热处理过程对Ti-6Al-4V-10Nb合金显微组织和拉伸性能的影响

来源期刊:中国有色金属学报(英文版)2019年第1期

论文作者:孙红 余黎明 刘永长 张立业 刘晨曦 李会军 吴杰峰

文章页码:59 - 66

关键词:Ti-6Al-4V-10Nb 合金;热处理;显微组织;初生α相;次生α相;强度

Key words:Ti-6Al-4V-10Nb alloy; heat treatment; microstructure; primary α phase; secondary α phase; strength

摘 要:研究热处理过程对Ti-6Al-4V-10Nb合金显微组织和力学性能的影响。采用扫描电镜、透射电镜和X射线衍射仪对合金显微组织进行研究,并通过拉伸试验对其室温和高温力学性能进行评估。结果表明,锻造和热处理后的主要组织为板条和球状初生α相、次生α相和β相。次生α相的尺寸明显小于初生α相的尺寸。热处理后,初生α相的体积分数减少,次生α相的体积分数增加。随着固溶温度的升高,初生α相的体积分数明显减少,次生α相的体积分数明显增加。随着固溶温度的升高,Ti-6Al-4V-10Nb合金的屈服强度和抗拉强度明显提高。

Abstract: Effects of heat treatment processing on the microstructure and mechanical properties of Ti-6Al-4V-10Nb alloy were investigated. The microstructures were investigated by SEM, TEM and XRD, and the mechanical properties were evaluated by tensile tests at room and elevated temperatures. The results indicate that the lath-like and globular primary α phase, secondary α phase and β phase are obtained after forging and heat treatment processing. The size of secondary α phase is much smaller than that of primary α phase. After heat treatment, the volume fraction of primary α phase is decreased, and that of secondary α phase is increased. With the increase of solution temperature, the volume fraction of primary α phase is gradually decreased, and that of secondary α phase is obviously increased. The yield strength and tensile strength of Ti-6Al-4V-10Nb alloy are significantly enhanced with the solution temperature increasing.

Trans. Nonferrous Met. Soc. China 29(2019) 59-66

Hong SUN1,2, Li-ming YU1,2, Yong-chang LIU1,2, Li-ye ZHANG1,2, Chen-xi LIU1,2, Hui-jun LI1,2, Jie-feng WU3

1. State Key Laboratory of Hydraulic Engineering Simulation and Safety, Tianjin University, Tianjin 300072, China;

2. Tianjin Key Lab of Composite and Functional Materials, Tianjin University, Tianjin 300072, China;

3. Institute of Plasma Physics, Chinese Academy of Sciences, Hefei 230031, China

Received 13 November 2017; accepted 8 March 2018

Abstract: Effects of heat treatment processing on the microstructure and mechanical properties of Ti-6Al-4V-10Nb alloy were investigated. The microstructures were investigated by SEM, TEM and XRD, and the mechanical properties were evaluated by tensile tests at room and elevated temperatures. The results indicate that the lath-like and globular primary α phase, secondary α phase and β phase are obtained after forging and heat treatment processing. The size of secondary α phase is much smaller than that of primary α phase. After heat treatment, the volume fraction of primary α phase is decreased, and that of secondary α phase is increased. With the increase of solution temperature, the volume fraction of primary α phase is gradually decreased, and that of secondary α phase is obviously increased. The yield strength and tensile strength of Ti-6Al-4V-10Nb alloy are significantly enhanced with the solution temperature increasing.

Key words: Ti-6Al-4V-10Nb alloy; heat treatment; microstructure; primary α phase; secondary α phase; strength

1 Introduction

Owing to the light weight, high strength, good creep resistance and oxidation resistance, titanium (Ti) alloys have been regarded as ideal materials in many fields, such as aerospace, automotive, military and biomedical applications [1,2]. Among various Ti alloys, Ti-6Al-4V alloy, one typical duplex alloy containing α phase and β phase, exhibits great advantages over other Ti alloys in properties, which is related to the optimum micro- structure and volume ratio of α phase and β phase [3]. Therein, α phase is the predominant strengthening phase and different morphologies of α phase have different strengthening effects. Previous researches indicate that the refinement of α lath leads to the improvement of mechanical strength [4], and the formations of globular α phase and fine β grain contribute significantly to the increase of plasticity of Ti alloy [5].

In recent years, with respect to Ti-6Al-4V alloy, considerable attention is focused on adding alloying elements [6,7] to refine microstructure and enhance mechanical performance, as well as the adjustment of thermo-mechanical processing parameters [8,9]. Nb, a β stable element, has a positive effect on the microstructure refinement, including α lath, globular α phase and prior β phase, which conduces to improve the mechanical properties of Ti alloy [10,11]. Moreover, the presence of Nb is beneficial to slowing down the process of recovery, recrystallization and dislocation climb and glide with high melting point and low rate of diffusion [12]. This is beneficial for Ti alloy to serve in high temperature environment for a long time. To some extent, Nb element is supposed to have a more obvious optimization effect on the Ti-6Al-4V alloy compared with other elements.

Ti alloy has allotropic modification. β phase with body-centered cubic (bcc) structure is stable at high temperature, and α phase with hexagonal close packed (hcp) structure is stable at low temperature. When the temperature is high enough, the phase transformation from α to β would occur. Therefore, the microstructure of Ti alloy is sensitive to the thermo-mechanical processing parameters, such as deformation temperature, deformation time and cooling rate. The effect of heat treatment on the microstructure and mechanical properties of Ti alloy has been reported [13-15]. LI et al [13] investigated the effect of heat treatment on the microstructure evolution and mechanical properties of Ti alloy. It was found that the comprehensive property of aged alloys is better than that of other heat treated alloys, which benefits from the precipitation of fine secondary α phase.

However, the effect of different solution temperatures on the microstructure and mechanical properties of Ti-6Al-4V alloy with Nb addition has not really been clear yet. On the basis of our previous studies, adding 10 wt.% Nb to the Ti-6Al-4V alloy significantly decreases the size of α phase and β phase. Therefore, in this work, the relationship between the microstructure of α phase and the mechanical properties of forged and aged Ti-6Al-4V-10Nb alloys was studied and discussed in details, as well as the size and volume fraction of α phase. The size and morphology of α phase were studied by SEM. The microstructure of α phase was investigated by TEM and HRTEM. The phase compositions were analyzed by XRD. In addition, tensile properties were evaluated by tensile tests at room and elevated temperatures.

2 Experimental

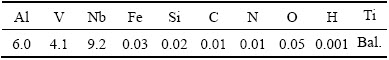

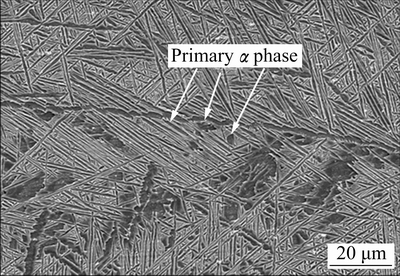

The Ti-6Al-4V-10Nb alloy was prepared by mixing appropriate amounts of high-purity Ti rod (99.99%), Al piece (99.99%) and intermediate alloys (Al-60V and Ti-50Nb). The mixtures were melted under a high-purity argon atmosphere in a vacuum consumable arc melting. The actual chemical compositions are listed in Table 1 and the initial microstructure is shown in Fig. 1. The β transus temperature obtained by differential scanning calorimeter (DSC) for the Ti-6Al-4V-10Nb alloy was about 900 °C. The ingot casting was produced by heat forging at 1000 °C (in the β phase field) and then at 870 °C (in the α+β phase field) to refine grain size. Subsequently, the sample was annealed at 750 °C for 1 h. The alloy produced after annealing was known as forged alloy. Following this, the sample was subjected to a series of heat treatments, as illustrated in Fig. 2, including solution treatment and aging treatment. The samples were solution treated at 780 °C or 880 °C for 1 h, respectively. And then, these specimens were quenched into water to room temperature. Subsequently, all the specimens were aged at 500 °C for 3 h. Finally, these specimens were air cooled to room temperature. Generally speaking, solution treatment above β transus temperature would tend to result in the coarsening of grains and the brittleness of the alloy. Therefore, the solution treatment temperature was set in the two-phase field.

Table 1 Actual chemical compositions of Ti-6Al-4V-10Nb alloy (wt.%)

Fig. 1 SEM image of as-cast Ti-6Al-4V-10Nb alloy

Fig. 2 Heat treatment processing of forged Ti-6Al-4V-10Nb alloy

The size and morphology of α phase in forged and aged Ti-6Al-4V-10Nb alloys were measured and observed by scanning electron microscopy (SEM). The microstructural characterization was investigated by transmission electron microscopy (TEM), and the phase compositions were analyzed by X-ray diffraction (XRD). XRD and SEM specimens were prepared by a standard metallographic preparation method, and subsequently, SEM specimens were etched by Kroll’s reagent. TEM specimens were prepared by mechanical grinding to about 50 μm in thickness and then punched into 3 mm TEM discs. The TEM discs were etched by a twin-jet electro-polishing machine using 34 vol.% methanol, 60 vol.% n-butyl alcohol and 6 vol.% perchloric acid polishing solution under 15-20 V at 233 K.

The mechanical properties of forged and aged Ti-6Al-4V-10Nb alloys have been evaluated by tensile tests at room temperature (RT) and elevated temperature (455, 550 and 650 °C) with a nominal strain rate of 0.5 mm/min in a universal electronic material testing machine. The rod-shaped specimens for tensile tests were cut from forged and aged alloy with a gauge length of 50 mm and a diameter of 5 mm.

3 Results and discussion

3.1 Microstructure and phase composition of Ti-6Al-4V-10Nb alloys

Fig. 3 SEM images (a, c, e) and corresponding enlarged micrographs (b, d, f) of Ti-6Al-4V-10Nb alloys

Since α phase is the predominant strengthening phase, the microstructure of α phase is detailedly analyzed. Therein, α phase contains primary and secondary α phases. Figure 3 shows the SEM images and corresponding enlarged micrographs of forged and aged Ti-6Al-4V-10Nb alloys. As shown in Figs. 3(a, c, e), certain amount of lath-like and globular primary α phases marked by the black arrows are precipitated in β transformed matrix. This indicates that the microstructure of forged and aged alloys is a duplex structure. It can also be seen from Figs. 3(a, c, e) that both the size and the amount of primary α phase containing lath-like and globular primary α phases are decreased after heat treatment, and with the increase of solution temperature, those of primary α phase are gradually decreased. In Figs. 3(a, c, e), the average thicknesses of lath-like α phase are about 1.75, 1.52 and 1.23 μm, respectively, and the mean sizes of globular α phase are about 2.66, 2.42 and 2.13 μm, respectively. The enlarged micrographs in Figs. 3(b, d, f) reveal that a large number of dispersively distributed secondary α particles are precipitated around primary α phase in the matrix as marked by the black arrows. The mean sizes of secondary α phase in Figs. 3(b, d, f) are about 0.14, 0.11 and 0.07 μm, respectively, which are much finer than those of lath-like and globular primary α phases. It can be seen clearly from Figs. 3(b, d, f) that compared with the forged alloy, the size of secondary α phase is decreased and the amount of secondary α phase is increased in aged alloys. With the solution temperature increasing, the size of secondary α phase is gradually decreased, and the amount of secondary α phase is obviously increased. The amount of primary α phase is mainly affected by solution treatment processing. And the secondary α phase is precipitated during aging treatment. It is worth mentioning that solution treatment processing can increase the stability of the matrix and provide the driving force of secondary α phase formation during subsequent aging treatment [16,17]. Therefore, the amount of primary α phase is decreased and the amount of secondary α phase is increased after heat treatment. The high annealing temperature causes the growth of secondary α phase in forged alloy. While the growth of the secondary α phase precipitated after heat treatment cannot occur because of the low aging temperature. Therefore, the size of secondary α phase is decreased after heat treatment.

The relationship between the morphology of α phase and mechanical properties of Ti-6Al-4V-10Nb alloy may be related to the microstructure of α phase. Therefore, the effects of microstructure of α phase on performance are studied and discussed with aged Ti-6Al-4V-10Nb alloy solution-treated at 880 °C as an example, considering that the effects of α lath on mechanical property of these three alloys are similar, as well as the effect of globular α phase. Figure 4 shows the TEM images of α phase in the alloy. Figures 4(a) and (b) show the TEM images of micro-structure of α lath and Fig. 4(c) shows the TEM image of microstructure of globular α phase. Figure 4(a) shows the existence of dislocation in the alloy. Some are distributed in α phase (marked by white arrows), and some are accumulated at α/β interface (marked by red arrows) which hinder the movable dislocation and in turn enhance the mechanical strength of the alloy [5,13]. Moreover, α lath can make dislocation movement more difficult by intertwining with each other (see Fig. 4(a)), and such α lath boundaries which have high energy barrier increase the resistance of dislocation motion and prevent the formation of dislocation cell by orientating parallel to each other (see Fig. 4(b)) [18]. Therefore, the dispersive distribution of α lath is beneficial to enhancing mechanical strength of the alloy. As seen in Fig. 4(c), the density of dislocation distributed in globular α phase and at grain boundary is less than that in α lath and α/β interface of Fig. 4(a). Moreover, the thickness of grain boundary in Fig. 4(c) is decreased compared with that in Fig. 4(a). Therefore, the formation of globular α phase is a result of dislocation movement and re-arrangement, and is also a process of recrystallization. This configuration reveals the minimum strain energy for a given dislocation content. In other words, the formation of globular α phase is a process involving release of strain energy, which contributes significantly to the increase of plasticity of the alloy [19]. There exists a large number of defects on the grain boundaries, making it the preferred position for the nucleation of primary α phase; whereas it is relatively difficult for the primary α phase to precipitate in the interior of grains. Therefore, lath-like primary α phases tend to precipitate along the grain boundaries of prior β, and a small amount of globular primary α phases tend to precipitate inside the grains. The primary α phase in as-cast alloy is coarse. Forging processing is employed to break down those coarse α phases and introduce strain energy [20]. The strain energy would provide the driving force for the subsequent recrystallization process. The alloy then possesses a large number of fine lath-like and globular primary α phases. Subsequently, the alloy could attain secondary α phase during heat treatment, where the size of secondary α phase is much smaller than that of primary α phase (see Fig. 3). Therefore, the forged and aged alloys contain lath-like and globular α phases. From the above results, it can be concluded that coexistence of α lath and globular α phase makes the alloy exhibit better mechanical strength and higher ductility.

Fig. 4 TEM and HRTEM micrographs of α phase in aged Ti-6Al-4V-10Nb alloy solution-treated at 880 °C

Fig. 5 X-ray diffraction patterns for Ti-6Al-4V-10Nb alloys

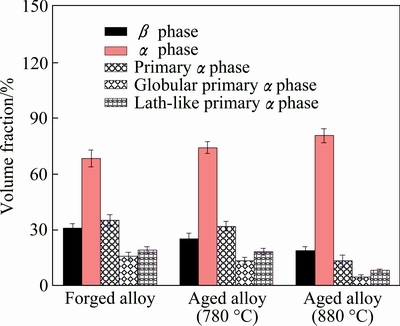

Fig. 6 Volume fractions of β phase, α phase, primary α phase, globular and lath-like primary α phases in forged and aged Ti-6Al-4V-10Nb alloys at different solution temperatures

In order to further investigate the effect of solution temperature on the microstructure of Ti-6Al-4V-10Nb alloy, the volume fraction of each phase is calculated. Figure 5 illustrates the XRD patterns of forged and aged Ti-6Al-4V-10Nb alloys. As shown in Fig. 5, these three alloys are all comprised of α phase and β phase. According to XRD patterns, the volume fractions of α phase and β phase in the three alloys are calculated. Therein, α phase contains primary and secondary α phases. In addition, according to the different morphologies of primary α phase in Fig. 3, the volume fractions of lath-like and globular primary α phases are measured. Variation of the volume fraction of each phase in the three alloys is plotted in Fig. 6. As seen in Fig. 6, the volume fraction of α phase is much more than that of β phase in the three alloys. After heat treatment, the volume fraction of α phase is increased and that of β phase is decreased. With the solution temperature increasing, the volume fraction of α phase is obviously increased and that of β phase is gradually decreased. It can also be seen from Fig. 6 that the volume fractions of lath-like and globular primary α phases in aged alloys are decreased with the increase of solution temperature, and are less than those in forged alloy, which is consistent with Fig. 3. From Fig. 6, it can be clearly seen that the volume fraction of secondary α phase in aged alloys shows a rising tendency with the increase of the solution temperature, and is much more than that in forged alloy, which is also in accordance with Fig. 3. Moreover, the volume fraction of secondary α phase is more than that of primary α phase in the two aged alloys. The volume fraction of secondary α phase is less than that of primary α phase in forged alloy, which can be seen from Fig. 6. However, low solution temperature increases the stability of the matrix further and reduces the driving force of secondary α phase formation during subsequent aging treatment, because the α phases precipitated after solution treatment pin the grain boundaries of prior β phases and hinder their mobility [16,17]. Therefore, low solution temperature is beneficial to retaining more primary α phase after heat treatment processing. The amount of secondary α phase precipitated during aging treatment is relatively less because of low solution temperature. From the above, high solution temperature (880 °C) could result in the precipitation of more fine secondary α phase, while the volume fraction of primary α phase would be relatively decreased after aging treatment.

3.2 Tensile properties

3.2.1 Tensile properties at room temperature

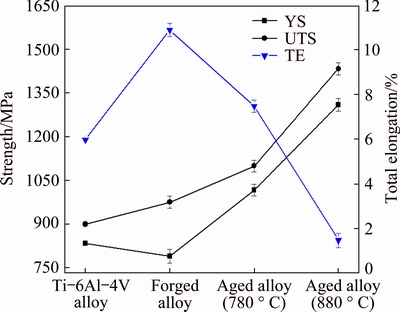

Figure 7 shows the tensile properties at room temperature of Ti-6Al-4V alloy, forged and aged Ti-6Al-4V-10Nb alloys. SEN et al [7] reported that the yield strength (YS), ultimate tensile strength (UTS) and total elongation (TE) of Ti-6Al-4V alloy are 833.9 MPa, 900 MPa and 6%, respectively. As seen in Fig. 7, the two aged alloys exhibit superior tensile strengths to Ti-6Al-4V alloy and forged Ti-6Al-4V-10Nb alloy, which can be attributed to the precipitation of a large number of fine secondary α phase and the formation of a large number of dislocation density accumulated at lath-like α/β interface. Moreover, with the increase of solution temperature, the YS and UTS are obviously enhanced, owing to the increase of the volume fraction of fine secondary α phase. It can also be seen from Fig. 7 that compared with the Ti-6Al-4V alloy, the YS of forged Ti-6Al-4V-10Nb alloy has no significant variation. The UTS and TE of the forged Ti-6Al- 4V-10Nb alloy are larger than those of the Ti-6Al-4V alloy. In particular, the TE of forged Ti-6Al-4V-10Nb alloy exhibits relatively high values. The TE of forged Ti-6Al-4V-10Nb alloy is about 10.9%. These might be related to the Nb addition, since Nb can act as β stabilizer and grain refiner in the Ti alloy [10], as well as the grain refinement by forging technology. After heat treatment, the TE is decreased. With the increase of solution temperature, the TE deteriorates significantly, due to the decrease of volume fraction of β phase and globular primary α phase. Therein, the TE of aged Ti-6Al-4V-10Nb alloy solution treated at 780 °C is about 7.5%, which is higher than that of the Ti-6Al-4V alloy. The aged Ti-6Al-4V-10Nb alloy solution treated at 780 °C has superior comprehensive performance at room temperature, including YS, UTS and TE.

Fig. 7 Tensile properties of Ti-6Al-4V alloy, forged and aged Ti-6Al-4V-10Nb alloys with different solution temperatures at room temperature

3.2.2 Tensile properties at elevated temperature

Based on the operating temperature (455 °C) of Ti-6Al-4V alloy, three tensile temperatures (455, 550, 650 °C) are designed. Figure 8 shows the tensile stress-strain curves measured at various temperatures (455-650 °C) for the forged and aged Ti-6Al-4V-10Nb alloys. As shown in Fig. 8, the mechanical strengths containing YS and UTS in aged alloys show a rising tendency with the increase of the solution temperature, and are much larger than those in forged alloy at all tensile temperatures; while the TE is decreased after heat treatment. With the increase of solution temperature, the TE is gradually decreased. From the above results, we can conclude that the aged Ti-6Al-4V-10Nb alloy with high solution temperature (880 °C) has better comprehensive performance at elevated temperature, including YS, UTS and TE.

Fig. 8 Tensile stress-strain responses of forged and aged Ti-6Al-4V-10Nb alloys with different solution temperatures at elevated temperature

It is seen from Figs. 7 and 8 that the Ti-6Al-4V alloy with 10 wt.% Nb addition has superior mechanical properties after heat treatment, which is mainly attributed to the microstructural characteristics. The mechanical strength and the size of α phase follow Hall-Petch strengthening mechanism [7]. According to Hall-Petch model, the mechanical strength is inversely proportional to the size of α phase:

σ=σ0+Kd-1/2 (1)

where σ is the mechanical strength (MPa), σ0 is the single crystal yield strength (MPa), d is the size of α phase (μm), and K is a constant related to the material.

According to the microstructure evolution of Ti-6Al-4V-10Nb alloys before and after heat treatment, the volume fractions of lath-like and globular primary α phases are decreased and the volume fraction of secondary α phase is increased after heat treatment. With the increase of solution temperature, the volume fractions of lath-like and globular primary α phases are gradually decreased and the volume fraction of secondary α phase is obviously increased. Moreover, the volume fraction of secondary α phase is higher than that of primary α phase in two aged alloys, while the volume fraction of secondary α phase is less than that of primary α phase in forged alloy. Compared with the sizes of lath-like and globular primary α phases, the size of secondary α phase is obviously smaller. Therefore, the mechanical strength can be increased after heat treatment, and with the increase of solution temperature, the mechanical strength is significantly enhanced. The relatively high strength can be attributed to the formation of a large number of fine secondary α particles [21,22]. It is also known that a large number of dislocations are accumulated at lath-like α/β interface, impeding the movable dislocation and enhancing the mechanical strength of Ti alloy. Additionally, α lath which intertwines with each other or distributes parallel to each other could increase the resistance to dislocation motion and improve mechanical strength. The volume fraction of total α lath containing primary and secondary lath-like α phases is increased after heat treatment and is significantly increased with the solution temperature increasing. The increase of the volume fraction of total α lath results in the increase of the number of lath-like α/β interface. These can further impede the movement of dislocation and conduce to obtain higher strength. From the above, heat treatment processing is beneficial to refining the microstructure and improving the mechanical performance of Ti alloy.

4 Conclusions

(1) Certain amount of lath-like and globular primary α phases are precipitated in β transformed matrix. Meanwhile, a large amount of dispersively distributed secondary α particles are precipitated around primary α phase in the matrix. Therein, the size of secondary α phase is much smaller than that of primary α phase in the three alloys.

(2) The volume fraction of primary α phase is decreased and the volume fraction of secondary α phase is increased after heat treatment. With the increase of solution temperature, the volume fraction of primary α phase is gradually decreased, and the volume fraction of secondary α phase is obviously increased.

(3) The mechanical strengths of Ti-6Al-4V-10Nb alloy could be improved after heat treatment and significantly enhanced with the increase of solution temperature at all tensile temperatures. The aged Ti-6Al-4V-10Nb alloy solution treated at 780 °C has superior strength and ductility at room temperature. Better strength and ductility at elevated temperature are obtained for the aged Ti-6Al-4V-10Nb alloy solution- treated at 880 °C, owing to their unique microstructures.

References

[1] BOYER R R, BRIGGS R D. The use of β titanium alloys in the aerospace industry [J]. Journal of Materials Engineering and Performance, 2005, 14: 681-685.

[2] WILLIAMS J C, STARKE E A Jr. Progress in structural materials for aerospace systems [J]. Acta Materialia, 2003, 51: 5775-5799.

[3] DONACHIE M J. Titanium: A technical guide [M]. 2nd ed. Ohio: ASM International, 2000.

[4] YAPICI G G, KARAMAN I, LUO Z P, RACK H. Microstructure and mechanical properties of severely deformed powder processed Ti-6Al-4V using equal channel angular extrusion [J]. Scripta Materialia, 2003, 49: 1021-1027.

[5] SHI Yin-dong, ZHANG Guo-sheng, LI Ming. Effect of heat treatment on the microstructure and tensile properties of deformed α/β Ti-47Zr-5Al-3V alloy [J]. Journal of Alloys and Compounds, 2016, 665: 1-6.

[6] IBRAHIM K M, HUSSEIN A H, ABDELKAWY M. Effect of Si-addition as a grain refiner on microstructure and properties of Ti-6Al-4V Alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1863-1874.

[7] SEN I, TAMIRISAKANDALA S, MIRACLE D B, RAMAMURTY U. Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys [J]. Acta Materialia, 2007, 55: 4983-4993.

[8] YUMAK N, ASLANTAS K, PEKBEY Y. Effect of cryogenic and aging treatments on low-energy impact behaviour of Ti-6Al-4V alloy [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 514-526.

[9] LUAN J H, JIAO Z B, CHEN G, LIU C T. Effects of boron additions and solutionizing treatments on microstructures and ductility of forged Ti-6A-4V alloys [J]. Journal of Alloys and Compounds, 2015, 624: 170-178.

[10] KURZ W, FISHER D J. Fundamentals of solidification [M]. 4th revised ed. Switzerland: Trans Tech Publications Ltd, 2005.

[11] ZHANG Lin-bo, WANG Ke-zheng, XU Li-juan, XIA Shu-long, CHEN Yu-yong. Effect of Nb addition on microstructure, mechanical properties and castability of β-type Ti-Mo alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2214-2220.

[12] SAHA R L, JACOB K T. Casting of titanium and its alloys [J]. Defence Science Journal, 2014, 36: 121-141.

[13] LI C, CHEN J, LI W. Effect of heat treatment variations on the microstructure evolution and mechanical properties in a β metastable Ti alloy [J]. Journal of Alloys and Compounds, 2016, 684: 466-473.

[14] IBRAHIM K M, EL-HAKEEM A M M, ELSHAER R N. Microstructure and mechanical properties of cast and heat treated Ti-6.55Al-3.41Mo-1.77Zr alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23, 3517-3524.

[15] BANUMATHY S, PRASAD K S, MANDAL R K, SINGH A K. Effect of thermomechanical processing on evolution of various phases in Ti-Nb alloys [J]. Bulletin of Material Science, 2011, 34: 1421-1434.

[16] DUERIG T W, TERLINDE G T, WILLIAMS J C. Phase transformations and tensile properties of Ti-10V-2Fe-3Al [J]. Metallurgical Transactions A, 1980, 11: 1987-1998.

[17] LI C L,MI X J,YE W J,HUI S X,YU Y. A study on the microstructures and tensile properties of new beta high strength titanium alloy [J]. Journal of Alloys and Compounds, 2013, 550: 23-30.

[18] HALL I W, HAMMOND C. Fracture toughness and crack propagation in titanium alloys [J]. Materials Science and Engineering, 1978, 32: 241-253.

[19] LUO J, LIU S F, LI M Q. Quantitative analysis of microstructure and deformation mechanisms during isothermal compression of Ti-5Al-5Mo-5V-1Cr-1Fe alloy [J]. Materials Characterization, 2015, 108: 115-123.

[20] BOYER R R. An overview on the use of titanium in the aerospace industry [J]. Materials Science and Engineering A, 1996, 213: 103-114.

[21] JONES N G, DASHWOOD R J, JACKSON M, DYE D. Development of chevron-shaped α precipitates in Ti-Al-Mo-V-Cr [J]. Scripta Materialia, 2009, 60: 571-573.

[22] DEHGHAN-MANSHADI A, DIPPENAAR R J. Development of α-phase morphologies during low temperature isothermal heat treatment of a Ti-5Al-5Mo-5V-3Cr alloy [J]. Materials Science and Engineering A, 2011, 528: 1833-1839.

孙 红1,2,余黎明1,2,刘永长1,2,张立业1,2,刘晨曦1,2,李会军1,2,吴杰峰3

1. 天津大学 水利工程仿真与安全国家重点实验室,天津 300072;

2. 天津大学 天津市材料复合与功能化重点实验室,天津 300072;

3. 中国科学院 等离子体物理研究所,合肥 230031

摘 要:研究热处理过程对Ti-6Al-4V-10Nb合金显微组织和力学性能的影响。采用扫描电镜、透射电镜和X射线衍射仪对合金显微组织进行研究,并通过拉伸试验对其室温和高温力学性能进行评估。结果表明,锻造和热处理后的主要组织为板条和球状初生α相、次生α相和β相。次生α相的尺寸明显小于初生α相的尺寸。热处理后,初生α相的体积分数减少,次生α相的体积分数增加。随着固溶温度的升高,初生α相的体积分数明显减少,次生α相的体积分数明显增加。随着固溶温度的升高,Ti-6Al-4V-10Nb合金的屈服强度和抗拉强度明显提高。

关键词:Ti-6Al-4V-10Nb 合金;热处理;显微组织;初生α相;次生α相;强度

(Edited by Bing YANG)

Foundation item: Projects (2015GB107003, 2015GB119001) supported by the International Thermonuclear Experimental Reactor (ITER) Program, China; Projects (51474155, 11672200, 51674175) supported by the National Natural Science Foundation of China

Corresponding author: Li-ming YU; Tel: +86-15022781376; E-mail: lmyu@tju.edu.cn

DOI: 10.1016/S1003-6326(18)64915-5