文章编号:1004-0609(2012)09-2492-08

AZ31镁合金板材低温双向反复弯曲及退火下的织构弱化

霍庆欢1,杨续跃1, 2,马继军1,孙 欢1,王 军1,郭俊成1,秦 佳1

(1. 中南大学 材料科学与工程学院,长沙410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙410083)

摘 要:对AZ31镁合金热轧板材在423 K进行6道次双向反复弯曲变形,随后在523 K退火1 000 s,利用光学显微镜和电子背散射衍射(EBSD)技术研究该工艺过程中组织及织构的演变规律。结果表明:孪生是主要变形机制;在523 K退火1 000 s后,边部组织已经完全静态再结晶,晶粒明显细化,而中部组织仅发生晶粒长大,最终形成两边晶粒细小、中间晶粒粗大的双向梯度组织。退火态样品内部织构得到弱化,从板材几何中心处至两表面,织构强度逐渐降低,沿板厚方向呈不严格的对称梯度分布;靠近板材上表面区域织构发生弱化和随机化,靠近板材下表面区域晶粒取向集中在取向因子为0.5的方向,而板材几何中心处仅部分晶粒取向发生偏转,取向因子呈双峰分布。

关键词:镁合金;双向反复弯曲;孪晶;晶粒细化;织构弱化

中图分类号:TG 146.2 文献标志码:A

Texture weakening of AZ31 Mg alloy sheet under

bidirectional cyclic bending at low temperature and subsequent annealing

HUO Qing-huan1, YANG Xu-yue1, 2, MA Ji-jun1, SUN Huan1, WANG Jun1, GUO Jun-cheng1, QIN Jia1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The microstructure and texture evolution in the sheets of AZ31 Mg alloy was studied by bidirectional cyclic bending for 6 passes at 423 K followed by annealing at 523 K for 1 000 s. The deformed and subsequent annealed microstructures were investigated by optical microscopy and EBSD techniques. The results show that twinning is the main deformation mechanism. After annealing at 523 K for 1 000 s, the grains near the surfaces have full recrystallization. Thus, they are obviously refined. But the grains in the middle of the sheet just grow up. Finally, a gradient structure with fine grains in the regions near the surfaces and, in contrast, the coarse grains in the center of the sheet are induced. The texture in the annealed sample is weakened. The texture intensity decreases gradually from the center of the sheet to the surfaces, and has a relaxed gradient distribution along the thickness direction. The texture of the regions near the upper surface is weakened and randomized. Near the lower surface, the crystal orientation focuses on the direction that Schmid factor is 0.5. However, only a few grains tilt in the center of the sheet, in which the Schmid factor has a bimodal distribution.

Key words: magnesium alloy; bidirectional cyclic bending; twin; grain refinement; texture weakening

基金项目:国家重点基础研究发展计划资助项目(2013CB632204);国家自然科学基金资助项目(51071182)

收稿日期:2011-08-02;修订日期:2012-01-09

通信作者:杨续跃,教授,博士;电话:0731-88879195;E-mail: yangxuyue@mail.csu.edu.cn

镁合金板材因其密度低、比强度高、加工性能优良和零件尺寸稳定等优点,在航空、航天、汽车和家电等领域具有良好的应用前景[1-3],但较差的低温塑性严重影响了其发展及应用[4]。镁合金板材塑性差的原因主要有两个方面:一是大多数镁合金均为HCP结构,低温时只能启动有限的滑移系,难以满足von Mises准则;二是镁合金板材的内部晶粒基面通常平行于板面,使其具有很强的基面织构[4-6],这种织构很难通过普通变形或退火工艺来减轻或消除[7-8],后续塑性变形困难。而热变形虽可以增加滑移系,使晶粒取向发生偏转,但并未明显弱化织构,且动态再结晶产生的新晶粒极易长大[7-9]。因此,弱化镁合金板材织构对提高其塑性及二次成形能力具有重要理论意义和实际生产价值。

目前,已有多种调控镁合金板材织构的工艺,WATANABE等[10]通过573~473 K的降温异步轧制使基面织构发生倾转,板材伸长率提高至473 K下同步轧制的1.5倍。CHENG等[11]利用等径角轧制使AZ31镁合金板材的晶粒取向发生偏转,开动了非基面滑移系。CHINO等[12]对AZ31镁合金板材进行交叉轧制 后,(0002)织构向TD方向偏转10°左右,伸长率得到大幅提高。但是,这些工艺均仅使基面织构发生偏转,并未使织构强度明显下降。

作为镁合金低温变形时的主要机制之一,孪生会引起晶粒取向突变,继续退火可产生再结晶织构,进而改变初始织构,将原始基面织构弱化[13-15];同时,累积大量的孪生变形,可使孪晶相互交叉,分割细化原始晶粒,并利于再结晶的发生[14-15];织构弱化与晶粒细化将共同提高板材延性。

TAKAYAMA等[16]的研究表明,利用多个相互交错的轧辊对Al-4.7%Mg-0.7%Mn(质量分数)板材进行连续弯曲变形,可制备出累积应变量和晶粒度沿板厚方向均呈对称梯度分布的组织。文献[17-18]研究表明:室温下单向反复弯曲变形及退火处理可引起镁合金板材基面织构偏转以弱化基面织构,而中高温下变形反而会强化基面织构。为此,本文作者利用低温下双向反复弯曲AZ31镁合金板材所累积的大量孪生变形及再结晶退火的协调作用,产生双向对称梯度组织,弱化板材基面织构,改善板材低温塑性,并通过光学显微镜和电子背散射衍射(EBSD)技术研究该工艺过程中的组织及织构的演变规律。

1 实验

实验采用的材料为AZ31镁合金热轧板材,其化学成分(质量分数,%)如下:Al 3.1,Mn 0.48,Zn 0.88,Si 0.01,Fe 0.002 7,Cu 0.001 5,Ni 0.000 5,Mg 余量;板厚为1.6 mm。样品在723 K均匀化退火30 min后空冷,得到平均晶粒尺寸约为46 μm的等轴晶组织。

样品在423 K沿RD方向循环进行弯曲—平直—反向弯曲—平直的双向反复弯曲变形,每次弯曲并平直后称为1个变形道次,并将首次弯曲时的凸面和凹面分别定义为上表面和下表面。弯曲凸、凹模呈V字形,其夹角为120°,尖端导圆弧半径为8 mm,上、下表面的理论道次应变量由式(1)计算[19]:

(1)

(1)

式中:R为弯曲半径;t为板厚。将板厚t=1.6 mm代入式(1)即可计算板材上、下表面的道次变形量约为0.2。当炉温调至变形温度时,将模具和样品放入炉内静置5 min,然后进行变形,达6个道次后,将样品取出并水淬。随后将炉温升至523 K,将待退火的样品放入炉内,1 000 s后取出空冷。

将变形态和退火态样品的侧面(RD-ND面)依次进行研磨、机械抛光和电解抛光,样品于2.1 g苦味酸+ 35 mL乙醇 + 5 mL醋酸 + 5 mL蒸馏水的混合溶液中进行侵蚀后,在OLYMPUS TH 4-100光学显微镜下进行组织观察。由于变形集中在模具尖端导圆弧处,离开导圆弧的部分可能不变形,因此,选取变形区的中间部位进行组织观察,且沿板厚方向分别对紧靠上表面、板厚方向几何中心处、紧靠下表面共3个区域进行观察,并依次定义为板材的上部、中部和下部。EBSD试样经机械抛光后,在硝酸、丙三醇和无水乙醇体积比为1:3:6的混合溶液中进行电解抛光,电压为10 V,电解时间在10 s以内,然后直接采用Sirion 200型场发射扫描电镜上装配的美国TSL公司生产的OIM/EBSD附件和软件进行微观结构及取向变化测试和分析。

2 结果

2.1 光学组织演化

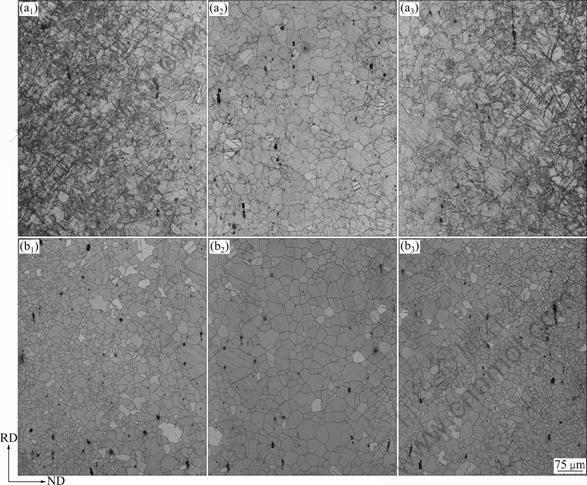

图1(a1)~(a3)所示分别为初始样品在423 K变形6个道次后,板材上、中和下部的光学组织。可以看到,变形态样品上、下部的组织形貌极为相似。越靠近板材表面,线条状的压缩孪晶数量越多,孪晶交叉现象越显著,晶粒被分割细化越剧烈;而中部仅有少量孪晶产生,孪晶交叉现象不明显。可见,AZ31镁合金板材在423 K双向反复弯曲变形时,孪生为主要变形机制,且边部组织所产生的大量孪晶相互交叉,分割细化了原始晶粒;孪晶数量和密度沿板材ND方向呈对称梯度分布,边部密度高,中部密度低。

图1 变形态和退火态样品上、中和下部的光学组织

Fig. 1 Microstructures of top ((a1), (b1)), middle ((a2), (b2)) and bottom ((a3), (b3)) parts of AZ31 Mg alloy sheets after deformation ((a1), (a2), (a3)) and annealing ((b1), (b2), (b3)) (ND is normal direction, RD is rolling direction)

图1(b1)~(b3)所示为变形态样品在523 K退火 1 000 s后的光学组织。可以看出,退火1 000 s后,样品上、下部均已完全静态再结晶,孪晶几乎全部消失,靠近上、下表面的晶粒被急剧细化,且再结晶新晶粒呈等轴状均匀分布;而中部组织仅孪晶有所减少,晶粒发生长大。在靠近上、下表面已完全再结晶区域和中部之间,仍各有一层未再结晶或再结晶不完全的区域,但其孪晶数量和密度已较退火前大为下降。可见,双向反复弯曲变形使得上、下部累积大量的孪晶和储能,有利于再结晶,而中部由于累积的变形量和孪晶较少,再结晶驱动力不足,无明显的再结晶现象,只发生晶粒长大,最终形成两边晶粒细小、中间晶粒粗大的双向梯度组织。

2.2 EBSD分析结果

对初始态及退火态样品的侧面(即RD-ND面)进行EBSD分析,选取A、B、C、D和E 5个区域进行观察,依次表示靠近板材上表面、上表面与板材几何中心处的中间位置、几何中心处、下表面与板材几何中心处的中间位置和靠近下表面的组织。为便于明确样品织构等数据的变化信息,以下分析中涉及到的RD、TD和ND方向均表示板材实际的方向。

图2所示为初始及退火态样品A~E区的EBSD取向图。其中,色彩标记方向为RD方向,{0001}基面与轧制方向垂直的晶粒用红色表示(见网站电子版), 或

或 面与轧制方向垂直(即{0001}面和轧制方向平行)的晶粒分别用蓝色和绿色表示。可以看到,原始组织中几乎所有晶粒的

面与轧制方向垂直(即{0001}面和轧制方向平行)的晶粒分别用蓝色和绿色表示。可以看到,原始组织中几乎所有晶粒的 或

或 面均垂直于RD方向,且晶粒较大。而退火组织的A、B、D和E区的晶粒已明显细化,蓝色和绿色晶粒减少,红色晶粒增多,表明部分晶粒的取向相对于变形前发生了近90°的突变,且A和E区的晶粒细化和取向偏转程度较B和D区更为显著。C区基本保持变形态组织,晶粒细化效果不明显,仍有孪晶存在于大晶粒中或贯穿于晶粒间,但也出现了少量桃红色和紫色晶粒,说明C区部分晶粒发生了取向偏转。可见,经变形及退火后,越靠近样品表面的区域,晶粒细化效果越好,取向偏转程度越大,基面偏转至垂直于RD方向的晶粒所占比例也越高。

面均垂直于RD方向,且晶粒较大。而退火组织的A、B、D和E区的晶粒已明显细化,蓝色和绿色晶粒减少,红色晶粒增多,表明部分晶粒的取向相对于变形前发生了近90°的突变,且A和E区的晶粒细化和取向偏转程度较B和D区更为显著。C区基本保持变形态组织,晶粒细化效果不明显,仍有孪晶存在于大晶粒中或贯穿于晶粒间,但也出现了少量桃红色和紫色晶粒,说明C区部分晶粒发生了取向偏转。可见,经变形及退火后,越靠近样品表面的区域,晶粒细化效果越好,取向偏转程度越大,基面偏转至垂直于RD方向的晶粒所占比例也越高。

图2 初始样品及退火态样品A~E区的EBSD取向图

Fig. 2 EBSD-orientation maps of as-received sample (a) and A (b), B (c), C (d), D (e) and E (f) regions of annealed sample (Red grains―{0001}^RD; Blue grains― ^RD; Green grains―

^RD; Green grains― ^RD, available online)

^RD, available online)

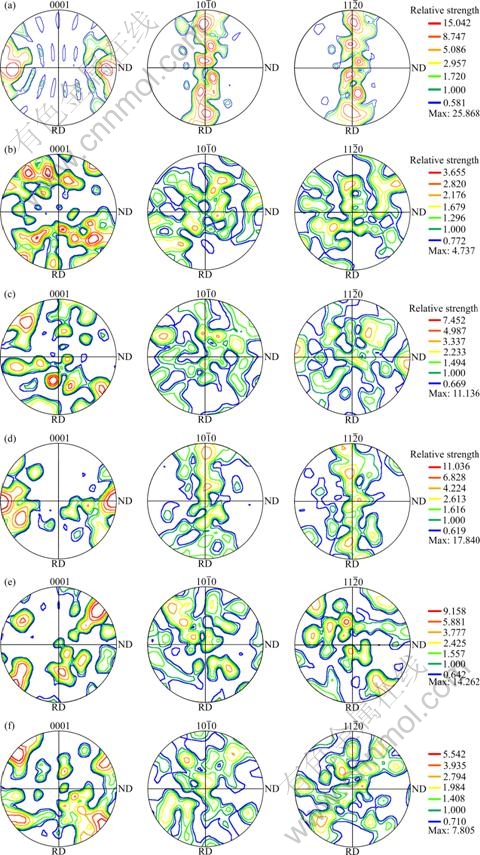

图3所示为初始及退火态样品A~E区的{0001}、 和

和 极图。从图3(a)可以看到,初始样品具有很强的基面织构,晶粒的基面严格分布在ND方向上,其最大相对强度达25.868。经变形及退火后,A区的织构最大强度仅为4.737,{0001}极图的等高线峰值点也由两处变为多处,且分布较为杂乱,ND方向上的峰值点消失,说明初始织构被消除和随机化,且形成的新织构强度较弱。B区的{0001}极图强度峰主要位于从RD方向向ND方向偏转45°的位置上,织构最大强度为11.136,在ND方向附近仍有强度高达3以上的峰值,织构弱化程度明显弱于A区的。C区织构与变形前相似,{0001}极图的强度峰严格集中在ND方向上,但其最大强度下降到了17.840,这可能是由变形过程中少量孪生引起的。D区织构变化与B区的相似,其最大强度为14.262,略高于B区的。E区织构变化与A区的不同,其{0001}极图的峰值主要有4个,分布在由RD方向向ND方向偏转45°的两个呈十字交叉的方向上,说明E区的织构变化主要为晶粒取向发生偏转,而非随机化;其最大强度下降到7.805,弱化效果不如A区的。可见,样品在变形及退火后,内部织构得到弱化,并以A区(靠近板材上表面的区域)的弱化程度为最大,板材中间位置的织构强度虽然有所下降,但仍显著高于靠近表面的区域;织构强度沿板厚方向呈不严格的对称梯度分布,两边织构较弱,中间织构较强。退火后,靠近样品表面区域不仅晶粒细化,而且织构也明显弱化,有利于样品延性的提高。

极图。从图3(a)可以看到,初始样品具有很强的基面织构,晶粒的基面严格分布在ND方向上,其最大相对强度达25.868。经变形及退火后,A区的织构最大强度仅为4.737,{0001}极图的等高线峰值点也由两处变为多处,且分布较为杂乱,ND方向上的峰值点消失,说明初始织构被消除和随机化,且形成的新织构强度较弱。B区的{0001}极图强度峰主要位于从RD方向向ND方向偏转45°的位置上,织构最大强度为11.136,在ND方向附近仍有强度高达3以上的峰值,织构弱化程度明显弱于A区的。C区织构与变形前相似,{0001}极图的强度峰严格集中在ND方向上,但其最大强度下降到了17.840,这可能是由变形过程中少量孪生引起的。D区织构变化与B区的相似,其最大强度为14.262,略高于B区的。E区织构变化与A区的不同,其{0001}极图的峰值主要有4个,分布在由RD方向向ND方向偏转45°的两个呈十字交叉的方向上,说明E区的织构变化主要为晶粒取向发生偏转,而非随机化;其最大强度下降到7.805,弱化效果不如A区的。可见,样品在变形及退火后,内部织构得到弱化,并以A区(靠近板材上表面的区域)的弱化程度为最大,板材中间位置的织构强度虽然有所下降,但仍显著高于靠近表面的区域;织构强度沿板厚方向呈不严格的对称梯度分布,两边织构较弱,中间织构较强。退火后,靠近样品表面区域不仅晶粒细化,而且织构也明显弱化,有利于样品延性的提高。

图3 初始样品及退火态样品A~E区的{0001}、 和

和 极图

极图

Fig. 3 {0001},  and

and  pole figures of as-received sample (a) and A (b), B (c), C (d), D (e) and E (f) regions of annealed sample (ND showing actual normal direction of sheet, RD showing actual rolling direction of sheet)

pole figures of as-received sample (a) and A (b), B (c), C (d), D (e) and E (f) regions of annealed sample (ND showing actual normal direction of sheet, RD showing actual rolling direction of sheet)

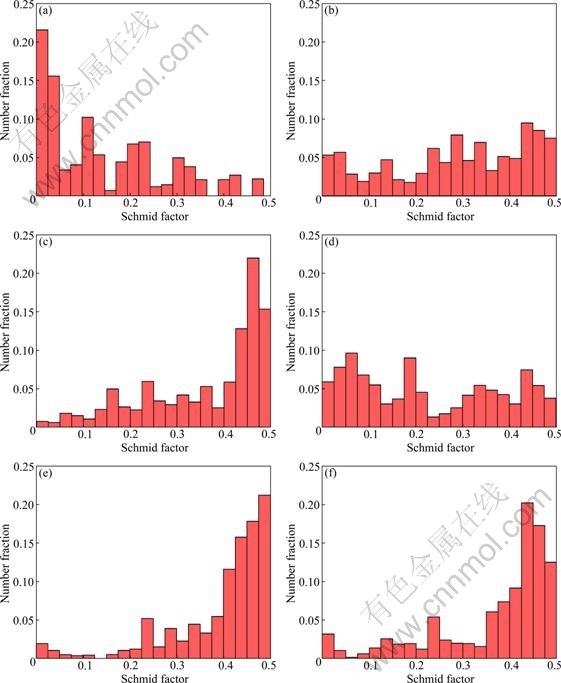

图4所示为初始及退火态样品A~E区的{0001} á ?基面滑移系在RD方向的Schmid因子分布图。可以看到,初始样品的取向因子集中在小于0.1的区域,处于硬取向,滑移系难以启动。在变形及退火后,A区取向因子小于0.1的晶粒比例迅速下降,大于0.4的晶粒比例上升,表明A区部分晶粒已转动至有利于后续变形的取向;A区取向因子在各处的分布很接近,说明A区的初始织构被随机化。而B、D和E 3区域取向因子大于0.4的晶粒比例相对于A区的则显著上升,达20%以上,并在取向因子为0.5附近形成一个最大的峰值,表明这些区域大部分晶粒的基面滑移系均易开动,且织构变化主要为取向突变,而非随机化。

?基面滑移系在RD方向的Schmid因子分布图。可以看到,初始样品的取向因子集中在小于0.1的区域,处于硬取向,滑移系难以启动。在变形及退火后,A区取向因子小于0.1的晶粒比例迅速下降,大于0.4的晶粒比例上升,表明A区部分晶粒已转动至有利于后续变形的取向;A区取向因子在各处的分布很接近,说明A区的初始织构被随机化。而B、D和E 3区域取向因子大于0.4的晶粒比例相对于A区的则显著上升,达20%以上,并在取向因子为0.5附近形成一个最大的峰值,表明这些区域大部分晶粒的基面滑移系均易开动,且织构变化主要为取向突变,而非随机化。

图4 初始样品及退火态样品A~E区的{0001}á ?基面滑移系在RD方向的Schmid因子分布图

?基面滑移系在RD方向的Schmid因子分布图

Fig. 4 {0001}á ? basal slip system’s Schmid factor distribution maps of as-received sample (a) and A (b), B (c), C (d), D (e) and E (f) regions of annealed sample in RD

? basal slip system’s Schmid factor distribution maps of as-received sample (a) and A (b), B (c), C (d), D (e) and E (f) regions of annealed sample in RD

C区的取向因子呈双峰分布,分别在0.1以下和0.5附近形成峰值,表明C区只有部分晶粒的取向突变至取向因子为0.5的方位,而很大一部分晶粒仍处于硬取向,不利于滑移系的开动。当对初始样品进行双向反复弯曲变形及退火再结晶处理,使晶粒偏转至取向因子为0.5附近的方向,有利于沿RD方向变形时,即可开动更多的滑移系,并在一定程度上抑制压缩孪晶的产生。鉴于压缩孪晶是一种常见的镁合金断裂源,样品经该形变热处理后,将提高镁合金板材的低温延性,并避免迅速的失稳断裂。

3 讨论

初始样品变形6个道次后,上、下部承受了循环的拉、压应力,累积了大量的压缩孪晶和拉伸孪晶,呈现不同类型及不同方向的孪晶相互交叉并分割细化原始晶粒的形貌(见图1(a))。在静态再结晶过程中,新晶粒主要在压缩孪晶内部、压缩孪晶与拉伸孪晶交叉处及拉伸孪晶变体交叉处形成。这是由于压缩孪晶引起的形变极不均匀,其内部与周围易发生剧烈的组织和取向变化,成为有效的再结晶形核点[14]。相反,拉伸孪晶界面易于迁移,伴随的形变较均匀,很难积累应变能,无法有效促进再结晶形核。但是,随着变形道次的增加,拉伸孪晶不断累积,并与其变体及压缩孪晶交叉,在一定程度上可促进再结晶。同时,伴随上、下部累积应变量的增加而产生的二次孪晶[20]与初始孪晶也会相互交叉,故储能高且孪晶数量多的上、下部再结晶现象显著,而累积应变量及孪晶密度低的中部则不明显,退火后晶粒发生长大。可见,孪生变形及随后的再结晶退火可协调细化晶粒,这可能使镁合金在室温下发生晶界滑动,导致晶粒取向发生变化,进而弱化织构[13]。

镁合金板材内部的{0001}基面织构使得晶粒的c轴平行于ND方向,故首次弯曲时上表面(即凸面) 沿RD方向受拉应力作用,相当于沿晶粒c轴压缩,有利于 压缩孪晶的产生;下表面(即凹面) 受压应力作用,相当于沿晶粒c轴拉伸,有利于

压缩孪晶的产生;下表面(即凹面) 受压应力作用,相当于沿晶粒c轴拉伸,有利于 拉伸孪晶的产生[20-21]。由于塑性变形的起始阶段不易产生压缩孪晶,而拉伸孪晶极易产生,并可起到释放局部应力集中、协调相邻晶粒间应变不协调性的作用[22],因此,拉伸孪晶体积分数从上表面至下表面逐渐增 大,在产生大量拉伸孪晶的E区组织中,晶粒倾转至有利取向,并在后续变形过程中,逐渐偏转至取向因子为0.5的方向;而对于产生各类孪晶皆较少的A区组织,晶粒偏转程度较小,仅在后续变形过程中,产生大量的压缩孪晶、拉伸孪晶以及拉伸孪晶变体,因拉、压孪晶交叉处形变复杂,故形成的新晶粒取向混乱[14-15];B和D两区域产生的拉伸孪晶较A区的多,织构变化与E区的相似。因此,A区织构表现为晶粒取向随机化,而B、D和E 3区域则表现为强度降低,取向因子在0.5处形成峰值。对于C区,因累积的孪生变形较少,仅引起部分晶粒倾转至有利取向,取向因子呈双峰分布,织构弱化程度小。经6道次变形后,越靠近表面的区域,累积的孪晶越多,孪晶交叉引起晶粒取向突变的程度越大,织构强度下降越明显;再结晶退火后,织构基本保持变形态样品的分布情 况[13],即两边织构弱、中间织构强。

拉伸孪晶的产生[20-21]。由于塑性变形的起始阶段不易产生压缩孪晶,而拉伸孪晶极易产生,并可起到释放局部应力集中、协调相邻晶粒间应变不协调性的作用[22],因此,拉伸孪晶体积分数从上表面至下表面逐渐增 大,在产生大量拉伸孪晶的E区组织中,晶粒倾转至有利取向,并在后续变形过程中,逐渐偏转至取向因子为0.5的方向;而对于产生各类孪晶皆较少的A区组织,晶粒偏转程度较小,仅在后续变形过程中,产生大量的压缩孪晶、拉伸孪晶以及拉伸孪晶变体,因拉、压孪晶交叉处形变复杂,故形成的新晶粒取向混乱[14-15];B和D两区域产生的拉伸孪晶较A区的多,织构变化与E区的相似。因此,A区织构表现为晶粒取向随机化,而B、D和E 3区域则表现为强度降低,取向因子在0.5处形成峰值。对于C区,因累积的孪生变形较少,仅引起部分晶粒倾转至有利取向,取向因子呈双峰分布,织构弱化程度小。经6道次变形后,越靠近表面的区域,累积的孪晶越多,孪晶交叉引起晶粒取向突变的程度越大,织构强度下降越明显;再结晶退火后,织构基本保持变形态样品的分布情 况[13],即两边织构弱、中间织构强。

4 结论

1) AZ31镁合金板材在423 K双向反复弯曲时,孪生为主要变形机制。在523 K退火1 000 s后,边部组织已经完全静态再结晶,晶粒明显细化,而中部组织只发生晶粒长大,最终形成两边晶粒细小、中间晶粒粗大的双向梯度组织。

2) 初始样品经低温双向反复弯曲及再结晶退火协调作用后,内部织构得到弱化,并以靠近板材上表面的区域弱化效果为最佳;从板材几何中心处至两表面,织构强度逐渐降低,沿板厚方向呈不严格的对称梯度分布。

3) 退火后,靠近板材上表面的区域织构发生弱化和随机化,靠近板材下表面的区域晶粒取向集中在取向因子为0.5的方向,而板材几何中心处仅部分晶粒取向发生偏转,取向因子呈双峰分布。

REFERENCES

[1] 曾荣昌, 柯 伟, 徐永波, 韩恩厚, 朱自勇. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei, XU Yong-bo, HAN En-hou, ZHU Zi-yong. Recent development and application of magnesium alloys [J]. Acta Metallurgica Sinica, 2001, 37(7): 673-685.

[2] KOJIMA Y. Platform science and technology for advanced magnesium alloy [J]. Materials Science Forum, 2000, 350/351(3): 3-12.

[3] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 278-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Study, development and application of wrought magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 278-288.

[4] MACKENZIE L W F, PEKGULERYUZ M O. The recrystallization and texture of magnesium-zinc-cerium alloys [J]. Scripta Materialia, 2008, 59(6): 665-668.

[5] YI S B, DAVIES C H J, BROKMEIER H G, BOLMARO R E, KAINER K U, HOMEYER J. Deformation and texture evolution in AZ31 magnesium alloy during uniaxial loading [J]. Acta Materialia, 2006, 54(1): 549-562.

[6] YANG Q, GHOSH A K. Deformation behavior of ultrafine-grain (UFG) AZ31B Mg alloy at room temperature [J]. Acta Materialia, 2006, 54(19): 5159-5170.

[7] YANG Xu-yue, MIURA H, SAKAI T. Recrystallization behaviour of fine-grained magnesium alloy after hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1139-1142.

[8] YANG Xu-yue, ZHU Ya-kun, MIURA H, SAKAI T. Static recrystallization behaviour of hot-deformed magnesium alloy AZ31 during isothermal annealing [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1269-1274.

[9] 杨续跃, 张 雷, 姜育培, 朱亚坤. Mg-Y及AZ31镁合金高温变形过程中微观织构的演化[J]. 中国有色金属学报, 2011, 21(2): 269-275.

YANG Xu-yue, ZHANG Lei, JIANG Yu-pei, ZHU Ya-kun. Microtexture evolution in Mg-Y and AZ31 Mg alloy during hot deformation [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 269-275.

[10] WATANABE H, MUKAI T, ISHIKAWA K. Effect of temperature of differential speed rolling on room temperature mechanical properties and texture in an AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2007, 182(2): 644-647.

[11] CHENG Y Q, CHEN Z H, XIA W J, ZHOU T. Effect of channel clearance on crystal orientation development in AZ31 magnesium alloy sheet produced by equal channel angular rolling [J]. Journal of Materials Processing Technology, 2007, 184(4): 97-101.

[12] CHINO Y, SASSA K, KAMIYA A, MABUCHI M. Enhanced formability at elevated temperature of a cross-rolled magnesium alloy sheet [J]. Materials Science and Engineering A, 2006, 441(1/2): 349-356.

[13] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 321-340.

CHEN Zhen-hua. Wrought magnesium alloy [M]. Beijing: Chemical Industry Press, 2005: 321-340.

[14] 李 萧, 杨 平, 孟 利, 崔凤娥. AZ31镁合金中拉伸孪晶静态再结晶的分析[J]. 金属学报, 2010, 46(2): 147-154.

LI Xiao, YANG Ping, MENG Li, CUI Feng-e. Analysis of the static recrystallization at tension twins in AZ31 magnesium alloy [J]. Acta Metallurgica Sinica, 2010, 46(2): 147-154.

[15] LI X, YANG P, WANG L N, MENG L, CUI F E. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31 [J]. Materials Science and Engineering A, 2009, 517(1/2): 160-169.

[16] TAKAYAMA Y, SZPUNAR J A, JEONG H T. Cube texture development in an Al-Mg-Mn alloy sheet worked by continuous cyclic bending [J]. Materials Transactions, 2001, 42(10): 2050-2058.

[17] HUANG Guang-sheng, SONG Bo, XU Wei, ZHANG Lei. Structure and properties of AZ31B magnesium alloy sheets processed by repeatedly unidirectional bending at different temperatures [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(10): 1815-1821.

[18] HUANG G S, XU W, HUANG G J, LI H C, SONG B. Textural evolution of AZ31B magnesium alloy sheets undergoing repeated unidirectional bending at room temperature [J]. Journal of Materials Science and Technology, 2009, 25(3): 365-369.

[19] ZRNIK J, DOBATKIN S V, MAMUZI? I. Processing of metals by severe plastic deformation (SPD)—Structure and mechanical properties respond [J]. Metalurgija, 2008, 47(3): 211-216.

[20] 杨续跃, 张 雷. 镁合金温变形过程中的孪生及孪晶交叉[J]. 金属学报, 2009, 45(11): 1303-1308.

YANG Xu-yue, ZHANG Lei. Twinning and twin intersection in AZ31 Mg alloy during warm deformation [J]. Acta Metallurgica Sinica, 2009, 45(11): 1303-1308.

[21] 刘 庆. 镁合金塑性变形机理研究进展[J]. 金属学报, 2010, 46(11): 1458-1472.

LIU Qing. Research progress on plastic deformation mechanism of Mg alloys [J]. Acta Metallurgica Sinica, 2010, 46(11): 1458-1472.

[22] SONG B, HUANG G S, LI H C, ZHANG L, HUANG G J, PAN F S. Texture evolution and mechanical properties of AZ31B magnesium alloy sheets processed by repeated unidirectional bending [J]. Journal of Alloys and Compounds, 2010, 489(1): 475-481.

(编辑 陈卫萍)