文章编号:1004-0609(2010)11-2192-07

CeO2对纯铜表面料浆包渗Cr-Al渗层组织和耐磨性能的影响

王红星, 李迎光

(南京航空航天大学 机电学院,南京 210016)

摘 要:采用浆料包渗法,以Cr2O3 粉为渗Cr源,纯Al 粉为还原剂,NH4Cl为活化剂,Al2O3为惰性添加剂,蛋白质(鸡蛋清)为粘结剂,在纯Cu表面预先镀Ni,随后表面浆料包渗Cr、Al,制备Cr、Al共渗层;研究稀土氧化物CeO2含量对Cr、Al渗层显微组织和耐磨性能的影响。采用SEM和XRD测定渗层的表面形貌和结构。结果表明:添加稀土氧化物CeO2后,渗层表面显微组织产生明显变化,颗粒由大变小,渗层变致密,组织由单一的Ni(Cr、Al)固溶体转变为由Ni3Al相和固溶体混合组成;随着稀土氧化物CeO2含量的增加,固溶体中Cr含量先增后减,渗层的摩擦因数先降后升,最小摩擦因数为纯铜的1/3。

关键词:纯铜;Cr2O3粉;CeO2;Cr-Al渗层;稀土氧化物;耐磨性

中图分类号:TG174.445 文献标志码:A

Effect of CeO2 on microstructure and wear resistance of Cr-Al coating by slurry packing on copper

WANG Hong-xing, LI Ying-guang

(College of Mechanical and Electrical Engineering, Nanjing University of

Aeronautics and Astronautics, Nanjing 210016, China)

Abstract:By a slurry pack cementation, with Cr2O3 as chromizing source, pure Al powders as reducers, NH4Cl as activator and albumen (egg white) as cohesive agent, electroplated specimens with a layer of electroplated nickel originally deposited on copper were chromized to prepare Cr-Al coating. The effects of CeO2 content on the microstructure and wear resistance of Cr-Al coating were studied. The surface morphology and structure of coating were examined by means of SEM and XRD. The results show that the grain of the coating becomes small, the coating becomes dense, the microstructure of coating changes from a solid solution of Cr and Al in nickel of single phase into the mixture of Ni3Al phase and a solid solution after adding CeO2 oxides; the Cr content in coating firstly increases and then decreases with the increase of CeO2 content, but the coefficient of friction of coating firstly decreases and then increases with the increase of CeO2 content, and the minimum value is 1/3 that of pure copper.

Key words: pure copper; Cr2O3 powder; Ce2O; Cr-Al coating; rare earth oxide; wear resistance

纯铜因具有优良的导电性、导热性和韧性等,在实际生产中获得了广泛应用。如冶金行业的高炉风口、连铸机结晶器零部件等都用纯铜制造[1]。但铜的硬度较低,耐磨性能差,影响零部件的使用寿命,限制了其应用范围。

为了改善和提高纯铜表面的抗氧化性和抗磨损性能,一般有2种方法:一是整体合金化,二是表面涂覆进行改性。整体合金化虽可改善其性能,但同时会削弱铜的高导电、导热性能。文献[2]报道了Cu-Be合金化提高了铜的耐磨性能,但与纯铜相比,降低了导热性能。采用表面涂覆技术,可以在不牺牲铜的导热、导电性能的前提下,提高铜表面的抗氧化性能和耐磨性能。目前,对铜表面进行改性的方法主要有固体粉末包渗法,如渗铝[3-4]、渗钛[1] 、渗硅[5]和激光熔覆等技术[6-9]。在众多的表面改性技术中,固体粉末包渗技术,具有操作过程简单、不需要专门的设备、加工成本低,而且适用于处理形状复杂的零件,涂层和基体结合牢固的优点,但存在漏渗现象。浆料包渗技术具有固体粉末包渗技术的优点,克服了固体粉末包渗漏渗的不足,渗层厚度均匀,并且涂层和基体呈冶金结合。

渗剂中添加微量稀土元素或稀土氧化物可加速渗镀,改善渗层组织,降低渗层的脆性,提高渗层的耐磨性和抗高温氧化性[10-13]。本文作者在纯Cu表面预先电镀纯Ni层,然后采用浆料包渗法,在镀Ni层表面扩散渗入Cr、Al元素,形成Cr-Al共渗层;在此基础上,在渗剂中添加微量稀土元素的氧化物,通过微量元素的作用来改善Cr-Al渗层的耐磨性能;研究渗剂中氧化铈(CeO2)含量对Cr-Al共渗层组织和耐磨性能的影响。

1 实验

将纯度为99.99%的纯铜块切割成尺寸为 15 mm×10 mm×2 mm的试样。首先,使用800#金相砂纸磨亮,10% NaOH溶液清除试样表面油污,再用10% H2SO4溶液清洗,用去离子水冲洗后进行电镀。镀液组成及工艺参数参见文献[14]。将电镀后的试样清洗、烘干后备用。

采用纯铝粉为还原剂,Cr2O3为供铬剂,NH4Cl为活化剂,蛋白质(鸡蛋清)为粘结剂,Al2O3为惰性添加剂制备浆料,渗剂配方见表1。分别称取各种组分放入研钵中,研磨5 min,使混合均匀。加入适量的鸡蛋清,调制成膏状涂覆于待渗试样表面。在真空干燥箱内80 ℃干燥1 h,放入自制的真空炉中,抽真空,用纯度为99.99%的氩气洗炉3次,然后,通入氩气,升温至850 ℃,保温12 h,随炉冷却。

采用WTM-2E可控气氛微型摩擦磨损实验仪进行球-盘式磨损试验,对磨材料为d 2 mm的Si3N4球,硬度为1 590 HV300,试样分别为Cu基体、Ni镀层和不同条件制备的渗层。测试载荷为7.5 N,转速为500 r/min,回转半径为4 mm,滑动时间为30 min。采用HVS-1000显微硬度计测定渗层的显微硬度,载荷为0.98 N,保压时间为15 s。

采用FEI SIRION场发射扫描电子显微镜(SEM)分析渗层表面的形貌特征;利用能谱(EDX)分析渗层截面成分分布,X射线衍射(XRD,D/MAX-RA)分析渗层表面的相组成;用OLYMPUS-B202光学显微镜观察渗层的显微组织。

2 结果与分析

2.1 稀土氧化物CeO2对渗层显微组织的影响

图1所示为在850 ℃包渗12 h后渗层表面的显微微观形貌。从图1(a)可看出,渗层表面颗粒粗大,存在少量的空洞。对渗层表面微区进行EDS元素能谱分析,表明含有Al、Cr和O元素,摩尔分数分别为2.04%、15.93%和1.03%。当稀土氧化物添加量为3%(质量分数)时,渗层表面粗糙、疏松,颗粒大小不均匀。在微区A有较高浓度的Cr和Al元素,质量分数分别为43.42%和45.13%;微区B主要含有Cr,质量分数高达95.32%,大大高于不加稀土氧化物时的渗层,而Al的质量分数很低,为0.86%。

当稀土氧化物加入量为6%时,渗层表面致密,颗粒呈片状结构,生成物具有明显的方向性。元素能谱分析表明,渗层表面主要含有铬元素,其质量分数高达98%,高于低稀土含量时渗层表面铬元素含量,即渗层表面几乎为纯铬层(见图1(c))。

当继续增加渗剂中稀土氧化物含量到10%时,渗层表面变得粗糙、不平,颗粒之间出现一些微孔(见图1(d))。渗层表面微区能谱分析表明,与6% 稀土氧化物对应的比较,渗层表面铬元素的质量分数稍微下降,为93.17%,仍远高于不加稀土氧化的渗层和低稀土氧化物的渗层表面铬元素质量分数。实验结果表明:当

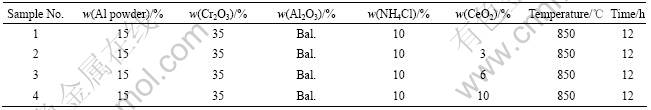

表1 料浆包渗Cr-Al渗层的渗剂配方及工艺

Table 1 Formation of slurry and technology for Cr-Al coating by slurry pack cementation

图1 在850 ℃包渗12 h后含有不同CeO2含量渗剂的渗层表面形貌

Fig.6 SEM surface morphologies of coatings with different contents of CeO2 after slurry pack cementation at 850 ℃ for 12 h: (a) Without CeO2; (b) 3% CeO2; (c) 6% CeO2; (d) 10% CeO2

渗剂中的CeO2加入量为6%时,渗层致密,铬元素含量最高;若继续增加稀土氧化物的含量,渗层中铬的含量下降,同时渗层的致密度降低。

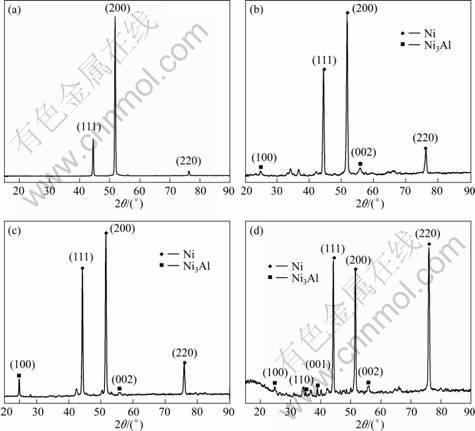

图2所示为在850 ℃包渗12 h后渗层表面的XRD谱。从图2(a)看出,不加稀土氧化物时,衍射图谱中只出现单质镍的衍射峰,结合EDS分析结果,表明渗层组织为Al、Cr在Ni中的固溶体。添加CeO2后,衍射图谱中除了镍的衍射峰外,在低指数晶面(100)、(002)和(001)出现了Ni3Al金属间化合物衍射峰,但没有出现有关Cr元素单质及其化合物的衍射特征峰(见图2(b)~(d))。这可能是在12 h内扩散形成的渗层厚度很薄,因而,在XRD谱中只出现了Ni3Al相和Ni的特征峰。同时,在2θ为42.33?的位置出现一些衍射峰,通过与PDF卡片比较,没有找到相对应的物质。这可能是稀土元素与铬或铝形成的化合物的衍射峰,还需进一步确定。金属元素之间一般都能形成置换固溶体,但固溶度的大小相差很大。根据Hume-Rothery提出的有利于形成固溶体的原子半径差低于15%的判据,镍和铬的原子半径差Δr = 1.6%,可能形成有较大溶解度的固溶体,而镍和铝的原子半径差Δr=15%,固溶度较小。另外,当溶质原子和溶剂原子的负电性相差很大,即两者之间化学亲和力很大时,则它们往往形成比较稳定的金属化合物,即使形成固溶体,其固溶度也较小。镍的电负性为1.9,铬的电负性为1.6,两者比较接近,有利于形成固溶体;而铝的电负性为1.5,和镍的电负性相差较大。从以上的分析可知,元素Ni与Cr更易形成固溶体,而与Al则易形成化合物。

图3所示为在850 ℃包渗 12 h后渗层的截面显微组织。可看出,经包渗后,Cu基体表面形成了由内层Ni镀层和外层渗层Ni3Al+Ni(Cr)组成的多层结构,并呈冶金结合。不加稀土氧化物时,渗层厚度较薄 (见图3(a));当CeO2加入量为3%时,渗层由表面疏松层和内层呈树枝状晶组成,枝晶较粗大(见图3(b));当加入量为6%时,渗层由单一的树枝状晶组成,枝晶得到细化(见图3(c));加入量为10%时,枝晶粗化(见图3(d))。

渗层表显微组织和结构表明,稀土氧化物对渗层的显微组织和结构产生了明显影响。稀土氧化物在包渗过程通过某种机制影响了渗层组织的形成过程。在高温下,CeO2颗粒和渗剂中活化剂产生高浓度的气态卤化物反应,生成气态稀土卤化物,在浓度梯度的作用下,向渗层表面进行扩散,在表面基体元素的作用下,产生稀土原子,通过扩散到达晶界,阻碍晶粒的长大,从而起到了细化晶粒的作用[15]。在本实验条件

图2 在850 ℃包渗12 h后含有不同CeO2含量的渗剂的渗层表面XRD谱

Fig.2 XRD patterns of coating surfaces with different contents of CeO2 after slurry pack cementation at 850 ℃ for 12 h: (a) Without CeO2; (b) 3% CeO2; (c) 6% CeO2; (d) 10% CeO2

图3 在850 ℃包渗12 h后含有不同CeO2含量的渗剂的渗层截面组织

Fig.3 Microstructures of cross sections of coatings with different contents of CeO2 after slurry pack cementation at 850 ℃ for 12 h: (a) Without CeO2; (b) 3% CeO2; (c) 6% CeO2; (d) 10% CeO2

下,加入6% CeO2对料浆包渗层的显微组织具有明显的改善作用。在表面的位错、空位等晶体缺陷处,形成活性中心,而且稀土原子对其周围的Al原子、Cr原子有很强的吸附能力;当被吸附的Al原子、Cr原子等达到一定浓度后,就向镍层中扩散;随后,稀土活性中心又可以吸附其他的活性原子,维持新的平衡,使活性原子不断向镍层中扩散,从而使表面浓度提高,扩散速度加快,促进渗层厚度的增加[16-17]。

有研究[18-20]指出:稀土的化学活性很强,能加速渗剂的分解;它易吸附于金属的表面,使系统能量降低,促进渗铬、铝的进行;由于稀土原子半径较大,它的渗入会导致空位的产生,为铬、铝原子的渗入提供通道,使渗速加快。当渗剂中稀土量很少时,稀土元素对渗剂的分解促进作用较小,同时,稀土活性中心在试样表面的覆盖率也较少,使铬、铝原子浓度增加不多;而当渗剂中加入稀土量较多时,较多的稀土原子堆积在试样表面形成“活性稀土原子堆积层”,增加了铬、铝原子扩散阻力,反而使到达试样表面的铬、铝原子减少。故只有当稀土含量适宜时,稀土原子的活性作用才能充分发挥,催渗效果达到最佳。

2.2 稀土氧化物CeO2含量对渗层耐磨性能的影响

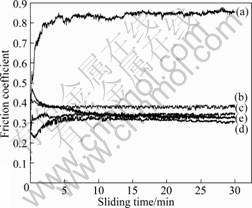

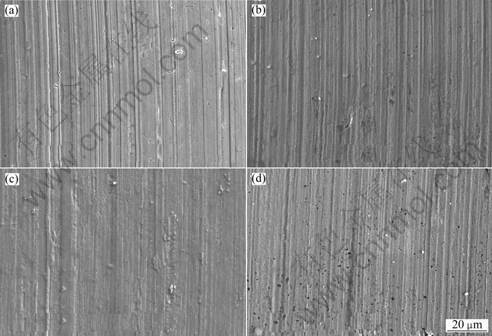

图4和图5所示分别为Cr-Al渗层的摩擦因数曲线和磨痕形貌。从图4看出,渗层的摩擦因数随稀土含量的增加而降低。在载荷7.5 N下,随着磨损时间的延长,摩擦因数曲线一直比较平缓,摩擦因素在0.37左右,为纯铜的1/2左右(纯铜摩擦因数为0.81)。当稀土含量为3%时,在整个磨损过程中,摩擦因数曲线一直处于缓慢下降的状态,30 min后,摩擦因素约为0.31,在磨痕表面出现较深的犁沟现象;当稀土含量为6%时,在前5 min内,摩擦因数呈上升

图4 在850 ℃包渗12 h后含有不同CeO2含量的渗剂的Cr-Al渗层摩擦因数曲线

Fig.4 Friction coefficient curves of Cr-Al coatings with various contents of Ce2O after slurry pack cementation at 850 ℃ for 12 h: (a) Pure Cu; (b) 15% Al; (c) 15%Al+3%CeO2; (d) 15%Al+6%CeO2; (e) 15%Al+10%CeO2

图5 在850 ℃包渗12 h后含有不同CeO2含量的渗剂的渗层磨痕形貌

Fig.5 Worn morphologies of Cr-Al coatings with various contents of Ce2O after slurry pack cementation at 850 ℃ for 12 h: (a) Without CeO2; (b) 3% CeO2; (c) 6% CeO2; (d) 10% CeO2

的趋势,随后一直缓慢递减至0.28,为纯铜的1/3,磨痕表面的犁沟的宽度和深度明显减轻;当稀土含量为10%时,摩擦因数一直处于平稳的状态,维持在0.32,磨痕表面出现较轻的犁沟现象。

从以上分析可以看出,与不加稀土氧化物的渗层相比,加入稀土氧化后,渗层的耐磨性得到提高,这与渗层中形成了Ni3Al相和富铬相有关。尤其是加入6% CeO2时,耐磨性最好。由此可见,CeO2对料浆包渗层耐磨性的影响与其加入量有很大的关系,过高或过低的均不能最有效地提高渗层的耐磨性。在本实验条件下,加入6% CeO2对提高料浆包渗层的耐磨性具有较好的效果。渗层耐磨性的提高主要是由于加入稀土氧化物后渗层的结构得到改善、晶粒得到细化以及渗层中各种缺陷减少的缘故。

3 结 论

1) 在纯铜表面预先镀镍,随后料浆包Cr-Al渗层制备的Cu基体/Ni镀层/渗层Ni3Al+Ni(Cr)的多层结构,层之间呈冶金结合。

2) 渗剂中添加稀土氧化物,改变了渗层组织,提高了耐磨性能。当渗剂中加入6%CeO2时,渗层中形成表层富铬相和Ni3Al金属间化合物,渗层中的空隙明显减少,其摩擦因数与纯铜的相比,由不加稀土氧化物的1/2降低到1/3。

REFERENCES

[1] BATENI M R, MIRDAMADI S, ASHRAFIZADEH F. Oxidation behavior of titanium coated substrate[J]. Surface and Coatings Technology, 2001, 139(2/3): 192-199.

[2] SUBRAMANIAN C, CAVALLARO G, WINKELMAN G. Wear maps for titanium nitride coatings deposited on copper and brass with electroless nickel interlayer[J]. Wear, 2000, 241(2): 228-233.

[3] 孙远敬, 岳立新, 张亚玲. 纯铜多元共渗及热处理工艺研究[J]. 煤矿机械, 2006, 27(6): 1021-1022.

SUN Yuan-jin, YUE Li-xin, ZHANG Ya-ling. Multi-element penetration of copper and heat treatment technology[J]. Coal Mine Machinery,2006, 27(6): 1021-1022.

[4] 张 毅, 田保红, 陈小红, 高颖颖, 刘 平, 李 炎. 纯铜稀土催渗渗铝及及其内氧化[J]. 铸造技术, 2006, 27(3): 134-136.

ZHANG Yi, TIAN Bao-hong, CHEN Xiao-hong, GAO Ying-ying, LIU Ping, LI Yan. Study on aluminizing with RE and internal oxidation treatment of commericial pure copper[J]. Foundry Technology, 2006, 27(3): 134-136.

[5] 甘正浩, 毛志远, 沈复初, 郦 剑, 叶必光. 铜的表面含硅渗层的结构与性能[J]. 材料科学与工程, 1997, 15(1): 50-53.

GAN Zheng-hao, MAO Zhi-yuan, SHEN Fu-chu, LI Jian, YE Bi-guang. Structure and properties of siliconized layer for copper[J]. Materials Science & Engineering, 1997, 15(1): 50-53.

[6] KANG H K. Microstructure and electrical conductivity of high volume Al2O3-reinforced copper matrix composites produced by plasma spray[J]. Surface and Coatings Technology, 2005, 190(2/3): 448-452.

[7] 田风杰, 刘伟军, 尚晓峰. 纯铜基体上激光熔覆Ni60涂层的试验研究[J]. 金属热处理, 2008, 33(12): 35-37.

TIAN Feng-jie, LIU Wei-jun, SHANG Xiao-feng. Study on Ni60A coating on copper by laser cladding[J]. Heat Treatment of Metal, 2008, 33(12): 35-37.

[8] 陈志坤, 刘 敏, 曾德长, 马文有, 李福海, 邓畅光. 铜表面激光熔覆镍基合金的显微组织与硬度[J]. 机械工程材料, 2009, 33(1): 51-54.

CHEN Zhi-kun, LIU Min, ZENG De-chang, MA Wen-you, LI Fu-hai, DENG Chang-guang. Microstructure and hardness of the laser cladding Ni-based alloy coating on the surface of Cu[J]. Materials for Mechanical Engineering, 2009, 33(1): 51-54.

[9] YANG Gui-rong, SONG Wen-ming, LU Jin-jun, HAO Yuan, LI Ya-min, MA Ying. Microstructure of surface composite Al2O3/Ni on copper substrate produced by vacuum infiltration casting[J]. Mater Sci Eng A, 2006, 418(1/2): 223-228.

[10] 谢 飞, 马宝钿, 何家文. 钢中稀土对化学处理的影响与作用机理[J]. 稀有金属材料与工程, 1997, 26(1): 52-55.

XIE Fei, MA Bao-tian, HE Jia-wen. The effect of rare earth in steels on the thermochemical treatments and the functional mechanisms of the rare earths[J]. Rare Metal Materials and Engineering, 1997, 26(1): 52-55.

[11] 文九巴, 杨柳松, 张金民, 朱利敏, 李全安. CeO2改性渗铝层的动力学研究[J]. 材料热处理学报, 2007, 28(S1): 165-168.

WEN Jiu-ba, YANG Liu-song, ZHANG Jin-min, ZHU Li-min, LI Quan-an. Research on the growth kinetics of CeO2 –modified aluminide coating[J]. Transactions of Materials and Heat Treatment, 2007, 28(S1): 165-168.

[12] 朱丽敏, 杨景洪, 王长生, 高习文. CeO2改性渗铝层及其氧化性能研究[J]. 材料热处理学报, 2007, 28(2): 110-112.

ZHU Li-min, YANG Jing-hong, WANG Chang-sheng, GAO Xi-wen. Microstructure and oxidation behavior of novel CeO2-modified aluminizing coating[J]. Transactions of Materials and Heat Treatment, 2007, 28 (2): 110-112.

[13] PENG X. Effect of La2O3 particles on microstructures and cracking-resistance of NiO scale on electrodeposited nickel films[J]. Mater Sci and Eng A, 2001, 298(1/2): 100-109.

[14] 王红星, 盛晓波, 储成林, 林萍华, 董寅生. Cu基体电镀Ni层表面渗铝组织及其形成机理[J]. 中国有色金属学报, 2007, 17(10): 1616-1621

WANG Hong-xing, SHENG Xiao-bo, CHU Cheng-lin, LIN Ping-hua, DONG Yin-sheng. Aluminizing microstructure and its formation mechanism on electro-deposited nickel layer on copper matrix[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1616-1621

[15] 黄拿灿. 稀土元素在表面工程技术中的应用[J]. 金属热处理, 2003, 28(4): 7-10.

HUNG Na-can. Application of rare-earth elements in surface engineering[J]. Heat Treatment of Metals, 2003, 28(4): 7-10.

[16] 黄拿灿, 胡社军. 稀土化学热处理与稀土材料表面改性[J]. 稀土, 2003, 24(3): 59-63.

HUANG Na-can, HU She-jun. Rare earth thermo-chemical treatment and rare earth material surface modification[J]. Chinese Rare Earths, 2003, 24(3): 59-63.

[17] 钟华仁. 钢的稀土化学热处理[M]. 北京: 国防工业出版社, 1998: 12-14.

ZHONG Hua-ren. Rare earth chemical-heat treatment of steel [M].Beijing: Defense Industry Press, 1998: 12-14.

[18] 张克从, 张 乐. 晶体生长科学与技术: 上册[M]. 北京: 科学出版社, 1981: 223.

ZHANG Ke-cong, ZHANG Le. Science and technology of growth of crystal: Volume 1[M]. Beijing: Science Press, 1981: 223.

[19] 王世清, 王立铎, 杨爱华. 稀土元素在化学热处理中的应用[J]. 金属热处理, 1988(3): 52-59.

WANG Shi-qing, WANG Li-duo, YANG Ai-hua. Application of rare earths in thermo-chemical treatment[J]. Heat Treatment of Metals, 1988(3): 52-59.

[20] 刘长禄, 王丽风. 硼稀土粉末共渗及渗硼层的性能[J]. 金属热处理, 1989(8): 32-35.

LIU Chang-lu, WANG Li-feng. Powdered cementation of boron with rare earth element(RE) and the properties of its layer[J]. Heat Treatment of Metals, 1989(8): 32-35.

(编辑 杨 华)

收稿日期:2009-07-15;修订日期:2010-09-09

通信作者:李迎光, 教授, 博士;电话:025-84891836;E-mail: welcome.li@nuaa.edu.cn