文章编号:1004-0609(2012)02-0566-06

高碳石煤流态化氧化焙烧提高钒的浸出率

汪 平1,冯雅丽1,李浩然2,刘欣伟1,张 萍1

(1. 北京科技大学 土木与环境工程学院,北京 100083;

2. 中国科学院 过程工程研究所 生化工程国家重点实验室, 北京 100080)

摘 要:采用流态化氧化焙烧方式预处理广西某难浸高碳石煤以提高钒的浸出率,对氧化焙烧过程的热力学和钒的氧化动力学进行了分析,并考察了流态化焙烧对钒浸出率的影响。结果表明:石煤在氧化焙烧过程中,碳、黄铁矿的氧化反应在热力学上比V(Ⅲ)氧化反应更易进行,它们的存在对钒氧化具有抑制作用。钒的氧化反应受扩散动力学控制,其表观活化能为347.00 kJ/mol。钒浸出率随焙烧温度的增加先增加后减小,当焙烧温度为700 ℃和750 ℃时,钒浸出率随焙烧时间的延长而增加;当焙烧温度为800 ℃,焙烧时间0.5 h时,钒浸出率最高,达97.51%,延长焙烧时间反而不利于钒浸出。与传统的钠化氧化焙烧法相比,浸出率高,环境污染少。

关键词:钒;高碳石煤;流态化氧化焙烧;活化能

中图分类号:TF803.21 文献标志码:A

Leaching rate improvement of vanadium by

high-carbon stone coal fluidized through oxidizing roasting

WANG Ping1, FENG Ya-li1, LI Hao-ran2, LIU Xin-wei1, ZHANG Ping1

(1. School of Civil and Environmental Engineering, University of Science and Technology Beijing,

Beijing 100083, China;

2. National Key Laboratory of Biochemical Engineering, Institute of Process Engineering,

Chinese Academy of Science, Beijing 100080, China)

Abstract: In order to enhance the leaching rate of vanadium, the fluidized oxidizing roasting was adopted to pretreat the high-carbon stone coal from Guangxi province, China. The thermodynamics of oxidizing roasting process and the oxidation kinetics of vanadium were analyzed, and the effect of fluidized roasting conditions on leaching rate of vanadium was investigated. The results indicate that the oxidation reaction of carbon and pyrite occurs more easily than that of V(Ⅲ) during the roasting process. Therefore, the vanadium oxidation reaction is inhibited by the existence of carbon and pyrite. The vanadium oxidation reaction is controlled by diffusion kinetics and the apparent activation energy is 347.00 kJ /mol. As the roasting temperature increases, the leaching rate of vanadium firstly increases and then decreases. Under roasting temperatures of 700 ℃ and 750 ℃,the leaching rate increases with the extension of roasting time. The leaching rate of vanadium reaches its maximum value (97.51%) under the roasting conditions of 800 ℃ and 0.5 h, the extension of roasting time (>0.5 h) was not favorable for vanadium leaching. Compared with the traditional salt roasting method, the technique has the characteristics of high leaching rate and more environment safety.

Key words: vanadium; high-carbon stone coal; fluidized oxidizing roasting; activation energy

我国钒资源主要赋存在石煤中,其储量巨大,占我国V2O5总储量的87%[1-2]。由于目前石煤提钒工艺对原矿选择性强、移植性差,多数难浸高碳石煤矿并没得到充分开发利用[3]。这类石煤钒矿因含碳量高,矿物结构复杂,存在石煤综合利用率不高、钒总回收率低、成本高等问题。仅吴惠玲等[4]、魏昶等[5]以及屈启龙等[6]对某些高碳石煤进行了提钒研究,但都侧重于提钒工艺的研究,相关基础理论研究较薄弱。高碳石煤提钒过程中,原则上需预先脱碳富钒后浸出。焙烧既可使其脱碳,也可使其中的钒由低价(V(Ⅲ)或V(Ⅳ))氧化为五价,并进一步转化为可溶性钒酸盐。因此,焙烧是从高碳石煤提钒工艺中一个重要的环节,在一定程度上决定全流程的钒总回收率。因流态化燃烧方式有燃烧效率高、燃料适应性强、清洁燃烧等特点,为提高钒的浸出率,本研究采用流态化氧化焙烧方式预处理广西某难浸高碳石煤,对氧化焙烧过程进行了研究,重点考察焙烧过程热力学、焙烧过程中钒的氧化动力学及流态化焙烧过程对钒浸出率的影响。这些基础研究对于深入了解石煤焙烧过程钒的氧化,提高钒的氧化率,改善焙烧条件及完善焙烧机理具有一定的指导意义,同时为其他此类高碳石煤开发利用提供指导和借鉴[7]。

1 实验

1.1 实验原料

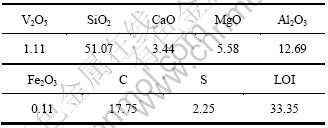

含钒石煤矿样取自广西省某石煤矿区,化学成分分析结果见表1。该石煤主要含二氧化硅、碳和三氧化二铝,碳含量17.75%(质量分数),属于高碳石煤[8]。

表1 高碳石煤主要化学成分

Table 1 Main chemical compositions of high-carbon stone coal (mass fraction, %)

1.2 实验试剂及装置

所用硫酸、二氧化锰和氢氟酸试剂均为分析纯,水为去离子水。所用装置主要有马弗炉、自制流态化焙烧反应装置(图1)和KH-50高压反应釜。

图1 流态化焙烧反应装置示意图

Fig. 1 Schematic diagram of fluidized roasting reactor: 1—Air pump; 2—Air intake; 3—Rotor flow meter; 4—Crucible furnace; 5—Quartz glass; 6—Air outlet; 7—Temperature controller; 8—Gas jar

图1所示为自制流态化焙烧反应装置,主要由空气泵、转子流量计、坩埚电阻炉及石英玻璃管组成。核心部件为坩埚电阻炉内的石英玻璃管5,它上长66 cm,下长25 cm;上为出气口,下为进气口;放焙烧料管内径3 cm。

1.3 实验方法

马弗炉焙烧试验:取预先焙烧试验样品(马弗炉内550 ℃焙烧2 h)作为动力学试验研究对象。将预焙烧试验样品置入马弗炉内,通入N2保持惰性气氛,分别升温至650 ℃、750 ℃、800 ℃和850 ℃后停止通N2,接通干燥的新鲜空气,各温度下分别焙烧15、30、60、90和120 min。取出迅速冷却至室温,进行钒价态测定。钒的氧化率(a)按式(1)计算[9]。

(1)

(1)

式中:a为钒的氧化率,%;w0为总钒质量分数;w1为五价钒的质量分数,%。

流态化焙烧酸浸试验:将粒径为0.2~0.71 mm的石煤矿样,置入设定温度的自制流态化焙烧反应装置中,焙烧一定时间,转子流速为0.2 m3/h,自然冷却后研磨至粒度<74 μm(70%)作为浸出用样。酸浸条件为:40%硫酸、3%二氧化锰和2%氢氟酸(添加量均为矿样的质量比),添加去离子水使液固质量比为0.8:1,搅拌均匀后置于烘箱,150 ℃浸出6 h。反应后,室温下磁力搅拌1 h,真空过滤,分析钒含量,按式(2)计算钒浸出率[10]。

(2)

(2)

式中:η为钒的浸出率,%;m为浸出试样质量,g;w2为试样中钒的质量分数,%;ρ为浸出液密度,g/mL;V为浸出液体积,mL;w3为浸出液中钒的质量分数,%。

2 结果及讨论

2.1 高碳石煤焙烧过程热力学分析

石煤钒矿焙烧需在氧化气氛中进行,若矿石含碳量较高,焙烧气氛呈还原性,低价钒很难氧化。已有研究发现,石煤直接焙烧存在钒转化率不高,矿石中低价钒很难氧化和转化为利于浸出的高价钒。针对上述问题,进行了焙烧热力学分析。根据物理化学基本原理,对V-O-C-Fe四体系直接焙烧可能发生的反应进行热力学计算,得到图2所示的碳、黄铁矿和钒氧化反应吉布斯自由能图[11]。

图2 碳、黄铁矿和钒氧化反应吉布斯自由能

Fig. 2 ?GΘ—T diagrams of carbon, pyrite and vanadium oxidation reaction

由图2可知,体系中VO氧化为V2O3的吉布斯自由能最低,说明该反应较易发生。钒氧化反应(4VO2+O2=2V2O5,2V2O3+O2=4VO2)与碳氧化反应(C+O2=CO2)的吉布斯自由能相比,前者高于后者,故体系处于平衡时,只有当碳氧化完全后,低价钒才有可能氧化成高价。从图2中还可看出,随着温度的升高,石煤中低价钒氧化的吉布斯自由能逐渐增大,不利于三价钒和四价钒的氧化[3]。比较钒氧化反应与黄铁矿氧化反应的吉布斯自由能,当温度低于700 K时,V(Ⅲ)氧化反应吉布斯自由能较低;当温度高于700 K时,黄铁矿氧化反应吉布斯自由能较低,在图2所示的温度范围内,Fe氧化曲线总在三价钒氧化曲线下方[11]。可见,石煤中黄铁矿的还原性对石煤提钒焙烧过程钒的氧化具有抑制作用。本试验所用石煤全铁总量为0.11%,所以,石煤中占17.75%的碳是影响钒氧化和转化的关键因素。

2.2 高碳石煤焙烧过程钒的氧化动力学

石煤中钒的氧化反应属于区域反应,该反应发生在石煤颗粒内部具有一定厚度的区域内,颗粒的形态结构对反应的影响可忽略。在含钒矿物晶格表面,自由焓较高,易形成反应核。反应初期,空气中O2向颗粒内部扩散,到达活性核心,氧化反应迅速开始,反应核不断生长,相界面增大,钒氧化反应速率不断加快。当核长大彼此相接触汇合时,相界面达到最大,反应速率亦达到最大值。此后,核发生彼此兼并,末反应核逐渐收缩,界面缩小,反应速率下降。由于固体产物层不断生长,氧气扩散受阻的影响逐渐明显,随固体产物层逐渐增厚,钒氧化过程也由动力学方式转为扩散方式[11]。

反应核的形成和长大是区域反应中重要的步骤,核形成和长大的时间t和转化率(在本研究中即钒的氧化率)a之间的函数关系,可用依洛菲耶夫动力学方程式描述,即

(3)

(3)

式中:α为时间t内参与反应的物质分数,%;n为指数;k为常数。

其中:n是恒定的正值,表征核长大时经过的串联反应步骤数,与初始核心形成过程动力学特征有关,同时也反映核形成过程的几何形状。当n>1时,反应过程为界面化学反应动力学所控制;当n<1时,反应过程为扩散动力学所控制;n=1时,反应为一级反应,反应速率正比于未参与反应物质的分数。

将式(3)取对数,得

(4)

(4)

对石煤中钒的氧化反应试验数据(见图3)t和a进行数学处理可求得n和k[7]。

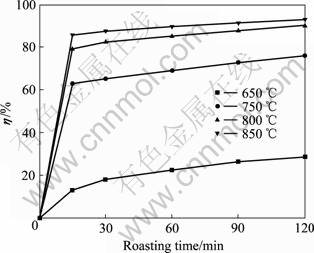

2.2.1 焙烧温度和时间对钒氧化率的影响

焙烧温度和时间对钒氧化率的影响如图3所示。由图3可看出,当温度低于650 ℃时,钒的氧化反应缓慢,随焙烧时间延长,η(Ⅴ)逐渐上升。而温度升高到750 ℃时,钒的氧化反应速度加快,在较短时间内V(Ⅴ)的转化率几乎不改变,曲线呈一直线,处于平衡状态。提高焙烧温度至800和850 ℃,钒氧化率剧增,继续延长焙烧时间对钒氧化率影响不大[7]。

图3 焙烧时间和温度对钒氧化率的影响

Fig. 3 Effect of roasting temperature and time on oxidation rate of vanadium

2.2.2 高碳石煤钒氧化动力学计算及分析

以 对

对 作图(见图4),得到各温度条件下的n和k:

作图(见图4),得到各温度条件下的n和k:

当650 ℃时,n=0.423 04,k=0.045 05;

当750 ℃时,n=0.171 47,k=0.604 81;

当800 ℃时,n=0.178 48,k=0.947 71;

当850 ℃时,n=0.143 95,k=1.295 64。

由于各温度下n均小于1,可判断在试验所测焙烧温度和时间范围内,石煤中钒的氧化反应受扩散动力学控制。从而推断出石煤在焙烧初期(<15 min),含钒矿物晶格表面上的活性核心先发生氧化反应,随着反应的进行,空气中的氧穿过反应产物层向石煤深部扩散,反应也由界面化学反应动力学控制转为扩散动力学控制。

图4 高碳石煤中钒氧化过程 和

和 的关系

的关系

Fig. 4 Relationship between  and

and  in process of vanadium oxidation from high-carbon stone coal

in process of vanadium oxidation from high-carbon stone coal

根据得出的n和k值,得

(5)

(5)

可以求出不同焙烧温度下氧化速率常数K:650 ℃,K=0.000 28;750 ℃,K=0.009 13;800 ℃,K=0.132 10;850 ℃,K=0.870 23。

表观活化能测定由阿累尼乌斯公式(Arrhenius)确定

(6)

(6)

式中:T为热力学温度,K;E为反应活化能,kJ/mol;R为气体常数,J/(mol·K)。

取ln K值对1/T作图,得到Arrhenius线性图。由图5所示线性拟合所得直线斜率为-4.173 7×104,计算出高碳石煤钒氧化反应的活化能为347.0 kJ/mol[7]。

图5 ln K与1/T关系图

Fig. 5 Relationship between ln K and 1/T

由700 ℃钒的氧化率试验数据求得其n= 0.256 42,k=0.290 97,根据公式(5)求得其氧化速率常数K为0.002 08,进而求得活化能为347.1 kJ/mol,与上述计算得出的活化能近似,表明依洛菲耶夫动力学方程式能较好地描述高碳石煤钒氧化反应。

2.3 高碳石煤流态化焙烧过程对钒浸出的影响

焙烧热力学和钒氧化动力学分析结果表明,焙烧过程钒价态的变化是石煤提钒工艺的关键,它直接影响石煤中V(Ⅲ)向V(Ⅴ)的转化率、V(Ⅴ)进一步向可溶性钒的转化率及钒的浸出与沉淀。为了提高钒的浸出率,笔者对广西某难浸高碳石煤进行了焙烧试验研究,发现流态化氧化焙烧方式能将更多的低价钒氧化成高价钒,利于浸出剂浸出更多的钒,而且环境污染少。因此,开展了流态化焙烧过程对钒浸出率影响试验研究。

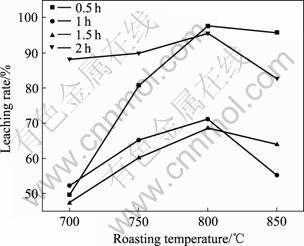

影响石煤焙烧过程中钒氧化的因素很多,有内因也有外因。内因是无法改变的,外因中对钒氧化影响较大的是焙烧温度和焙烧时间。焙烧温度决定化学反应和物相变化的可能性[12],焙烧时间决定反应的进行和物相变化的程度。图6和7所示分别为不同焙烧时间(0.5、1、1.5和2 h)下焙烧温度和不同焙烧温度(700、750、800和850 ℃)下焙烧时间对钒浸出率的影响。

图6 不同焙烧时间下焙烧温度对钒浸出率的影响

Fig. 6 Effect of roasting temperature on leaching rate of vanadium at different roasting times

图7 不同焙烧温度下焙烧时间对钒浸出率的影响

Fig. 7 Effect of roasting time on leaching rate of vanadium at different temperatures

从图6可以看出,不同焙烧时间下,随着焙烧温度的改变,钒浸出率的变化趋势是一致的。温度低于800 ℃时,浸出率随焙烧温度提高而增加,且在800 ℃时,各焙烧时间下浸出率都达到最大值,继续提高温度,浸出率反而下降。这是由于在焙烧温度较低时,由热力学分析结果可知,还原性物质碳未燃尽,钒没有氧化完全,浸出率不高。随着焙烧温度的提高,钒氧化反应速率加快,越来越多的钒转变为可溶于酸的高价钒化合物,因而浸出率提高。当焙烧温度达到800 ℃时,钒氧化反应达到平衡,浸出率达到最大值。温度再提高,被氧化的低价钒进行二次反应,生成钒酸铁(FeVO4)、钒酸钙(Ca(VO4)2)、钒酸钙钠(NaCaVO4)等难溶性化合物,将部分钒裹入其中,使这些钒既不溶于水,也不溶于酸,钒的浸出率下降[13-15]。所以,焙烧温度不宜过高,选定800 ℃为宜。

由图7可以看到,焙烧温度为700 ℃和750 ℃时,钒浸出率随焙烧时间的延长而增加;继续提高温度至800 ℃和850 ℃时,焙烧时间为0.5 h时浸出率最高,延长焙烧时间反而不利于钒浸出。由钒氧化动力学分析结果可知,在焙烧温度较低时,钒氧化反应完成需要的时间较长,所以,随着焙烧时间的延长,钒氧化趋于完全,浸出率提高。随着焙烧温度的升高,钒氧化反应时间缩短,继续延长焙烧时间,物料烧结现象较严重,导致氧化的钒被包裹,浸出率下降。所以,当焙烧温度为800 ℃时,选焙烧0.5 h就能得到较高的钒浸出率。

3 结论

1) 热力学分析结果表明,石煤中碳、黄铁矿和钒的氧化反应在热力学上都是可自发进行的,碳、黄铁矿的氧化反应在热力学上比V(Ⅲ)氧化反应更易进行,它们的存在对钒氧化具有抑制作用。

2) 动力学研究表明,石煤中钒的氧化反应属于区域反应,采用依洛菲耶夫动力学方程式 能较好地描述钒的氧化过程。在所测焙烧温度时间范围内,石煤中钒的氧化反应受扩散动力学控制,其表观活化能为347 kJ/mol,与试验得到的Arrhenius线性图数据基本一致。

能较好地描述钒的氧化过程。在所测焙烧温度时间范围内,石煤中钒的氧化反应受扩散动力学控制,其表观活化能为347 kJ/mol,与试验得到的Arrhenius线性图数据基本一致。

3) 流态化焙烧过程对钒浸出率的影响结果表明,不同焙烧时间下钒浸出率随焙烧温度的增加先增后减,焙烧温度为700 ℃和750 ℃,钒浸出率随焙烧时间的延长而增加;在焙烧温度为800 ℃、焙烧时间 0.5 h时,钒浸出率最高,达97.51%,延长焙烧时间反而不利于钒浸出。

REFERENCES

[1] 宾智勇. 石煤提钒研究进展和五氧化二钒的市场状况[J]. 湖南有色金属, 2006, 22(1): 16-20.

BIN Zhi-yong. Progress of the research on extraction of vanadium pentoxide from stone coal and the market of the V2O5[J]. Hunan Nonferrous Metals, 2006, 22(1): 16-20.

[2] LAN Yao-zhong, LIU Jin. Review of vanadium processing in China[J]. Engineer Sciences, 2005, 3(3): 58-62.

[3] 朱保仓. 高碳石煤提钒新工艺研究[D]. 西安: 西安建筑科技大学, 2007: 41-49.

ZHU Bao-cang. Study on a new technology of extracting vanadium from high-carbon stone-coal[D]. Xi’an: Xi’an University of Architecture and Technology, 2007: 41-49.

[4] 吴惠玲, 赵 伟, 李旻廷, 邓志敢, 葛怀文, 魏 昶. 高碳石煤优先选煤富集钒新工艺研究[J]. 中国稀土学报, 2008, 26: 530-533.

WU Hui-ling, ZHAO Wei, LI Min-ting, DENG Zhi-gan, GE Huai-wen, WEI Chang. New craft study on enriching vanadium by means of priority coal flotation from high carbon stone-coal[J]. Journal of the Chinese Rare Earth Society, 2008, 26: 530-533.

[5] 魏 昶, 吴惠玲, 李存兄, 李旻廷, 梁艳辉, 赵 伟. 高碳石煤直接酸浸提钒探索性研究[J]. 中国稀土学报, 2008, 26: 534-536.

WEI Chang, WU Hui-ling, LI Cun-xiong, LI Min-ting, LIANG Yan-hui, ZHAO Wei. Exploratory research on recovering vanadium from high carbon stone-coal by means of direct acid leaching[J]. Journal of the Chinese Rare Earth Society, 2008, 26: 534-536.

[6] 屈启龙, 谢建宏, 王冠甫. 高碳钒矿综合回收石墨试验研究[J]. 矿业快报, 2007(4): 35-37.

QU Qi-long, XIE Jian-hong, WANG Guan-fu. Study of comprehensive recovery of graphite from high carbon vanadium ore[J]. Express Information of Mining Industry, 2007(4): 35-37.

[7] 陈铁军, 邱冠周, 朱德庆. 石煤循环氧化法提钒焙烧过程氧化机理研究[J]. 金属矿山, 2008(6): 62-66.

CHEN Tie-jun, QIU Guan-zhou, ZHU De-qing. Oxidation mechanism of vanadium extraction in stone coal roasting with cyclic oxidation[J]. Metal Mine, 2008(6): 62-66.

[8] 魏 昶, 吴惠玲, 樊 刚, 李存兄, 李旻廷, 梁艳辉. 酸浸法从高碳石煤中提钒[J]. 钢铁钒钛, 2009, 30(1): 7-11.

WEI Chang, WU Hui-ling, FAN Gang, LI Cun-xiong, LI Min-ting, LIANG Yan-hui. Recovering vanadium from high carbon stone coal by means of direct acid leaching[J]. Iron Steel Vanadium Titanium, 2009, 30(1): 7-11.

[9] 陈铁军, 邱冠周, 朱德庆. 石煤提钒焙烧过程钒的价态变化及氧化动力学[J]. 矿冶工程, 2008, 28(3): 64-67.

CHEN Tie-jun, QIU Guan-zhou, ZHU De-qing. Valence variation and oxidation kinetics of vanadium during vanadium- bearing stone coal roasting[J]. Mining and Metallurgical Engineering, 2008, 28(3): 64-67.

[10] 罗小兵, 冯雅丽, 李浩然, 杜竹玮, 王宏杰, 刘 巍. 湿法浸出粘土钒矿中钒的研究[J]. 矿冶工程, 2007, 27(6): 48-53.

LUO Xiao-bing, FENG Ya-li, LI Hao-ran, DU Zhu-wei, WANG Hong-jie, LIU Wei. Investigation on extraction of V2O5 from clay containing vanadium by acid process[J]. Mining and Metallurgical Engineering, 2007, 27(6): 48-53.

[11] 何东升. 石煤型钒矿焙烧-浸出过程的理论研究[D]. 长沙: 中南大学, 2009: 74-77.

HE Dong-sheng. Theoretical investigation of roasting and leaching processes of stone coal-type vanadium ore[D]. Changsha: Central South University, 2009: 74-77.

[12] 何东升, 冯其明, 张国范, 欧乐明, 卢毅屏. 含钒石煤的氧化焙烧机理[J]. 中国有色金属学报, 2009, 19(1): 195-200.

HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Mechanism of oxidizing roasting process of vanadium containing stone coal[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 195-200.

[13] 何东升, 冯其明, 张国范, 欧乐明, 卢毅屏, 邵延海. 碱法从石煤中浸出钒试验研究[J]. 有色金属: 冶炼部分, 2007(4): 15-17.

HE Dong-sheng, FENG Qi-ming, ZHANG Guo-fan, OU Le-ming, LU Yi-ping, SHAO Yan-hai. The Study on leaching vanadium from stone coal with alkali[J]. Nonferrous Metals: Melting, 2007(4): 15-17.

[14] 鲁兆伶, 谷万成. 从石煤中提取钒的焙烧试验研究[J]. 湿法冶金, 2008, 28(2): 88-91.

LU Zhao-ling, GU Wan-cheng. Research on roasting of stone coal for extraction vanadium[J]. Hydrometallurgy of China, 2008, 28(2): 88-91.

[15] 宾智勇. 钒矿石无盐焙烧提取五氧化二钒试验[J]. 钢铁钒钛, 2006, 27(1): 21-26.

BIN Zhi-yong. Study on extraction of V2O5 from vanadium ore by roasting and acid leachig process [J]. Iron Steel Vanadium Titanium, 2006, 27(1): 21-26.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(20876160)

收稿日期:2010-07-16;修订日期:2011-01-20

通信作者:冯雅丽,教授,博士;电话:010-62311181;E-mail: ylfeng126@126.com