatment at 400 °C for 6 h. However, the CTE and the flexural strength of annealed composites are decreased slightly, and the TC is improved. The TC, CTE and flexural strength of the Al/SiC composite with average SiC particle size of 75 μm are 156 W/(m·K), 11.6×10-6 K-1 and 229 MPa, respectively.

Trans. Nonferrous Met. Soc. China 26(2016) 2647-2652

Fei TENG1,2, Kun YU1,2, Jie LUO1, Hong-jie FANG1, Chun-li SHI1, Yi-long DAI2, Han-qing XIONG2

1. Department of Materials Science and Engineering, Yantai Nanshan University, Yantai 265713, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 30 September 2015; accepted 6 April 2016

Abstract: Al-50%SiC (volume fraction) composites containing different sizes of SiC particles (average sizes of 23, 38 and 75 μm) were prepared by powder metallurgy. The influences of SiC particle sizes and annealing on the properties of the composites were investigated. The results show that SiC particles are distributed uniformly in the Al matrix. The coarse SiC particles result in higher coefficient of thermal expansion (CTE) and higher thermal conductivity (TC), while fine SiC particles decrease CTE and improve flexural strength of the composites. The morphology and size of SiC particles in the composite are not influenced by the annealing treatment at 400 °C for 6 h. However, the CTE and the flexural strength of annealed composites are decreased slightly, and the TC is improved. The TC, CTE and flexural strength of the Al/SiC composite with average SiC particle size of 75 μm are 156 W/(m·K), 11.6×10-6 K-1 and 229 MPa, respectively.

Key words: Al-50%SiC composites; powder metallurgy; thermal properties; flexural strength; electronic packaging material

1 Introduction

Electronic packaging requires effective heat removal and dissipation during the operation of the components to avoid the failure of semiconductor devices [1,2]. However, it is estimated that 30% of the current chip performances are limited by the electronic packaging materials, especially considering the component size reduction and the increase of computing capability [3,4]. The traditional packaging materials, such as W-Cu, Kovar alloys or AlN ceramics, are difficult to meet the requirement of the advanced electronic packaging. The ideal packaging materials should have a coefficient of thermal expansion (CTE) ((7-17)×10-6 K-1) matching that of ceramic substrates or semiconductors to avoid thermally induced stress, high thermal conductivity (TC) (>100 W/(m·K)) to remove heat fast, and good mechanical properties and low density(<3 g/cm3), etc. The SiC/Al composites with high volume fraction of SiC attract considerable interest as potential materials for electronic packaging due to their outstanding properties such as tailored coefficient of thermal expansion (CTE), high thermal conductivity (TC), and low density and excellent mechanical properties (e.g., high specific modulus and high specific strength) [5,6].

There are many manufacturing processes to fabricate the Al/SiC composites, including melt infiltration [5], squeeze casting [7] and powder metallurgy [8,9], etc. In the infiltration and casting process, the molten Al liquid is filled into the pre-produced porous billet. However, the ratio of Al to SiC is difficult to control strictly in such a process, and some closed pores may not be filled with melt Al and remain in the composites. Powder metallurgy is a simple process to produce Al-matrix composite, including blending, molding and sintering. In the powder metallurgy process, the ratio of Al power particles to reinforcement particles is easy to manage strictly, and near-net shape forming is fulfilled to improve the production efficiency. Therefore, powder metallurgy is chosen to produce the SiC/Al composite in the present study. During the past decades, different fabrication methods and material properties of Al matrix composites with SiC particles have been widely studied. SONG [10] studied the effect of volume fraction of SiC particles on mechanical properties of SiC/Al composites by both model simulation and experiment. LI et al [11] worked on thermophysical properties of SiC/Al composites with three-dimensional interpenetrating network structure and it was shown that three-dimensional interpenetrating network structure improved TC and reduced CTE of the composite. MOLINA et al [12] investigated the effect of monomodal and bimodal particle size distribution on thermal conductivity of the Al-SiC composites. YAN et al and LIN [13] and YANG et al [14] studied influence of particle size on CTE of SiC/Al composites and the results showed that the larger the particle size was, the higher the CTEs of the composites were. However, literature dealing with the effect of SiC particle size and annealing on properties of SiC/Al composites is limited.

In the present study, Al-50%SiC composites with different sizes of SiC particles were fabricated by powder metallurgy, and the effects of SiC particle size and annealing on the thermal and mechanical properties, such as CTE, TC and flexural strength, were investigated in order to enhance the thermal and mechanical properties of the Al/SiC composites for electronic packaging application.

2 Experimental

The commercially available SiC powders with a purity of 99.9% and Al powders with a purity of 99.9% as the volume fraction of 1:1 were mixed in a high-speed planetary miller (MTI-SFM1) for 5 h at a rotation speed of 100 r/min. The average sizes of SiC particle were 23, 38, and 75 μm, respectively. The obtained Al/SiC mixtures were cold pressed at 200 MPa, and then sintered in a graphite die with inner walls coated with BN slurry. The sintering temperature, hot pressing pressure, heating rate and holding time were 700-750 °C, 50-55 MPa, 60 °C/min and 15 min, respectively. At last, the sintered specimens were annealed at 400 °C for 6 h.

The microstructures of Al/SiC composite specimens were observed by POLYVAR-MET optical microscope. The densities of the specimens were measured by a method based on Archimedes law and compared with the theoretical density to obtain the relative density. The CTEs of specimens (5 mm × 5 mm × 25 mm) were tested on DIL 457402C thermal analyzer from 25 to 200 °C at a heating rate of 10 °C/min. The thermal diffusion ratio of the specimens (a gauge diameter of 12.5 mm and gauge thickness of 2.5 mm) was measured by LFA 457Micro Flash, and then the TC (λ) was calculated according to the following equation [3]:

λ=αρcp (1)

where α, ρ and cp are thermal diffusion ratio, the specimen density and the specific heat capacity, respectively. The crystal structure was examined by X-ray diffractometer (DMAX-2500X). Three-point flexural strength was measured on a MTS810 test mechanic at room temperature, and the dimensions of the specimens were 3 mm ×10 mm × 60 mm with a span of 40 mm.

3 Results and discussion

3.1 Microstructure

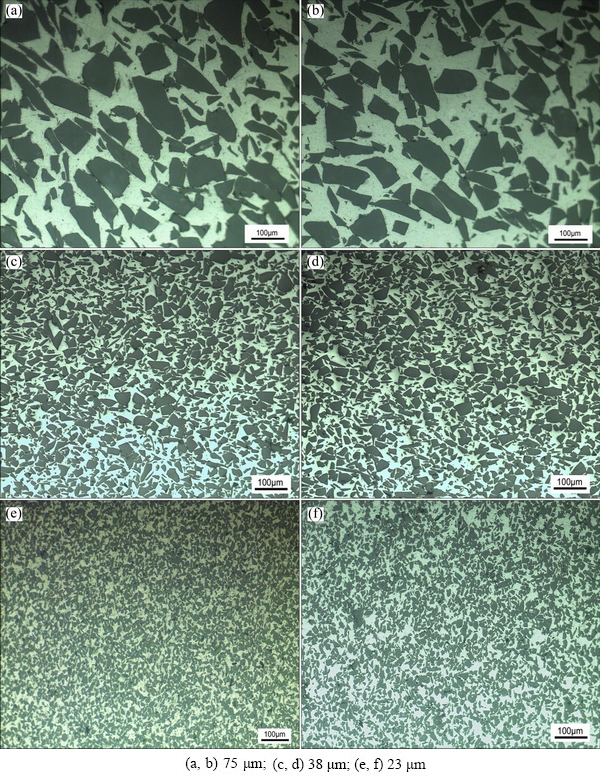

It is well-known that the thermal and mechanical properties of the composites with a high fraction of SiC phase depend much less on the matrix grain sizes, but the properties are mainly determined by the reinforced phases. Figures 1(a), (c) and (e) show the microstructures of the sintered specimens with different average SiC particle sizes of 23, 38 and 75 μm, respectively. It is obvious that the SiC particles are surrounded by the Al matrix and distribute uniformly in the composites, and only a slight SiC particle cluster is observed in Fig. 1(e). Good interfacial bonding between the Al matrix and SiC particles is achieved. As the distribution of the reinforcement particles is one of the significant factors to enhance the properties of the composites, excellent mechanical and thermophysical properties would be expected. As shown in Figs. 1(a), (c) and (e), the pores are scarcely seen in Fig. 1(a), while a few pores exist in Fig. 1(c). Meanwhile, the number of the pores in Fig. 1(e) is more than those in Figs. 1(a) and (c). It is obvious that the porosity in the composites increases with the decrease of SiC particle sizes. The reason is that the gaps between the fine SiC particles are smaller than those between the coarse SiC particles, which makes it more difficult for melt Al to flow into and fill up the gaps during the sintering process. The pores as the defect have a bad effect on the properties of the composites, such as TC, mechanical properties and relative density. As seen in Table 1, the relative densities of the composites with average SiC particle sizes of 23, 38 and 75 μm are 97.1%, 98.6% and 99.1%, respectively. It is clear that the more the pores are, the smaller the relative density is. Figures 1(b), (d) and (f) show the microstructures of the annealed specimens. It is observed that compared with those in the sintered specimens, the shape and size of SiC particles are scarcely changed after annealing. This means that the annealing treatment at 400 °C for 6 h almost has no effect on the shape and size of SiC particles.

Table 1 Density and relative density of Al-50%SiC composites with different sizes of SiC

Fig. 1 Microstructures of sintered (a, c, e) and annealed (b, d, f) Al-50%SiC composites with different sizes of SiC

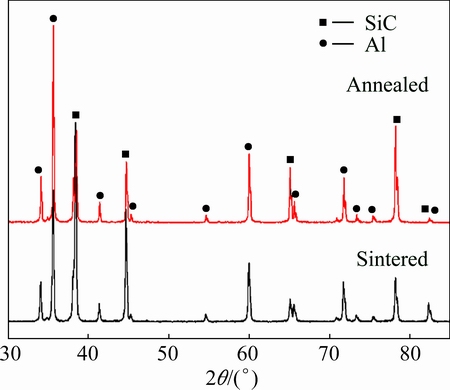

The XRD patterns of the sintered and annealed Al-50%SiC composites are shown in Fig. 2. It is obvious that only the diffraction peaks indexed to Al and SiC phases can be observed, which demonstrates that the composites consist of Al phase and SiC phase without any interaction. In addition, no detectable quantity of impurities, such as alumina, is found in the composites, and any interfacial reactions do not happen during the sintering and annealing processes.

3.2 Coefficient of thermal expansion

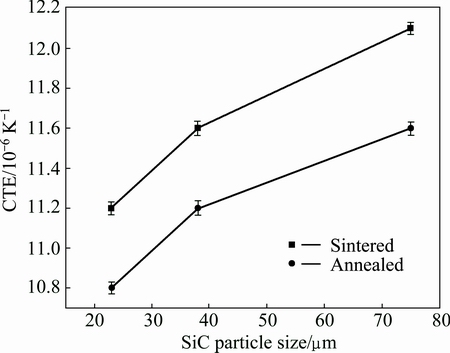

In general, coefficient of thermal expansion (CTE) of metal matrix composites (MMCs) is mainly attributed to the thermal expansion behavior of the matrix and reinforcement, but the pore and interfacial area have a crucial effect on the CTE of the MMCs [15]. In order to study the effects of SiC particle size and annealing on the CTE of Al/SiC composites, the average CTEs from 25 to 200 °C of Al-50%SiC composites with different average sizes of SiC being 23, 38 and 75 μm are shown in Fig. 3, and the CTEs of the sintered composites are 11.2×10-6, 11.6×10-6, and 12.1×10-6 K-1, respectively. It is clearly seen that the CTEs of the composites increase with the increase of SiC particle size. The phenomenon is involved in several reasons. Firstly, when the composites are heated, part of Al expands into the pores, thus limiting the increase of the bulk volume of the composites. In addition, the interface between the matrix and reinforcement can restrict the thermal expansion of the matrix. With the same SiC volume fraction, fine SiC particles have larger total surface area than coarse SiC particles, which results in a more effective restriction of the thermal expansion of the Al matrix [15]. Therefore, the CTE of the composites of fine SiC particles is lower than that of the composites with coarse SiC particles.

Fig. 2 XRD patterns of sintered and annealed Al-50%SiC composites

Fig. 3 CTE of sintered and annealed Al-50%SiC composites versus SiC particle size

It is also seen in Fig. 3 that after annealing, the CTEs of the annealed composites are lower than those of the sintered composites. It is known that due to the mismatch of CTE between Al matrix and SiC particles, the residual stress will be generated in the composites during cooling from the fabrication temperature. The stress in the composites plays the role of helping the plastic strain of the matrix and promoting the thermal expansion [16,17]. During annealing, the residual stress is relaxed gradually, leading to decreasing the CTE of the composites. Therefore, the CTEs of the annealed composites are lower than those of the sintered composites.

3.3 Thermal conductivity

The thermal conductivity (TC) is an important parameter to evaluate the property of electronic packaging materials. It is generally known that thermal conductivity is actually an energy transmission process. In the Al/SiC composites, the Al matrix mainly depends on free electron to transfer heat, and the SiC particle as the non-metal mainly depends on the phonon to transfer heat. When Al and Si particles are combined into one kind of material, phonon and free electron coact to transfer heat [18]. In general, the TC of the composites is mainly controlled by adjusting the volume fraction of the matrix, but the TC is also influenced by the size of reinforcement particles, residual stress, pore, particle distribution, and interface area.

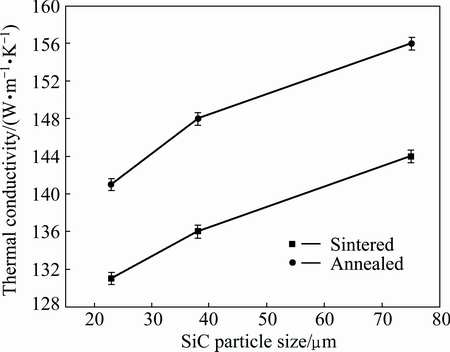

Figure 4 shows the relationship between TC and SiC particle size. It is illustrated obviously that with increase of SiC particle size, the TC of the composites also increases. There are several reasons to explain the phenomenon. Firstly, compared with the specimens with coarse SiC particles, the specimens with fine SiC particles have more pores and lower relative density. The pores as a kind of defect have a scattering effect on phonon and free electron motions, resulting in reducing the TC of the composites. In addition, the fine SiC particles have larger total surface area than the coarse SiC particles in the Al/SiC composites, and the interface also has a scattering effect on phonon and free electron motions, which is regarded as the interfacial thermal barrier resistance. Large interface area can enhance the influence on interfacial thermal barrier resistance. At last, it is well known that it is easy for the finer particles to cluster. As shown in Figs. 1(e) and (f), a slight cluster can be observed, and the discontinuous net distribution of Al matrix is formed. The continuous net distribution of Al matrix is helpful to reduce the interface area, and the heat can be transferred fluently through the network. It was confirmed that the interface area in the continuous net structure of the Al matrix is smaller than that in the discontinuous structure of the Al matrix [19]. In short, the continuous net structure of Al matrix possesses a small interface area, which decreases the heat scattering probability to obtain a high TC.

It is found in Fig. 4 that the annealing has a good effect on the TC of the composites. It is observed obviously that the TC of the annealed composites is improved, and the TC of annealed specimens with SiC particles of average size 75 μm is 156 W/(m·K) and increases by 8% compared with that of sintered specimens with the same size of SiC particles. This is because residual stress as thermal barrier resistance is generated in the sintered composites in air-cooling process. After annealing, the residual stress is relaxed, which eliminates the thermal barrier resistance. Thus, the annealing can improve the TC of the composites.

Fig. 4 TC of sintered and annealed Al-50%SiC composites versus SiC particle size

3.4 Flexural strength

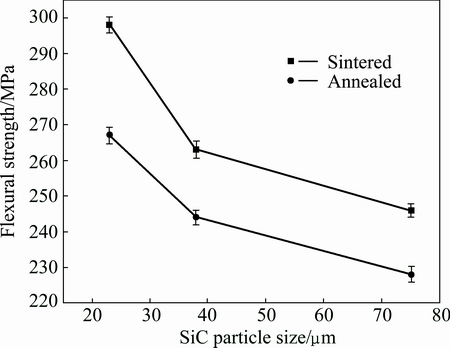

Apart from fine thermophysical properties, good mechanical properties are also critical to support and protect the chips for thermal management application. The relationship between flexural strength and SiC particle size is shown in Fig. 5. It is seen that with the increase of SiC particle size, the flexural strength of the Al/SiC composites decreases. In general, the flexural strength is connected with the reinforcement particle distribution, particle size, volume fraction and porosity. The fine SiC particles uniformly distributing in the Al matrix can make the movement of dislocation difficult, thus the Al matrix is reinforced. In addition, SiC particle size can affect the distribution of inner stress in the composites. The larger the SiC particle size is, the more serious the stress concentration is. Thus, the cleavage fracture occurs preferentially in coarse SiC particles. In addition, coarse SiC particles have larger surface area than a fine SiC particles. The larger the particle surface area is, the more the pre-set defects on the surface or inner of SiC particle are, which are suitable sites for the microcrack formation and propagation, leading to the decrease of the flexural strength of the composites. Lastly, the gap between the fine particles is smaller than that of the coarse particles, which can improve the force to wind second-phase particles for the dislocation. Therefore, the composites with fine SiC particles possess higher flexural strength than those with coarse SiC particles.

Figure 5 shows that after annealing, the flexural strength of the sintered specimens declines. The reason for the phenomenon is that due to the large difference in CTE between SiC particles and Al matrix, the residual tensile stress is generated in air-cooling process, which makes the Al matrix reinforced and improves the flexural strength of the composites. However, annealing treatment can make the residual tensile stress relaxed effectively, thus reducing the flexural strength of the materials.

Fig. 5 Flexural strength of sintered and annealed Al-50%SiC composites versus SiC particle size

4 Conclusions

1) In the Al-50%SiC composites with different sizes of SiC particles (average sizes of 23, 38 and 75 μm) were prepared by the powder metallurgy. The SiC particles distribute uniformly in the Al matrix, and relative densities are 97.1%, 98.6% and 99.1%, respectively.

2) Al/SiC composites with coarse SiC particles can obtain higher thermal conductivity, higher coefficient of thermal expansion and higher relative density than the composites with fine SiC particles. On the contrary, fine SiC particles can lower the coefficient of thermal expansion and enhance the flexural strength of the Al/SiC composites effectively.

3) The annealing treatment has certain influences on the coefficient of thermal expansion, thermal conductivity and flexural strength of the Al/SiC composites. Because of the relaxation of residual tensile stress, annealed Al/SiC composites possess higher thermal conductivity, lower coefficient of thermal expansion and lower flexural strength than the sintered Al/SiC composites.

References

[1] YU Kun, LI Shao-jun, CHEN Li-san, ZHAO Wei-shang, LI Peng-fei. Microstructure characterization and thermal properties of hypereutectic Si-Al alloy for electronic packaging applications [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1412-1417.

[2] WANG Kai-kun, KANG Yong-lin, SONG Pu-guang, XU Feng, LI Xian-hui. Preparation of SiCp/A356 electronic packaging materials and its thixo-forging [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 988-992.

[3] YU J H, WANG C B, SHEN Q, ZHANG L M. Preparation and properties of Si/Al composites by spark plasma sintering [J]. Materials and Design, 2012, 41: 198-202.

[4] CHIEN C W, LEE S L, LIN JC, JAHN M T. Processing and properties of high volume fraction aluminum/silicon composites [J]. Materials Science and Technology 2003, 19(9): 1231-1234.

[5] ZHU Xiao-min, YU Jia-kang, WANG Xin-yu. Microstructure and properties of Al/Si/SiC composites for electronic packaging [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1686-1692.

[6] ZHU Meng-jian, LI Shun, ZHAO Xun, XIONG De-gan. Laser-weldable Sip–SiCp/Al hybrid composites with bilayer structure for electronic packaging [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1032-1038.

[7] LEE H S, HONG S H. Pressure infiltration casting process and thermophysical properties of high volume fraction SiCp metal matrix composites [J]. Materials Science and Technology, 2003, 19(8): 1057-1064.

[8] FATHY A, SADOUN A, ABDELHAMEED M. Effect of matrix/reinforcement particle size ratio (PSR) on the mechanical properties of extruded Al-SiC composites [J]. The International Journal of Advanced Manufacturing Technology, 2014, 73(5-8): 1049-1056.

[9] NI Zeng-lei, WANG Ai-qin, XIE Jing-pei, FANG Ming. Effect of SiCp volume fraction on the microstructure and performance of SiCp/Al-30Si composite [J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(1): 78-82. (in Chinese)

[10] SONG Min. Effects of volume fraction of SiC particles on mechanical properties of SiC/A1 composites [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1400-1404.

[11] LI Shun, XIONG De-gan, LIU Meng, BAI Shu-xin, ZHAO Xun. Thermophysical properties of SiC/Al composites with three dimensional interpenetrating network structure [J]. Ceramics International, 2014, 40(5): 7539-7544.

[12] MOLINA J M, NARCISO J, WEBER L, MORTENSEN A. Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution [J]. Materials Science and Engineering A, 2008, 480(1-2): 483-488.

[13] YAN Yi-wu, LIN Geng. Effects of particle size on the thermal expansion behavior of SiCp/Al composites [J]. Journal of Materials Science, 2007, 42(15): 6433-6438.

[14] YANG Mei-jun, ZHANG Dong-ming, GU Xiao-feng, ZHANG Lian-meng. Effects of SiC particle size on CTEs of SiCp/Al composites by pulsed electric current sintering [J]. Materials Chemistry and Physics, 2006, 99(1): 170-173.

[15] PARK C, KIM C, KIM M, LEE C. The effect of particle size and volume fraction of the reinforced phases on the linear thermal expansion in the Al-Si-SiCp system [J]. Materials Chemistry and Physics, 2004, 88(1): 46-52.

[16] SHEN Y L, NEEDLEMAN A. Thermal expansion of metal-ceramic composites: A three-dimensional analysis [J]. Materials Science and Engineering A, 1998, 252(2): 269-275.

[17] ELOMARI S. Thermal expansion behavior of particulate metal-matrix composites [J]. Composites Science and Technology, 1998, 58(3): 369-376.

[18] REN Shu-bin, QU Xuan-hui, GUO Jia, HE Xin-bo, QIN Ming-li, SHEN Xiao-yu. Net-shape forming and properties of high volume fraction SiCp/Al composites [J]. Journal of Alloys and Compounds, 2009, 484(1-2): 256-262.

[19] LIN Jun-pin, ZHANG Yong, CHEN Guo-liang. Microstructure and properties of Skeleton reinforced composites [J]. Journal of Materials Engineer, 2000, 6: 20-21.

滕 飞1,2,余 琨1,2,罗 杰1,房宏杰1,史春丽1,戴翌龙2,熊汉青2

1. 烟台南山学院 材料科学与工程学院,烟台 265713;

2. 中南大学 材料科学与工程学院,长沙 410083

摘 要:采用粉末冶金法制备体积分数为50%、不同SiC颗粒尺寸(平均尺寸为23、38和75 μm)的Al/SiC复合材料。研究SiC颗粒尺寸和退火对Al/SiC复合材料组织和性能的影响。结果表明,在所得复合材料中,SiC颗粒均匀分布在铝基体中。粗SiC颗粒能提高材料的热膨胀系数和热导率,细SiC颗粒降低材料的热膨胀系数和提高抗弯强度。经过400 °C、6 h退火后,SiC颗粒的尺寸和形态没有发生变化,但材料的热膨胀系数和抗弯强度降低,热导率增大。退火后,SiC颗粒尺寸为75 μm复合材料的热导率为156 W/(m·K),热膨胀系数为11.6×10-6 K-1, 抗弯强度为229 MPa。

关键词:Al-50%SiC复合材料;粉末冶金;热性能;抗弯强度;电子封装材料

(Edited by Wei-ping CHEN)

Foundation item: Project support by the 2015 Shandong Province Project for Outstanding Subject Talent Group, China

Corresponding author: Kun YU; Tel: +86-731-88879341; Fax: +86-731-88876692; E-mail: yukun2010@csu.edu.cn

DOI: 10.1016/S1003-6326(16)64358-3