DOI:10.19476/j.ysxb.1004.0609.2019.11.08

TA15钛合金等温多向锻造晶粒细化机理与力学性能

纪小虎,李 萍,时迎宾,严思梁,薛克敏

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:在600 ℃条件下,对近α型TA15钛合金进行等温多向锻造实验,分别利用金相显微镜(OM)、电子背散射衍射技术(EBSD)、准静态拉伸测试和扫描电子显微镜(SEM),对其晶粒细化机理、力学性能和断口形貌进行分析。结果表明:经3道次变形后,TA15钛合金晶粒细化显著,初生等轴α相晶粒直径由9.8 μm细化至5.1 μm,次生片状α相晶粒厚度由4.6 μm降至2.3 μm;晶粒细化机理为交滑移主导的应变诱导连续动态再结晶和机械几何破碎的共同作用;材料的综合性能提升显著,极限抗拉强度升高至1782 MPa,较初始态增幅达54%,而伸长率仅下降5.8%;通过定量分析发现细晶强化和位错强化共同导致拉伸强度的提高,且晶粒细化对应的贡献更为显著。

关键词:TA15钛合金;等温多向锻造;晶粒细化机理;力学性能;细晶强化;位错强化

文章编号:1004-0609(2019)-11-2515-09 中图分类号:TG379 文献标志码:A

钛合金具有比强度高、韧性好、耐腐蚀、耐高温、可焊接和无磁性等优异性能,在航空航天、石油、船舶、兵器、化工、医疗和电子等众多领域已得到广泛应用[1-2]。TA15钛合金作为中强度级别的近α型钛合金,因其良好的综合力学性能、工艺性能及可焊接性,广泛应用于发动机叶片、机匣、航空航天领域重要结构及焊接零件[3]。随着航空航天技术的发展,对轻质高强材料提出了更高要求。

材料强度的提高常伴随塑性的剧烈下降,而通过剧烈塑性变形(Severe plastic deformation, SPD)使晶粒细化能有效提高材料的综合性能。因此,SPD技术成为获取性能优异的轻质高强材料的有效途径之一[4]。多向锻造(Multi-directional forging, MDF)技术作为SPD技术的一种代表性工艺[5],其实质是对材料3个轴向反复镦粗、拔长,引入大的塑性变形,达到细化晶粒、提高性能的目的。该技术具有工艺简单、成本低、易于实现等优点,被广泛应用于钛合金组织改善过程中[6-7]。

SALISHCHEV等[8]通过MDF技术制备出晶粒尺寸为135 nm的Ti-6Al-4V合金,并对其低温超塑性进行了研究。ZHEREBTSOV等[9]对大尺寸坯料Ti-6Al-4V合金进行多向等温锻造(Multi-directional isothermal forging,MDIF),获得了尺寸约为0.4 μm的均匀细晶组织,力学性能提高明显。陈卓[10]采用MDIF和包套轧制技术对Ti2AlNb合金板材进行研究,制备出良好的超塑性和高温强度细晶板材。钛合金MDF研究主要集中在纯钛[11]、Ti-6Al-4V[9, 12]及其他Ti-Al系合金[13-15],针对TA15钛合金的研究却多集中于热变形行为、组织演变及工艺参数对组织性能影响、超塑性行为等方面[16-18]。然而,针对TA15钛合金温热变形条件下MDIF过程中晶粒细化机理及力学性能研究却少有报道。

基于此,本文针对TA15钛合金开展温热MDIF实验研究,探索其晶粒细化机理,为工业生产获得综合性能优异的TA15钛合金提供理论指导。

1 实验

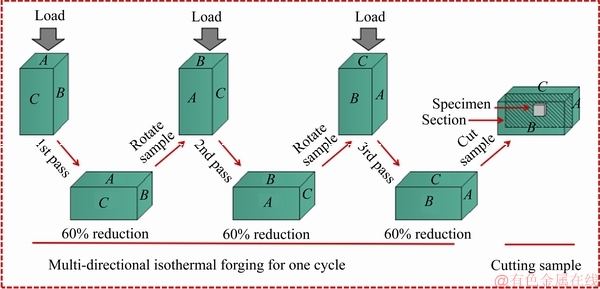

实验材料为北京航空材料研究院提供的TA15钛合金棒材,其化学成分(质量分数)为:6.6%Al,2.31%V,1.7%Mo,2.2%Zr,0.06%Fe,87.13%Ti,(α+β)/β转变温度为995 ℃,再结晶温度为750 ℃。采用如图1所示工艺方案,在RZU200HF液压机上进行MDIF实验,所用长方体试样尺寸为15 mm×15 mm×30 mm,变形温度为600 ℃,单次压下量为60%,冲头下行速度约为1 mm/s。每依次完成3个方向变形为一个道次,获得初始态、1道次、2道次和3道次共4种状态试样,实验结束立即淬火冷却。

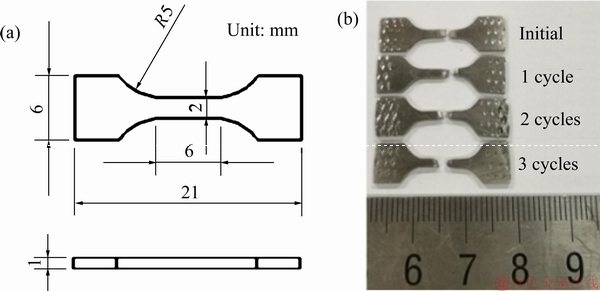

采用MR5000型金相显微镜观察4种状态TA15钛合金微观组织形态,利用线切割机将试样沿最终压缩方向剖开,取中心部位4 mm×4 mm×2 mm制备金相试样,取样位置如图1所示;采用Image pro-plus软件对初始态及不同道次MDIF态等轴α直径、片状α厚度及其轴比进行统计;采用Instron万能拉伸实验机对4种状态TA15钛合金进行准静态室温拉伸实验,拉伸试样尺寸及部分拉断试样如图2所示。拉断试样经超声波清洗后,采用JEOL-JSM-6500F 场发射型扫描电镜实现EBSD和断口形貌观察。

在MDIF实验中,由于压头与试样间存在摩擦,试样在变形后出现明显“鼓肚”现象,变形存在不均匀性。因此,本文结合理论计算和数值模拟方法对图1所示位置获取的试样在每个MDIF变形道次中内部累积等效应变( )进行确定。

)进行确定。 可以采用如下公式进行计算[19]。

可以采用如下公式进行计算[19]。

(1)

(1)

式中:N代表按顺序压缩次数,对于完成1道次试样,N=3; 、

、 、

、 分别代表3个正交轴向的应变;h0和h分别代表试样的初始高度和变形后高度。

分别代表3个正交轴向的应变;h0和h分别代表试样的初始高度和变形后高度。

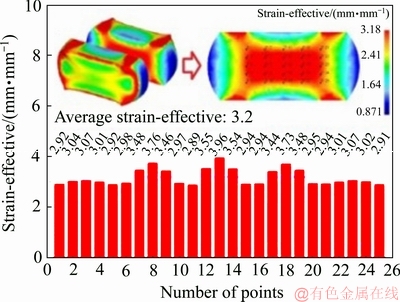

由计算结果可知,经1道次变形后其理论值约为3.18。同时,采用Deform软件对TA15钛合金MDIF实际变形过程进行仿真,分析1道次变形后试样的应变场分布,如图3所示。对完成1道次变形后试样的平面中心25个点进行线性追踪、统计,其累积等效应变平均值约为3.2,与式(1)计算结果一致。

图1 单道次多向等温锻造工艺示意图

Fig. 1 Schematic illustration of MDIF for one cycle

图2 拉伸试样尺寸和拉断试样

Fig. 2 Size of tensile specimen(a) and fracture specimens(b)

图3 有效变形区域应变场分布

Fig. 3 Strain field distribution in effective deformation area

2 结果及分析

2.1 微观组织演化

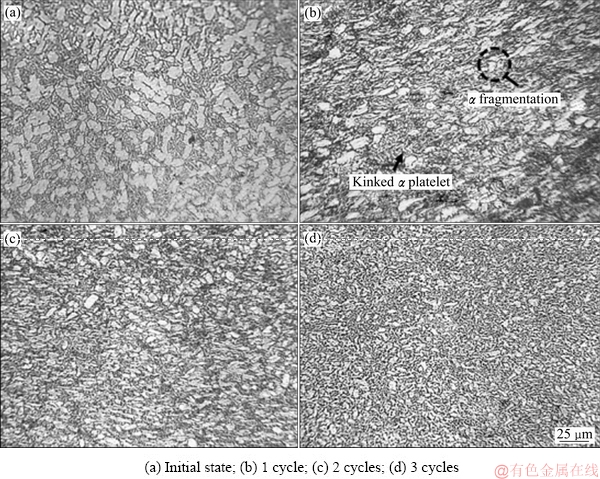

TA15钛合金初始态及不同道次MDIF态微观组织如图4所示。由初生等轴α、次生片状α和残余β基体组成的初始态微观组织,经1道次变形后,部分等轴α破碎,片状α出现不同程度的扭折、拉长,晶粒细化比较明显,但晶粒尺寸分布较不均匀,如图4(a)和(b)所示。由图4(c)可知,经2道次变形后,等轴α进一步破碎,拉长扭折后的片状α部分断开,整体晶粒大小较1道次变形后更为细小。图4(d)显示3道次变形后,等轴α充分破碎细化,片状α经拉长-扭折-断开后晶粒细化显著、分布较为均匀。

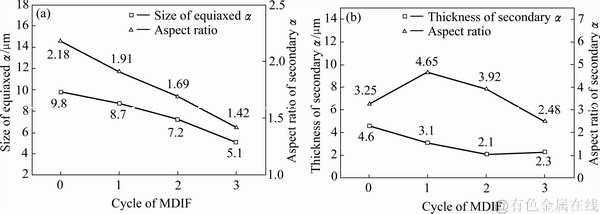

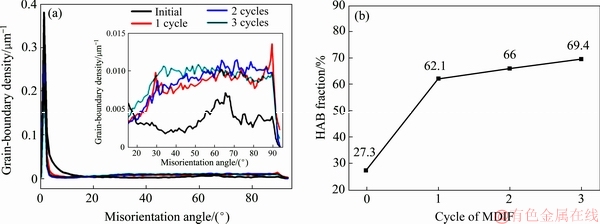

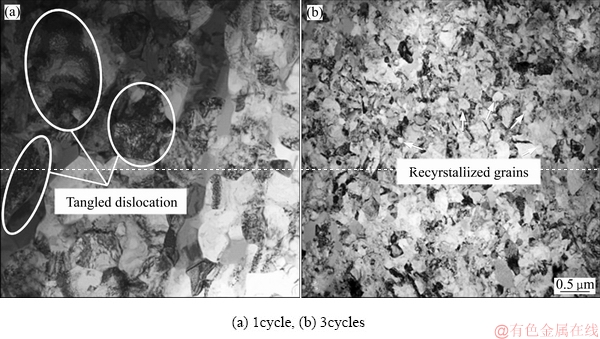

图5所示为采用IPP软件对初始态及不同道次MDIF态微观组织中等轴α直径和片状α厚度及其轴比(长轴与短轴之比)量化统计。由图5(a)可知,等轴α直径随变形道次的增加而减小,平均直径由初始态的9.8 μm细化至3道次的5.1 μm。等轴α晶粒轴比随变形道次的增加而减小,表明晶粒等轴度提高。由图5(b)可知,片状α晶粒片层厚度随变形道次增加,呈先减小后平稳趋势。在3道次时,细化至2.3 μm。片状α晶粒轴比随变形道次增加,呈先增大后减小趋势,且在1道次时获得最大值。这与片状α晶粒在经1道次变形时发生严重的拉长有关;另一方面,上述结果也表明初生α相在第2道次和第3道次MDIF变形过程中发生了破碎细化。由图6所示EBSD数据分析可以发现,随着变形道次的增加,大角度晶界(HAB)所占的比例也随之增加。对比图7可见经1道次变形后,发生位错增殖和缠结,当变形道次增加至3道次时,位错密度显著减小且可见大量动态再结晶特征的无位错细小等轴晶粒。这是因为,一方面,TA15钛合金作为高层错能金属,易于产生交滑移,交滑移促使位错重组形成小角度晶界(LAB),即亚晶界的产生,如位错墙等,随变形量的进一步增大,亚晶界持续吸收位错,应变诱导位错墙发生连续动态再结晶,导致位错晶界取向差增大,即HAB的产生,最后形成均匀细小等轴晶粒;另一方面,由于多向锻造加载方向不断变化的工艺特点,促使晶粒在剪应力的作用下发生机械几何破碎,形成大量细小等轴晶粒。因此,其晶粒细化机制为交滑移主导的应变诱导连续动态再结晶和机械几何破碎的共同作用。

图4 TA15钛合金初始态及不同道次MDIF态微观组织

Fig. 4 Microstructures of TA15 alloy during MDIF after different cycles

图5 TA15钛合金初始态及不同道次MDIF态等轴α和次生片状α晶粒尺寸及轴比

Fig. 5 Size and aspect ratio of equiaxed α(a) and secondary α(b) for TA15 alloy during MDIF at different cycles

图6 TA15钛合金形变前后取向差角分布和大角度晶界占比

Fig. 6 Effect of MDIF cycles on misorientation angle distribution(a) and HAB fraction(b)

图7 TA15钛合金1道次和3道次变形后TEM组织形貌

Fig. 7 Microstructure of TA15 alloy during MDIF at different cycles by TEM

2.2 力学性能

2.2.1 室温拉伸性能

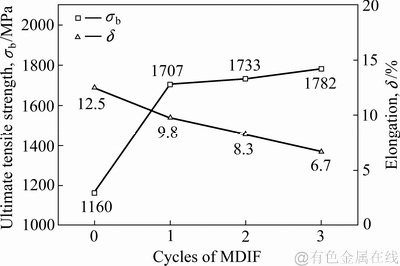

图8所示为TA15钛合金初始态及不同道次MDIF态极限抗拉强度和伸长率。可见,随变形道次增加,极限抗拉强度增大。且经1道次变形后,极限抗拉强度提高最为显著,随后,提高幅度趋于平缓,在3道次时,由初始态1160 MPa增大至1782 MPa,提高幅度为54%。此外,经多道次MDIF后,TA15钛合金伸长率呈下降趋势,在3道次MDIF条件下,其伸长率为6.7%,较初始态12.5%仅下降5.8%。钛合金在经剧烈变形后,室温强度的提高通常伴随着伸长率的下降,但相较抗拉强度的提高幅度,伸长率的下降幅度较小,材料综合力学性能得到提高[8-9, 20]。基于强化机制相互独立且对于宏观应力的贡献可直接累加,材料的拉伸强度可表示为下式:

(2)

(2)

式中: 、

、 和

和 分别为晶格阻力、位错强化相关的应力以及晶界强化相关的应力。

分别为晶格阻力、位错强化相关的应力以及晶界强化相关的应力。 可表示为

可表示为

(3)

(3)

式中:M泰勒因子; 为材料常数;G为剪切模量;b为Burgers矢量;

为材料常数;G为剪切模量;b为Burgers矢量; 为位错密度。

为位错密度。

细晶强化相关的 应力可表示如下:

应力可表示如下:

(4)

(4)

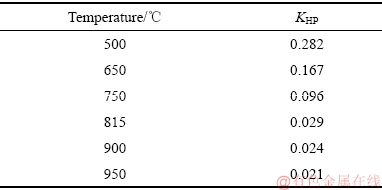

式中:KHP为Hall-Petch系数,对应的值见表1。

由图8可得,与初始组织相比,1、2、3道次后强度提高值分别为547 MPa、573 MPa和622 MPa。参照DYAKONOV等[21]的研究工作,当应变超过2.8时,位错密度将达到饱和,约为1×1015 m-2。在本文研究中,1道次后的应变达到3.2,因此,可以认为每一道次变形后的位错密度均达到饱和,其位错强化对应的强度约为140 MPa[21]。结合式(2)~(4)可以推断1、2、3道次后由于细晶强化所对应的强度分别为407 MPa、433 MPa和482 MPa。所以,通过定量估算可以得出温热变形条件下等温多向锻造后的性能提升是由晶粒细化和位错强化共同造成,且晶粒细化的贡献更为显著。

表1 KHP在不同温度下对应的值[22]

Table 1 Value of KHP at different temperatures[22]

图8 TA15钛合金初始态及不同道次MDIF态拉伸性能

Fig. 8 Tensile properties for TA15 alloy after MDIF with different cycles of forging

2.2.2 断口形貌

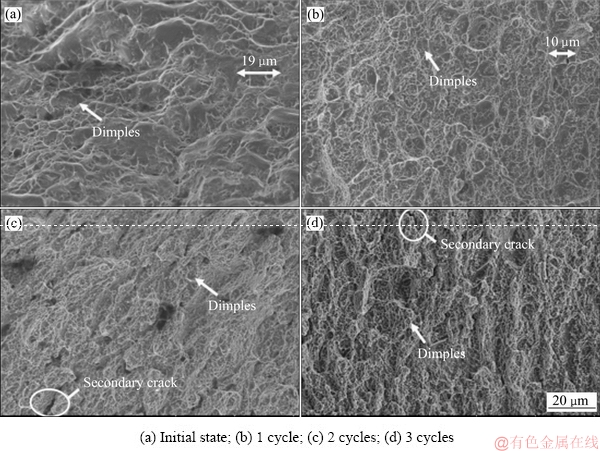

图9和10所示为TA15钛合金初始态及不同道次MDIF态拉伸断口宏观和微观形貌。由图9可知,4种状态TA15钛合金在准静态拉伸过载断裂时,其宏观断口形貌呈杯锥状,其锥底垂直于主应力方向,锥面与主应力方向呈45°,且颈缩明显,为典型的韧性断裂断口形貌。观察4种状态宏观断口特征,发现随变形道次增加,TA15钛合金断口纤维区不断减小,而剪切唇呈增大趋势。由图10可知,4种状态微观断口中都分布有大量韧窝。然而,其韧窝形态各不相同。一方面,随变形道次增加,韧窝尺寸不断减小,韧窝尺寸与其等轴α晶粒尺寸相当。另一方面,随变形道次增加,断口形貌趋于平坦,在3道次MDIF变形后,断口具有准解理断裂特征,即断裂模式有向脆性断裂转变趋势。观察图10(c)和(d)可见,韧窝边缘存在明显二次裂纹。由拉伸断口宏观和微观形貌分析可知,随变形道次的增加材料塑性有所下降[23]。这与图8所示的测试结果一致。

图9 TA15钛合金初始态及不同道次MDIF态准静态拉伸宏观断口形貌

Fig. 9 Macroscopic morphologies of fracture surface for quasi-static tensile testing of TA15 alloy after MDIF with different cycles

图10 TA15钛合金初始态及不同道次MDIF态准静态拉伸微观拉伸断口形貌

Fig. 10 Microscopic morphologies of fracture surface for quasi-static tensile testing of TA15 alloy after MDIF with different cycles

图11 TA15钛合金初始态及不同道次MDIF态裂纹扩展路径金相图

Fig. 11 Metallographs at crack propagation paths for TA15 alloy after MDIF with different cycles

图11所示为初始态及不同道次MDIF态TA15钛合金的裂纹扩展路径金相图。观察可知,初始态及不同道次MDIF态裂纹扩展路径与其断口形貌较为统一,随变形道次增大,断口形貌趋于平坦。文献[24-25]表明,裂纹在通过长而粗的晶粒时,其裂纹偏转效应增强致使扩展路径更为曲折,即断口形貌更为粗糙。而文献[26]则表明,主裂纹在通过细小晶粒时,其切断能力较强,即断口形貌较为平坦。因此,初始态及不同道次MDIF态TA15钛合金在准静态拉伸断裂失效过程中,其断裂失效机制同时受等轴α和片状α晶粒形态影响,且等轴α晶粒形态对其影响更为显著。

3 结论

1) TA15钛合金经温热MDIF时,晶粒细化明显。经3道次变形后,初生等轴α晶粒直径由9.8 μm细化至5.1 μm,片状α晶粒厚度由4.6 μm细化至2.3 μm,晶粒等轴度和尺寸分布均匀性提高。通过EBSD取向分析可得晶粒细化的机理为交滑移主导的应变诱导连续动态再结晶和机械几何破碎的共同作用。

2) TA15钛合金经温热多向压缩后,综合力学性能提高。经3道次MDIF后,极限抗拉强度提高54%,伸长率仅下降5.8%。通过定量估算可以发现,细晶强化与位错强化两种机制的共同作用导致了极限抗拉强度的增加,且晶粒细化对应的贡献更为显著。

3) 初始态及不同道次MDIF态TA15钛合金的准静态拉伸断裂失效机制同时受等轴α和片状α晶粒影响,但等轴α晶粒对其影响更为显著,断口形貌随变形道次增加趋于平坦。

REFERENCES

[1] 张利军, 常 辉, 薛祥义. 钛及钛合金的热加工[J]. 热加工工艺, 2013, 42(2): 82-87.

ZHANG Li-jun, CHANG Hui, XUE Xiang-yi. Hot process of titanium and titanium alloy[J]. Hot working Technology, 2013, 42(2): 82-87.

[2] 李卓梁, 丁 桦, 李继忠. 钛及钛合金剧烈塑性变形的研究进展[J]. 航空制造技术, 2013, 16: 139-142.

LI Zhuo-liang, DING Hua, LI Ji-zhong. Progress in severe plastic deformation of Ti and Ti alloy[J]. Aeronautical Manufacturing Technology, 2013, 16: 139-142.

[3] HAN D, ZHAN M, YANG H. Deformation mechanism of TA15 shells in hot shear spinning under various load conditions[J]. Rare Metal Materials and Engineering, 2013, 42(2): 243-248.

[4] 徐 烽, 颜银标. 多向锻造法细化钛及钛合金晶粒的研究现状[J]. 钛工业进展, 2012, 29(2): 15-18.

XU Feng, YAN Yin-biao. The research situation of refining titanium and titanium alloys by using multi-direction forging[J]. Titanium Industry Progress, 2012, 29(2): 15-18.

[5] SALISHCHEV G A, VALIAKHMETOV O R, GALEYEV R M. Formation of sub-microcrystalline structure in the titanium alloy VT8 and its influence on mechanical properties[J]. Journal of Materials Science, 1993, 28(11): 2898-2902.

[6] VALIEV R Z, ESTRIN Y, HORITA Z, LANGDON T G, ZEHETBAUER M J, ZHU Y T. Producing bulk ultrafine-grained materials by severe plastic deformation[J]. JOM, 2006, 58(4): 33-39.

[7] MIURA H, YU G, YANG X. Multi-directional forging of AZ61Mg alloy under decreasing temperature conditions and improvement of its mechanical properties[J]. Materials Science & Engineering A, 2011, 528(22): 6981-6992.

[8] SALISHCHEVG A, KUDRYAVTSEVE A, ZHEREBTSOV S V, SEMIATIN S L. Low temperature superplasticity of Ti-6Al-4V processed by warm multidirectional forging[J]. Materials Science Forum, 2013, 735: 253-258.

[9] ZHEREBTSOV S, SALISHCHEV G, GALEYEV R, VALIAKHMETOV O R, MIRONOV S, SEMIATIN S L. Production of sub-microcrystalline structure in large-scale Ti-6Al-4V billet by warm severe deformation processing[J]. Scripta Materialia, 2004, 51(12): 1147-1151.

[10] 陈 卓. Ti2AlNb基合金多向等温锻造组织与力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2013: 46-74.

CHEN Zhuo. Research on microstructure and mechanical properties of Ti2AlNb based alloy fabricated by multiple isothermal forging[D]. Harbin: Harbin Institute of Technology, 2013: 46-74.

[11] SALISHCHEV G A, VALIAKHMETOV O R, VALITOV V, MUKHTAROV S K. Submicrocrystalline and nanocrystalline structure formation in materials and search for outstanding superplastic properties[J]. Materials Science Forum, 1994, 170/172(1): 121-130.

[12] KIM J Y, PARK K T, SHIM I O, HONG S H. Globularization behavior of ELI grade Ti-6Al-4V alloy during non-isothermal multi-step forging[J]. Materials Transactions, 2008, 49: 215-223.

[13] IMAYEV R M, IMAYEV V M, SALISHCHEV G A. Formation of sub-microcrystalline structure in TiAl intermetallic compound[J]. Journal of Materials Science, 1992, 27(16): 4465-4471.

[14] IMAYEV V M, SALISHCHEV G A, SHAGIEV M R, KUZNETSOV A V, IMAYEV R M, SENKOV O, FROES F H. Low-temperature superplasticity of sub-microcrystalline Ti-48Al-2Nb-2Cr alloy produced by multiple forging[J]. Scripta Materialia, 1998, 40(2): 183-190.

[15] HUANG Z W. Thermal stability of Ti-44Al-4Nb-4Hf- 0.2Si-1B alloy[J]. Intermetallics, 2013, 37(5): 11-21.

[16] 曹京霞, 方 波, 黄 旭, 李臻熙. 微观组织对TA15钛合金力学性能的影响[J]. 稀有金属, 2004, 28(2): 362-364.

CAO Jing-xia, FANG Bo, HUANG Xu, LI Zhen-xi. Effects of microstructure on properties of TA15 titanium alloy[J]. Chinese Journal of Rare Metals, 2004, 28(2): 362-364.

[17] LIU Y, ZHU J C, YUE Y, WANG Y. Effects of strain rate on dislocation for TA15 alloy during hot compressive deformation[J]. Journal of Wuhan University of Technology, 2011, 26(2): 186-189.

[18] 赵张龙, 郭鸿镇, 姚泽坤, 张霜银, 林 鑫, 黄卫东. 激光烧结/等温锻造TC17粉末钛合金的组织与性能[J]. 稀有金属材料与工程, 2009, 38(6): 1104-1107.

ZHAO Zhang-long, GUO Hong-zhen, YAO Ze-kun, ZHANG Shuang-yin, LIN Xin, HUANG Wei-dong. Microstructures and properties of TC17 powder metallurgy titanium alloy prepared by laser sintering/isothermal forging[J]. Rare Metal Materials & Engineering, 2009, 38(6): 1104-1107.

[19] GHANBARI B F, ARABI H, ABBASI S M, BOUTORABI S M A. Manufacturing of nanostructured Ti-6Al-4V alloy via closed-die isothermal multi-axial-temperature forging: Microstructure and mechanical properties[J]. International Journal of Advanced Manufacturing Technology, 2016, 87(1/4): 1-9.

[20] ZHEREBTSOV S, KUDRYAVTSEV E, KOSTJUCHENKO S, MALYSHEVA S, SALISHCHEV G. Strength and ductility-related properties of ultrafine grained two-phase titanium alloy produced by warm multi-axial forging[J]. Materials Science & Engineering A, 2012, 536(3): 190-196.

[21] DYAKONOV G S, MIRONOV S, SEMENOVA I P, VALIEV R Z, SEMIATIN S L. The microstructure-strength relationship in severely-deformed commercial-purity titanium[J].Materials Letters, 2017, 192: 165-168.

[22] KIM J H, SEMIATIN S L, LEEY H, LEE C S. A self-consistent approach for modeling the flow behavior of the alpha and beta phases in Ti-6Al-4V[J]. Metallurgical & Materials Transactions A, 2011, 42(7): 1805-1814.

[23] 钟群鹏, 赵子华, 张 峥. 断口学的发展及微观断裂机理研究[J]. 机械强度, 2005, 27(3): 358-370.

ZHONG Qun-peng, ZHAO Zi-hua, ZHANG Zheng. Development of “fractography” and research of fracture micro-mechanism[J]. Journal of Mechanical Strength, 2005, 27(3): 358-370.

[24] YODER G R, COOLEY L A, CROOKER T W. Quantitative analysis of microstructural effects on fatigue crack growth in widmanstatten Ti-6A1-4V and Ti-8Al-1Mo-1V[J]. Engineering Fracture Mechanics, 1979, 11(4): 805-816.

[25] SINHA V, SOBOYEJO W O. An investigation of the effects of colony microstructure on fatigue crack growth in Ti-6Al-4V[J]. Materials Science & Engineering A, 2001, 319(2): 607-612.

[26] MINE Y, TAKASHIMA K, BOWEN P. Effect of lamellar spacing on fatigue crack growth behavior of a TiAl-based aluminide with lamellar microstructure[J]. Materials Science & Engineering A, 2012, 532(1):13-20.

Grain refinement mechanism and mechanical properties of TA15 alloy during multi-directional isothermal forging

JI Xiao-hu, LI Ping, SHI Ying-bin, YAN Si-liang, XUE Ke-min

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The multi-directional isothermal forging (MDIF) experiments of TA15 alloy were carried out on at 600 ℃. The grain refinement mechanism, mechanical properties and fracture morphologies were analyzed by metallographic microscopy, electron backscattered diffraction, quasi-static tensile testing and scanning electron microscopy, respectively. The results show that, after 3 cycles of MDIF, the grains are refined significantly. The size of equiaxed α is reduced from 9.8 μm to 5.1 μm and the thickness of lamellar α is reduced from 4.6 μm to 2.3 μm. The grain refinement mechanism is the interaction of strain-induced continuous dynamic recrystallization by cross-slip and mechanical geometry breaking. The comprehensive mechanical properties are significantly improved. After 3 cycles of MDIF, the ultimate tensile strength increases to 1782 MPa, 54% higher than that of the initial state alloy, and the elongation rate only decreases by 5.8%. Through quantitative analysis, it is found that the combination of fine grain strengthening and dislocation strengthening results in an increase in ultimate tensile strength, and the contribution of fine grain strengthening is more significant.

Key words: TA15 alloy; multi-directional isothermal forging; grain refinement mechanism; mechanical properties; fine grain strengthening; dislocation strengthening

Foundation item: Project(2017ZEP4003) supported by Aviation Science Fund, China; Project(51675154) supported by the National Natural Science Foundation of China

Received date: 2018-11-12; Accepted date: 2019-03-11

Corresponding author: XUE Ke-min; Tel: +86-551-62905110; E-mail: xuekm0721@sina.com

(编辑 王 超)

基金项目:航空科学基金资助项目(2017ZEP4003);国家自然科学基金资助项目(51675154)

收稿日期:2018-11-12;修订日期:2019-03-11

通信作者:薛克敏,教授,博士;电话:0551-62905110;E-mail:xuekm0721@sina.com