热压烧结镍钛合金的微观结构与力学性能

李婧,杨海林,阮建明,节云峰

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用真空热压烧结技术,分别以NiTi预合金粉末和Ni,Ti纯元素混合粉末制备等摩尔比的NiTi形状记忆合金(SMA)。利用X线衍射仪、金相显微镜、扫描电子显微镜及电子万能试验机对其物相组成,显微结构及力学性能进行分析。研究结果表明:在1 100 ℃和25 MPa真空热压条件下,可制备出近全致密且组织及性能优良的镍钛合金,其中预合金粉末和元素混合粉末所制备样品的相对密度分别可达到99.64%和98.03%,并且预合金粉末样品比元素混合粉末样品具有更均一的组织和更好的力学性能。

关键词:镍钛合金;真空热压;相对密度;微观组织

中图分类号:TG139.6 文献标志码:A 文章编号:1672-7207(2012)05-1678-06

Microstructure and mechanical properties of nickel-titanium alloy by vacuum hot-pressing sintering

LI Jing, YANG Hai-lin, RUAN Jian-ming, JIE Yun-feng

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A procedure for producing equiatomic high-density NiTi shape memory alloy (SMA) from pre-alloyed NiTi powders and the mixture of elemental Ni and Ti powders by vacuum hot pressing sintering was described, respectively. Phase composition, microstructure and mechanical properties of such a procedure were discussed by XRD, metallurgical microscope, SEM and electronic universal testing machine. The results show that at 1 100 ℃ and 25 MPa, nearly full density and homogeneous TiNi microstructures are produced. The relative density values of NiTi from pre-alloyed powders and mixture powders are 99.64% and 98.03%, respectively. Specimens, produced from pre-alloyed powders, are more homogeneous and have better mechanical properties.

Key words: nitinol; vacuum hot pressing; relative density; microstructure

NiTi合金是目前性能最为优越和应用最为广泛的形状记忆合金[1]。近等摩尔比的NiTi合金不仅具有独特的形状记忆性能和超弹性,在高阻尼、消振动、抗疲劳、耐磨性等方面亦有其他材料所不可比拟的优越性能[2],除此以外还兼具优良的生物化学相容性及生物惰性,因而在航空航天(如战斗机上使用的形状记忆管接头)、智能机械[3](如机械手、微型机器人)、生物医学[4-6](如骨组织替代、牙根管、血管扩张支架)以及娱乐器械(如网球拍、钓鱼线、玩具)等各个领域均有广泛且可观的应用前景。目前制备致密NiTi形状记忆合金最为常见的方法是熔炼法,但传统的熔炼方法合金成分难以精确控制,Ti和Ni的密度差异使其极易产生偏析,且熔炼过程中的坩埚严重影响样品的纯度,降低其性能和形状记忆效果[7]。加之熔炼方法的成本高、材料利用率很低,一般仅为40%左右,严重限制了该合金的应用潜力[8]。Otubo等[9]利用电子光束溶解法与真空感应熔炼(VIM)相结合,使碳杂质含量降低到普通VIM的40%,但仍未能很好的解决杂质氧的问题。近些年,为解决熔炼方法的缺陷,粉末冶金烧结技术在制备镍钛合金中迅速发展,目前较为常见的有常规粉末冶金方法(CS)[10-11]、自蔓延高温合成法(SHS)[12]和热等静压法[13],它们不仅大大提高了材料的可成形性和利用价值,还使得制备出的NiTi合金依然保持了良好的力学性能、形状记忆性能和生物相容性。但这些粉末冶金方法现主要集中在制备多孔镍钛合金方面,对于近致密镍钛材料的研究很少。本文作者采用真空热压方法制备出的镍钛合金材料实现了高致密度(98%以上)、组织均一且力学性能优良的特性,同时探讨了不同原料粉末对烧结样品的致密度、微观组织和形貌以及力学性能的影响。

1 实验

实验分别以NiTi预合金粉末和Ni,Ti纯元素混合粉末为原料,粉末的具体性能参数如表1所示。高纯Ti粉和Ni粉以1:1的摩尔比配制,经滚筒式球磨机均匀混合,球料比为4:1(质量比),转速200 r/min,混料4 h后进行真空热压。热压参数为:压力25 MPa,温度1 100 ℃,并保温3 h。

表1 原始Ti粉、Ni粉及NiTi预合金粉的性能

Table 1 Properties of Ti powder, Ni powder and NiTi pre-alloyed powder

采用X线衍射仪(Rigaku-3014型)对烧结样品相组成进行分析,金相显微镜(JSM-6360LV)对样品相的形貌和孔的分布情况进行观测,扫描电子显微镜(JSM-5200)对样品断面形貌及微观结构进行分析。利用电子万能试验机(CMT-7205)检测样品的力学性能。

利用密度仪测定烧结样品的实际密度。根据相对密度公式[14]计算样品烧结后的相对密度。

(1)

(1)

其中:d为相对密度;ρ为实际密度; 为理论密度。

为理论密度。

2 结果与讨论

2.1 物相组成

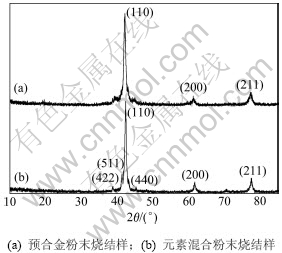

对2种粉末烧结后材料的相组成进行XRD分析,结果如图1所示。对其衍射峰的标定结果表明:合金粉末样品与元素混合粉末样品在2θ为42.48°,61.64°,77.73°附近处有3个明显的衍射峰,分别对应于立方晶系NiTi(B2相)(PDF卡65-4572)的(110)、(200)和(211)晶面,各个衍射峰的强度也与衍射图谱相符得很好。除此以外,在混合粉末样品的图谱中还可以明显观测到含有少量次生的Ti2Ni相(PDF卡18-0898)。这说明2种粉末烧结后的合金其主要组织均由奥氏体NiTi相(B2) 组成,而在混合粉末样中含有少量Ti2Ni相。衍射谱上并未发现明显的Ti,Ni和其他杂质相的衍射峰,因此在经过1 100 ℃,25 MPa真空热压烧结后,合金粉末与元素混合粉末均完成了合金化的转变,且未生成其他杂质相。对于混合粉而言,合金的生成依赖于Ni粉与Ti粉之间的反应程度,镍原子的扩散速率要大于钛原子的扩散速率,在反应的过程中质量传输的不平衡会使部分区域钛的含量要大于镍的含量,形成了富钛区,因而在冷却的过程中造成了少量Ti2Ni次生相的析出(NiTi→NiTi+Ti2Ni)[15]。

此外,从图1还可以明显看出:合金粉末样的衍射峰比起混合粉末样的衍射峰略微宽化,这是由于混合粉末样是由元素混合粉发生化学反应形成的,形成的NiTi相的衍射峰比较尖锐,而合金粉末样的形成过程是通过粉末间单纯的固相扩散来完成的,产生了严重的晶格畸变,晶格常数变化,故发生了衍射峰的宽化现象。

图1 粉末烧结后的XRD谱

Fig.1 XRD patterns of sintered specimens

2.2 密度与显微组织

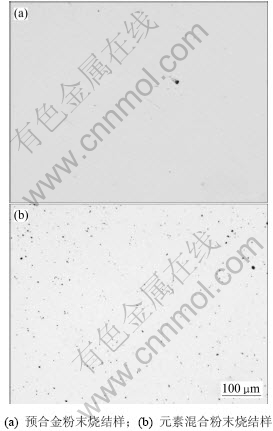

图2所示为2种粉末烧结后未经过腐蚀的金相照片。从图2(a)中可以看出合金粉末样仅有极少孔隙分布,而图2(b)中混合粉末样的孔隙较多,且孔隙在样品中弥散均匀分布。

图2 烧结后样品的金相照片

Fig.2 Micrographs of sintered specimens

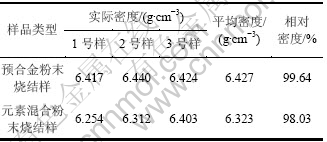

利用阿基米德原理测定烧结后样品的实际密度,表2对比了2种粉末烧结后的密度与相对密度,合金粉末样与混合粉末样的平均密度分别为6.427 g/cm3和6.323 g/cm3(致密态NiTi合金的理论密度为6.45 g/cm3),相对密度分别为99.64%和98.03%。

无论是金相图还是所测实际密度均表明,合金粉末样致密度要高于混合粉末样致密度。这是因为在烧结过程中,合金粉末样仅发生了简单的物理反应,通过粉末颗粒间的互扩散形成烧结颈,最终达到致密化;而混合的Ni粉与Ti粉之间除物理反应外,更重要的是发生了化学反应,使单纯的Ni粉与Ti粉形成NiTi合金。烧结过程中可能发生的反应如下[16]:

Ni+Ti→TiNi+67 kJ/mol (1)

Ni+Ti→Ti2Ni+83 kJ/mol (2)

表2 粉末烧结后的密度与相对密度

Table 2 Density and relative density of sintered specimens

Ni与Ti的反应是典型的放热反应,在其相互溶解与合成的过程中伴随着较强烈的放热反应,终而形成NiTi金属间化合物,这使得烧结体在反应过程中体积膨胀,在内部产生了较多的孔隙。

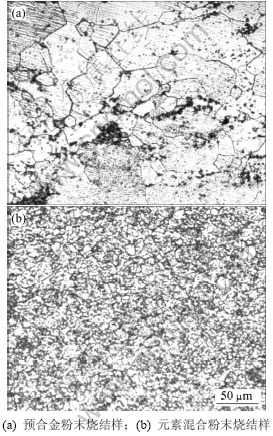

图3所示为2种粉末烧结样品腐蚀后的金相照片。从图3(a)中可以明显看出:在同样放大倍数下,合金粉末样的晶粒比较明显,晶粒尺寸从十几微米到几十微米。高倍数观测下,可在局部区域看到清晰的马氏体结构相,其相结构如图4所示。而图3(b)混合粉末样的晶粒非常细密。在同等的能量状态下,合金粉末中的大部分能量用于颗粒间的扩散和晶粒长大,且合金粉末颗粒与颗粒间的成分又比较均一,晶粒长大的阻力就相对较小。而混合粉末中能量除了提供粉末间的互扩散与晶粒长大,还要用于启动钛粉与镍粉间发生反应及维持反应的继续进行。而且钛粉与杂质元素的亲和力很强,这些元素易在已形成的晶粒边界富 集,这样就阻止了晶粒的进一步长大,造成了晶粒的细密化。

图3 腐蚀后烧结样品的金相照片

Fig.3 Micrographs of sintered specimens after etching

图4 预合金粉末烧结样中马氏体组织的形貌

Fig.4 Micrographs of Martensite in pre-alloyed powder sintered specimens

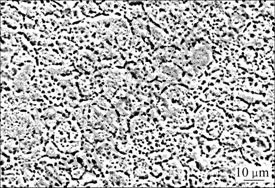

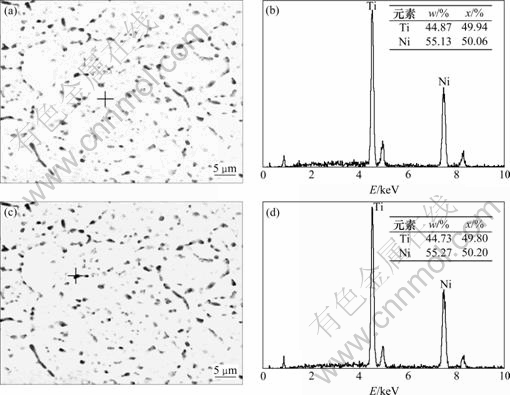

混合粉末样由于晶粒太细小,在常规的金相显微镜下无法观测到其中是否存在马氏体。增加放大倍数后,可发现其基体上弥散了许多孔洞,形貌如图5所示。对图中亮色与暗色的微区部位进行EDS分析,这2种区域的成分均为Ni与Ti摩尔比1:1的NiTi相,其结果如图6所示。分析认为,孔洞部分可能为Ti2Ni相。Ti2Ni相多呈球状或多边形状,是孔蚀的择优位 置[15]。经腐蚀液腐蚀后,Ti2Ni优先被腐蚀,而NiTi相保留。在腐蚀前样品的照片中,并未观察到此类形貌,同时XRD谱中也验证了在混合粉末样品中确实有Ti2Ni的存在。

2.3 力学性能

2.3.1 拉伸性能测试

材料的力学性能对孔的分布、数量及结构非常敏感,预合金化技术可以显著提高粉末冶金产品的力学性能。表3比较了2种粉末烧结试样的拉伸试验性能数据,从表3可以明显看出:合金粉末样的力学性能优于混合粉末样的力学性能,合金粉末样不仅保证了较高的强度同时还保持了较好的韧性。合金粉末样的相组织单一,样品致密化程度好,极少的孔隙也呈现了球形形貌。而混合粉末样虽然晶粒细小,但由于其中孔隙较多,孔隙弥散分布在样品的各个地方,再加之有Ti2Ni软质相的存在,这两者均为严重的缺陷源,明显影响了该样品的力学性能,造成其强度和韧性都显著下降。

图5 元素混合粉末烧结样腐蚀后的SEM像

Fig.5 SEM image of mixed powder sintered specimens after etching

图6 元素混合粉末烧结样腐蚀后BES像与相应区域的EDS谱

Fig.6 BES images and EDS patterns of mixed powder sintered specimens after etching

表3 烧结后样品的力学性能

Table 3 Mechanical properties of sintered specimens

2.3.2 断口分析

从断裂过程的表现来看,镍钛合金的断裂方式属于典型的脆性断裂。但从断口的宏观形貌来看,试样并不单纯的表现为一般脆性材料断裂时的比较齐平光亮的断面,而呈现放射状或结晶状的现象,在局部存在类似塑性断裂时出现的韧窝现象。从图7的断口SEM像中可以观测到7(a)中合金样断面呈现出典型的河流状解理面,其中还可观测到少量的韧窝;而7(b)中混合样断面为典型的沿晶断裂。从图8的SEM像中可以明显看出单独的晶粒。从断面也可以看出在力学性能上合金粉末样较混合粉末样呈现出相对比较好的塑性。镍钛合金粉末烧结后样品的性能很大程度上取决于粉末的原有性能和烧结的状况,而混合粉末样的性能大部分取决于Ti粉与Ni粉的化合反应,反应的是否完全和单一直接影响了烧结后样品的性能。

图7 合金粉末样和混合粉末样断口的SEM像

Fig.7 SEM images of fracture surface for pre-alloyed powder sintered specimen and mixed powder sintered specimen

图8 元素混合粉末烧结样断面的SEM像

Fig.8 SEM image of fracture surface of mixed powder sintered specimen

3 结论

(1) 真空热压烧结可制备出近全致密的NiTi合金,合金粉末样和混合粉末样的相对密度可分别达到99.64%和98.03%,其中合金粉末制备的NiTi合金可以得到更高致密度。

(2) 混合粉末烧结后的合金晶粒尺寸细小,而合金粉末制备的合金相组织更为均一、力学性能更优。

参考文献:

[1] Otsuka K, Ren X. Physical metallurgy of Ti-Ni-based shape memory alloys[J]. Progress in Materials Science, 2005, 50(5): 511-678.

[2] 尹燕, 罗志强, 徐仰涛, 等. 真空电弧重熔NiTi形状记忆合金[J]. 有色金属, 2009, 61(3): 6-9.

YIN Yan, LUO Zhi-qiang, XU Yang-tao, et al. Vacuum arc remelting NiTi shape memory alloy[J]. Nonferrous Metals, 2009, 61(3): 6-9.

[3] 杨凯, 辜承林. 形状记忆合金电机的研究与应用[J]. 微特电机, 2001(6): 16-19, 25.

YANG Kai, GU Cheng-lin. Some new progress on the research and application of the shape memory alloy actuator[J]. Small & Special Electrical Machines, 2001(6): 16-19, 25.

[4] Xiong J Y, Li Y C, Wang X J, et al. Titanium–nickel shape memory alloy foams for bone tissue engineering[J]. Mechanical Behavior of Biomedical Materials, 2008, 1(3): 269-273.

[5] Gustavo D D, Paulo G F. Influence of the NiTi rotary system on the debridement quality of the root canal space[J]. Oral Surgery, Oral Medicine, Oral Pathology, Oral Radiology, and Endodontology, 2009, 108(4): 71-76.

[6] LIU Xiang-mei, WU Shui-lin, Yeung K W K, et al. Relationship between osseointegration and super elastic biomechanics in porous NiTi scaffolds[J]. Biomaterials, 2011, 32: 330-338.

[7] Hey J C, Jardine A P. Shape memory TiNi synthesis from elemental powders[J]. Materials Science and Engineering, 1994, A188: 291-297.

[8] 廖政, 林建国, 马蓦. 钛镍多孔材料的制备及其显微组织与形状记忆性能[J]. 稀有金属材料与工程, 2010, 39(4): 642-646.

LIAO Zheng, LIN Jian-guo, MA Mo. Preparation of porous NiTi alloy and its microstructure and shape memory properties[J]. Rare Metal Materials and Engineering, 2010, 39(4): 642-646.

[9] Otubo J, Rigo O D, Moura Neto C, et al. The effects of vacuum induction melting and electron beam melting techniques on the purity of NiTi shape memory alloys[J]. Materials Science and Engineering A, 2006, 438/439/440: 679-682.

[10] Aydo?mus T, Bor S. Processing of porous TiNi alloys using magnesium as space holder[J]. Journal of Alloys and Compounds, 2009, 478: 705-710.

[11] Hosseini S A, Sadrnezhaad S K, Ekrami A. Phase transformation behavior of porous NiTi alloy fabricated by powder metallurgical method[J]. Materials Science and Engineering C, 2009, 29: 2203-2207.

[12] Wisutmethangoon S, Denmud N, Sikong L. Characteristics and compressive properties of porous NiTi alloy synthesized by SHS technique[J]. Materials Science and Engineering A, 2009, 515: 93-97.

[13] McNeese M D, Lagoudas D C, Pollock T C. Processing of TiNi from elemental powders by hot isostatic pressing[J]. Materials Science and Engineering A, 2000, 280: 334-348.

[14] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1997: 132.

HUANG Pei-yun. Power metallurgy theory[M]. Beijing: Metallurgical Intustry Press, 1997: 132.

[15] 郑玉峰, 赵连城. 生物医用镍钛合金[M]. 北京: 科学出版社, 2004: 25-26.

ZHENG Yu-feng, ZHAO Lian-cheng. Biomedical nitinol[M]. Beijing: Science Press, 2004: 25-26.

[16] LI Bing-yun, RONG Li-jian, LI Yi-yi. Stress-strain behavior of porous Ni-Ti shape memory intermetallics synthesized from powder sintering[J]. Intermetallics, 2000, 8(5/6): 643-646.

(编辑 杨幼平)

收稿日期:2011-04-28;修回日期:2011-08-11

基金项目:国家自然科学基金资助项目(50774096);中南大学中央高校基本科研业务费专项资金资助项目(2011QNT046);中国博士后基金资助项目(2011年);中南大学博士后基金资助项目(2011年)

通信作者:阮建明(1956-),男,河北霸州人,教授,博士生导师,从事生物材料及难熔金属材料的研究;电话:0731-88876644;E-mail: jianming@csu.edu.cn