文章编号:1004-0609(2010)S1-s0104-03

热加工工艺对BTi-6431S钛合金厚板组织与性能的影响

杨 伟1,王 俭1,王红武1,董震键1,王小翔1, 2,王韦琪1, 2

(1. 宝钛集团有限公司,宝鸡 721014;2. 宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:研究两种热加工工艺对BTi-6431S高温钛合金厚板显微组织和力学性能的影响。结果表明,(α+β)轧制的厚板组织类型为类似于等轴的两相区加工组织,β轧制的该合金厚板的显微组织为典型的细片状魏氏组织,该组织厚板的室温和高温强度明显高于α+β轧制厚板的,而塑性稍低;该合金厚板在650 ℃时具有较高的高温瞬时强度,可用于宇航工业650 ℃短时用结构件的制作。

关键词:BTi-6431S钛合金;厚板;高温强度;显微组织

中图分类号:TG 146.2+3 文献标志码:A

Effect of hot working process on microstructure and properties of BTi-6431S titanium alloy plate

YANG Wei 1, WANG Jian1, WANG Hong-wu1, DONG Zhen-jian1, WANG Xiao-xiang1, 2, WANG Wei-qi1,2

(1. Baoti Group Co., Ltd., Baoji 721014, China; 2. Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The effects of two hot working processes on microstructure and properties of BTi-6431S high temperature titanium alloy plate were studied. The results show that the microstructure of plate in α+β rolling is similar to equiaxed two-phase working microstructure, and the microstructure in β rolling is typical fine lamellar Widmannstaetten structure. The strengths in β rolling at room temperature and high temperature are obviously higher than those in α+β rolling, while the ductility of plate in β rolling is slightly lower. The plates have higher high-temperature transient strength at 650 ℃ and can be used to make short time structure components at 650 ℃ for aerospace industry.

Key words: BTi-6431S titanium alloy; plate; high-temperature strength; microstructure

我国自主研制开发的BTi-6431S钛合金名义成分为Ti-6.5Al-3Sn-3Zr-3Nb-3Mo-1W-0.2Si。它是一种使用温度在650~700 ℃的短时高温钛合金,其主要的强化机制是通过α稳定元素Al和β相的固溶强化。加入中性元素Zr和Sn以及β相稳定元素Nb、Mo和W,以改善工艺性能。该合金的名义Al当量为8.9,Mo当量为4.6,合金类型属高铝当量的马氏体型两相钛合金,具有良好的热强性和可焊性,并具有较好的加工塑性和工艺塑性。与BT18Y钛合金相比,BTi-6431S钛合金中Al当量不变,但提高了高熔点元素Mo含量和Nb含量,同时还增加了1%的W,相对提高了3.6%的Mo当量,通过增加高熔点元素来提高Mo当量,因此,提高了合金的高温强度,同时也改善了合金的加工塑性和工艺塑性。本文作者探讨了热加工工艺对BTi-6431S钛合金厚板组织与性能的影响,通过分析比较不同热工艺下厚板的室温和高温(650 ℃)性能及组织特征,为该合金的批量化生产提供一定的理论基础和工艺制订参考。

1 实验

本实验选用经2次真空自耗电弧熔炼的BTi-6431S钛合金d110 mm铸锭,除Zr元素采用纯金属加入外,高熔点元素W、Mo、Nb和低熔点元素等均采用中间合金形式加入,这保证了铸锭的高质量。

该合金的相转变温度为990~1 000 ℃。铸锭在1 180 ℃开坯锻造,最终在两相区制备成板坯,板坯为α+β两相区加工组织。板坯分别采用β和α+β两种加热温度轧制成20 mm厚的板材。

为比较热加工工艺对组织性能的影响,分别对两种工艺下的R态板材取样测试其室温拉伸,高温拉伸,650 ℃持久和蠕变性能。金相试样从R态板材上切取,腐蚀液为HNO3、HF和H2O的混合液,显微组织在Axiovert200MAT光学显微镜上观察。

2 结果与分析

2.1 两种轧制工艺厚板的显微组织

BTi-6431S钛合金的Mo当量为4.6,属高铝当量的马氏体型两相钛合金,两种轧制工艺下厚板显微组织如图1所示。从图1可以看出,板材经(α+β)相区温度成品轧制后,其组织为典型的α+β转变组织,初生α呈条状和等轴状形貌。β轧制工艺下,板材组织为细片层的魏氏组织,有不连续的晶界α,为典型的β加工组织[1]。

图1 不同轧制工艺BTi-6431S厚板的显微组织

Fig.1 Microstructures of BTi-6431S alloy plate under different rolling processes: (a) Rolling at (α+β) temperature; (b) β rolling

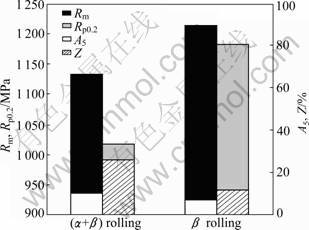

2.2 两种轧制工艺厚板的室温力学性能

两种轧制工艺厚板的室温力学性能如图2所示。从图2可以看出,板材经(α+β)相区温度轧制后,其室温抗拉强度(Rm)在1 140 MPa左右,屈服强度(Rp0.2)在1 020 MPa左右,伸长率(Z)约10%,断面收缩率(A5)约26%;β轧制厚板的室温抗拉强度在1 220 MPa左右,屈服强度在1 080 MPa左右,伸长率约为6.5%,断面收缩率约为12%。相比较而言,β轧制厚板的室温强度高于(α+β)轧制厚板的,但其塑性明显降低。这也符合两种工艺厚板显微组织对室温力学性能的影响规律,即魏氏组织与等轴组织相比较,其室温强度相对较高,但室温塑性较低[2]。

图2 不同轧制工艺BTi-6431S厚板的室温力学性能

Fig.2 Mechanical properties of BTi-6431S alloy plate under different rolling processes at room temperature

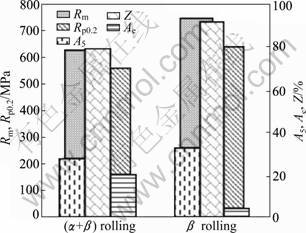

2.3 两种轧制工艺厚板的高温力学性能

图3所示为两种轧制工艺厚板650 ℃高温力学性能的比较。从图3可以看出,板材经(α+β)相区温度轧制后,其650 ℃高温抗拉强度在620 MPa左右,屈服强度在560 MPa左右,伸长率约28%,断面收缩率约80%;β轧制厚板的650 ℃高温抗拉强度在750 MPa左右,屈服强度在650 MPa左右,伸长率约32%,断面收缩率约90%。相比较而言,β轧制厚板的650温强度高于(α+β)轧制厚板的,其高温塑性也相对较高。

测试两种工艺下厚板在650 ℃和500 MPa持续30 min的短时蠕变性能,(α+β)轧制厚板的塑性伸长率为20%左右,β轧制厚板的塑性伸长率为3%~4%。可以看出,(α+β)轧制厚板的塑性伸长率明显大于β轧制厚板的,这与两种工艺厚板的显微组织特征一致。(α+β)轧制厚板的显微组织为α+β转变组织,初生α多数呈等轴状,少量为长条状,并有部分次生α;β轧制厚板的显微组织为片层状。根据相关文献[3],对于近α或α+β钛合金,通过在β转变温度以上进行热处理或加工可提高蠕变强度,冷却后,形成片层α组织;相反地,当在α+β两相区进行热加工及热处理时将形成由片状次生α(β转变组织)和球状初生α(等轴α)所组成的双态混合组织,导致蠕变阻力下降。因此,本研究结果与该文献中所研究的规律是一致的。

图3 不同轧制工艺BTi-6431S厚板高温(650 ℃)力学性能

Fig.3 Mechanical properties of BTi-6431S alloy plate under different rolling process on high temperature

3 结论

1) 对于BTi-6431S钛合金厚板,(α+β)相区温度成品轧制后,其组织为典型的α+β转变组织,β轧制工艺下,板材组织为细片层的魏氏组织,这种组织板材室温和高温(650 ℃)强度高、高温塑性好。

2) BTi-6431S钛合金具有较好的综合性能,尤其在650 ℃时,具有较高的高温强度和短时蠕变性能,是一种新型的宇航用短时高温钛合金。

REFERENCES

[1] 王金友, 葛志明, 周彦邦. 航空用钛合金[M]. 上海: 上海科学技术出版社, 1985: 115.

WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Aeronautical titanium alloys [M]. Shanghai: Shanghai Sciences and Technology Press, 1985: 115.

[2] 张 均, 李 冬. 高温钛合金中的α2相[M]. 沈阳: 东北大学出版社, 2002: 174.

ZHANG Jun, LI Dong. α2 ordered phase in high temperature titanium alloys [M]. Shenyang: Northeast University Press, 2002: 174.

[3] LEYENS C, PETERS M. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 27.

LEYENS C, PETERS M. Titanium and titanium alloys [M]. CHEN Zhen-hua transl. Beijing: Chemical Industry Press, 2005: 27.

(编辑 何学锋)

通信作者:杨 伟; 电话: 0917-3382481; E-mail: yyww1126@163.com