工艺参数对挤压铸造成形AlSi7Mg铝合金构件组织与性能的影响

来源期刊:中国有色金属学报2021年第3期

论文作者:姜巨福 王迎 肖冠菲 邓腾 刘英泽 张颖

文章页码:531 - 546

关键词:AlSi7Mg铝合金;挤压铸造; 微观组织; 力学性能

Key words:AlSi7Mg aluminum alloy; squeeze casting; microstructure; mechanical properties

摘 要:借助重力铸造和挤压铸造技术分别成形了AlSi7Mg铝合金模拟构件,利用拉伸试验机、金相显微镜和扫描电镜等手段研究了工艺参数对成形件组织与性能的影响规律。结果表明:与重力铸件相比,挤压铸造件的抗拉强度、伸长率和屈服强度分别提高了41%、562%和0.5%,挤压铸造件的平均晶粒尺寸随着浇注温度、模具温度和保压时间的增加呈现出先减小后增大的趋势。最佳挤压铸造工艺参数范围为浇注温度700~720 ℃、模具温度200~250 ℃、保压15~30 s,在该工艺条件下最好的综合力学性能为抗拉强度221 MPa、屈服强度121.5 MPa和伸长率7.6%。Si、Fe、Mn、Mg等元素在晶界处发生偏析,对挤压铸造成形件的力学性能会产生不利影响。

Abstract: AlSi7Mg aluminum alloy components were formed by gravity casting and squeeze casting. Influences of process parameters on microstructure and mechanical properties of formed parts were investigated by tensile test, optical microscopy and scanning electron microscopy. The results show that the yield strength, ultimate tensile strength and elongation of parts formed by squeeze casting increase by 41%, 562% and 0.5%, respectively, comparing with those of parts formed by gravity casting. The average grain size of parts formed by squeeze casting decreases and then increases with increases of pouring temperature, die temperature and dwell time. The optimal process parameters obtained in this research involve the pouring temperature range from 700 ℃ to 720 ℃, die temperature range from 200 ℃ to 250 ℃ and dwell times from 15 s to 30 s. The optimal mechanical properties such as yield strength of 121.5 MPa, ultimate tensile strength of 221 MPa and elongation of 7.6% are achieved under the optimal conditions. The alloy elements such as Si, Fe, Mn and Mg segregate on the grain boundary, which is detrimental to the mechanical properties of parts formed by squeeze casting.

DOI: 10.11817/j.ysxb.1004.0609.2020-35936

姜巨福1,王 迎2,肖冠菲1,邓 腾2,刘英泽1,张 颖1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 机电工程学院,哈尔滨 150001)

摘 要:借助重力铸造和挤压铸造技术分别成形了AlSi7Mg铝合金模拟构件,利用拉伸试验机、金相显微镜和扫描电镜等手段研究了工艺参数对成形件组织与性能的影响规律。结果表明:与重力铸件相比,挤压铸造件的抗拉强度、伸长率和屈服强度分别提高了41%、562%和0.5%,挤压铸造件的平均晶粒尺寸随着浇注温度、模具温度和保压时间的增加呈现出先减小后增大的趋势。最佳挤压铸造工艺参数范围为浇注温度700~720 ℃、模具温度200~250 ℃、保压15~30 s,在该工艺条件下最好的综合力学性能为抗拉强度221 MPa、屈服强度121.5 MPa和伸长率7.6%。Si、Fe、Mn、Mg等元素在晶界处发生偏析,对挤压铸造成形件的力学性能会产生不利影响。

关键词:AlSi7Mg铝合金;挤压铸造; 微观组织; 力学性能

文章编号:1004-0609(2021)-03-0531-15 中图分类号:TG249.9 文献标志码:A

引文格式:姜巨福, 王 迎, 肖冠菲, 等. 工艺参数对挤压铸造成形AlSi7Mg铝合金构件组织与性能的影响[J]. 中国有色金属学报, 2021, 31(3): 531-545. DOI: 10.11817/j.ysxb.1004.0609.2020-35936

JIANG Ju-fu, WANG Ying, XIAO Guan-fei, et al. Influence of process parameters on microstructure and mechanical properties of AlSi7Mg aluminum alloy components formed by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 531-545. DOI: 10.11817/j.ysxb.1004.0609.2020-35936

挤压铸造技术是铝合金轻量化材料成形技术之一。它是借助压力使铝液进行充型,且在高压下进行凝固结晶的技术[1-2]。通过高压下凝固结晶,可使铸造缺陷明显降低甚至消除,从而使挤压铸造技术成为高质量铝合金及其复合材料结构件的重要成形方法之一[3-6]。

为此,世界各国都针对挤压铸造技术开展了大量研究。最早开展挤压铸造技研究的是苏联,其针对钢铁合金和铝合金挤压铸造技术开展了大量研究[7-8]。美国伊利诺伊理工学院[9]和美国的NL工业公司[10]针对钢铁合金、铝合金、铜合金挤压铸造工艺及挤压铸造装备开展了相关研究。英国牛津大学GALLERNEAULT等[11]研究发现,与重力铸造相比,挤压铸造施加的压力会明显增加Al-Cu合冷却速度和细化枝晶尺寸。英国华威大学 BRITNELL等[12]研究了AlSi7Mg铝合金直接挤压铸造,发现薄壁件采用该工艺容易出现偏析。日本广岛大学 KIMURA等[13]研究发现降低非正常组织对提升挤压铸造件的力学性能有益。日本宇部生产株式会社对挤压铸造专用设备以及铝合金汽车轮毂、转向节等典型构件的挤压铸造工艺进行了研究[14]。韩国庆北大学的HONG等[15]和釜山国立大学的JIN等[16]也针对铝合金挤压铸造工艺进行了研究。意大利都灵理工学院ROSSO等[17]研究了A356和A380铝合金挤压铸造工艺。这些研究让挤压铸造工艺水平大大提高,同时也促进了挤压铸造工艺在工业生产中的广泛应用。

中国学者也针对钢铁、铝合金、镁合金挤压铸造技术开展了大量研究[18-21],其中最热门的研究方向是汽车铝合金结构件挤压铸造技术。学者们已经在汽车轮毂[22-23]、连杆[24-25]、空调器摇盘[26]、转向节[27]、副车架[28-29]、控制臂[30]、发动机拉杆弯臂[31]等汽车铝合金结构件的挤压铸造技术获得了很多研究成果。此外,他们在兵器[32]、摩托车[33]以及其他民用领域[34-35]也开展了铝合金挤压铸造技术的应用研究。这些基础理论的研究以及在军工和民用领域的应用大大促进了挤压铸造技术的发展,使得挤压铸造技术更加完善。

挤压铸造分为直接挤压铸造和间接挤压铸造。与间接挤压铸造相比,直接挤压铸造施加的压力更大,更能发挥合金在压力下凝固结晶细化组织和消除缺陷的效果。通常间接挤压铸造的比压一般为50~150 MPa,而直接挤压铸造的比压可达100~200 MPa。对于比压大于300 MPa的挤压铸造工艺,国内外研究均较少。因此,本文作者针对铝合金高比压直接挤压铸造工艺开展研究,目的是进一步密实成形件的组织,提升成形效果和成形件的组织及性能,为高比压挤压铸造成形工艺提供技术支撑。

1 实验

本研究中采用AlSi7Mg铸造铝合金为实验材料,其X射线荧光光谱仪分析结果如表1所示。AlSi7Mg铸造铝合金挤压铸造成形实验工艺参数主要包括浇注温度、模具温度、比压和保压时间。其中浇注温度根据示差扫描量热(DSC)分析结果确定。图1(a)所示为AlSi7Mg铸造铝合金DSC曲线。由图1(a)可知,AlSi7Mg的固相线温度是574.5 ℃,液相线温度是636.2 ℃。成形实验共设置660、680、700、720和740 ℃五个浇注温度。模具温度设置为200、250和300 ℃。挤压铸造成形实验在2000 kN液压机上进行,此时对应的比压是398 MPa。实验中保压时间选为5、15、30和45 s四个不同的保压时间。具体方案如表2所示。

图1(b)~(d)所示为AlSi7Mg合金轮毂模拟件挤压铸造模具结构、零件图和取样位置。由于成形模拟件为对称结构,所以取样只需在一半即可。将成形件截取的微观组织试样依次使用600#、1000#、1500#和2000#的砂纸进行粗磨和精磨后,使用粒径0.5 μm的金刚石抛光剂辅助抛光,然后利用体积分数为0.5%的HF水溶液对试样进行腐蚀。

表1 实验用AlSi7Mg铝合金的成分

Table 1 Chemical composition of AlSi7Mg aluminum alloy in this experiment (mass fraction, %)

表2 AlSi7Mg铝合金构件成形实验方案

Table 2 Experimental plan of forming AlSi7Mg aluminum alloy

图1 AlSi7Mg铝合金DSC曲线、构件挤压铸造模具结构、零件图和取样位置

Fig. 1 DSC curve, die design, part drawing and sampling locations of AlSi7Mg aluminum alloy components (Unit: mm)

利用Olympus GX71金相显微镜进行金相观察,采用岛津电子万能试验机(AG-X plus 20 kN)进行拉伸试验,拉伸速度为2 mm/min。采用图像处理软件Image Pro Plus计算金相图的晶粒面积,并通过式(1)计算平均晶粒直径d。

(1)

(1)

式中:Ai为第i个晶粒的面积;n为晶粒的个数。

2 结果与分析

2.1 成形方法对成形件组织与性能的影响

图2所示为普通重力铸造成形件和挤压铸造成形件的宏观形貌。由图2(a)所示,普通重力铸造成形的轮毂件表面粗糙,圆周凸台处有凹坑,中心处由于排气不畅,有憋气造成的充不满现象。所以直接浇注的重力铸造不能较好地反映轮毂件的表面特征。如图2(b)所示,挤压铸造件表面光滑,无表面缺陷,能够良好地表现轮毂件的结构特征。这是由于在成形时铝熔体在压力的作用下,气体排除顺畅,并且使铝熔体凝固直接与模具紧密接触,充型完整,表面质量高。

图2 重力铸造件和挤压铸造成形件的宏观形貌

Fig. 2 Macrographs of gravity casting and squeeze casting parts

图3 不同成形方式的制件的微观组织

Fig. 3 Microstructures of parts formed by different methods

图3所示为不同成形方式成形的轮毂件的微观组织。由图3(a)和(d)可见,重力铸造铸件其组织分布不均匀,晶粒粗大,共晶硅形貌以粗大片状和块状为主,尺寸较大的硅相多团聚在一起,严重割裂α(Al)基体,这会降低铸件的力学性能。如图3(b)、(c)和(f)所示,挤压铸造成形的制件的微观组织晶粒多为蔷薇状或等轴状,晶粒细小,组织致密,分布均匀,粗大形貌的共晶硅也较少,大多数为片状和长杆状。在铝硅系铸造合金凝固过程中,由于初生α(Al)的熔点高,所以在凝固的过程中是优先凝固的,形成了树枝晶状的初生相,呈浅灰色基底部分。共晶硅凝固是落后于初生α(Al)相的,其与后凝固的铝形成Al-Si共晶相。

图4所示为按照表2中第15号试验号试验的挤压铸造成形件不同位置的组织。如图4(a)所示,B位置的晶粒直径为36.3 μm。图4(b)所示为C位置的金相组织照片,经分析可知其平均晶粒直径为44.5 μm。在挤压铸造成形过程中,凸模中间凸出的部位会先与金属液接触,然后在压力的作用下挤压金属液到边缘部位;因此中间部位B位置的金属液温度会迅速降低,并率先凝固。由于B位置激冷的作用,其过冷度较高,形核率高,因此该位置的晶粒尺寸较低。而C位置由于是最后凝固区域,该区域铝合金熔体的过冷度低,形核率较B区域低,因此C位置的晶粒尺寸比B位置的要大。与其他两位置的组织相比,图3(b)中所示A位置的金属液在压力的作用下凝固,界面传热系数较重力铸造显著增加[36],从而导致铝合金熔体的过冷度增加,形核率上升,并且补缩效果良好,内部组织没有缺陷,所以A位置晶粒最细小,组织致密均匀,其平均晶粒直径为33.7 μm。

图4 在表2中实验号15条件挤压铸造成形件不同位置的微观组织

Fig. 4 Microstructure in different locations of squeeze casting part formed under experimental number 15 conditions

图5 不同方法成形的AlSi7Mg铝合金构件的力学性能对比

Fig. 5 Comparison of mechanical properties of AlSi7Mg aluminum alloy components formed by different methods

图5所示为不同成形方式的制件的抗拉强度。重力铸造件的抗拉强度、伸长率和屈服强度为148.0 MPa、1.3%和102.5 MPa,而挤压铸造成形件的力学性能普遍显著高于重力铸造件,尤其是伸长率的提升尤为显著。挤压铸造件1的成形条件为浇注温度660 ℃、模具温度200 ℃和保压30 s,是挤压铸造制件中力学性能最低的,其抗拉强度、伸长率和屈服强度分别为191.7 MPa、2.7%和109.1 MPa,比普通重力铸造件的力学性能分别提高29.5%、108%和6.4%;而挤压铸造件2是在与重力铸造件相同的浇注温度、模具温度下挤压铸造成形,其抗拉强度、伸长率和屈服强度分别为209.0 MPa、8.6%和103.0 MPa,比重力铸造件的力学性能分别提高41%、562%和0.5%。产生这种力学性能差异的主要原因是,在压力下凝固显著提高了挤压铸造件的力学性能。从热力学角度来看,挤压铸造成形的临界晶核半径rc如式(2)所示[37]:

(2)

(2)

式中:rc是晶核半径; 是体收缩率;p是比压;L是结晶潜热;T凝固温度;

是体收缩率;p是比压;L是结晶潜热;T凝固温度; 是固液界面张力;

是固液界面张力; 是过冷度。

是过冷度。

因此,挤压铸造成形的临界晶核半径小于普通重力铸造下的临界晶核半径,即挤压铸造成形的制件由于凝固时施加了压力,在凝固时参与结晶的原子团会更多,有利于凝固形核。过冷度是金属液凝固的热力学条件。根据Clausius-Clapeyron方程可知,熔点T与比压p以及过冷度与压力关系式如式(3)和(4)所示[1]。

(3)

(3)

(4)

(4)

式中: 和

和 分别是体积和焓随温度的变化;

分别是体积和焓随温度的变化; ,T0是常压下的凝固温度。A356铸造铝合金是凝固收缩的合金,

,T0是常压下的凝固温度。A356铸造铝合金是凝固收缩的合金, 大于0。因此,随着压力的增大,其熔点上升,过冷度增大,凝固的驱动力增加。铝合金和铸铁材料在压力下的结晶行为已经证实了这一点[1, 37]。铝合金凝固的动力学条件有两个,形核率和长大的线速度,其中形核率是晶粒细化的重要影响因素。形核率是指金属液在单位时间、单位体积中形成的晶核数。形核率(N)的表达式如式(5)所示[1, 37]:

大于0。因此,随着压力的增大,其熔点上升,过冷度增大,凝固的驱动力增加。铝合金和铸铁材料在压力下的结晶行为已经证实了这一点[1, 37]。铝合金凝固的动力学条件有两个,形核率和长大的线速度,其中形核率是晶粒细化的重要影响因素。形核率是指金属液在单位时间、单位体积中形成的晶核数。形核率(N)的表达式如式(5)所示[1, 37]:

(5)

(5)

式中:n是单位体积原子数;K是波尔兹曼常数;h是普朗克常数; 是形核功;

是形核功; 是扩散激活能。而

是扩散激活能。而 和

和 分别如式(6)和(7)所示[37]。

分别如式(6)和(7)所示[37]。

(6)

(6)

(7)

(7)

式中: 是常压下的扩散激活能;

是常压下的扩散激活能; 是系数且等于0.001 m2/MN。由式(6)和(7)可知,挤压铸造的形核功小于重力铸造的,而由式(5)可知,其形核率大于重力铸造的。因此,对于A356铸造铝合金这类凝固收缩型合金,挤压铸造构件凝固时其熔点升高,过冷度增大,临界晶核半径减小,导致更多的晶核参与凝固,使挤压铸造制件的晶粒要比普通重力铸造铸件的更细小,分布更均匀。在压力下凝固结晶,制件的晶粒得到细化,消除了制件内部的缩松缩孔和气孔缺陷,使得制件组织变得更加致密。根据霍尔-佩奇公式,制件的强度随着晶粒尺寸的减小而提高,因此挤压铸造制件的力学性能要普遍高于普通重力铸造铸件的力学性能。很多学者研究发现[20, 30, 38-40],随着比压的增大,挤压铸造成形件的力学性能会明显增加,这也验证了凝固过程中压力对组织和性能的有益影响。

是系数且等于0.001 m2/MN。由式(6)和(7)可知,挤压铸造的形核功小于重力铸造的,而由式(5)可知,其形核率大于重力铸造的。因此,对于A356铸造铝合金这类凝固收缩型合金,挤压铸造构件凝固时其熔点升高,过冷度增大,临界晶核半径减小,导致更多的晶核参与凝固,使挤压铸造制件的晶粒要比普通重力铸造铸件的更细小,分布更均匀。在压力下凝固结晶,制件的晶粒得到细化,消除了制件内部的缩松缩孔和气孔缺陷,使得制件组织变得更加致密。根据霍尔-佩奇公式,制件的强度随着晶粒尺寸的减小而提高,因此挤压铸造制件的力学性能要普遍高于普通重力铸造铸件的力学性能。很多学者研究发现[20, 30, 38-40],随着比压的增大,挤压铸造成形件的力学性能会明显增加,这也验证了凝固过程中压力对组织和性能的有益影响。

图6所示为普通重力铸造件拉伸试样的断口形貌。从图6(a)中可以看出,断口中有由缺陷引起的断裂源,说明该处有较大的内部缺陷。而从图6(b)中可以看到大量撕裂棱,还有明显的铸造留下的内部缺陷,断口形貌层次感较强,还能看到一些小的“河流”状花样,并且在晶界处的共晶硅形貌为狭长的片状,易产生裂纹并沿着晶界扩展,其断裂模式为准解理断裂。图6(c)和(d)所示为挤压铸造制件(表2中实验号15)的断口形貌。从图6(c)中可以看到存在大量韧窝,属于韧性断裂特征,也有少量撕裂棱。如图6(d)所示,韧窝比较小且深,分布更加密集,属于等轴韧窝。在拉伸过程中,试样产生塑性变形,容易在杂质或晶界周围产生孔洞,随着变形的继续进行,孔洞逐渐扩大并形成裂纹;当其达到一定程度后导致断裂,形成了断口的纤维状区域,韧窝就是断裂过程中孔洞分离留下的痕迹,因此该制件的断裂形式以为韧性断裂为主。

2.2 浇注温度对挤压铸造成形件制件组织与性能的影响

图6 重力铸件和挤压铸造成形件(表2中实验号15条件)的断口形貌

Fig. 6 Fracture morphologies of gravity casting and squeeze casting parts formed under experiment number 15 in Table 2

图7 不同浇注温度下的挤压铸造件的微观组织以及平均晶粒

Fig. 7 Microstructures and average grain size of squeeze casting parts at different pouring temperatures

图7所示为模具温度200 ℃、保压30 s、不同浇注温度条件下挤压铸造成形件的微观组织。从图7中看到,晶粒多为蔷薇晶和等轴晶,浇注温度对共晶硅的形貌没有显著影响。共晶硅的形貌都是片状或长杆状,并且共晶硅的分布都不太均匀,在不同的浇注温度下都出现了共晶硅组织团聚的现 象。图7(d)所示为浇注温度为720 ℃的微观组织。由图7(d)可见,此时晶粒细小致密,小晶粒团聚在大晶粒附近,且圆整度较好,类似于半固态成形的球晶[41]。而浇注温度为660 ℃和740 ℃时,晶粒为粗大的蔷薇晶,晶粒尺寸差异较大。如图7(f)所示,晶粒尺寸随着浇注温度的升高,呈现出先减小后增大的趋势。浇注温度为660 ℃时,制件的晶粒较大,为44.2 μm。这是由于浇注温度过低时,金属液的凝固速度快,内部补缩效果差,所以组织就会显得粗大且相对疏松。而浇注温度升高至720 ℃时,此时的平均晶粒直径最小,为35.2 μm。这是由于当浇注温度适宜时,提高浇注温度可以提高金属液的流动性和凝固速度,过冷度增大,形核率提高,从而细化晶粒。但继续提高浇注温度,金属液温度较高加上凝固时潜热的释放,使得金属液冷却速率下降,降低了形核率,从而导致了组织的粗化。因此,浇注温度为740 ℃时,平均晶粒直径已经增大到43.3 μm。张会[38]对AlSi7Cu3挤压铸造工艺参数对组织的研究中也发现了浇注温度过高或过低对组织均不利的现象。

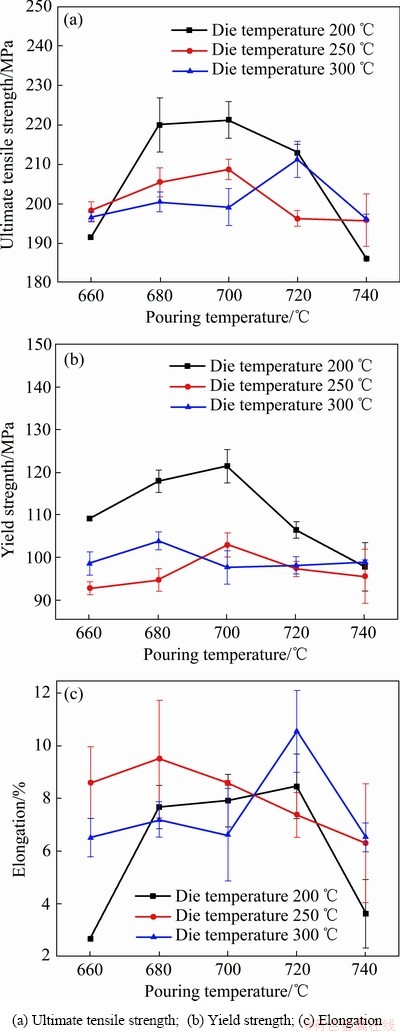

图8 不同浇注温度下挤压铸造件的力学性能

Fig. 8 Mechanical properties of squeeze casting parts at different pouring temperatures

图8所示为不同浇注度下保压30 s时挤压铸造件的力学性能。由图8可见,随着金属液浇注温度的升高,构件的力学性能先增加后减小。在不同的模具温度下,浇注温度为660 ℃或740 ℃的制件的力学性能最差,制件的力学性能在浇注温度为700或720 ℃时较好。综合抗拉强度、伸长率和屈服强度三个力学性能指标,模具温度为200 ℃时,浇注温度在700 ℃的制件是力学性能最好的,该制件的抗拉强度、伸长率和屈服强度分别为221 MPa、7.9%和121.5 MPa。模具温度为250 ℃时,浇注温度为700 ℃的制件是力学性能最好的,此时的抗拉强度、伸长率和屈服强度分别为209.0 MPa、8.6%和103.0 MPa;模具温度为300℃时,浇注温度为720 ℃的制件是力学性能最好的,此时的抗拉强度、伸长率和屈服强度分别为211.2 MPa、10.5%和98.1 MPa。这说明,浇注温度存在优化温度范围,过高或过低都对组织和性能不利。

A357铝合金变速箱箱体[39]、6082铝合金构件[40]以及ADC12铝合金连杆[42]的挤压铸造工艺研究中也发现类似规律。当浇注温度过低时,金属液凝固过早,凝固初期金属壳层的厚度增大,导致压力不能有效作用于内部金属,制件内部缺陷不能完全消除,严重降低了制件的力学性能。而当金属液浇注温度较高时,金属液吸气严重,体收缩增大,内部缺陷增多,并且合金元素烧损严重。此外,晶粒变大,组织粗化,也会降低制件的力学性能。因此,在挤压铸造成形时,要适当选取浇注温度。通过组织和性能分析,选取浇注温度700~720 ℃较为合适,此浇注温度下微观组织为等轴晶,晶粒细小,组织分布均匀、致密,并且制件的力学性能较好。

2.3 模具温度对挤压铸造成形件制件组织与性能的影响

图9所示为浇注温度740 ℃、保压30 s、不同模具温度条件下挤压铸造件的微观组织。由于浇注温度较高,所以在各个模具温度下,晶粒都为粒径较大的蔷薇晶。模具温度对凝固的影响是通过改变模具与金属液之间的传热来实现的。当模具温度为200 ℃时,模具与金属液的温差过大,金属液迅速凝固,施压困难,补缩效果差,所以此时的晶粒较大,尺寸差异也较大。提高模具温度,减小了模具与金属液之间的温差,使得压力能够良好补缩(见图9(a))。当模具温度过高时,会增加合金的吸气量,导致气孔等缺陷增多,并且由于金属液凝固过慢,可能会形成高成分液相,加重偏析(见图9(b))。图9(c)反映了平均晶粒直径随模具温度的变化情况,平均晶粒尺寸随着模具温度的提高先降低后升高。当模具温度为200 ℃时,平均晶粒尺寸较大,为43.3 μm;随着模具温度的增大,晶粒直径开始减小,增大模具温度至250 ℃,此时的平均晶粒直径为39.4 μm,而模具温度为300 ℃时,平均晶粒直径略有增加。

图9 不同模具温度下挤压铸造件的微观组织以及平均晶粒直径

Fig. 9 Microstructures and average grain size of squeeze casting parts at different pouring temperatures

如图8所示,模具温度对力学性能也有一定的影响。模具温度为200 ℃时,抗拉强度在186.2~221.3 MPa之间分布,伸长率在2.7%~8.5%之间分布,屈服强度在97.8~121.5 MPa之间分布;模具温度为250 ℃时,抗拉强度在195.6~208.8 MPa之间分布,伸长率在6.3%~9.5%之间分布,屈服强度在95.6~102.9 MPa之间分布。模具温度为300 ℃时,抗拉强度在196.5~211.2 MPa之间分布,伸长率在6.5%~10.5%之间分布,屈服强度在98.1~103.9 MPa之间分布。通过对比,模具温度为200 ℃时,其抗拉强度和屈服强度较好,但是不同浇注温度下制件的伸长率相差较大且伸长率较低,不利于质量控制。而在模具温度为300 ℃时,只有浇注温度为720 ℃的制件性能较好,其余浇注温度下的制件性能都较差,并且过高的模具温度不利于成形件脱模,使成形件脱模时容易出现裂纹。此外,模具温度为300 ℃时,晶粒开始粗化,晶粒尺寸大于模具温度为250 ℃时的。模具温度为250 ℃时,不同浇注温度下的制件力学性能都较好并且变化不大,并且在此模具温度下,组织致密,晶粒细小,因此模具温度选取200~250 ℃较为适宜。

2.4 保压时间对挤压铸造成形件制件组织与性能的影响

图10所示为浇注温度700 ℃、模具温度250 ℃条件下分别在不同保压时间下挤压铸造成形的轮毂件的微观组织。从图10中可以看到,晶粒尺寸随保压时间增大先减小后增大。当保压时间为5 s时,保压时间过短,此时的制件未完全凝固,最后凝固区域补缩效果差,所以铝合金基体晶粒尺寸粗大,共晶硅尺寸也较大,此时平均晶粒尺寸为41.4 μm(见图10(a))。当保压时间为15 s时,平均晶粒直径为35.0 μm,此时晶粒为细小致密的等轴晶(见图10(a))。继续增加保压时间对晶粒也没有明显细化作用(见图7(e)),保压时间为30s时的平均晶粒直径为33. 7 μm,相比保压时间为15 s的降低了3.7%。但当保压时间为45 s时,晶粒开始粗化,平均晶粒直径为40.1 μm (见图10(c)和(d))。这是由于随着保压时间的进一步延长,内部组织易产生相对位移,晶界变细甚至部分消失,晶粒融合变大,并且合金的冷却收缩被限制,容易产生裂纹。图10(e)所示为浇注温度700 ℃、模具温度250 ℃条件下分别保压5、15、30和45 s时挤压铸造制件的力学性能。随着保压时间的延长,制件的力学性能先增大后减小。侯文涛等[39]在A357铝合金变速箱箱体的挤压铸造工艺研究中也发现类似的规律。当保压时间为5 s时,制件的力学性能最差,抗拉强度、屈服强度和伸长率分别是195.4 MPa、93.3 MPa和5.4%;当保压时间增加到15 s时,伸长率达到最大值为9.7%;而保压时间为30 s时,抗拉强度和屈服强度有所上升,而伸长率下降;继续提高保压时间,制件的力学性能显著下降。当保压时间较短时,成形件晶粒尺寸较粗大(见图10(a)),会降低制件的力学性能。当保压时间为15和30 s时,成形件晶粒细小均匀(见图10(b)和图7(e)),制件的力学性能较好。过长的保压时间又会导致成形件晶粒尺寸增大(见图10(c)),导致制件的力学性能下降。

图10 不同保压时间下挤压铸造件的微观组织、平均晶粒直径及力学性能

Fig. 10 Microstructure, average grain size and mechanical properties of squeeze casting parts at different die temperatures

2.5 挤压铸造成形件制件的元素分布特征分析

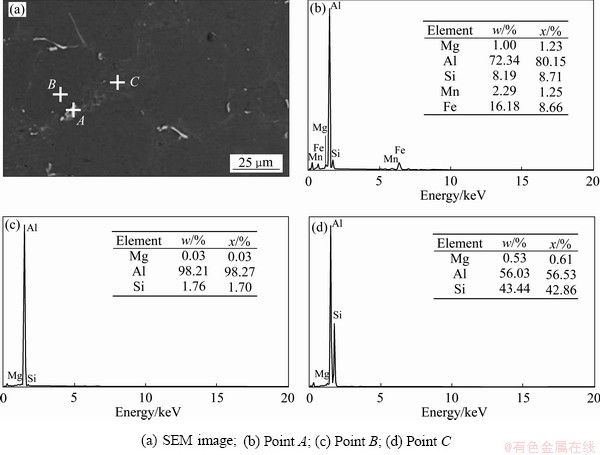

图11 挤压铸造成形件(表2中实验号15条件)点扫描能谱图

Fig. 11 Point EDS of squeeze casting part formed under experimental number 15 conditions in Table 2

图11所示为表2中15号挤压铸造成形件的微观组织点扫描分析能谱图。由图11(b)可见,该点Al含量(质量分数)最高,为72.34%,其次是Si含量和Fe含量,分别达到了8.19%和16.18%,而Mg含量为1.00%。对比表1中A356铸造铝合金的元素成分,Fe含量远远超出了正常的数值,Mg含量也高于点B和点C的。此外,点A还含有少量的Mn,其余两点的Mn含量为0。而对比同为晶界上的点C与点A的元素含量可知,依旧是Al含量最多,为56.03%;与A点不同的是,C点的Si含量较多,并且点C几乎不含Fe元素,Mg含量凝固低于点A。点B是晶内的点,其中Al含量最多,占比98.21%,其余元素含量极低,说明晶内几乎只有α(Al)相,其余相含量极低。

通过对比这三个点的元素含量,可以得出:除Al元素外,其他元素均在晶界处发生了富集,使得在晶内的元素含量远低于合金的元素含量,并且Fe元素在晶界上大量富集。在晶内,几乎只含有Al元素和少量的Si元素,所以晶粒内的相应该是Si元素溶于Al元素所得到的α(Al)相,该相是A356铝合金的基体,是影响抗拉强度的主要因素;而晶界处的主要相应该是Al元素溶于Si元素得到的共晶相,共晶相的形貌是影响塑性的主要因素。并且晶界晶内还存在Mg2Si相,该相是铝硅系铸造铝合金的强化相,而晶界处的高熔点杂质物中Si、Fe的摩尔比接近1:1,所以可能是β(Al9Si2Fe2)、AlMnSiFe相[43]。产生偏析的主要原因是:在A356铸造铝合金在凝固时,由于α(Al)的熔点高,α(Al)优先凝固形成晶粒,而共晶相最后凝固,所以只能在晶粒的间隙(晶界)处形核长大。Mg元素主要与Si元素形成Mg2Si相,该相是铝硅系合金的主要强化相,而Fe在晶界处富集形成了高熔点的杂质相。图12所示为挤压铸造成形的9号件的面扫描能谱图。图12更直观地反映了成形件微观组织的元素分布情况。图12(b)所示为Al元素的分布云图,可以明显看到Al元素是所有元素中分布最为密集的元素,但是晶界处分布明显减少。Si元素主要分布在晶界处,晶内Si含量较少,如图12(c)所示。而Mg含量不如Al、Si含量多,但其分布比较均匀,在晶界处的分布会比晶内的分布密集(见图12(d))。而Fe和Ti元素的分布较为稀疏,主要分布在晶界处(见图12(e)和(f))。由面扫描得出的结论与图11的点扫描结论一致,Al含量最多,Si、Mg、Fe元素在晶界处出现不同程度的富集。图11和12的能谱分析结果都表明,由于压力的影响,挤压铸造过程中铝熔体结晶凝固速度加大,会造成合金元素在晶界处的偏析,这对挤压铸造成形件的力学性能会有不利影响,所以挤压铸造成形件需要后续热处理,降低合金元素偏析的影响,进一步提升合金性能。

图12 挤压铸造件(表2中实验号9号条件)的SEM像和元素面扫描图

Fig. 12 SEM image and element mappings of squeeze casting formed component under experimental No. 9 conditions in Table 2

5 结论

1) 成形方法对构件微观组织和性能影响较大。挤压铸造件晶粒细小致密,分布均匀,共晶硅尺寸较小;而重力铸造件晶粒粗化严重,共晶硅呈现块状、狭长的片状等大尺寸形貌。在同一个挤压铸造构件内,中心区域的晶粒会要比其余区域的晶粒稍大。挤压铸造件的抗拉强度、伸长率和屈服强度分别为209.0 MPa、8.6%和103.0 MPa,比相同工艺参数下重力铸造件对应的力学性能分别高41%、562%和0.5%。压力可以有效降低临界形核半径和提高过冷度,从而增大形核率,因此挤压铸造件晶粒要比重力铸件的晶粒细小且致密。

2) 浇注温度、模具温度、保压时间都会对晶粒产生影响,平均晶粒尺寸随着这三个变量的增加呈现出先减小后增大的趋势。在晶粒尺寸较小时,晶粒多为等轴晶,而晶粒尺寸粗大时,晶粒多为蔷薇晶。通过对比不同工艺参数对性能的影响,确定了最佳工艺参数范围为浇注温度700~720 ℃、模具温度200~250 ℃、保压15~30 s。该工艺条件下最好的综合力学性能为抗拉强度221 MPa、屈服强度121.5 MPa、伸长率7.6%。

3) 从挤压铸造成形件的合金元素分布特征可知:Al元素是主要元素,而Si、Fe、Mn、Mg等元素都在晶界处发生偏析,Mn含量较少,且Fe、Mn元素在晶界处形成高熔点杂质相。由于压力的影响,挤压铸造过程中铝熔体结晶凝固速度加大,会造成合金元素的晶界偏析,这对挤压铸造成形件的力学性能会有不利影响。

REFERENCES

[1] 罗守靖, 陈炳光, 齐丕骧. 液态模锻与挤压铸造技术[M]. 北京: 化学工业出版社, 2007: 301-343.

LUO Shou-jing, CHEN Bing-guang, QI Pi-xiang. Liquid die forging and squeeze casting[M]. Beijing: Chemical Industry Press, 2007: 301-343.

[2] 邢书明. 挤压铸造合金材料及其工艺性能[J]. 铸造, 2015, 64(7): 628-631.

XING Shu-ming. Alloy for squeeze casting and their processing properties[J]. Foundry, 2015, 64(7): 628-631.

[3] BABAEE M H, MALEKI A, NIROUMAND B. A novel method to improve interfacial bonding of compound squeeze cast Al/Al-Cu macrocomposite bimetals: Simulation and experimental studies[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(6): 1184-1199.

[4] 罗继相. 我国挤压铸造技术研究现状及展望[J]. 大连交通大学学报, 2016, 37(5): 30-35.

LUO Ji-xiang. Research status and prospect of squeeze casting technology in china[J]. Journal of Dalian Jiaotong University, 2016, 37(5): 30-35.

[5] 姜 博, 吉泽升, 胡茂良, 等. 固溶时间对ADC12铝合金挤压铸造组织及力学性能的影响[J]. 中国有色金属学报, 2019, 29(2): 223-231.

JIANG Bo, JI Ze-sheng, HU Mao-liang, et al. Effect of solution time on microstructure and mechanical properties of ADC12 aluminum alloy by squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(2): 223-231.

[6] 徐进康, 陈 刚, 张振亚, 等. 挤压铸造对重熔原位α-Al2O3p/ZL109复合材料组织与性能的影响[J]. 中国有色金属学报, 2019, 29(3): 474-483.

XU Jin-kang, CHEN Gang, ZHANG Zhen-ya, et al. Effects of squeeze casting on microstructure and properties of remelted in-situ α-Al2O3p/ZL109 composites[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(3): 474-483.

[7] GHOMASHCHI M R, VIKHROV A. Squeeze casting: an overview[J]. Journal of Materials Processing Technology, 2000, 101(1): 1-9.

[8] SOSENUSHKIN E N, FRANTSUZOVA L S, KOZLOVA E M. Effect of pressure and temperature factors on the solidification of cast iron and its structure in liquid forging[J]. Metal Science and Heat Treatment, 2015, 57(5/6): 309-316.

[9] RAJAGOPAL S. Squeeze casting: A review and update[J]. Journal of Applied Metalworking, 1981, 1(4): 3-14.

[10] LYNCH R F. Squeeze casting apparatus and method: US, 4049040[P]. 1977-09-20.

[11] GALLERNEAULT M, DURRANT G, CANTOR B. The squeeze casting of hypoeutectic binary Al-Cu[J]. Metallurgical and Materials Transactions A, 1996, 27(12): 4121-4132.

[12] BRITNELL D J, NEAILEY K. Macrosegregation in thin walled castings produced via the direct squeeze casting process[J]. Journal of Materials Processing Technology, 2003, 138(1/3): 306-310.

[13] KIMURA R, YOSHIDA M, SASAKI G, et al. Influence of abnormal structure on the reliability of squeeze castings[J]. Journal of Materials Processing Technology, 2002, 130(2): 299-303.

[14] UENO T, UCHIDA M. Vertical die casting machines: US, 4088178[P]. 1978-05-09.

[15] HONG C P, LEE S M, SHEN H F. Prevention of macrodefects in squeeze casting of an Al-7 wt pct Si alloy[J]. Metallurgical and Materials Transactions B, 2000, 31(2): 297-305.

[16] JIN C K, KANG C G. A comparative study on the formability of aluminum bipolar plate with channels using indirect squeeze casting and stamping[J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(7): 1233-1238.

[17] ROSSO M, PETER I, BIVOL C, et al. Development of industrial components by advanced squeeze casting[J]. International Journal of Material Forming, 2010, 3(1): 787-790.

[18] 邢书明, 董 琦, 邱 博, 等. 挤压铸造钢铁及其复合材料零件进展与展望[J]. 特种铸造及有色合金, 2017, 37(1): 38-42.

XING Shu-ming, DONG Qi, QIU Bo, et al. Progress and prospect in squeezing casting iron-steel and its compound materials parts[J]. Special Casting and Nonferrous Alloys, 2017, 37(1): 38-42.

[19] WANG Y F, ZHAO S D, ZHANG C Y. Microstructures and mechanical properties of semi-solid squeeze casting ZL104 connecting rod[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(2): 235-243.

[20] 陈 云, 汪 锐, 邓 森, 等. 挤压铸造A356.2铝合金发动机悬置支架的组织与性能[J]. 特种铸造及有色合金, 2020, 40(2): 175-178.

CHEN Yun, WANG Rui, DENG Seng, et al. Forming process and mechanical properties of squeeze casting A356.2 aluminum alloy engine mounting bracket[J]. Special Casting and Nonferrous Alloys, 2020, 40(2): 175-178.

[21] JIANG J, WANG Y, CHEN G, et al. Comparison of mechanical properties and microstructure of AZ91D alloy motorcycle wheels formed by die casting and double control forming[J]. Materials and Design, 2012, 40: 541-549.

[22] 马春江, 陈玖新, 葛素静, 等. 挤压铸造重载汽车用铝合金车轮的组织及性能[J]. 特种铸造及有色合金. 2014, 34(10): 1063-1065.

MA Chun-jiang, CHEN Jiu-xin, GE Su-jing, et al. Microstructure and mechanical properties of squeezing casting aluminum alloy wheel[J]. Special Casting Nonferrous Alloys, 2014, 34(10): 1063-1065.

[23] 姜 峰, 何 波, 刘文琪. 铝铜合金汽车轮毂的液态模锻成形与组织性能研究[J]. 铸造技术, 2018, 39(12): 2798-2801.

JIANG Feng, HE Bo, LIU Wen-qi. Microstructure and properties of aluminum copper alloy for automotive wheel hub by liquid die forging forming[J]. Foundry Technology, 2018, 39(12): 2798-2801.

[24] 唐全波, 姜巨福, 王 迎. 两种工艺成形的ADC12铝合金连杆的力学性能对比[J]. 热加工工艺, 2010, 39(19): 107-110.

TANG Quan-bo, JIANG Ju-fu, WANG Ying. Comparison of mechanical properties of connecting rod of ADC12 aluminum alloy formed by two processes[J]. Hot Working Technology, 2010, 39(19): 107-110.

[25] WANG Yong-fei, ZHAO Sheng-dun, ZHANG Chen-yang. Microstructures and mechanical properties of semi-solid squeeze casting ZL104 connecting rod[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(2): 235-243.

[26] 胡茂良, 赵 密, 吉泽升, 等. 挤压铸造工艺对汽车空调器摇盘组织和性能的影响[J]. 中国有色金属学报, 2006, 16(3): 400-405.

HU Mao-liang, ZHAO Mi, JI Ze-sheng, et al. Effect of squeezing casting technology on structures and properties of air-conditioner swaying tray of automobile[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 400-405.

[27] 任俊成, 衡俐琼, 王泽忠, 等. 挤压铸造铝合金转向节开发[J]. 特种铸造及有色合金, 2017, 37(7): 735-738.

REN Jun-cheng, HENG Li-qiong, WANG Ze-zhong, et al. Development of squeeze casting aluminium alloy automobile steering knuckle [J]. Special Casting and Nonferrous Alloys, 2017, 37(7): 735-738.

[28] 孙 珏, 许善新, 汤 杰, 等. 汽车铝合金副车架挤压铸造工艺设计和产品开发[J]. 铸造, 2015, 64(1): 17-21.

SUN Jue, XU Shan-xin, TANG Jie, et al. Development of squeeze casting aluminium alloy automobile steering knuckle[J]. Foundry, 2015, 64(1): 17-21.

[29] 杨 青, 姜银方, 戴亚春, 等. 挤压铸造铝合金副车架的显微组织与力学性能[J]. 特种铸造及有色合金, 2016, 36(4): 376-378.

YANG Qing, JIANG Yin-fang, DAI Ya-chun, et al. Microstructure and mechanical properties of aluminum alloy sub-frame by squeeze casting process[J]. Special Casting and Nonferrous Alloys, 2016, 36(4): 376-378.

[30] 李宇飞, 余振龙, 石 飞, 等. 挤压铸造工艺对汽车控制臂铸件组织及性能的影响[J]. 特种铸造及有色合金, 2018, 38(8): 864-866.

LI Yu-fei, YU Zhen-long, SHI Fei, et al. Effects of squeeze casting process on microstructure and properties of automobile control arm[J]. Special Casting and Nonferrous Alloys, 2018, 38(8): 864-866.

[31] WANG S, JI Z, SUGIYAMA S, HU M. Segregation behavior of ADC12 alloy differential support formed by near-liquidus squeeze casting[J]. Materials and Design, 2015, 65: 591-599.

[32] 王长顺, 李宏伟, 陈利华, 等. 特种车辆新型高强韧铝合金负重轮液态模锻工艺成型研究[J]. 新技术新工艺, 2013, 7: 88-90.

WANG Chang-shun, LI Hong-wei, CHEN Li-hua, et al. Research on liquid-state forging of new and high strength-toughness alumimium alloy[J]. New Technology and New Process, 2013, 7: 88-90.

[33] 张占领, 张艳琴, 阎峰云, 等. 镁合金摩托车轮毂挤压铸造生产研究[J]. 热加工工艺, 2007, 36(13): 92-94.

ZHANG Zhan-ling, ZHANG Yan-qin, YAN Feng-yun, et al. Squeezing casting technology of Mg Alloys wheels in autocycle[J]. Hot Working Technology, 2007, 36(13): 92-94.

[34] 洪慎章, 曾振鹏. 自行车铝合金曲柄液态模锻工艺[J]. 模具工业, 2000, 10: 42-44.

HONG Shen-zhang, ZENG Zhen-peng. Liquid die forging technology of aluminum alloy crank of bicycle[J]. Die and Mould Industry, 2000, 10: 42-44.

[35] 洪慎章. 管子钳钳柄铝合金液态挤压工艺及模具设计[J]. 精密成形工程, 2013, 5(4): 40-42.

HONG Shen-zhang. Liquid extrusion technology and die design of aluminum alloy for the pipe wrench grip[J]. Journal of Netshape Forming Engineering, 2013, 5(4): 40-42.

[36] BATYSHEV K A. Casting of aluminum alloys with pressure crystallization. Part 1[J]. Metal Science and Heat Treatment, 2012, 53(9/10): 463-471.

[37] 罗守靖, 何绍元, 王尔德, 等. 钢质液态模锻[M].哈尔滨: 哈尔滨工业大学出版社, 1990: 21-22.

LUO Shou-jing, HE Shao-yuan, WANG Er-de, et al. Liquid die forging of steel[M]. Harbin: Harbin Institute of Technology Press, 1990: 21-22.

[38] 张 会. 工艺参数对Al-7Si-3Cu合金液态模锻组织及性能研究[J]. 热加工工艺, 2013, 42(3): 23-24.

ZHANG Hui. Influence of process parameters on microstructure and properties of liquid die forging Al-7Si-3Cu alloy[J]. Hot Working Technology, 2013, 42(3): 23-27.

[39] 侯文涛, 汪建敏, 程科升, 等. A357铝合金变速箱体液态模锻工艺研究及优化[J].铸造技术, 2015, 36(12): 2930-2933.

HOU Wen-tao, WANG Jian-min, CHENG Ke-sheng, et al. Study and optimization on liquid forging technique for A357 aluminum alloy gearbox[J]. Foundry Technology, 2015, 36(12): 2930-2933.

[40] 王家宣, 姜丽红, 诸葛跃, 等. 工艺参数对液态模锻6082合金组织及力学性能的影响[J]. 锻压技术, 2010, 35(3): 76-79.

WANG Jia-xuan, JIANG Li-hong, ZHU Ge-yue, et al. Effect of technological parameters on microstructure and mechanical properties of liquid forged 6082 alloy[J]. Forging and Stamping Technology, 2010, 35(3): 76-79.

[41] 李 超, 杨湘杰, 郭洪民, 等. 工艺参数对热平衡法制备半固态A356铝合金组织的影响[J]. 特种铸造及有色合金, 2019, 39(11): 1205-1208.

LI Chao, YANG Xiang-jie, GUO Hong-min, et al. Effect process parameters on microstructure of semi-solid A356 aluminum alloy prepared by thermal equilibrium method[J]. Special Casting and Nonferrous Alloys, 2019, 39(11): 1205-1208.

[42] 唐全波, 姜巨福, 王 迎. 工艺参数对ADC12铝合金连杆端盖挤压铸造过程的影响[J]. 特种铸造及有色合金, 2010, 30(8): 734-736.

TANG Quan-bo, JIANG Ju-fu, WANG Ying. Effects of processing parameters on squeezing casting ADC12 aluminum alloy connecting rod's cap[J]. Special Casting and Nonferrous Alloys, 2010, 30(8): 734-736.

[43] 韩延峰, 刘相法, 边秀房. 压铸条件对Al-Si合金组织中Fe相形态的影响[J]. 轻合金加工技术, 2001, 29(1): 5-8.

HAN Yan-feng, LIU Xiang-fa, BIAN Xiu-fang. Influence of die casting condition on the morphologies of iron compounds in Al-Si alloy[J]. Light Alloy Fabrication Technology, 2001, 29(1): 5-8.

JIANG Ju-fu1, WANG Ying2, XIAO Guan-fei1, DENG Teng2, LIU Ying-ze1, ZHANG Ying1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: AlSi7Mg aluminum alloy components were formed by gravity casting and squeeze casting. Influences of process parameters on microstructure and mechanical properties of formed parts were investigated by tensile test, optical microscopy and scanning electron microscopy. The results show that the yield strength, ultimate tensile strength and elongation of parts formed by squeeze casting increase by 41%, 562% and 0.5%, respectively, comparing with those of parts formed by gravity casting. The average grain size of parts formed by squeeze casting decreases and then increases with increases of pouring temperature, die temperature and dwell time. The optimal process parameters obtained in this research involve the pouring temperature range from 700 ℃ to 720 ℃, die temperature range from 200 ℃ to 250 ℃ and dwell times from 15 s to 30 s. The optimal mechanical properties such as yield strength of 121.5 MPa, ultimate tensile strength of 221 MPa and elongation of 7.6% are achieved under the optimal conditions. The alloy elements such as Si, Fe, Mn and Mg segregate on the grain boundary, which is detrimental to the mechanical properties of parts formed by squeeze casting.

Key words: AlSi7Mg aluminum alloy; squeeze casting; microstructure; mechanical properties

Foundation item: Project(2019YFB2006500) supported by the National Key Research and Development Program of China; Project(51875124) supported by the National Natural Science Foundation of China

Received date: 2020-04-08; Accepted date: 2020-06-25

Corresponding author: JIANG Ju-fu; Tel: +86-18746013176; E-mail: jiangjufu@hit.edu.cn

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2019YFB2006500);国家自然科学基金资助项目(51875124)

收稿日期:2020-04-08;修订日期:2020-06-25

通信作者:姜巨福,教授,博士;电话:18746013176;E-mail:jiangjufu@hit.edu.cn