DOI: 10.11817/j.issn.1672-7207.2018.08.004

B2O3对含钛低镁渣系流动性的影响及其机理研究

范筱玥,张建良,许仁泽,焦克新,王凯迪

(北京科技大学 冶金与生态工程学院,北京,100083)

摘要:基于京唐现场渣中主要氧化物成分,采用内柱体旋转法对CaO-SiO2-15.2%Al2O3-4.8%MgO-TiO2-B2O3(质量分数)渣系进行黏度试验,结合Factsage软件热力学分析,探究TiO2和B2O3对低镁渣系黏度、熔化性温度和活化能的影响及影响机理。研究结果表明:质量分数为0~4.0%的TiO2使低镁渣系黏度、熔化性温度和活化能均降低;质量分数为0~2.0%的B2O3能降低含钛低镁渣系黏度和熔化性温度;含钛低镁渣中B2O3质量分数为1.0%左右较为合理。

关键词:低镁渣系;TiO2;B2O3;流动性

中图分类号:TF534.1 文献标志码:A 文章编号:1672-7207(2018)08-1863-06

Effect of B2O3 on fluidity of low MgO slag containing titanium

FAN Xiaoyue, ZHANG Jianliang, XU Renze, JIAO Kexin, WANG Kaidi

(School of Metallurgical and Ecological Engineering,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Based on the main oxide composition of Jingtang blast furnace slag, viscosity of CaO-SiO2-15.2%Al2O3- 4.8%MgO-TiO2-B2O3 (mass fraction) slag was measured by rotating cylinder method. Combined with thermodynamic analysis of factsage software, the effects of TiO2 and B2O3 on viscosity, break point temperature, activation energy of low MgO slag were investigated. The results show that viscosity, break point temperature and activation energy of low MgO slag remarkably decrease with the addition of 0-4.0% TiO2. The viscosity and break point temperature of low MgO slag containing titanium also decrease with the addition of 0-2.0% B2O3. The optimal mass fraction of B2O3 in low MgO slag containing titanium is about 1.0%.

Key words: low MgO slag; TiO2; B2O3; fluidity

高炉渣的冶金性能对高炉稳定运行和铁水质量的重要性不能忽视,而其组分决定冶金性能。高炉渣中典型的碱性氧化物MgO主要由原料带入,能明显改善炉渣流动性[1]。国内研究者提出MgO质量分数应为8%~12%[2]。而KIM等[3]认为应将渣中MgO质量分数控制在5%以下,其优势是减少熔剂和燃料消耗,降低生产成本。然而,高炉低镁冶炼可能带来炉渣黏度增加、性能不稳定的问题[1]。因此,如何在低镁条件下保证炉渣的流动性是现代冶金工业的重要研究内容。以京唐大型高炉优化冶炼为例,含钛球团的应用使得渣中出现一定质量的TiO2[4]。质量分数低于5%的TiO2能降低中镁渣系黏度[5],改善炉渣流动性,但含钛低镁渣系的合理组成尚不明确。B2O3是一种良好的助熔剂[6],渣中MgO质量分数较高(8%左右)时B2O3能显著降低冶金熔渣黏度[7-9],在改善炉渣流动性方面具有很大潜力,但有关B2O3对含钛低镁渣系影响的研究仍然较少。为此,本文作者基于京唐现场高炉渣主要成分,通过黏度试验探究B2O3和TiO2对低镁渣系黏度、熔化性温度和活化能的影响,结合Factsage热力学软件分析,明确B2O3对含钛低镁渣系黏度和结构的影响机理,为含钛低镁渣系性能优化提供参考依据。

1 实验

1.1 实验原料

为验证单一变量的影响,根据京唐高炉渣实际成分将二元碱度固定为1.16。MgO质量分数为4.8%,Al2O3质量分数为15.2%,TiO2质量分数为0~4.0%。考虑到B2O3具有良好助熔剂作用,在保证炉渣组分稳定的条件下,参考京唐高炉现场渣中TiO2质量分数即w(TiO2)=2.0%,B2O3质量分数在0~2.0%之间变化。为排除试样中杂质对实验结果的干扰,称量前对试样进行干燥处理。每次实验渣样总质量为125 g,称量后将合成渣样进行充分混合,以保证成分的均匀性。实验炉渣的化学成分如表1所示。

表1 实验炉渣的化学成分(质量分数)

Table 1 Chemical composition of experimental slag %

1.2 实验设备及方法

采用旋转柱体法测量炉渣黏度,使用的设备是RTW-10熔体物性综合测定仪。实验装置示意图如图1所示。

图1 实验装置示意图

Fig. 1 Diagram of experimental device

试验前在常温下用已知黏度的蓖麻油校准,然后将合成渣样置于钼坩埚中,通精纯氩气作为保护气,升温至1 550 ℃,保证炉渣完全熔化后继续保温3 h。实验时将钼转子居中降至距离钼坩埚底部10 mm处,以3 ℃/min的速率进行连续降温测量黏度,并用计算机记录黏度。

2 实验结果与讨论

2.1 TiO2对低镁渣系的影响

2.1.1 TiO2对低镁渣系黏度的影响

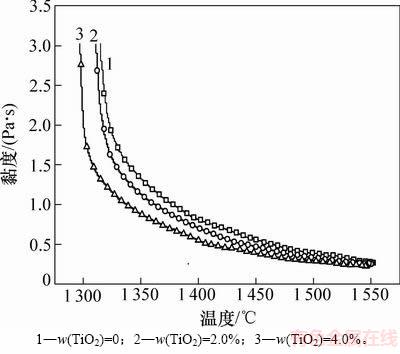

根据黏度试验结果得到质量分数为0~4.0%的TiO2炉渣黏度随温度变化曲线,如图2所示。

图2 不同TiO2质量分数高炉渣黏度-温度曲线图

Fig. 2 Viscosity-temperature curves of blast furnace slag with different mass fraction of TiO2

由图2可知:低镁渣系黏度随TiO2质量分数增加而逐渐降低,TiO2质量分数越高,对炉渣黏度降低的影响作用越大。炉渣黏度在温度高于1 400 ℃时变化较为平缓,在温度低于1 400 ℃且黏度小于3.0 Pa·s时变化显著,这与文玲等[10-12]的研究结果相一致。TiO2会解聚低钛渣中复杂的硅氧四面体结构,使得渣中聚合程度较高的Si—O键减少,炉渣结构趋于简单,从而黏度降低,流动性改善[5]。张金柱等[13]发现,在还原性气氛下随着TiO2质量分数增加,炉渣黏度增大,流动性变差。这是由于渣中生成钙钛矿和Ti(C,N)等高熔点物质,使炉渣流动性变差。因此,本文作者在惰性气氛下的钼坩埚中进行实验,避免了高熔点物质的生成,实验中并未出现黏度增大的现象,炉渣黏度可满足高炉的需求,即在低镁渣系条件下,炉渣中适量的TiO2能降低炉渣黏度,改善炉渣流动性。

2.1.2 TiO2对低镁渣系活化能的影响

炉渣黏度与温度的关系通常采用Arrhenius公式表征:

(1)

(1)

式中:η为黏度,Pa·s;A为指前因子;R为气体常数,J·mol-1·K-1;T为热力学温度,K;Eη为炉渣活化能,J·mol-1。

活化能Eη可以表征渣液流动过程中的摩擦阻力,同时活化能的变化表明炉渣结构可能发生改变[14]。Arrhenius公式仅适用于全溶液区域,即公式中涉及的温度T应不低于熔化性温度[15]。熔化性温度可以通过黏度曲线与斜率为-1的切线的切点温度得到。由实验所得的熔化性温度及其对应黏度,利用Factsage软件Equilib模块、Viscosity模块计算的低镁渣系熔化温度及其对应黏度如图3所示。

图3 TiO2质量分数对低镁渣系熔化性温度、熔化温度及其对应黏度的影响

Fig. 3 Effects of TiO2 mass fraction on break temperature,liquidus temperature and viscosity of low MgO slag

由图3可知:用Factsage软件计算的完全熔化温度高于实验所得熔化性温度,二者均随TiO2增加而逐渐降低,尤其是当w(TiO2)=4.0%时,实验熔化性温度达到最低值1 326.93 ℃。随着TiO2质量分数增加,实验熔化性温度对应的黏度不断降低,而Factsage软件计算的熔化温度对应的黏度不断升高。这可能是由于Factsage软件考虑熔渣中生成固相质点,使得黏度增加[16]。对式(1)等号两边同时取对数可得:

(2)

(2)

由式(2)可知lnη与温度的倒数1/T呈线性相关,故活化能Eη和指前因子A可分别由图像的斜率和截距获得。图4所示为不同TiO2质量分数下lnη与1/T拟合曲线(其中,r2为拟合优度)。

由图4可知:在不同TiO2质量分数下,lnη与1/T呈明显线性关系。通过图4中的拟合曲线斜率计算得到渣系活化能,结果如图5所示。

图4 不同TiO2质量分数下lnη与1/T拟合曲线

Fig. 4 Fitting curves of lnη and 1/T with different mass fractions of TiO2

图5 TiO2质量分数对炉渣活化能的影响

Fig. 5 Effects of TiO2 mass fractions on activation energy of the slag

低镁渣系活化能随TiO2质量分数增加而降低,在w(TiO2)为4.0%时活化能达到最低值148.66 kJ/mol,活化能变化与渣系结构有关。由于低钛渣中Ti—O键的强度远低于Si—O键的强度,因此,渣中TiO2并不能形成类似硅氧四面体的复杂结构;而TiO2生成的最小结构单元会弥散地镶嵌在硅酸盐结构中解聚网状结构[17]。加入TiO2使炉渣结构趋于简单,因此,活化能降低,炉渣流动性随之改善。

2.2 B2O3对含钛低镁渣系的影响

2.2.1 B2O3对含钛低镁渣系黏度的影响

图6所示为当w(TiO2)=2.0%时,不同B2O3质量分数下含钛低镁渣系黏度随温度变化曲线。由图6可知:含钛低镁渣系黏度随着B2O3质量分数不断增加而降低;B2O3质量分数越高,炉渣黏度降低程度越大。B2O3对不同组分炉渣黏度的影响与王文忠等[6-7, 18]的研究结果相似。

图6 不同B2O3质量分数下高炉渣黏度-温度曲线

Fig. 6 Viscosity-temperature curves of the blast furnace slag with different mass fractions of B2O3

利用Factsage软件中的Phase Diagram模块,得到1 350 ℃下CaO-SiO2-15.2%Al2O3-4.8%MgO- 2.0%TiO2-B2O3的伪三元相图,结果如图7所示。其中顶点成分分别为MgO,CaO和SiO2;TiO2和Al2O3质量分数固定在2.0%和15.2%;沿着图中箭头方向B2O3质量分数依次为0,0.2%,1.0%和2.0%。从图7可以看出:随着炉渣中B2O3质量分数增加,炉渣液相区逐渐向MgO,CaO和SiO2区域延伸,尤其在CaO范围内这种趋势更为明显。钛渣中B2O3能与碱性氧化物生成MgO·B2O3和CaO·B2O3等低熔点物质[7]。低熔点物质的生成导致液相区范围扩大,炉渣流动性改善。因此,随着渣中B2O3质量分数增加,炉渣黏度降低。

图7 1 350 ℃下B2O3质量分数对炉渣液相区的影响

Fig. 7 Effects of B2O3 mass fraction on liquid region of slag at 1 350 ℃

2.2.2 B2O3对含钛低镁渣系活化能的影响

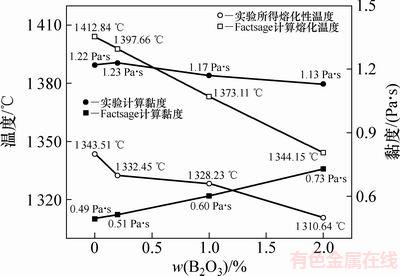

B2O3对含钛低镁渣系实验熔化性温度和Factsage软件计算熔化温度及黏度的影响如图8所示。

图8 B2O3质量分数对低镁渣系熔化性温度、熔化温度及黏度的影响

Fig. 8 Effects of B2O3 mass fraction on break temperature,liquidus temperature and viscosity of low MgO slag

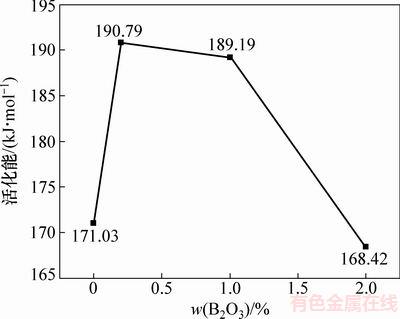

由图8可知:实验炉渣熔化性温度与Factsage软件计算的熔化温度均随B2O3质量分数增加而降低,并在w(TiO2)=2.0%和w(B2O3)=2.0%处达到最低值。质量分数为0.2%的B2O3使炉渣熔化性温度降低幅度较大,但熔化性温度应控制在合适的范围内以保证渣铁顺利分离[16]。因此,含钛低镁渣中B2O3质量分数不能过高也不能过低,B2O3质量分数在1.0%左右较为合理。不同B2O3质量分数下lnη与1/T拟合曲线如图9所示。由图9可知:lnη与1/T呈明显的线性关系。B2O3质量分数对含钛低镁渣系活化能的影响如图10所示。

由图10可知:当炉渣中B2O3质量分数小于0.2%时,炉渣活化能随B2O3质量分数增加而随之升高。活化能增加表明渣中可能有新的结构单元出现。事实上,随着B2O3加入,渣中出现新的B—O键结构类型[7],因此,初始加入的B2O3使得活化能升高。随着B2O3质量分数进一步增加,[BO3]平面单元结构成为渣中 B—O键的主要连接方式,这种结构简单且在高温下比较稳定的单元体在渣中不断生成,导致炉渣活化能降低。在炉渣组分为2.0%TiO2和2.0%B2O3时,活化能达到最低值168.42 kJ/mol。

图9 不同B2O3质量分数下lnη与1/T拟合曲线

Fig. 9 Fitting curves of lnη and 1/T with different mass fractions of B2O3

图10 B2O3质量分数对炉渣活化能的影响

Fig. 10 Effects of B2O3 mass fraction on activation energy of the slag

2.2.3 B2O3对含钛低镁渣系结构的影响

高炉渣的微观结构直接影响着炉渣的宏观性能。硅氧四面体结构是高炉渣中基本结构单元,一般有5种类型即Q0,Q1,Q2,Q3和Q4(其中上标数字代表硅氧四面体聚合结构中桥氧键的个数)。桥氧键的数量是表征炉渣结构复杂程度的标准之一。SUN等[19]的研究表明,B2O3在渣中表现为典型的酸性氧化物,加入B2O3后会促进如下反应的发生[19]:

(3)

(3)

硅氧四面体中桥氧键数量增加会使得炉渣结构复杂程度上升,进而导致炉渣流动性变差。但实验证明随着B2O3质量分数增加,炉渣黏度降低,流动性明显改善,表明炉渣黏度并不仅由渣中结构单元聚合程度决定。渣中B—O键主要表现为[BO4]和[BO3]这2种连接方式,在碱性氧化物或碱金属氧化物(Ca2+和Na+)存在的条件下会发生以下反应[17]:

(4)

(4)

(5)

(5)

含B2O3渣中基本结构单元如图11所示。由图11可知:式(4)中生成的(BO4-)四面体聚合结构携带3个桥氧原子,式(5)中(BO3-)平面三角结构携带2个桥氧原子。当网络改良子(CaO+MgO)的质量分数超过30%时,式(5)为渣中主要反应。

实验渣系中w(CaO+MgO)>40%,故炉渣B—O键主要连接形式为平面三角型。尽管加入B2O3使得炉渣结构聚合度上升,但BO3 平面三角结构单元的存在很大程度上降低了流动过程中的黏滞阻力,使得B2O3作为酸性氧化物使炉渣黏度增大的影响要弱于BO3简单平面结构降低黏度的影响,从而使炉渣的黏度降低,流动性改善。

图11 含B2O3渣中基本结构单元

Fig. 11 Basic structural units in the slag containing B2O3

3 结论

1) 当TiO2质量分数在0~4.0%范围内变化时,含钛低镁渣系黏度、熔化性温度及活化能均随TiO2质量分数增加而降低。

2) 加入B2O3使渣中出现低熔点物质,降低含钛低镁渣黏度;利用Factsage软件计算发现B2O3加入后使得含钛低镁渣液相区范围扩大,炉渣流动性改善;加入质量分数为1.0%的B2O3较合理。

3) B2O3在渣中表现为典型酸性氧化物,可增加含钛低镁渣系结构聚合度。但BO3平面结构单元是B2O3在渣中B—O键的主要连接方式,简单结构单元的出现会降低炉渣流动阻力,且这种作用强于酸性氧化物B2O3对炉渣流动性的恶化作用,最终表现为炉渣黏度降低。

参考文献:

[1] 茅沈栋, 杜屏. 降低MgO含量对高炉渣黏度和熔化性温度的影响[J]. 钢铁研究学报, 2015, 27(9): 33-38.

MAO Shendong, DU Ping. Effect of reduction of MgO content in BF slag on viscosity and melting temperature[J]. Journal of Iron and Steel Research, 2015, 27(9): 33-38.

[2] 张旭升, 吕庆, 刘小杰, 等. 高炉炉渣中钛、镁、铝最优配比[J]. 钢铁, 2015, 50(6): 8-14.

ZHANG Xusheng, LU Qing, LIU Xiaojie, et al. Optimal proportion of Ti, Mg and Al in BF slag[J]. Iron and Steel, 2015, 50(6): 8-14.

[3] KIM J R, LEE Y S, MIN D J, et al. Influence of MgO and Al2O3 contents on viscosity of blast furnace type slags containing FeO[J]. ISIJ International, 2004, 44(8): 1291-1297.

[4] 李朋, 霍吉祥, 骆振勇, 等. 京唐球团厂自产含钛球团试验研究[J]. 烧结球团, 2014, 39(5): 23-26.

LI Peng, HUO Jixiang, LUO Zhenyong, et al. Experimental study on self-production of titanium-containing pellets in Jingtang pelletizing plant[J]. Sinter and Pelletizing, 2014, 39(5): 23-26.

[5] PARK H, PARK J Y, KIM G H, et al. Effect of TiO2 on the viscosity and slag structure in blast furnace type slags[J]. Steel Research International, 2012, 83(2): 150-156.

[6] 王文忠, 余琨, 徐金铎. 含硼炉渣性能研究[J]. 钢铁, 1980(4): 57-62.

WANG Wenzhong, YU Kun, XU Jinduo. Study on properties of boron containing slag[J]. Journal of Iron and Steel Research, 1980(4): 57-62.

[7] GAO Yanhong, BIAN Lingtao, LIANG Zhongyu. Influence of B2O3 and TiO2 on viscosity of Titanium-bearing blast furnace slag[J]. Steel Research International, 2014, 86(4): 386-390.

[8] SUN Yongqi, LIAO Junlin, ZHENG Kai, et al. Effect of B2O3 on the structure and viscous behaviour of Ti-bearing blast furnace slags[J]. JOM, 2014, 66(10): 2168-2175.

[9] LIN Yinhe, WEN Yongcai, FU Weiguo, et al. Effect and mechanism of B2O3 on apparent viscosity of slag during smelting of vanadium-titanium magnetite in the blast furnace[J]. Metallurgical Research & Technology, 2016, 113(5): 506-514.

[10] 文玲, 张金柱. 含钛高炉渣性能的研究进展[J]. 钢铁研究学报, 2011, 23(5): 1-3.

WEN Ling, ZHANG Jinzhu. Research progress on properties of Ti bearing blast furnace slag[J]. Journal of Iron and Steel Research, 2011, 23(5): 1-3.

[11] 王福佳, 吕庆, 陈树军. TiO2/SiO2对含钒钛高炉炉料熔滴性能的影响[J]. 钢铁钒钛, 2015, 36(6): 79-83.

WANG Fujia, LU Qing, CHEN Shujun. Research of TiO2/SiO2 influence on furnace burden’s dropping performance of vanadium-titanium magnetite[J]. Iron Steel Vanadium Titanium, 2015, 36(6): 79-83.

[12] 沈龙龙, 孙向伟, 刘彪, 等. 高炉低w(TiO2)炉渣流动性的研究[J]. 钢铁研究, 2013, 41(3): 19-21.

SHEN Longlong, SUN Xiangwei, LIU Biao, et al. Study on fluidity of BF slag with low w(TiO2)[J]. Journal of Iron and Steel Research, 2013, 41(3): 19-21.

[13] 张金柱, 施丽丽, 敖万忠. 高炉高铝低钛渣的熔化性[J]. 钢铁研究学报, 2010, 22(4): 16-19.

ZHANG Jinzhu, SHI Lili, AO Wanzhong. Melting property of high-titanium and low-titanium BF slag[J]. Journal of Iron and Steel Research, 2010, 22(4): 16-19.

[14] SUN Yongqi, LIAO Junlin, ZHENG Kai, et al. Effect of P2O5 addition on the viscosity and structure of Titanium bearing blast furnace slags[J]. ISIJ International, 2014, 54(7): 1491-1497.

[15] YAN Zhiming, LU Xuewei, ZHANG Jie, et al. The effect of TiO2 on the liquidus zone and apparent viscosity of SiO2- CaO-8wt.%MgO-14wt.%Al2O3 system[J]. ISIJ International, 2017, 57(1): 31-36.

[16] 张士举, 胥有利, 谢金洋, 等. 高炉渣主要组分对其熔化特性及黏度的影响[J]. 有色金属工程, 2016, 6(6): 50-54.

ZHANG Shiju, XU Youli, XIE Jinyang, et al. Effect of blast furnace slag main components on its melting characteristics and viscosity properties[J]. Nonferrous Metals Engineering, 2016, 6(6): 50-54.

[17] 袁骧, 张建良, 毛瑞, 等. 高炉低钛渣粘度和熔化性能[J]. 过程工程学报, 2014, 14(4): 664-670.

YUAN Xiang, ZHANG Jianliang, MAO Rui, et al. Viscosity and melting behavior of low titanium-containing blast furnace slag[J]. Chinese Journal of Process Engineering, 2014, 14(4): 664-670.

[18] HUANG Xinghuai, LIAO Junlin, ZHENG Kai, et al. Effect of B2O3 addition on viscosity of mould slag containing low silica content[J]. Ironmaking & Steelmaking, 2014, 41(1): 67-74.

[19] SUN Yongqi, ZHANG Zuotai. Structural roles of boron and silicon in the CaO-SiO2-B2O3 glasses using FTIR, Raman and NMR spectroscopy[J]. Metallurgical and Materials Transactions B, 2015, 46(4): 1549-1554.

(编辑 伍锦花)

收稿日期:2017-08-06;修回日期:2017-09-26

基金项目(Foundation item):北京市科技计划项目(Z161100002716017)(Project(Z161100002716017) supported by the Beijing Municipal Science and Technology Program)

通信作者:张建良,博士,教授,从事直接还原、富氧喷煤、熔融还原等研究;E-mail:jlzhang@ustb.edu.cn