文章编号:1004-0609(2014)12-3169-08

湖南某酸性浸锑渣的浸金特性

杨永斌,刘 波,李 骞,姜 涛,曾冠武

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:结合化学成分、物相分析和氰化浸金实验,研究酸性浸锑渣的浸金特性以及氧化焙烧预处理对浸金的影响机理,并考察酸法浸锑-氧化焙烧脱硫-氰化浸金的工艺流程。结果表明:黄铁矿包裹金是造成酸性浸锑渣中金难浸的主要原因,经氧化焙烧后,焙砂中单质硫和硫化物的含量显著降低,总硫含量降至0.15%(质量分数),硫化物转变为赤铁矿,焙砂的氰化浸金率达95.92%,比酸性浸锑渣直接浸金提高了24%。

关键词:浸锑渣;氧化焙烧;脱硫;氰化浸金

中图分类号:TF831 文献标志码:A

Characteristics of gold leaching from acidic antimony leaching residue in Hunan Province, China

YANG Yong-bin, LIU Bo, LI Qian, JIANG Tao, ZENG Guan-wu

(School of Mineral Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Combined with chemical composition, physical phase analysis and gold cyanidation experiment, the characteristics of gold leaching and the affecting mechanism of oxidizing roasting pretreatment were studied on an acidic antimony leaching residue. The process of acid antimony leaching-oxidizing roasting desulfurization-gold cyanidation was also investigated. The results show that being wrapped in pyrite is the primary cause for low leaching rate of gold in the acidic antimony leaching residue. Pretreated by oxidizing roasting, the contents of elemental sulfur and sulfide decrease sharply. As a result, the total sulfur content in the calcine diminishes to only 0.15% (mass fraction) and the ferrous sulfide converts into hematite. The leaching rate of gold cyanidation from the calcine increases up to 95.92%, showing a favorable increment of 24% compared with that of direct leaching from the acidic antimony leaching residue.

Key words: antimony leaching residue; oxidizing roasting; desulfurization; gold cyanidation

基于氧化锑易挥发的特性,工业生产中硫化锑矿、氧化锑矿及其复合型矿物(如黝铜矿、脆硫锑铅矿等)的冶炼主要采用挥发焙烧(熔炼)-还原熔炼工艺[1-2],其中以湖南辰州矿业采用的鼓风炉挥发熔炼-贵锑电解工艺最具代表性,但该工艺存在流程复杂、相伴生贵贱金属直收率低、能耗高和环境污染严重等问题[3-4]。为解决此类问题,目前研究最多的方法主要有沉淀熔炼法和造锍熔炼法,通过加入添加剂与硫反应形成沉淀产物达到固硫的目的,避免释放出二氧化硫,过程中可直接制得粗锑,但都仅限于实验室研究阶段,同时在处理锑金矿时存在金无法回收的缺点[5-7]。

相比火法工艺,湿法炼锑工艺具有工艺简单、流程短、产品灵活和环境污染小等优点,湿法炼锑主要包括酸法炼锑和碱法炼锑[8-9],碱法炼锑存在Na2S增生严重,浸出过程中硫酸钠、硫代硫酸钠、亚硫酸钠和硫代锑酸钠等积累严重,废液处理量大且较繁杂等问题,给电积沉锑带来了困难,20世纪70年代大部分碱法炼锑工艺均已停产[10];此外,硫化钠在浸出过程中会被氧化成硫代硫酸盐和多硫化物,这些物质会与金反应,阻碍锑和金分离[11-13]。相比碱法炼锑,酸法炼锑在处理锑金矿时金、锑具有良好的选择性分离特性,但浸锑过程中硫以单质的形式富集于渣中,造成浸金的困难,故脱硫成为酸性浸锑渣提金的首要条件。已有研究表明,脱硫主要方法有选矿法、焙烧法、煤油浸出和加热蒸馏等[14-15],目前除焙烧外,其他方法工业化应用仍存在问题,如对不同矿物的适应性不强,相伴生的贵金属回收率偏低。

本文作者针对酸性浸锑渣浸金率较低的问题,对湖南某锑金精矿经过酸法浸锑后的浸锑渣进行研究,通过分析工艺流程中各原料的成分、物相变化以及相关性实验,分析造成金难浸的原因,探讨提高金浸出率的方法,为酸性浸锑渣提金提供一定的理论指导。

1 实验

1.1 原料

所用到原料包括锑金精矿、浸锑渣和焙砂。锑金精矿是湖南湘西某锑金共生矿经过浮选后的精矿,该锑金共生矿属于典型的Sb-Si-Au体系形成的石英脉型含金、锑多金属矿。主要金属矿物有自然金、辉锑矿和黄铁矿等,毒砂的含量较低,脉石矿物以石英为主。可回收的有价元素为金和锑,金主要以单体金和连生金的形式存在,部分赋存于氧化矿物和硫化矿物中;锑矿物主要为辉锑矿(10.62%,质量分数)、锑华及方锑华(12.97%,质量分数),少量以锑酸盐的形式存在,锑金精矿中硫化矿物主要为辉锑矿和黄铁矿,氧化矿物主要有赤褐铁矿、锑华及方锑华。

浸锑渣是锑金精矿经过酸法浸锑后的浸出渣,实验表明,最佳浸锑工艺参数如下:温度为95 ℃,时间为30 min,液固比为4.0,FeCl3的过量系数为1.1,HCl浓度为4.0 mol/L。在此条件下浸锑渣含锑0.71%,锑的浸出率达到了99.05%,含金106.66 g/t,进入浸锑液中的金仅为0.99%,说明酸法浸锑在处理锑金精矿时,锑和金具有良好的选择性分离特性。

焙砂是浸锑渣经过氧化焙烧后的产物,焙烧温度为600 ℃,焙烧时间为1 h。

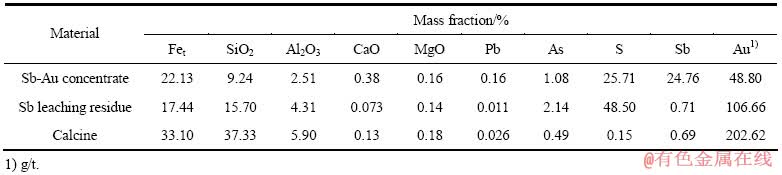

原料的化学成分通过化学分析滴定法测定,其主要化学成分如表1所列。

由表1可知,锑金精矿的主要化学成分(质量分数)为锑、硫和铁,锑的含量为24.76%,金的含量为48.80 g/t;浸锑渣锑含量为0.71%,以锑酸盐为主,硫含量高达48.50%,砷含量较低,为2.14%,可作为一种高硫低砷金精矿,焙烧法是预处理此类矿物常见的方法[16-17]。焙砂中硫含量为0.15%,砷含量为0.49%,硫和砷得到有效脱除,金得以有效暴露。整个工艺是一个除锑、硫和砷并富集金的过程。

1.2 实验流程

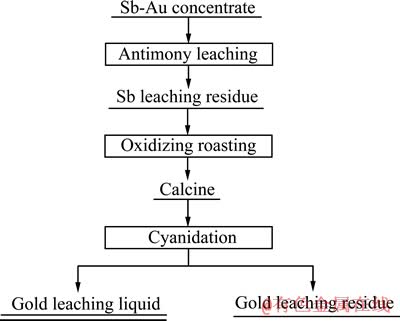

考虑到氯气和碱性浸出锑时会使部分金进入溶液中,而SbCl5具有剧毒、易挥发、遇见空气发烟等特性,在实验室条件下,较难控制与操作,本研究中采用酸性FeCl3溶液浸锑。

对原矿进行取样、磨矿处理(粒度小于0.074 mm的占80%以上),实验过程中采用水浴加热、冷凝回流装置。根据酸度、液固比以及FeCl3的过量系数来确定HCl和FeCl3的用量,将配制好的浸出剂加入三口瓶并置于恒温水浴锅中加热,待浸出剂的温度升至所需温度时加入30 g锑金精矿,搅拌浸出,反应达到终点时趁热过滤。为了防止SbCl3的水解,用浓度为1 mol/L的盐酸洗涤数次[18-19],然后过滤,干燥,称量,分析。氧化焙烧在卧式管炉中进行,产生的SO2气体通过抽气用NaOH洗气瓶吸收,工业上产生的SO2可用来制取硫酸。最后,对焙砂进行氰化浸金。具体工艺流程如图1所示。

表1 原料的主要化学成分

Table 1 Chemical components of raw materials

图1 氰化浸金实验流程图

Fig. 1 Experimental process of gold cyanidation

2 结果与讨论

2.1 物相分析

为了研究金的浸出特性,对工艺流程中的锑金精矿、浸锑渣和焙砂3种物料进行X射线衍射(XRD)分析和化学物相分析,根据金与各物相的赋存关系,初步查明了浸锑渣中金难浸的原因。

2.1.1 XRD谱分析

X射线衍射仪型号为D8-Advance,根据XRD谱(见图2)可知,锑金精矿的主要物相为辉锑矿(Sb2S3)、黄铁矿(FeS2)和石英(SiO2),还含有少量氧化铁矿物以及单质硫;浸锑过程中随着辉锑矿的分解,锑以相应氯化物的形式进入溶液中,硫以单质的形式富集于渣中,浸锑渣的主要物相为单质硫、黄铁矿(FeS2)、石英(SiO2)以及少量氧化铁矿物;焙砂的主要物相为石英(SiO2)和赤铁矿(Fe2O3),说明浸锑渣中的单质硫和黄铁矿经过焙烧后被充分的氧化。

2.1.2 化学物相分析

图2 3种物料的XRD谱

Fig. 2 XRD patterns of three materials

表2表明,锑金精矿中硫主要以硫化物的形式存在,硫化物主要包括辉锑矿以及黄铁矿;浸锑后,辉锑矿分解,使得浸锑渣中硫化物所占比率降至42.99%;与此同时,单质硫富集于渣中使得单质硫所占比率提高到56.97%;经过焙烧后,浸锑渣中大量的单质硫以及黄铁矿中的硫被氧化脱除,总硫含量降至0.15%,硫的脱除率达到99.84%,残余的硫以硫酸盐为主。

表3表明,锑金精矿中47.83%的金以单体金和连生金的形式存在,33.18%和18.83%的金分别赋存于硫化矿物和氧化矿物中,赋存于硅酸盐中的金所占比例极小;浸锑过程中金得到富集,浸锑渣金品位达到106.66g/t,随着辉锑矿和锑华以及方锑华的分解,部分金被解离,以单体金和连生金形式存在的金所占比例提高至71.54%,同时,赋存于硫化矿物和氧化矿物中的金所占比例均降低,但依然高达28.33%;焙砂中金随着硫的脱除进一步富集,基本上是以单体金和连生金的形式存在,少量赋存于赤铁矿中。

表2 原料中硫的物相分析结果

Table 2 Physical phase analysis results of sulfur in raw materials

表3 原料中金的物相分析结果

Table 3 Physical phase analysis results of gold in raw materials

2.2 结果分析

氰化浸金条件如下:常温、液固比2.5:1、NaCN浓度0.3%(质量分数)、时间48 h、搅拌速率600 r/min。在此条件下直接对浸锑渣进行氰化浸金,金的浸出率为71.93%,浸出效果不理想。根据物相分析可知,浸锑渣中以单体金和连生金形式存在的金所占比例达到了71.54%,赋存于硫化物(主要为FeS2)中的金和氧化物(主要为Fe2O3)中的金分别为24.10%和4.23%,由此推测,影响金浸出的因素可能是黄铁矿和赤铁矿的包裹。此外,对氰化浸金后浸锑渣中硫含量进行化学分析,浸金前后的硫含量由48.5%降至45.95%,降低了2.5%左右,说明单质硫在浸金过程中被消耗,众所周知,单质硫的存在会对浸金造成很大影响,因此,大量富集于渣中的单质硫也可能是金难浸的原因之一。

2.2.1 渣中单质硫和黄铁矿对浸金特性的影响

为了进一步明确单质硫和黄铁矿对浸金的影响程度,采用20% NaOH(质量分数)溶液在温度为98 ℃、液固比为5:1和时间为6 h的条件下进行热碱脱硫,消除单质硫的影响,脱硫渣中的总硫含量为29.05%,脱硫率为60.65%,而浸锑渣中单质硫所占比率为56.97%(见表2),因此推断单质硫已完全反应。为了证明这一推断,对热碱脱硫渣进行XRD分析,结果如图3所示。

图3 热碱脱硫渣的XRD谱

Fig. 3 XRD pattern of desulfurized residue by hot-alkaline

由热碱脱硫渣的XRD谱(见图3)可知,单质硫基本被脱除完全,符合预测结果,对热碱脱硫渣氰化浸金,得到渣中含金量为45.1 g/t,金的浸出率为71.68%,与浸锑渣直接氰化浸金结果(71.93%)相差不大,说明单质硫的存在虽然可能会消耗一定量的氰化物以及溶解氧,但不是影响浸金的最主要因素。已有研究表明,酸法浸锑过程中析出的单质硫在反应界面形成的固体产物层,扫描电镜表明矿粒表面生成的单质硫呈疏松、多孔状,浸出过程中,不存在硫膜阻滞作用[20],因此,单质硫对浸锑渣浸金的影响极小,这和实验结果完全吻合。

同时,为了证明黄铁矿是影响金浸出最主要的因素,对热碱脱硫渣进行了化学氧化,各取热碱脱硫渣25 g,分别采用H2O2和浓HNO3两种化学物质来氧化黄铁矿,其化学反应如下:

FeS2+15/2H2O2=1/2Fe2(SO4)3+1/2H2SO4+7H2O

=-1042.58 kJ/mol (1)

=-1042.58 kJ/mol (1)

FeS2+15HNO3=1/2Fe2(SO4)3+1/2H2SO4+15NO2+7H2O

=-308.43 kJ/mol (2)

=-308.43 kJ/mol (2)

双氧水氧化条件:常温、时间12 h、H2O2浓度0.3%(质量分数)、液固比5:1、pH为酸性。

浓硝酸氧化条件:温度80 ℃、时间6 h、浓HNO3浓度200 g/L、液固比5:1。

在上述条件下分别对热碱脱硫渣进行化学氧化,所得氧化渣的氰化浸金结果如表4所列。

由表4可知,热碱脱硫渣在H2O2和浓HNO3氧化后,金的浸出率均有所提高,说明黄铁矿包裹金是阻碍金浸出的主要因素,而热碱脱硫-化学氧化这一过程存在诸多问题,在热碱脱硫过程中,由于反应产物不稳定且易被氧化为硫代硫酸盐以及多硫化合物,这些物质会溶解渣中的金[21],不利于金的富集回收,且采用双氧水氧化热碱脱硫渣时,虽然控制pH可以在一定程度上控制双氧水的分解,但Fe3+的存在会加剧双氧水的分解[22],故增加了双氧水的用量,提高了成本。此外,浓硝酸氧化时,会生成大量的有害气体二氧化氮,需要回收处理。

综上所述,采用焙烧法作为浸锑渣脱硫的主要方法。

2.2.2 氧化焙烧对金浸出影响及机理

在氧化焙烧过程中,由于渣中含有大量的单质硫,所以加热的过程中,只要温度达到硫的燃点,硫燃烧将释放大量的热,焙烧过程就能快速地进行,因此实验过程中没有考虑焙烧温度对浸金的影响。在不同焙烧时间时研究了焙砂中的硫含量对金浸出率的影响,结果如表5所列。

表5表明,随着焙烧时间的延长,脱硫率也相应增加,金得以富集,从而使得焙砂中金的品位也相应增加。焙烧时间为60 min时,脱硫率为99.84%,脱除完全,随着脱硫率的提高,金的浸出率也相应地提高,说明随着黄铁矿被逐渐破坏,黄铁矿包裹金也逐步暴露出来,这进一步印证了黄铁矿包裹金是阻碍金浸出的最主要原因,其次还有一部分氧化铁包裹金也是造成金难浸的原因之一,同时证明了对浸锑渣进行焙烧可以提高金浸出率的可行性。

为了更进一步了解焙烧过程中单质硫和黄铁矿被氧化的过程以及焙烧机理,分别对经不同时间焙烧的焙砂进行XRD分析,结果如图4所示。

图4 不同焙烧时间焙砂的XRD谱

Fig. 4 XRD patterns of calcine for different calcination times

由图4可知,氧化焙烧过程中,单质硫首先被氧化,且氧化速度十分迅速,当焙烧时间为5 min时,渣中的单质硫基本被脱除,焙烧时间达到15 min时单质硫被完全脱除。氧化焙烧过程中,反应由外到内逐渐进行,由于单质硫燃烧时消耗了大量氧气,在未反应界面层内部的黄铁矿没有足够的氧气参与反应,首先解离为磁黄铁矿(Fe1-xS),而外层中的黄铁矿则被氧气直接氧化为赤铁矿,随着单质硫的逐渐脱除,反应逐步向内层推进,黄铁矿解离生成的中间产物磁黄铁矿也被氧化为赤铁矿,当焙烧时间为60 min时,黄铁矿完全转变为赤铁矿。氧化焙烧过程中各反应产物的演变过程如下:单质硫逐渐消失、黄铁矿逐渐消失、磁黄铁矿先逐渐生成后逐渐消失、赤铁矿逐渐生成。此外,单质硫燃烧放热还可以降低能耗,节约生产成本。

表4 不同氧化渣的浸金结果

Table 4 Gold leaching results of different oxidation residues

表5 焙砂硫含量与金浸出率的关系

Table 5 Relationship between sulfur content of calcine and leaching rate of gold

表6 氰化钠浓度对金浸出率的影响

Table 6 Effect of sodium cyanide concentration on gold leaching rate

表7 浸出时间对金浸出率的影响

Table 7 Effect of leaching time on gold leaching rate

3 浸金实验结果

浸金实验采用XJT搅拌器常温下搅拌浸出,实验前,先将20 g焙砂加入250 mL烧杯中,根据液固比、浸出剂浓度等调节适宜的矿浆浓度,用NaOH溶液调节适宜的pH值,研究氰化钠浓度以及浸出时间对金浸出率的影响,浸出条件及结果如表6和7所列。

由表6可知,随着氰化钠浓度的增加,金的浸出率逐渐增大。氰化钠浓度为0.3%时,金的浸出率为81.84%,当氰化钠浓度增加到0.4%时,金的浸出率为83.37%,变化不明显,故选0.3%为最佳含量。由表7可知,氰化钠浓度为0.3%,金的浸出率随着时间的延长逐渐增大,当浸出时间为48 h时,金的浸出率达到95.92%,浸金效果良好,为了进一步确定氰化钠最佳浓度范围,研究氰化钠浓度为0.4%,浸出48 h后,金的浸出率达到96.35%,较浓度为0.3%时金的浸出率仅增加了0.43%。综上所述,氰化钠的最佳浓度为0.3%,最佳浸出时间为48 h。

得到的浸金液可通过活性炭吸附、电解、分离提纯等制得金锭,浸出渣铁含量为33.1%,可以作为一种低品位铁精矿回收处理。此外,焙砂中仍有8 g/t左右的金没有被浸出,占金总含量的4%左右,由焙砂金物相分析可知,剩余的金主要是氧化铁包裹金,研究表明,铁氧化物包裹金属于难处理金矿[23],目前还没有简单、经济的方法来提取。

4 结论

1) 对酸性浸锑渣进行直接氰化浸出时,金的浸出率仅为71.93%;热碱脱硫-化学氧化实验结果表明,富集于渣中的硫元素虽然可能消耗氰化钠和溶解氧,但不是影响金浸出的主要因素,而黄铁矿包裹金才是造成浸金率偏低的主要因素。此外,还有部分氧化铁包裹金。

2) 酸性浸锑渣氧化焙烧后,焙砂总含硫量降至0.15%,硫的脱除率达到99.84%,单质硫和黄铁矿基本被氧化完全,使包裹金充分地暴露,最终在常温、液固比2.5、pH 11、搅拌速率600 r/min、氰化钠浓度0.3%,浸出时间48 h的条件下,金的浸出率达到了95.92%,比直接对浸锑渣氰化浸出的提高了24%,不能被浸出的剩余金为氧化铁包裹金(4%左右)。

REFERENCES

[1] 高 亮, 杨建广, 陈胜龙, 刘小文, 李 静, 唐谟堂. 硫化锑精矿湿法清洁冶金新工艺[J]. 中南大学学报: 自然科学版, 2012, 43(1): 28-37.

GAO Liang, YANG Jian-guang, CHEN Sheng-long, LIU Xiao-wen, LI Jing, TANG Mo-tang. A new process for cleaning hydrometallurgy of antimony sulfide[J]. Journal of Central South University: Science and Technology, 2012, 43(1): 28-37.

[2] 雷 霆, 朱从杰, 张汉平. 锑冶金[M]. 北京: 冶金工业出版社, 2009: 362-372.

LEI Ting, ZHU Cong-jie, ZHANG Han-ping. Antimony metallurgy[M]. Beijing: Metallurgical Industry Press, 2009: 362-372.

[3] 龚福保, 邓卫华. 降低锑精矿鼓风炉挥发熔炼渣含锑的研究与实践[J]. 中国有色冶金, 2011, 40(6): 9-12, 33.

GONG Fu-bao, DENG Wei-hua. Practice and study on reducing content of antimony in slag of antimony concentrate volatilization and smelting with blast furnace[J]. China Nonferrous Metallurgy, 2011, 40(6): 9-12, 33.

[4] 廖光荣, 刘放云, 龚福保. 锑鼓风炉富氧挥发熔炼新工艺研究与应用[J]. 中国有色冶金, 2010, 39(5): 17-20.

LIAO Guang-rong, LIU Fang-yun, GONG Fu-bao. Study and application on new technology of oxygen-enriched air smelting of antimony smelting blast furnace[J]. China Nonferrous Metallurgy, 2010, 39(5): 17-20.

[5] 陈永明, 黄 潮, 唐谟堂, 姚维义, 唐朝波, 皮关华. 硫化锑精矿还原造锍熔炼一步炼锑[J]. 中国有色金属学报, 2005, 15(8): 1311-1316.

CHEN Yong-ming, HUANG Chao, TANG Mo-tang, YAO Wei-yi, TANG Chao-bo, PI Guan-hua. Production of antimony by directly reducing-matting smelting of stibnite concentrate[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1311-1316.

[6] 叶龙刚, 唐朝波, 唐谟堂, 杨建广, 陈永明, 杨声海, 何 静. 硫化锑精矿低温熔炼新工艺[J]. 中南大学学报: 自然科学版, 2012, 43(9): 3338-3343.

YE Long-gang, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. Separation antimony from stibnite concentrate through a low temperature smelting[J]. Journal of Central South University: Science and Technology, 2012, 43(9): 3338-3343.

[7] 刘小文, 杨建广, 伍永田, 李 静, 唐朝波, 陈永明, 唐谟堂. 由辉锑矿低温固硫熔炼制取粗锑[J]. 中国有色金属学报, 2012, 22(10): 2896-2901.

LIU Xiao-wen, YANG Jian-guang, WU Yong-tian, LI Jing, TANG Chao-bo, CHEN Yong-ming, TANG Mo-tang. Separation of needle antimony from stibnite through low-temperature sulfur-fixing smelting process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2896-2901.

[8] 王成彦, 邱定蕃, 江培海. 国内锑冶金技术现状及进展[J]. 有色金属: 冶炼部分, 2002(5): 6-10.

WANG Cheng-yan, QIU Ding-fan, JIANG Pei-hai. Status and development of antimony metallurgy technology in China[J]. Nonferrous Metals: Extractive Metallurgy, 2002(5): 6-10.

[9] UBALDINI S, VEGLIO F, FORNARI P, ABBRUZZESE C. Process flow-sheet for gold and antimony recovery from stibnite[J]. Hydrometallurgy, 2000, 57(3): 187-199.

[10] 姜 涛. 提金化学[M]. 长沙: 湖南科学技术出版社, 1998: 315-316.

JIANG Tao. Chemistry of extractive metallurgy of gold[M]. Changsha: Hunan Science & Technology Press, 1998: 315-316.

[11] 黄云阶, 刘述平, 刘 敏. 金锑共生矿石综合利用试验研究[J]. 黄金, 2003, 24(4): 33-36.

HUANG Yun-jie, LIU Shu-ping, LIU Min. Experimental study on comprehensive utilization of associated mineral of gold and antimony[J]. Gold, 2003, 24(4): 33-36.

[12] CELEP O,  , DEVECI H. Improved gold and silver extraction from a refractory antimony ore by pretreatment with alkaline sulphide leach[J]. Hydrometallurgy, 2011, 105(3): 234-239.

, DEVECI H. Improved gold and silver extraction from a refractory antimony ore by pretreatment with alkaline sulphide leach[J]. Hydrometallurgy, 2011, 105(3): 234-239.

[13] RASCHMAN P,  E. Kinetics of leaching of stibnite by mixed Na2S and NaOH solutions[J]. Hydrometallurgy, 2012, 113: 60-66.

E. Kinetics of leaching of stibnite by mixed Na2S and NaOH solutions[J]. Hydrometallurgy, 2012, 113: 60-66.

[14] 何桂春. 复杂高硫金矿石浮选试验研究[J]. 黄金, 2010, 31(6): 45-49.

HE Gui-chun. Experimental study on floatation of some complex high-grade-sulfide gold ore[J]. Gold, 2010, 31(6): 45-49.

[15] 章 青, 郭年祥, 谭秀珍, 胡 娇. 湿法冶金渣中硫的化学回收[J]. 有色金属科学与工程, 2013(1): 40-43.

ZHANG Qing, GUO Nian-xiang, TAN Xiu-zhen, HU Jiao. Sulfur’s chemical recycle out of hydrometallurgical slag[J]. Nonferrous Metals Science and Engineering, 2013(1): 40-43.

[16] 黄礼煌. 金银提取技术[M]. 北京: 冶金工业出版社, 2001: 132-157.

HUANG Li-huang. Gold and silver extraction technology[M]. Beijing: Metallurgical Industry Press, 2001: 132-157.

[17] 李 峰, 丁德馨, 胡 南, 彭志成, 陈 伟. 难处理含金硫精矿的焙烧氧化-硫代硫酸盐浸出[J]. 中国有色金属学报, 2014, 24(3): 831-837.

LI Feng, DING De-xin, HU Nan, PENG Zhi-cheng, CHEN Wei. Roasting oxidation-thiosulfate leaching of gold from refractory gold-bearing sulfur concentrates[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 831-837.

[18] 唐谟堂, 赵天从. 三氯化锑水解体系热力学研究[J]. 中南矿冶学院学报, 1987, 18(5): 522-528.

TANG Mo-tang, ZHAO Tian-cong. Study on the thermodynamic in the systems of hydrolysis of antimony trichloride[J]. Journal of Central South Institute of Mining and Metallurgy, 1987, 18(5): 522-528.

[19] CORREIA M, CARVALHO J R, MONHEMIUS A J. The leaching of tetrahedrite in ferric chloride solutions[J]. Hydrometallurgy, 2000, 57(2): 167-179.

[20] 邓纶浩, 杨显万. Sb2S3矿浆电解热力学[J]. 昆明理工大学学报, 2000, 25(6): 49-53.

DENG Lun-hao, YANG Xian-wan. Thermodynamics for electro-slurry process of Sb2S3[J]. Journal of Kunming University of Science and Technology, 2000, 25(6): 49-53.

[21] CELEP O,  D, THIBAULT Y. Implementation of sodium hydroxide pretreatment for refractory antimonial gold and silver ores[J]. Hydrometallurgy, 2011, 108(1): 109-114.

D, THIBAULT Y. Implementation of sodium hydroxide pretreatment for refractory antimonial gold and silver ores[J]. Hydrometallurgy, 2011, 108(1): 109-114.

[22] 刘中兴, 谢传欣, 石 宁, 徐 伟. 过氧化氢溶液分解特性研究[J]. 齐鲁石油化工, 2009, 37(2): 99-102.

LIU Zhong-xing, XIE Chuan-xin, SHI Ning, XU Wei. Study on decomposition behavior of hydrogen peroxide solution[J]. Qilu Petrochemical Technology, 2009, 37(2): 99-102.

[23] 王力军, 罗远辉, 高洪山, 郑 其, 张景怀, 陈 松. 难处理金矿二次包裹现象研究[J]. 稀有金属, 2005, 29(4): 424-428.

WANG Li-jun, LUO Yuan-hui, GAO Hong-shan, ZHENG Qi, ZHANG Jing-huai, CHEN Song. Research on encapsulation of roasted refractory gold concentrate[J]. Chinese Journal of Rare Metals, 2005, 29(4): 424-428.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51074182)

收稿日期:2014-04-16;修订日期:2014-07-09

通信作者:杨永斌,副教授,博士;电话:13873120592;E-mail:ybyangcsu@126.com