DOI:10.19476/j.ysxb.1004.0609.2017.12.12

粉末冶金制备50%SiCp/Al复合材料的结构及性能

茅学志1,洪 雨2,张玉君3,冯 东3,杨 磊3,史常东3,吴玉程4,汤文明1, 4

(1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 合肥工业大学 分析测试中心,合肥 230009;

3. 中国电子科技集团公司 第43研究所,合肥 230088;

4. 合肥工业大学 安徽省功能材料与器件重点实验室,合肥 230009)

摘 要:采用球磨加常压烧结的粉末冶金工艺制备50%SiCp/6061Al(体积分数)复合材料,研究了烧结温度对该高体积分数SiCp/Al复合材料结构与性能的影响。结果表明:球磨有利于形成成分均匀的50% SiCp6061Al复合粉体;随着烧结温度的升高,50%SiCp/6061Al复合材料的致密度及抗弯强度先增后减。710 ℃烧结的复合材料性能最佳,致密度达到97%,抗弯强度大于400 MPa。该复合材料中SiCp呈解理断裂,而Al合金基体呈韧性撕裂的断裂特征。750 ℃烧结的50%SiCp/6061Al复合材料中,SiCp/Al界面反应加剧,生成较多的Al4C3相,导致复合材料结构劣化,性能降低。

关键词:SiCp/Al复合材料;粉末冶金;烧结温度;显微组织;力学性能

文章编号:1004-0609(2017)-12-2493-08 中图分类号:TG146.21 文献标志码:A

相较于单相铝合金,以碳化硅颗粒增强铝合金(SiCp/Al)为代表的铝基复合材料具有更高的比强度、比刚度、耐磨损性能以及较低且可控的热膨胀系数[1]。为充分发挥材料的潜能,充分拓展其在航空航天、汽车、电子等领域内的应用,在实现该复合材料显微组织结构及性能最优化的前提下,开展铝基复合材料高效、低成本制备技术的研究一直是人们追求的目标。迄今为止,已开发出的SiCp/Al复合材料制备技术有粉末冶金、搅拌铸造、喷射成型、无压熔渗等。它们各具特点,各有优势[2-5]。

采用粉末冶金工艺制备SiCp/Al复合材料具有如下优点:1) SiCp在铝合金基体中的含量连续可调,保证复合材料结构的均匀性、一致性;2) 制备工艺简单,且可实现SiCp/Al复合材料及制品的近净成形,少无切削加工,大大降低加工成本;3) 烧结温度降低,有效抑制铝合金基体与SiCp间的界面反应,改善复合材料的结构。因此,粉末冶金工艺已成为制备SiCp/Al复合材料最主要的方法之一。ZHAO等[6]的研究表明,对8%SiCp/Al(体积分数)混合粉进行脱气处理可显著提升其压制性及素坯强度。PADMAVATHI等[7]研究真空烧结SiCp含量(5%~20%)对SiCp/6711Al复合材料时发现,含10%SiCp的复合材料组织均匀,烧结致密度、耐磨和耐腐蚀性能最佳;当SiCp含量超过10%时,易出现粉体团聚,致使其致密度及性能降低。PIECZONKA等[8]研究烧结气氛及SiCp含量(5%~15%)对SiCp/Al烧结性能。高纯N2是最合适的烧结气氛,增加SiCp的含量导致复合材料烧结性降低。致密化烧结是粉末冶金制备SiCp/Al复合材料的关键,不仅受工艺条件的影响,SiCp含量的影响也很明显。采用粉末冶金制备方法高体积分数(50%以上)SiCp/Al复合材料时,容易出现SiCp分布不均且致密度不高等关键技术问题,而目前国内外相关研究报道较少,也未提出有效的解决措施。因此,开展高体积分数SiCp/Al复合材料粉末冶金制备技术研究,实现高体积分数SiCp/Al复合材料中SiCp均匀分布和烧结致密化,具有重要意义。

本文作者以含50%SiCp的SiCp/Al复合材料(记为50%SiCp/Al)为对象,采用球磨+常压烧结的粉末冶金工艺,着重研究烧结温度对该复合材料结构与性能的影响,实现复合材料中SiCp的均匀分布与复合材料的烧结致密化,为高体积分数SiCp/Al复合材料及制品的低成本制备探索一条新的路径。

1 实验

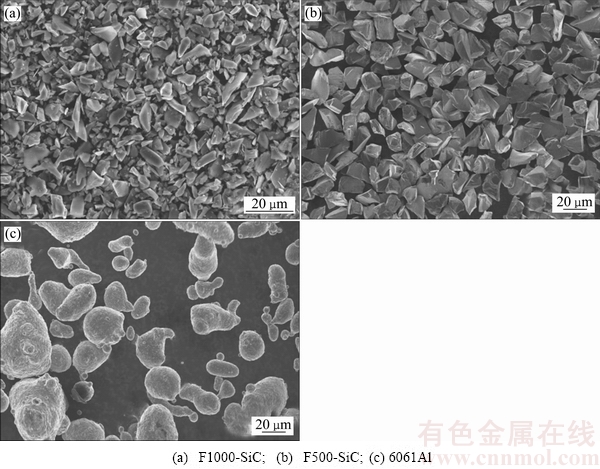

采用长沙天久金属材料公司提供的氮气雾化6061Al合金粉以及从挪威进口的F1000、F500两种规格的SiC粉体作为原材料。雾化6061Al合金粉的平均粒径(d50)为50 um,其化学成分见表1。F1000、F500两种规格的SiC粉体的纯度均大于98%,平均粒径分别为5和16 μm,且粉体粒度分布窄(见图1)。

表1 6061Al合金粉体的化学成分

Table 1 Chemical composition of 6061 Al powders (mass fraction, %)

SiC粉体先经150 ℃保温5 h干燥预处理,分别称取6.7935和40.7610 g 的F-1000和F-500 SiC粉体(质量比为1:6)与45.6520g 6061Al合金粉混合,得到50%SiCp/Al复合粉体100 g。50%SiCp/Al复合粉体的球磨在QM-3SP2型行星式球磨机中进行,转速400 r/min,球磨时间9 h。加入直径分别为10和5 mm的ZrO2球(质量比为1:6)为球磨介质,球料比为7:1。为了防止球磨过程中发生Al合金粉体的过度冷焊,加入无水乙醇作为过程控制剂。球磨后,将混合料放在真空干燥箱中50 ℃保温2 h干燥,去除无水乙醇。

球磨后的50%SiCp/Al复合粉体须进行500 ℃保温2 h的退火处理,以消除球磨过程中引入的内应力,改善压制性能。退火过程在OTF-1200X型真空管式炉中执行,采用流动的高纯N2 (99.999%,体积分数)为气氛保护,气体流速100 mL/min。退火后的复合粉体填入钢制模具中,采用769YP-40C型粉末压片机单向模压成形,成形压力400 MPa,保压时间1 min。素坯放入刚玉舟中,表面覆盖一层6061Al合金与SiCp的混合粉,置于OTF-1200X型真空管式炉中,分别在680、700、710、720和750 ℃下保温2 h烧结,升温速率为5℃/min,随炉冷却。试样烧结过程在流动的高纯N2气氛保护下进行,气体流速100 mL/min。

烧结50%SiCp/Al复合材料的密度采用阿基米德排水法测定,并据此计算其相对密度。尺寸为50 mm×4 mm×3 mm的长条形试样,经研磨、抛光后,参照GB/T 4741—1999陶瓷材料抗弯强度测试标准,采用三点弯曲法在CMT5105型微机控制电子万能试验机上测定其抗弯强度,试样跨距32 mm,横梁位移速率0.5 mm/min。50%SiCp/Al复合材料试样用环氧树脂镶嵌,研磨、抛光后,再用Keller试剂(1 mL氢氟酸+1.5 mL浓盐酸+2.5 mL浓硝酸+95 mL去离子水)腐蚀处理,腐蚀时间为3 s。采用SU8020型场发射扫描电子显微镜(SEM)观察分析50%SiCp/Al复合材料的微观组织及断口形貌,采用Oxford INCA能谱仪(EDS)测试微区成分。采用D/MAX2500V型X射线衍射仪(XRD)测定复合材料的物相组成。测试条件:Cu靶(Kα,波长λ=0.154 nm),管电压、电流分别为20 kV和200 mA,扫描范围10°~90°,扫描速度3 (°)/min。

2 结果与讨论

2.1 粉体形貌

图1所示为SiC粉体和6061Al合金粉体颗粒的SEM像。该SiC粉体颗粒呈多棱角不规则形状, F1000-SiC中含有较多细小颗粒,F500-SiC粒度分布较为集中,而6061Al合金粉颗粒则呈不规则球形或者短棒状,粒度分布不均,颗粒尺寸相差较大。

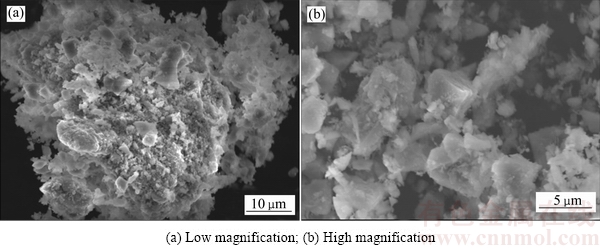

图2所示为球磨9 h的50%SiC/Al粉体的SEM像。从图2中可以看出,球磨9 h后的50%SiCp/Al复合粉体呈扁平结构。这是因为在球磨过程中,该复合粉体中的Al合金颗粒不断经历塑性变形、冷焊,形成片状结构[9]。刚性的SiCp则被嵌入Al合金层片中,形成较大尺寸的SiCp/Al片状团聚体颗粒(见图2(a)),该现象与SABERI等[10]观察到的结果一致。同时,在球磨过程中,这些大的片状团聚体颗粒部分碎化,形成较小的等轴状颗粒,构成SiCp镶嵌于Al合金颗粒内部的复合结构(见图2(b))。

2.2 组织与结构分析

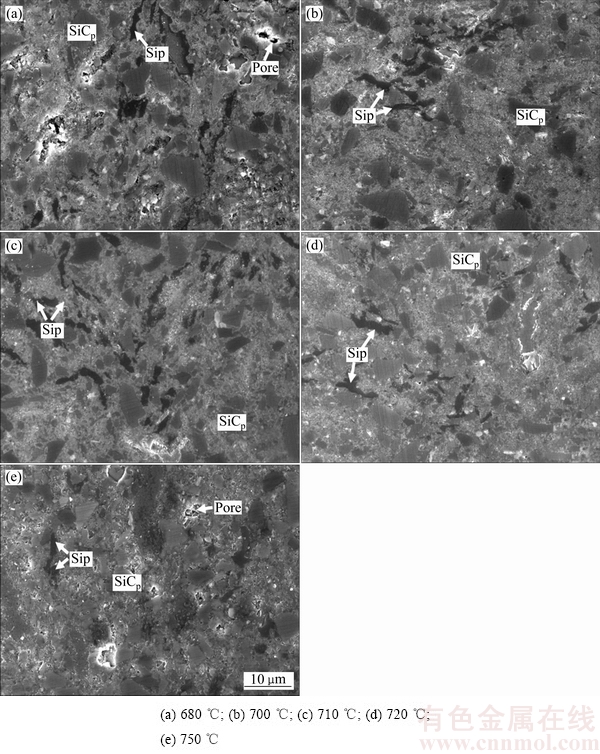

由图3可见, 50%SiCp/Al复合材料中的SiCp在Al合金基体中分布均匀,无明显团聚,且与Al合金基体结合致密。经EDS测试,复合材料中暗灰色的不规则状颗粒为SiCp,而暗黑色条带状或小颗粒状颗粒为Si,且Si含量随着烧结温度的升高而增加。由于复合材料中的Si单质主要是由高温烧结过程中的SiCp/Al界面反应产生的(见式(1)),因此,粉末冶金制备50%SiCp/Al复合材料时,在满足致密化的前提下,烧结温度应尽可能降低。50%SiCp/Al复合材料的SiCp粒径大部分在10 μm以下,明显小于SiC配料的主要组成F500-SiC的尺寸,说明SiCp/Al复合粉体的球磨导致大的SiCp的碎化,形成较小粒径的SiCp。这些新形成的细小SiCp表面新鲜,与Al合金基体间的反应活性大。因此,尽管球磨可以实现高体积分数SiCp/Al复合粉体的均匀混合,但加剧了复合材料的界面反应程度,对材料的结构与性能也会产生不利影响。迄今为止,虽有采用球磨实现SiCp/Al复合粉体均匀混合,并制备结构均匀的SiCp/Al复合材料的文献报道[11-13],但对球磨过程的上述不足缺乏关注,值得在今后的研究中关注。680℃烧结50%SiCp/Al复合材料含有较多的孔隙,这是因为烧结温度较低,难以实现致密化;而750 ℃烧结50%SiCp/Al复合材料中,孔隙含量较高,这是源于过量的SiCp/Al界面反应(见图3(a)和(e))。相对而言,700~720 ℃的烧结程度适中,SiCp/Al界面反应程度也不高,因此,50%SiCp/Al复合材料中气孔含量少,烧结致密化程度高(见图3(b)~(d))。

图1 SiC及6061Al合金粉的SEM像

Fig. 1 SEM images of SiC and 6061Al powders

图2 球磨9 h的50%SiC/Al复合粉体的SEM像

Fig. 2 SEM images of 50%SiC/6061Al composite powder milled for 9 h

图3 不同温度下烧结50%SiCp/Al复合材料的SEM像

Fig. 3 SEM images of 50%SiCp/6061Al composites sintered at different temperatures

在不同温度下烧结制备的50%SiCp/Al复合材料的XRD谱上,除含Al、SiC两种基体相的衍射峰外,还存在Si、SiO2、Mg2Si、AlN的衍射峰;此外,在750℃烧结试样的XRD谱上还出现了明显的Al4C3衍射峰(见图4)。在这些物相中,除了SiO2可能是随SiC粉体带入的杂质外,其他物相都是该复合材料在烧结过程中发生Al与SiCp以及Al与N2气氛间反应而形成的,且以SiCp/Al界面反应为主。

图4 不同温度下烧结50%SiCp/Al复合材料的XRD谱

Fig. 4 XRD patterns of 50%SiCp/6061Al composites sintered at different temperatures

首先,在680 ℃及以上的温度烧结时,6061Al合金(液相线温度为650 ℃)熔融,形成液相,与包含其中的SiCp发生反应,生成Al4C3和Si:

4Al+3SiC→Al4C3+3Si (1)

反应形成的Si大多以Si单质形式从熔体中结晶出来,还有部分Si与6061Al合金中的Mg元素反应,形成Mg2Si金属间化合物相[14]:

2Mg+Si→Mg2Si (2)

此外,根据SCHAFFER等的研究结果[15],Al合金及其表面氧化膜还会与N2气氛发生如下的反应:

2Al+N2→2AlN (3)

2Al2O3+2N2→4AlN+3O2 (4)

即在烧结过程中,熔融的Al合金熔体与N2气氛直接接触,发生化学反应(见式(3)),生成AlN;同时,试样孔隙中内含的O2不断被保护气氛中的N2交换或在烧结过程中与Al合金基体反应而消耗,导致气孔中的氧分压显著降低。在此热力学条件下,Al合金气孔内壁的氧化膜可与N2发生化学反应(见式(4)),同样也生成AlN。

根据热力学原理,随着烧结温度的升高,上述化学反应过程将趋于激烈,形成更多的反应产物。相应地,50%SiCp/Al复合材料中反应产物(如Si、Al4C3)的衍射峰也随之增强。

50%SiCp/Al复合材料中上述杂质相的存在对其性能将会产生一定的影响,SiO2的热导率低(1.5 W/(m·K)),SiCp表面SiO2层产生明显的热障效应,降低复合材料的热导率[16];脆性的Al4C3相不稳定,在环境中易发生分解[17],且Al4C3、Si同为脆性相,在外力作用下易诱发显微裂纹,会降低复合材料的力学性能[18];而Al合金基体中Mg2Si、AlN的存在起到强化Al合金基体的作用,导致烧结SiCp/Al复合材料硬度、强度增加,但韧性降低[19]。虽然,上述杂质相有些与工艺过程相关,其形成难以避免,但通过对原料粉体的预处理(如SiCp用氢氟酸酸洗处理),减少球磨过程中SiCp的碎化程度,优化粉末冶金工艺,降低烧结温度等手段,可在一定程度上降低杂质相的含量。

2.3 物理和力学性能

由图5(a)可见,随着烧结温度升高,50%SiCp/Al复合材料的相对密度由680 ℃时的91.5%迅速增加为710 ℃时的96.8%;但烧结温度继续升高时,该复合材料的相对密度却明显降低,750 ℃烧结复合材料的相对密度仅为93.8%。这是因为当烧结温度较低时,复合材料中形成的Al合金熔体量少,黏度高,流动性及填充能力较差,SiCp间的孔隙不能充分填充,材料中残留较多的气孔,烧结体致密度低。随着烧结温度升高,复合材料中Al合金熔体的量增多,黏度降低,流动性及填充能力随之增强,可充分填充SiCp间的孔隙,并借助于充填于SiCp间Al合金熔体的毛细管力造成的黏性压紧效应,促进复合材料的烧结致密化。但烧结温度超过710 ℃以后, 50%SiCp/Al复合材料致密度反而明显降低。其原因在于:一方面,高温下Al合金熔体与SiCp以及N2气氛间的反应增强,形成更多的结构疏松的反应产物;另一方面,过高的烧结温度致使50%SiCp/Al复合材料试样表层的Al合金及试样埋粉中的Al合金粉迅速熔化,形成的熔体连续包裹试样,阻止试样中气体(空气)的排除及保护气氛中的N2与试样中残留气体间的交换,导致试样气孔内压力高、氧分压高,显著阻碍试样烧结收缩,并加剧试样内氧化,烧结活性进一步降低。从已报道的文献看,采用模压成形+常压烧结的常规粉末冶金工艺制备SiCp/Al复合材料均难以像热压烧结那样获得高的致密度[20-22]。本实验中主要从控制球磨混料及烧结制度入手,采用常规粉末冶金工艺成功制备出含50%SiCp的高体积分数SiCp/Al复合材料,其致密度最高达97%,为高体积分数SiCp/Al复合材料及制品的制备探索出一个简单、高效且低成本的途径。

图5 50%SiCp/Al复合材料相对密度及抗弯强度与烧结温度的关系

Fig. 5 Relationships of relative density(a) and bending strength(b) of 50%SiCp/6061Al composites vs sintering temperature

由图5(b)可见,随着烧结温度从680 ℃升高至710 ℃,50%SiCp/Al复合材料的抗弯强度从225 MPa增加至400 MPa;但随着烧结温度进一步升高,复合材料的抗弯强度快速降低,当烧结温度为750 ℃时,其抗弯强度降至260 MPa。50%SiCp/Al复合材料的抗弯强度随着烧结温度的变化规律与相对密度基本相同,说明致密度是影响粉末冶金制备的50%SiCp/Al复合材料性能的主要原因。

一般地,SiCp/Al复合材料的性能取决于其中SiCp的粒径与分布均匀性、烧结致密化程度、界面反应及界面结合状态等诸多因素[23-24]。本实验中研制的50%SiCp/Al复合材料通过球磨混料实现SiCp在Al合金基体中的均匀分布,采用颗粒级配引入细小的F-1000 SiCp,降低复合材料中SiCp的平均粒径,并实现复合材料的致密化烧结,复合材料的显微组织结构及性能均得到较大幅度的改善与提高。烧结态50%SiCp/Al复合材料的抗弯强度可达400 MPa,高于LIU等[25]采用无压熔渗工艺制备的相近成分SiCp/Al复合材料的性能(381 MPa)。且通过对Al合金基体进行热处理,50%SiCp/Al复合材料的强度可进一步提高。

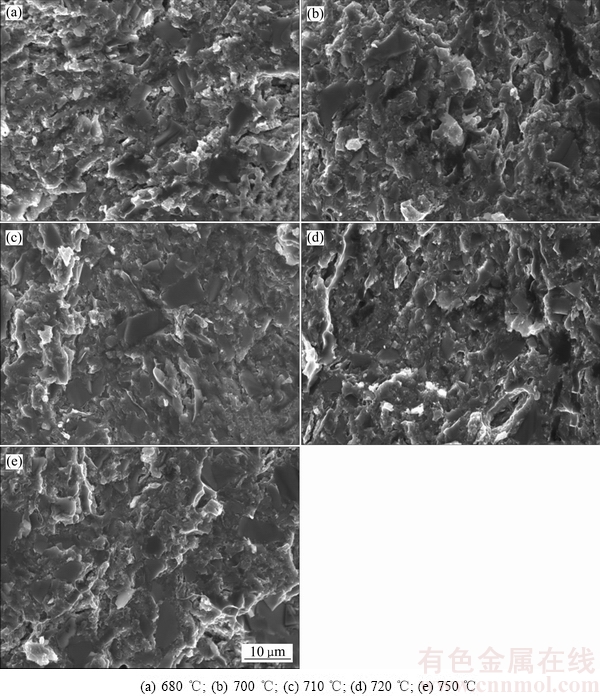

图6 不同烧结温度下50%SiCp/Al复合材料的断口形貌

Fig. 6 SEM images showing fractographs of 50%SiCp/6061Al composites sintered at different temperatures

680 ℃烧结复合材料的断面平整度较低,断面上有较多细小且形状不规则的气孔,气孔集中于Al合金基体中及SiCp/Al界面处,Al合金塑性变形特征不明显,绝大多数的SiCp发生解理断裂,仅个别SiCp被拔出,与Al基体合金界面脱粘(见图6(a))。随着烧结温度升高,50%SiCp/Al复合材料断面平整度提高,断面上气孔明显减少,趋于规则的球形,复合材料中SiCp几乎全部发生解理断裂,SiCp/Al界面结合进一步增强,Al合金撕裂清晰可见,塑性变形特征明显(见图6(b)和(c)),从而赋予复合材料高的抗弯强度。但当烧结温度过高时,复合材料断面上气孔增多,断面的平整度也降低,SiCp/Al界面反应增强,复合材料中SiCp虽仍呈主体解理断裂,但SiCp/Al界面反应增强,界面结合强度降低,Al合金基体的塑性程度低,复合材料的抗弯强度降低(见图6(d)和(e))。

3 结论

1) 球磨混料形成SiCp镶嵌于Al合金基体中的复合粉体,实现SiCp在高体分SiCp/Al复合材料中均匀分布。

2) 烧结过程中Al合金基体与SiCp及N2气氛反应,形成Si、Mg2Si、AlN等反应产物,且随着烧结温度升高,界面反应加剧,750 ℃烧结的50%SiCp/Al复合材料中形成了较多的Al4C3相。

3) 50%SiCp/Al复合材料的致密度及抗弯强度随烧结温度的升高呈现先增加后减小的趋势,提高烧结温度有利于改善复合材料的烧结性,但烧结温度过高会导致界面反应加剧,且试样内的气体难以排除,造成内氧化,复合材料的气孔率反而明显增加。710 ℃烧结的50%SiCp/Al复合材料的性能最佳,致密度达97%,抗弯强度达400 MPa。

4) 烧结致密的50%SiCp/Al复合材料的断裂方式以SiCp解理断裂及Al合金基体撕裂为主要特征,SiCp/Al界面结合强度高。

REFERENCES

[1] 曾 婧, 彭超群, 王日初, 王小峰. 电子封装用金属基复合材料的研究进展[J]. 中国有色金属学报, 2015, 25(12): 3255-3270.

ZENG Jing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng. Research and development of metal matrix composites for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3255-3270.

[2] ERVINA E, SITI S N, ABDULLAH M B. Fabrication method of aluminum matrix composite (AMCs): A review[J]. Key Engineering Materials, 2016, 700: 102-110.

[3] 苏 海, 高文理, 毛 成, 张 辉, 刘洪波, 卢 健, 陆 政. 搅拌铸造SiCp/2024铝基复合材料的显微组织与力学性能[J]. 中国有色金属学报, 2010, 20(2): 217-225.

SU Hai, GAO Wen-li, MAO Cheng, ZHANG Hui, LIU Hong-bo, LU Jian, LU Zheng. Microstructures and mechanical properties of SiCp/2024 aluminum matrix composite synthesized by stir casting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 217-225.

[4] 解立川, 彭超群, 王日初, 王小峰, 蔡志勇, 刘 兵. 高硅铝合金电子封装材料研究进展[J]. 中国有色金属学报, 2012, 22(9): 2578-2587.

XIE Li-chuan, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, CAI Zhi-yong, LIU Bing. Research progress of high aluminum-silicon alloys in electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2578-2587.

[5] 刘玫潭, 蔡旭升, 李国强. 高性能SiC增强Al基复合材料的显微组织和热性能[J]. 中国有色金属学报, 2013, 23(4): 1040-1046.

LIU Mei-tan, CAI Xu-sheng, LI Guo-qiang. Microstructure and thermal properties of high-performance SiC reinforced Al matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1040-1046.

[6] ZHAO N, NASH P. Effect of degassing of SiC reinforced 6061 aluminium alloy composites on properties[J]. Powder Metallurgy, 2013, 44(4): 333-338.

[7] PADMAVATHI C, UPADHYAYA A. Densification, microstructure and properties of supersolidus liquid phase sintered 6711 Al-SiC metal matrix composites[J]. Science of Sintering, 2010, 42(3): 363-382.

[8] PIECZONKA T, GACSI Z, KRETZ F, KOVACS J. Sintering behaviour of Al-SiC powder mixtures controlled by dilatometry[C]// Proceedings of the European Powder Metallurgy. Brussels, Belgium: The European Powder Metallurgy Association, 2004: 95-100.

[9] LIU Hai-li, TANG Wen-ming, WANG Yue-xia, LIU Chao, XU Guang-qing, ZHENG Zhi-xiang . Structural evolutions of the Fe-40Al-5Cr powders during mechanical alloying and subsequent heat treatment[J]. Journal of Alloys and Compounds, 2010, 506(2): 963-968.

[10] SABERI Y, AKBARI G, ZEBARJAD S M. The effect of milling conditions on morphology and grain size of Al/SiC nanocomposite powders produced by mechanical alloying method[J]. Journal of the Electrochemical Society, 2008, 155(2): 315-315.

[11] XIONG Bo-wen, XU Zhi-feng, YAN Qing-song, CAI Chang-chun, ZHENG Yu-hui, LU Bai-ping. Fabrication of SiC nanoparticulates reinforced Al matrix composites by combining pressureless infiltration with ball-milling and cold-pressing technology[J]. Journal of Alloys and Compounds, 2010, 497(1): L1-4.

[12] GU Wan-li. Bulk Al/SiC nanocomposite prepared by ball milling and hot pressing method[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S1): s398-s401.

[13] XIONG Bo-wen, XU Zhi-feng, YAN Qing-song, LU Bai-ping, CAI Chang-chun. Effects of SiC volume fraction and aluminum particulate size on interfacial reactions in SiC nanoparticulate reinforced aluminum matrix composites[J]. Journal of Alloys and Compounds, 2011, 509(4): 1187-1191.

[14] 李 敏, 王爱琴, 谢敬佩, 孙亚丽, 张 衡. SiC颗粒增强Al基复合材料的研究现状与进展[J]. 粉末冶金工业, 2015, 25(3): 55-60.

LI Min, WANF Ai-qin, XIE Jing-pei, SUN Ya -li, ZHANG Heng. The present research situation and progress of SiC particle reinforced aluminum matrix composites[J]. Powder Metallurgy Industry, 2015, 25(3): 55-60.

[15] SCHAFFER G B, HALL B J. The influence of the atmosphere on the sintering of aluminum[J]. Metallurgical and Materials Transactions A, 2002, 33(10): 3279-3284.

[16] XUE C, YU J K. Enhanced thermal transfer and bending strength of SiC/Al composite with controlled interfacial reaction[J]. Materials & Design, 2014, 53(1): 74-78.

[17] 兖利鹏, 王爱琴, 谢敬佩, 王 行. SiC_p/Al-30Si复合材料的界面反应机理[J]. 粉末冶金材料科学与工程, 2014, 23(4): 191-196.

YAN Li-peng, WANG Ai-qin, XIE Jing-pei, WANG Hang. Interface reaction mechanism of SiC reinforced Al-30Sialloy composites[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 23(4): 191-196.

[18] WANG Dong-mei, ZHENG Zhi-xiang, LV Jun, XU Guang-qing, ZHOU Shiang, TANG Wen-ming,WU Yu-cheng. Enhanced thermal conductive 3D-SiC/Al-Si-Mg interpenetrating composites fabricated by pressureless infiltration[J]. Ceramics International, 2017, 43(2): 1755-1761

[19] 徐 跃, 高 霖, 崔 崇, 钱 凤. 浸渗时间对无压浸渗制备Al/SiCp陶瓷基合材料的影响[J]. 材料开发与应用, 2011, 26(4): 20-23.

XU Yue, GAO Lin, CUI Chong, QIAN Feng. Infiltration time effect of pressureless infiltration preparation of Al/SiCp ceramic matrix composites[J]. Development and Application of Materials, 2011, 26(4): 20-23.

[20] PARVIN N, ASSADIFARD R, SAFARZADEH P, SHEIBANI S, MARASHI P. Preparation and mechanical properties of SiC-reinforced Al6061 composite by mechanical alloying[J]. Materials Science and Engineering A, 2008, 492(1/2): 134-140.

[21] SLIPENYUK A, KUPRIN V, MILMAN Y, GONCHARUK V, ECKERT J. Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio[J]. Acta Materialia, 2006, 54(1): 157-166.

[22] SUN Chao, SHEN Ru-juan, SONG Min. Effects of sintering and extrusion on the microstructures and mechanical properties of a SiC/Al-Cu composite[J]. Journal of Materials Engineering and Performance, 2011, 21(3): 373-381.

[23] DILER E A, IPEK R. An experimental and statistical study of interaction effects of matrix particle size, reinforcement particle size and volume fraction on the flexural strength of Al-SiCp, composites by P/M using central composite design[J]. Materials Science and Engineering A, 2012, 548: 43-55.

[24] WANG Zhang-wei, SONG Min, SUN Chao, XIAO Dai-hong, HE Yue-hui. Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al-Cu alloy composites[J]. Materials Science and Engineering A, 2010, 527(24/25): 6537-6542.

[25] LIU Jun-wu, ZHENG Zhi-xiang, WANG Jian-min, WU Yu-cheng, TANG Wen-ming, LU Jun. Pressureless infiltration of liquid aluminum alloy into SiC performs to form near-net-shape SiC/Al composites[J]. Journal of Alloys and Compounds, 2008, 465(1): 239-243.

Microstructures and properties of 50%SiCp/Al composites fabricated by powder metallurgy

MAO Xue-zhi1, HONG Yu2, ZHANG Yu-jun3, FENG Dong3, YANG Lei3, SHI Chang-dong3, WU Yu-cheng4, TANG Wen-ming1, 4

(1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Analysis and Test Center, Hefei University of Technology, Hefei 230009, China;

3. 43 Institute, China Electronics Technology Group Corporation, Hefei 230088, China;

4. Key Laboratory of Functional Materials and Devices of Anhui Province, Hefei University of Technology, Hefei 230009, China)

Abstract: 50%SiCp/6061Al (volume fraction) composites were fabricated using powder metallurgy technique via ball-milling and pressureless sintering. The effect of sintering temperature on microstructures and properties of the SiCp/Al composites with high SiCp volume fraction was especially stressed. The results show that ball milling is beneficial to the uniform composition distribution of the 50%SiCp/6061Al composites powder. With increasing the sintering temperature, the density and bending strength of the 50%SiCp/Al composites increase initially and then decrease. The SiCp/Al composite sintered at 710 ℃ has the optimal properties, i.e. the relative density is 97% and the bending strength is above 400 MPa. The SiC particles and Al alloy matrix in the composite follow the cleavage and plastic tearing fracture modes, respectively. As the sintering temperature increases to 750 ℃, an intensive SiCp/Al interfacial reaction takes place to form more Al4C3 phase, resulting in the structural degradation and property reduction of the SiCp/Al composite.

Key words: SiCp/Al composite; powder metallurgy; sintering temperature; microstructure; mechanical property

Foundation item: Project(2014DFA50860) supported by the International Science & Technology Cooperation Program of China

Received date: 2016-09-27; Accepted date: 2017-02-23

Corresponding author: TANG Wen-ming; Tel: +86-551-62901362; E-mail: wmtang69@126.com

(编辑 龙怀中)

基金项目:国家国际科技合作专项资助项目(2014DFA50860)

收稿日期:2016-09-27;修订日期:2017-02-23

通信作者:汤文明,教授,博士;电话:0551-62901362;E-mail: wmtang69@126.com