文章编号:1004-0609(2010)11-2118-06

基于末端淬火试验2124铝合金的淬透性

刘君城, 张永安, 刘红伟, 李锡武, 李志辉, 朱宝宏, 熊柏青

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:通过Jominy末端淬火实验研究2124铝合金的淬透性。利用温度数据采集、布氏硬度检测、差示量热法(DSC)和透射电子显微镜(TEM)等手段分析淬火冷却速率对时效后第二相析出行为的影响。结果表明:Jominy末端淬火2124铝合金室温水淬硬度下降小于10%的淬透深度大约为50 mm,该位置处合金在222.7~350.0 ℃温度区间的平均淬火冷却速率大于2.0 ℃/s;较低的淬火冷却速率致使过饱和的溶质原子和空位损失,导致时效析出相变驱动力不足,显著削弱了时效强化效果。

关键词:2124铝合金;末端淬火;淬透性;脱溶析出

中图分类号:TG166.3;TG146.21 文献标志码:A

Hardenability of 2124 aluminum alloy based on Jominy end quench test

LIU Jun-cheng, ZHANG Yong-an, LIU Hong-wei, LI Xi-wu, LI Zhi-hui, ZHU Bao-hong, XIONG Bai-qing

(State Key Laboratory of Nonferrous Metals and Processes,

General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The hardenability of 2124 aluminum alloy was investigated by means of Jominy end quench test. The effects of cooling rate on ageing precipitation and strengthening behavior were analyzed by temperature data acquisition, Brinell hardness measurement, differential scanning calorimetry (DSC) and transmission electron microscopy (TEM) observation. The results show that the hardening depth with hardness loss below 10% of 2124 alloy Jominy specimen quenched by room temperature water is approximately 50mm where the average cooling rate through the temperature range from 222.7 ℃ to 350.0 ℃ is above 2.0 ℃/s. The age hardening response of 2124 alloy is obviously weakened at slower quenching rate, which is caused by the loss of vacancies and solutes.

Key words: 2124 aluminum alloy; end quenching; hardenability; precipitation

自发现Al-Cu-Mg合金的时效硬化现象以来,2000系铝合金以其高强度以及良好的耐热性能和抗腐蚀性能广泛应用于航空工业[1-2]。1939年,美铝公司发明的2024铝合金为飞机制造业做出了重大贡献。1970年,美铝公司通过在2024铝合金基础上降低Fe、Si杂质的含量,研制了2124铝合金,这种改进型合金不但继承了2024铝合金的高强度,而且具有较好的断裂韧性、抗应力腐蚀性能和疲劳性能。此后,2224、2324、2424和2524铝合金的成功研制,与2024和2124铝合金一起形成了2x24系列铝合金,其中2124铝合金在航空工业中应用较为广泛。

2124铝合金超厚板是航空航天应用中的一种关键性结构材料,然而厚板热处理后性能沿厚度方向存在不均匀现象[3]。NEWKIRK和MACKENZIE[4]采用Jominy末端淬火方法研究了7050铝合金和7075铝合金在不同淬火冷却速率下力学性能和微观组织析出形貌的变化。王国军等[5]采用一种用于研究铝合金淬透性的实验方法,探讨了2D70铝合金的淬透性。熊柏青等[6]对7150和7B04以及一种新型铝合金的淬透性展开研究,并比较了几种合金的淬透性差异。张新明等[7]就7055铝合金的淬火敏感性方面做了较为深入的研究,指出淬火速率减小导致铝合金力学性能下降。因此,为了使厚板能够获得满意的芯部性能,研究铝合金的淬透性并测定其淬火临界冷却速率就成为一项非常有意义的工作[5, 8]。本文作者采用Jominy方法[4, 9] 对广泛应用的2124铝合金进行末端淬火实验,绘制了2124铝合金室温水淬的淬透性曲线,获得了2124铝合金室温水淬的淬透深度,并进一步探讨了淬火冷却速率对合金淬火过程中过饱和固溶体脱溶析出行为以及时效过程中析出强化行为的影响,为2124铝合金厚板的淬火热处理和厚板的工程应用奠定了理论和实验依据。

1 实验

本实验所使用的2124铝合金厚板由国内某生产企业提供,铸锭经均匀化处理后热轧成140 mm厚板,合金的化学成分列于表1。

表1 合金的化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

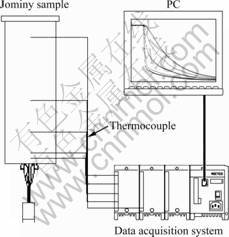

Jominy末端淬火试样沿厚板的短横向切取,尺寸为d48 mm×140 mm。在距淬火端5、10、30、60和120 mm处布置K分度热电偶。为方便表述,本文用“J”表示距淬火端的距离。试样经493 ℃固溶处理80 min后,由自d15 mm的喷咀喷出的室温水淬火冷却至50 ℃以下,末端淬火装置如图1所示,由电脑连接MX100温度数据采集系统实时记录J=5 mm、J=10 mm、J=30 mm、J=60 mm、J=120 mm处温度数据。淬火过程中,末端淬火试样圆周外表包有石棉保温垫,试样上端也有石棉垫覆盖,仅喷水冷却端存在换热,以保证淬火过程近似一维冷却。淬火结束后,分别于J=5 mm、J=45 mm、J=120 mm处切取DSC样,自然时效168 h后[10],使用DSC Q100热分析仪以10 ℃/min的扫描速度进行分析,温度范围为室温到400 ℃。经过191 ℃时效处理12 h后,用HBS-62.5数显小负荷布氏硬度计测量硬度,并分别于J=5 mm、J=45 mm、J=120 mm处制取TEM样片,用25%硝酸+75%甲醇的电解液双喷减薄,在JEM-2000FX分析电子显微镜上观察显微组织。

图1 Jominy末端淬火实验装置示意图

Fig.1 Schematic diagram of Jominy end quench testing device

2 实验结果

2.1 淬火冷却曲线

图2所示为Jominy末端淬火试样上不同位置处的测试时间—温度曲线。从图2可以看出,距淬火端距离越大,温度响应越慢,冷却速率也越小。距淬火端距离J=5 mm处冷却响应最快,冷却速率也最大,淬火不到10 s温度就降至200 ℃以下,而J=120 mm处要降温到200 ℃以下至少用时190 s。据此曲线,便可得知试样不同深度处淬火冷却速率的差别。

图2 Jominy末端淬火试样的测试时间—温度曲线

Fig.2 Measure time—temperature curves of Jominy end quench specimens

2.2 淬透性曲线

图3所示为2124铝合金Jominy末端淬火试样经191 ℃时效处理12 h后的硬度曲线。由图3可见:随着距淬火端距离的增加,硬度值逐渐下降;当J较小时,硬度值变化较为平缓;当J为50 mm左右时,硬度值迅速下降;当J大于65 mm时,硬度值变化趋于平缓。取90%最大硬度为是合金的淬透硬度,则其对应的距离就是临界淬透距离,依照此评价标准可以认为2124铝合金室温水淬的临界淬透深度约为50 mm。

图3 2124铝合金Jominy末端淬火试样经室温水淬火后在191 ℃时效12 h的硬度曲线

Fig.3 Hardness curve of 2124 aluminum Jominy end quench specimen after being water quenched at room temperature and aged at 191 ℃ for 12 h

2.3 DSC分析

图4所示为2124铝合金自然时效态DSC试验结果,曲线中的放热峰对应着沉淀析出,吸热峰对应着溶解。研究发现,自然时效168 h所形成的GP区在升

图4 2124铝合金自然时效168 h后的DSC曲线

Fig.4 DSC curves of 2124 aluminum alloy after being naturally aged 168 h

温过程中溶解,其溶解对应的峰值温度为222.7 ℃;第一个放热峰出现在268.2 ℃,第二个放热峰与前一个有叠加现象,其峰值温度为285.0 ℃,SMITH等[11]称第一个为S′相析出的峰值温度,第二个放热峰是θ′相析出所致。综上所述,2124铝合金在222.7~350.0 ℃之间析出相大量形成。

SMITH[12]对2124铝合金以10 ℃/min的扫描速度做了DSC分析,其结果与本研究结果对比见表2,两者峰值温度相差不大。

表2 2124铝合金DSC数据

Table 2 Differential scanning calorimetry data for 2124 aluminum alloy (scan rate 10 ℃/min)

结合图2的淬火冷却曲线,对比分析DSC曲线发现,淬火冷却速率最快的J=5 mm处自然时效GP区析出较多,所以溶解吸热也最多,主要强化相S′相析出峰最高,且放热峰的面积最大;淬火冷却速率较慢的J=45 mm处,不管是GP区溶解的吸热峰还是S′相析出的放热峰的峰高都较前者低;淬火冷却速率最慢的J=120 mm处,吸热峰和放热峰的峰高最低。由此可见,较低的淬火冷却速率会使淬火过程中在缺陷处出现脱溶析出行为[7],降低过饱和固溶体的过饱和度,致使在时效过程中第二相形核驱动力不足,形核率下降,从而削弱了时效强化效果。

2.4 TEM观察

图5(a)~5(c)分别为J=5 mm、J=45 mm、J=120 mm晶内析出相的TEM像,由图(a)~(c)可以看出,这3个部位都存在一些深灰色棒状相[13],经能谱分析发现其为富Mn相,淬火冷却速率对其分布及析出形貌基本没有影响。但随着距淬火端距离的增加,细长板条状的S′相显著趋向于不均匀分布。图5(a)中合金的强化相S′相数量很多,且细小弥散;图5(b)中的S′相数量较少,大部分集中在富Mn相周围,且有部分S′强化相明显长大;图5(c)中强化相数量明显减少,分布不均匀,且有明显的团聚长大趋势。

图5(d)~5(f)分别为J=5 mm、J=45 mm、J=120 mm晶界的TEM像。可以看出,随着距淬火端距离的增加,晶界上析出相数量增加,晶界有加宽趋势,图5(f)中晶界处析出相长大尤其严重。

图5 2124铝合金在距淬火端不同距离处的TEM像

Fig.5 TEM images of 2124 aluminum alloy at different positions on Jominy end quench bar: (a), (d) J=5 mm; (b), (e) J=45 mm, (c), (f) J=120 mm;(a), (b) and (c) Intragranular images; (d), (e) and (f) Intergranular images

3 分析与讨论

2124铝合金的主要强化相为S′相和少量θ′相,控制其脱溶析出时机和方式就能使合金获得满意的的强化效果[14-17]。DSC分析发现222.7~350.0 ℃为2124铝合金主要强化相大量析出的温度区间,2124铝合金在此区间内的淬火冷却速率将决定其后续强化效果。

图6所示为2124铝合金在222.7~350.0 ℃温度区间内的平均冷却速率与其布氏硬度值的关系曲线。由图6可以看出,2124铝合金室温水淬临界淬透深度处(50 mm)的冷却速率约为2.0 ℃/s,小于此淬火冷却速率,合金将不能达到90%最大硬度的要求。

图6 222.7~350.0 ℃之间平均冷却速率与硬度值关系曲线

Fig.6 Brinell hardness as function of average cooling rate between 222.7 ℃ and 350.0 ℃

2124铝合金属于时效硬化合金,第二相析出相变为形核长大型,析出相长大需要进行长程扩散。2124铝合金的第二相形核由吉布斯自由能差决定,过冷度越大,相变驱动力越大,所需的临界形核功就越小,越容易形核。同时,时效析出还受扩散控制,温度越低则扩散越慢,第二相长大的速度就越慢。

淬火过程中,2124铝合金在高温区间内冷速较慢时,自由能差较小,不易形核;在低温区间内冷速较慢时,扩散缓慢析出相不能长大;而在中温区间内的淬火冷却速率过低时,第二相从过饱和固溶体中优先于缺陷处脱溶析出,并吸收附近的溶质原子和空位,从而降低了溶质原子和空位的过饱和度。在后续的时效过程中,由于过饱和溶质原子减少,使得第二相形核的相变驱动力不足,导致形核率下降;同时,由于过饱和空位浓度的下降,使得2124铝合金内缺陷数减少,第二相就优先在晶界处形核,致使晶界加宽。这样,在中温区间内淬火冷却速率不够高,就会出现淬火先析出相在时效过程中继续长大,新析出相形核率低且分布不均匀的现象。因此,中温区间内的淬火冷却速率,是决定2124铝合金时效强化效果的重要原因。

4 结论

1) 淬火冷却速率是2124铝合金能否淬透的关键因素,2124铝合金在222.7~350.0 ℃温度区间内的平均淬火冷却速率大于2.0 ℃/s时才能被淬透,末端淬火试验2124铝合金室温水淬的淬透深度大约为50 mm。

2) 较低的淬火冷却速率致使淬火过程中第二相从过饱和固溶体中脱溶析出,消耗过饱和溶质原子,致使时效过程中第二相形核率降低,沉淀析出相不均匀分布;同时,由于过饱和空位浓度的下降,使得2124铝合金内缺陷数减少,第二相就优先在晶界处形核,致使晶界加宽。

REFERENCES

[1] 徐崇义, 李念奎. 2xxx系铝合金强韧化的研究与发展[J]. 轻合金加工技术, 2005, 33(8): 13-17.

XU Chong-yi, LI Nian-kui. Development and research of strengthening and toughening of 2xxx aluminium alloy[J]. Light Alloy Fabrication Technology, 2005, 33(8): 13-17.

[2] 张君尧. 铝合金材料的新进展(1)[J]. 轻合金加工技术, 1998, 26(5): 1-6, 10.

ZHANG Jun-yao. Recent development of aluminum alloy materials(1)[J]. Light Alloy Fabrication Technology, 1998, 26(5): 1-6, 10.

[3] 彭志辉. 航空用新型高强度铝合金[J]. 材料导报, 1997, 11(6): 16-19.

PENG Zhi-hui. New high-strength aluminium alloys for aeronautic facilities[J]. Materials Review, 1997, 11(6): 16-19.

[4] NEWKIRK J W, MACKENZIE D S. The Jominy end quench for light-weight alloys development[J]. Journal of Material Engineering and Performance, 2000, 9(4): 408-415.

[5] 王国军, 熊柏青, 张永安, 李志辉, 李培跃. 2D70铝合金淬透性研究[J]. 稀有金属, 2009, 33(3): 304-308.

WANG Guo-jun, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, LI Pei-yue. Hardenability of 2D70 aluminum alloy[J]. Chinese Journal of Rare Metals, 2009, 33(3): 304-308.

[6] 熊柏青, 李锡武, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 新型高强韧低淬火敏感性Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr合金[J]. 中国有色金属学报, 2009,19(9): 1539-1547.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Novel Al-7.5Zn-1.65Mg-1.4Cu-0.12Zr alloy with high strength high toughness and low quench sensitivity[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1539-1547.

[7] 张新明, 刘胜胆, 游江海, 张 翀, 张小艳. 时效对7055铝合金淬火敏感效应的影响[J]. 中国有色金属学报, 2007, 17(2): 260-264.

ZHANG Xin-ming, LIU Sheng-dan, YOU Jiang-hai, ZHANG Chong, ZHANG Xiao-yan. Influence of aging on the quench sensitivity effect of 7055 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 260-264.

[8] SHNEIDER G L, DRITS A M. Hardenability of aluminum-lithium alloys[J]. Metal Science and Heat Treatment, 1995, 37: 373-377.

[9] MA S H, MANIRUZZAMAN M D, MACKENZIE D S, SISSON R D. A methodology to predict the effects of quench rates on mechanical properties of cast aluminum alloys[J]. Metallurgical and Materials Transactions B, 2007, 38B: 583-589.

[10] STARINK M J, GAO N, YAN J L. The origins of room temperature hardening of Al-Cu-Mg alloys[J]. Materials Science and Engineering A, 2004, 387/389: 222-226.

[11] SMITH G W, BAXTER W J, MISHRA R K. Precipitation in 339 and 2124 aluminum: A caveat for calorimetry[J]. Journal of Materials Science, 2000, 35: 3871-3880.

[12] SMITH G W. Precipitation kinetics in solutionized aluminum alloy 2124: Determination by scanning and isothermal calorimetry[J]. Thermochimica Acta, 1998, 317: 7-23.

[13] 邓才智, 刘志义, 马飞跃, 喻翠平, 韩向楠. Al-3.6Cu-1.6Mg-0.1Zr铝合金的时效析出与硬化机理分析[J]. 材料热处理技术, 2008, 37(22): 48-51, 55.

DENG Cai-zhi, LIU Zhi-yi, MA Fei-yue, YU Cui-ping, HAN Xiang-nan. Analysis on precipitation and hardening mechanism of Al-3.6Cu-1.6Mg-0.1Zr alloy during artificial aging[J]. Hot Working Technology, 2008, 37(22): 48-51, 55.

[14] 刘志义, 李云涛, 刘延斌, 夏卿坤. Al-Cu-Mg-Ag 合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, XIA Qing-kun. Development of Al-Cu-Mg-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[15] WANG S C, STARINK M J, GAO N. Precipitation hardening in Al-Cu-Mg alloys revisited[J]. Scripta Materialia, 2006, 54: 287-291.

[16] FONTECCHIO M. Quench probe and quench factor analysis of aluminum alloys in distilled water[D]. Worcester, MA: Worcester Polytechnic Institute, 2002.

[17] WANG S C, STARINK M J. The assessment of GPB2/S”structures in Al-Cu-Mg alloys[J]. Materials Science and Engineering A, 2004, 386: 156-163.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50904010)

收稿日期:2009-08-25;修订日期:2010-02-28

通信作者:张永安,教授,博士;电话: 010-82241165; Email: zhangyongan@grinm.com