文章编号:1004-0609(2012)05-1298-06

连接温度对C/C复合材料及Cu连接接头残余应力的影响

张小英,张福勤,夏莉红,于 奇

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用热弹塑性有限元数值模拟方法,研究了连接温度对C/C复合材料与Cu平面对接接头残余应力的影响。结果表明:最大拉应力的分布具有方向性,在连接界面法线方向上,最大拉应力出现在靠近接头界面的C/C复合材料侧,位于连接件的棱边上;在平行连接界面方向上,最大拉应力出现在靠近接头界面的Cu侧表面。最大剪切应力位于接头界面处。随着连接温度的升高,接头残余应力峰值逐渐增大,但接头残余应力的分布形态相似。对于连接界面尺寸为4 mm×4 mm的接头,在连接温度为1 000 ℃时,离接头界面1.2 mm的C/C复合材料侧最容易发生断裂。

关键词:C/C复合材料;Cu;连接温度;残余应力

中图分类号:TG404 文献标志码:A

Effect of joining temperature on residual stress of C/C composites and Cu joints

ZHANG Xiao-ying, ZHANG Fu-qin, XIA Li-hong, YU Qi

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The effect of joining temperature on the residual stress in carbon/carbon (C/C) composites and copper plane butt joints was studied using thermal-elastic-plastic finite element method. The results show that the distribution of the maximum tensile stress has directionality. The maximal value of the tensile stress vertical to the joined surface is at the C/C composites side near the interface. However, in parallel to the joined surface, the maximal tensile stress reaches on the Cu side near the interface. The maximal shear stress is found at the interface. With the increase of the joining temperature, the maximal residual stress increases, but the residual stress distribution is similar. When the size of the interface is 4 mm×4 mm at 1 000 ℃, the fracture may occur mostly at the C/C composites side near interface at a distance of 1.2 mm from the edge.

Key words: C/C composites; copper; joining temperature; residual stress

C/C复合材料具有导热性好、耐热冲击和抗疲劳等特点,并具有极低的中子激活能、低的原子序数以及很高的熔点和升华温度[1-2],是热聚变实验反应堆(ITER)面壁的候选材料[3-7]。但是,C/C复合材料在ITER中的应用必须解决其与Cu热沉材料之间的连接问题。由于C/C复合材料与Cu的热膨胀系数差异大,在焊接后的冷却过程中,膨胀失配导致焊接接头产生残余应力,降低焊接强度,造成连接失败。膨胀失配导致的残余应力与连接温度密切相关,因此,有必要探明C/C复合材料与Cu连接(C/C-Cu)接头中残余应力的大小及分布规律,进而合理地选择连接温度,降低残余应力。

接头残余应力的分析方法主要有实测法和计算法。实测法有多种,如X射线衍射法、电阻应变片法、热膨胀示差法和中子衍射方法等,但这些方法均无法对焊接过程中的应力变化进行实时测量,且不能直接测量接头内部的应力。鉴于此,研究者转而采用有限元法进行计算[8-9]。

近年来,随着计算机技术的快速发展,采用有限元方法研究陶瓷/金属焊接应力成为应力研究中的一个热点,如SHEN等[10]采用有限元分析了Al2O3-TiC/ W18Cr4V扩散焊的接头残余应力,发现最大轴向残余拉应力出现在靠近接头界面的Al2O3-TiC侧,最大轴向残余压应力出现在靠近接头界面的W18Cr4V侧;张小勇等[11]采用有限元方法研究了SiC陶瓷与金属Ta连接的残余应力,发现最大轴向残余应力出现在距界面0.6 mm的陶瓷侧。因此,采用有限元分析软件可以预测残余应力的大小和分布,使分析过程更加优质高效[8-12]。但对于C/C-Cu接头残余应力的有限元分析,目前国内外还未见相关报道。

为此,本文作者采用热弹塑性有限元数值模拟方法,研究C/C-Cu接头残余应力的大小和分布以及连接温度对C/C-Cu接头残余应力的影响。

1 实验

1.1 C/C-Cu接头的几何模型

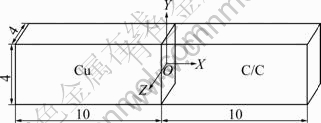

对C/C-Cu连接接头进行有限元模拟时作如下假设:1) C/C复合材料与Cu材料的界面是连续的,存在密度、比热容、导热系数和泊松比等物理性质的突变,但界面不存在过渡层;2)连接结构除了温度以外没有其他外部约束;3)在焊后冷却过程中,冷却速度相对较慢,连接试样本身不存在温差。连接试样几何形状及尺寸如图1所示,坐标原点位于连接界面中心。

图1 连接试样的几何模型

Fig. 1 Geometrical model of joined specimen (mm)

1.2 材料性能参数

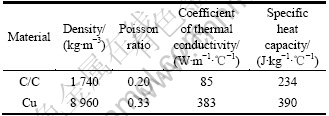

随着焊接温度的升高,C/C复合材料与Cu的物 理性质(弹性模量、热膨胀系数、屈服强度和切变模量)发生了很大变化。在有限元模拟过程中,假设C/C复合材料为弹性体,铜材料为理想的弹塑性体,并考虑材料属性随温度的变化情况,这样计算就可以认为是热弹塑性有限元问题。C/C复合材料和Cu的物性参 数见表1~3[13-14]。

表1 C/C复合材料和Cu的物性参数[13-14]

Table 1 Material properties of C/C composites and Cu[13-14]

表2 不同温度下C/C复合材料的物性参数[13-14]

Table 2 Properties of C/C composites at different temperatures[13-14]

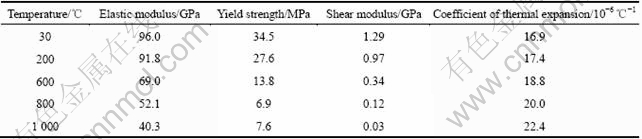

1.3 模拟过程

采用热弹塑性有限元数值模拟C/C-Cu接头的残余应力分布,选用三维8节点六面体Solid5单元对连接试样进行对应网格划分[15]。靠近接头界面的区域通常是明显的应力集中区域,因此,沿焊缝方向均匀划分网格,垂直于焊缝方向呈阶梯状划分网格,如图2所示。

表3 不同温度下Cu的物性参数[13-14]

Table 3 Properties of copper at different temperatures[13-14]

图2 C/C-Cu接头有限元单元网格划分

Fig. 2 Element meshes configuration for FEM on C/C-Cu joint

本研究主要考虑冷却过程,钎焊温度设定为600~1 000 ℃,模型的初始温度分别设定为600~1 000 ℃,终了温度设定为室温(20 ℃),计算从钎焊温度降至室温时接头的残余应力。

2 结果与讨论

2.1 C/C-Cu接头残余应力的分布特点

由于连接件沿X轴呈轴对称,其Z方向的正应力(σZ)和Y方向的正应力(σY)分布具有相同的特点,同时XY方向剪切应力τXY和XZ方向剪切应力τXZ的分布情况也具有相同的特点,因此,只对σX、σY和τXY的分布情况进行分析。

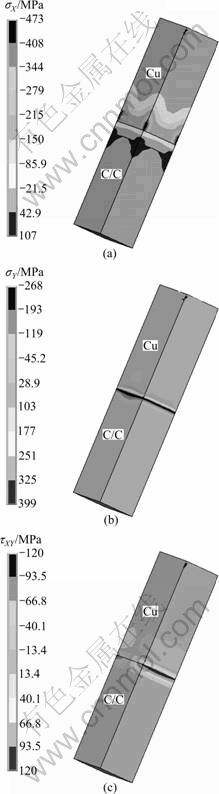

图3所示为连接温度为1 000 ℃时C/C-Cu接头表面残余应力分布情况。由X方向的应力(σX)分布云图(图3(a))可见,靠近接头界面的区域,Cu侧受压应力,C/C复合材料一侧主要受拉应力,棱边上出现明显应力集中,最大拉应力和压应力都位于棱边上。由σY的分布云图(图3(b))可见,靠近界面的区域,Cu侧受拉应力,C/C复合材料一侧主要受压应力。图3(c)所示为τXY的分布云图。正负只表示剪切应力的方向,可 见,最大剪切应力位于连接界面处。

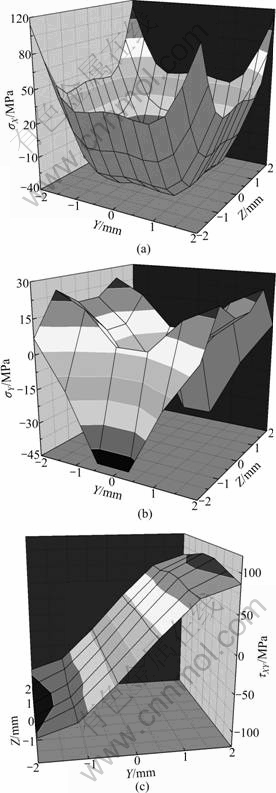

图4所示为C/C-Cu接头内部残余应力分布情况,沿X轴分别截取3个平行于连接界面的截面。可见,随着离界面中心距离的增大,σX由压应力转变为拉应力,截面上的最大拉应力位于4个顶点上(见图4(a))。随着离界面中心距离的增大,σY沿Y方向由压应力转变为拉应力;沿Z方向由拉应力转变为压应力,截面上的最大拉应力和压应力位于截面的边缘(见图4(b))。图4(c)所示为连接界面τXY的分布情况。可见,沿Y方向,随着离界面中心距离的增大,剪切应力增大;沿Z方向,剪切应力基本不变。

图3 C/C-Cu接头应力分布云图

Fig. 3 Distribution contours of stress on C/C-Cu joints: (a) σX; (b) σY; (c) τXY

上述分析表明:σX、σY和τXY的最大值均出现在连接件的表面。其中:σX, max位于靠近界面的棱边上, σY, max位于靠近界面的表面,τXY, max位于连接界面处。

图4 C/C-Cu接头的截面应力分布

Fig. 4 Stress distribution on C/C-Cu joints section: (a) σX at X=1.24 mm;(b) σY at X=-0.12 mm;(c) τXY at X=0 mm

2.2 连接温度对C/C-Cu接头残余正应力的影响

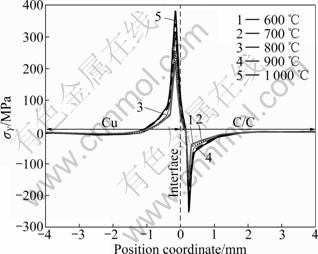

图5所示为在不同连接温度下C/C-Cu接头棱边 (Y=2, Z=2)上σX的分布情况。由图5可见,在600~1 000 ℃的连接温度下,σX的分布形态相似。在靠近接头界面的区域,Cu受压应力,随着离界面距离的增大,压应力先增大,然后减小。C/C复合材料一侧的应力分布比较复杂,在界面处受压应力,随着离连接界面距离的增大,压应力迅速降低为0,距离进一步增大,产生拉应力,拉应力先增大后减小。随着连接温度从600 ℃升高到1 000 ℃,应力峰位不随连接温度改变,但峰值发生变化:最大压应力均位于距连接界面0.4 mm的Cu侧,压应力峰值从-278 MPa变化到-473 MPa;最大拉应力均位于距连接界面1.2 mm的C/C复合材料侧,拉应力峰值从63 MPa增大到107 MPa。

图5 不同连接温度下C/C-Cu接头棱边(Y=2 mm, Z=2 mm)上σX的分布

Fig. 5 Stress (σX) distribution on C/C-Cu joints at Y=2 mm, Z=2 mm and different joining temperaturers

图6所示为不同连接温度下C/C-Cu接头棱边 (Y=2, Z=1)上σY的分布情况。由图6可见,其应力分布形态与σX明显不同。靠近界面的区域,Cu侧受拉应力作用,随着离连接面距离的增大,拉应力先增大后减小。C/C复合材料一侧界面处受拉应力,随着离连接界面距离的增大,拉应力减小到0,距离进一步增大,压应力迅速达到最大值,随后逐渐减小为0。随着连接温度从600 ℃升高到1 000 ℃,最大拉应力均出现在距连接界面0.3 mm的Cu侧,拉应力峰值从235 MPa增大到399 MPa;最大压应力均出现在0.4 mm的C/C复合材料侧,压应力峰值从-157 MPa变化到-268 MPa。

一般情况下,Cu和C/C复合材料的抗拉强度分 别为440 MPa和120 MPa。随着连接温度的升高,最大拉应力和压应力都增大。当连接温度为1 000 ℃时,Cu侧最大拉应力σY, max为399 MPa;C/C复合材料侧最大拉应力σX, max为107 MPa。因此,当连接温度为 1 000 ℃时,距连接界面1.2 mm的C/C复合材料最容易发生断裂。Cu和C/C复合材料的抗压强度远大于 抗拉强度,因此,连接接头中的Cu和C/C复合材料不会因压应力而发生断裂。

图6 不同连接温度下C/C-Cu接头棱边(Y=2 mm, Z=1 mm)上σY的分布

Fig. 6 Stress (σY) distribution on C/C-Cu joints at Y=2 mm, Z=1 mm and different joining temperatures

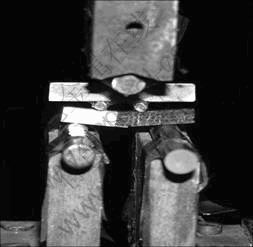

为验证有限元分析的有效性,制备了C/C与Cu的连接件,并进行了力学性能测试。图7所示为连接温度为1 000 ℃时C/C-Cu连接件的四点弯曲断裂形貌。由图7可见,在接头界面C/C复合材料一侧靠近下压头的区域发生了断裂。在四点弯曲实验过程中,试样靠近上压头的区域受到压应力作用,靠近下压头的区域受到拉应力作用。根据上述模拟分析结果,连接接头中X方向的最大拉应力出现在靠近接头C/C复合材料的棱边上。当四点弯曲实验的拉应力与σX叠加作用导致连接件中C/C复合材料所受的拉应力超过其抗拉强度时,靠近接头界面的C/C复合材料侧发生断裂。实验结果验证了热弹塑性有限元模拟分析的有效性。

图7 C/C-Cu连接接头四点弯曲断裂形貌

Fig. 7 Fractograph of four-point bending test on C/C-Cu joint

2.3 连接温度对C/C-Cu接头残余剪切应力的影响

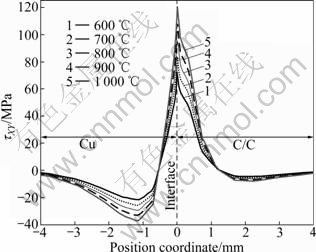

图8所示为在不同连接温度下C/C-Cu接头表面(Y=2 mm,Z=0 mm) τXY的分布情况。由图8可见,在600~1 000 ℃的连接温度下,τXY的分布形态相似。随着离连接界面距离的增大,C/C复合材料和Cu的剪 切应力开始都迅速变小,进而缓慢减小为0,最后改变应力方向,并缓慢增大。随着连接温度从600 ℃升高到1 000 ℃,最大剪切应力均出现在接头界面处,剪切应力峰值从70 MPa增大到120 MPa。

图8 不同连接温度下C/C-Cu接头棱边(Y=2 mm,Z=0 mm)上τXY的分布

Fig. 8 Shear stress (τXY) distribution on C/C-Cu joints at Y= 2 mm, Z=0 mm and different joining temperatures

图8表明:随着连接温度的升高,剪切应力峰值增大,接头强度降低。另一方面,当连接温度过低时,界面反应层薄且反应层本身和界面都不够致密,接头强度降低。随着连接温度的升高,界面反应层增厚且反应层本身和界面变得致密,接头强度提高;随着连接温度的进一步升高,界面反应层过厚导致反应层脆化,接头强度降低。当断裂发生在界面时,接头强度即为界面强度。综上所述,界面强度不能仅从残余应力的角度考虑,还需考虑反应层厚度[16]。因此, C/C-Cu接头剪切应力分布图(见图8)只能为实验提供理论指导。

综上所述,随着连接温度的降低,接头残余应力峰值都逐渐减小,其原因是冷却到室温时各材料间变形差异减小;当连接温度过低时,C/C复合材料与Cu界面冶金结合差。因此,连接C/C复合材料与Cu需要选择合适的连接温度。

3 结论

1) C/C-Cu接头最大拉应力的分布具有方向性, σX, max出现在靠近接头界面的C/C复合材料侧的棱边上;σY, max出现在靠近接头界面的Cu侧表面;τXY, max位于接头界面处。

2) 随着连接温度的升高,接头最大残余应力逐渐增大,但接头残余应力的分布形态相似。对于连接界面尺寸为4 mm×4 mm的接头,在连接温度为1 000 ℃时,离连接界面1.2 mm的C/C复合材料侧最容易发生断裂。

REFERENCES

[1] 陈茂爱, 陈俊华, 高进强. 复合材料的焊接[M]. 北京: 化学工业出版社, 2004: 79-88.

CHEN Mao-ai, CHEN Jun-hua, GAO Jin-qiang. Welding of composite materials [M]. Beijing: Chemical Industry Press, 2004: 79-88.

[2] TAYLOR R. Carbon matrix composites [J]. Comprehensive Composite Materials, 2003, 4: 387-426.

[3] HINO T, AKIBA M. Japanese developments of fusion reactor plasma facing components [J]. Fusion Engineering and Design, 2000, 49/50: 97-105.

[4] MEROLA M, AKIBA M, BARABASH V, MAZUL I. Overview on fabrication and joining of plasma facing and high heat flux materials for ITER [J]. Journal of Nuclear Materials, 2002, 307/311: 1524-1532.

[5] BARABASH V, MAZUL I, LATYPOV R, POKROVSKY P, WU C H. The effect of low temperature neutron irradiation and annealing on the thermal conductivity of advanced carbon-based materials [J]. Journal of Nuclear Materials, 2002, 307/311: 1300-1304.

[6] BARABASH V, AKIBA M, CARDELLA A, MAZUL I, ODEGARD Jr B C, PLOCHI L, TIVEY R , VIEIDER G. Armor and heat sink materials joining technologies development for ITER plasma facing components [J]. Journal of Nuclear Materials, 2000, 283/287: 1248-1252.

[7] TOKUNAGA K, Yoshida N, Kubota Y, NODA N, MOTOJIMA O, YOUCHISON D L, WATSON R D, NYGREN R E, MCDONALD J M, MARSHALL T D. Material damage and thermal response of LHD divertor mock-ups by high heat flux [J]. Journal of Nuclear Materials, 1998, 258/263: 1097- 1103.

[8] 孙 福. CMCS与金属的焊接接头设计与残余应力分析[D]. 西安: 西北工业大学, 2007: 5-6.

SUN Fu. Joint design and residual stress analysis in joining CMCS to metals [D]. Xi’an: Northwestern Polytechnical University, 2007: 5-6.

[9] 黄自谦, 贺跃辉, 蔡海涛, 肖逸锋, 黄伯云. TiAlN涂层的热残余应力的分析[J]. 中国有色金属学报, 2007, 17(6): 897-902.

HUANG Zi-qian, HE Yue-hui, CAI Hai-tao, XIAO Yi-feng, HUANG Bo-yun. Thermal residual stress analysis of TiAlN coating [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 897-902.

[10] SHEN Xiao-qin, LI Ya-jiang, PUTCHKOV U A, WANG Juan, HUANG Wang-qun. Finite-element analysis of residual stresses in Al2O3-TiC/W18Cr4V diffusion bonded joints [J]. Computational Materials Science, 2009, 45(2): 407-410.

[11] 张小勇, 吕 宏, 王林山, 楚建新. SiC陶瓷与金属Ta连接的残余应力[J]. 中国稀土学报, 2003, 21: 98-101.

ZHANG Xiao-yong, L? Hong, WANG Lin-shan, CHU Jian-xin. Calculation of welding residual stress between SiC ceramic and Ta [J]. Journal of the Chinese Rare Earth Society, 2003, 21: 98-101.

[12] 杨 建, 何 鹏, 周 宣. 陶瓷金属接头残余应力分析的后处理[J]. 焊接技术, 2003, 32(2): 15-18.

YANG Jian, HE Peng, ZHOU Xuan. Postprocessing methods in the analysis of residual stress in metal-ceramic joints [J]. Welding Technology, 2003, 32(2): 15-18.

[13] 黄伯云, 熊 翔. 高性能炭/炭航空制动材料的制备技术[M]. 长沙: 湖南科技技术出版社, 2007: 210-242.

HUANG Bai-yun, XIONG Xiang. Manufacturing of carbon/ carbon composites for aircraft brakes [M]. Changsha: Hunan Scientific and Technical Press, 2007: 210-242.

[14] CHIN E, REIS E E. Elastic-plastic-creep analyses of brazed carbon-carbon/OFHC divertor tile concepts for TPX [C]// Proceedings of the 16th International Symposium on Fusion Engineering. New York: IEEE, 1995: 1287-1290.

[15] 张朝辉, 范群波, 贵大勇, 张淑玲, 刘 颖. ANSYS8.0热分析教程与实例解析[M]. 北京: 中国铁道出版社, 2005: 4-6.

ZHANG Zhao-hui, FAN Qun-bo, GUI Da-yong, ZHANG Shu-ling, LIU Ying. Course of thermal analysis of ANSYS 8.0 and example analysis [M]. Beijing: China Railroad Press, 2005: 4-6.

[16] 陈 铮, 赵其章, 吴 斌, 许金泉, 李志章, 眭润舟, 楼宏青. Si3N4/Ti/Ni/Ti/Si3N4部分瞬态液相连接接头的强度与断裂[J]. 中国有色金属学报, 1999, 9(2): 166-171.

CHEN Zheng, ZHAO Qi-zhang, WU Bin, XU Jin-quan, LI Zhi-zhang, SUI Run-zhou, LOU Hong-qing. Joint strength and fracture in Si3N4/Ti/Ni/Ti/Si3N4 partial transient liquid-phase bonding [J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 166-171.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2011CB605803);国家高技术研究发展专项(2012AA03A207);湖南省科技计划项目(2011GK3212)

收稿日期:2011-04-28;修订日期:2011-09-16

通信作者:张福勤,教授,博士;电话:0731-88877880;E-mail: zhang_fuqin01@yahoo.com.cn