DOI: 10.11817/j.ysxb.1004.0609.2020-39298

超疏水铝合金表面的制备、耐腐蚀及防污性能

SULTONZODA Firdavs,王 晶,周瑾萱,冯利邦

(兰州交通大学 材料科学与工程学院,兰州 730070)

摘 要:探索用简单、环保的方法制备超疏水铝合金,并赋予铝合金优异的耐腐蚀和防污性能,对拓展铝合金的应用非常重要。本文在无需对铝合金表面进行打磨等预处理的情况下,采用简单、环保的醇水溶液一步浸泡法将烷基长链接枝到粗糙化的铝合金表面,制备得到超疏水铝合金,其表面水接触角达153.6°,滚动角小于5°。运用接触角测量、扫描电镜观察、红外光谱表征、防污和耐腐蚀实验依次对超疏水铝合金表面的润湿特性、微观结构、化学形貌及耐腐蚀和防污性能进行分析表征。结果表明:醇水溶液处理一方面使铝合金表面获得了微米-纳米二级粗糙化,另一方面接枝烷基长链,二者的共同作用赋予了铝合金表面优异的超疏水特性,而且其超疏水性能表现出多样性、普适性和良好的稳定性。正是基于这种超疏水特性,铝合金获得了优异的耐腐蚀和防污自清洁性能。

关键词:铝合金;一步浸泡法;超疏水;防污;耐腐蚀

文章编号:1004-0609(2020)-10-2316-06 中图分类号:TB383 文献标志码:A

铝是地壳中含量最丰富的金属元素,是有色金属领域使用最广泛的金属元素之一[1]。铝合金在许多领域有着广泛的应用,但在恶劣的工作环境下容易受到污染或损伤[2],在潮湿和盐水等环境中很容易被腐蚀,造成铝制设备损坏或故障,失去其使用价值[3-4]。而自然界中的荷叶、水稻叶等具有自清洁、耐腐蚀和损伤自修复等功能,研究人员对自然界中荷叶表现出来的“荷叶效应”现象进行研究,发现荷叶表面具有超疏水性(与水接触角大于150°且滚动角低于10°),因而表现出很好的耐腐蚀、防污和防覆冰等特性[5-7]。通过在铝合金上构建超疏水表面,从而可扩大铝合金在工业和日常生活中的应用范围,尤是在航空航天、军事、建筑、医疗等领域[8-10]。目前,制备超疏水铝合金表面的方法多种多样,如电化学法、溶胶-凝胶法及化学蚀刻法等[11-13]。然而,以上所述的制备方法首先要对铝合金表面进行打磨处理,有些制备方法还需要特殊的设备或苛刻的化学处理,这严重阻碍了这些方法在实际中的应用。因此,探索更简单有效的方法来制备超疏水铝合金表面,并提高其表面耐腐蚀和防污性能等则显得尤为重要[14-15]。在本文中,提出在无需对铝合金表面进行打磨处理的情况下,通过一步简便、环境友好的醇水溶液浸泡法构建得到超疏水铝合金表面,制备过程简单,对设备要求低,环保且成本低。而且制备得到的超疏水铝合金表面呈现出疏水普适性、多样性和良好的稳定性,并且具有优异的耐腐蚀和防污性能。

1 实验

1.1 实验材料

商业用6063铝合金片,规格:20 mm×10 mm×2 mm,东洋特钢(中国)有限公司;甲醇,分析级,天津医药化学有限公司;丙酮,分析级,北京化工厂;硬脂酸(STA),分析级,上海中奏化学试剂有限公司;无水乙醇,分析级,天津市光复精细化工研究所。

1.2 超疏水铝合金的制备方法

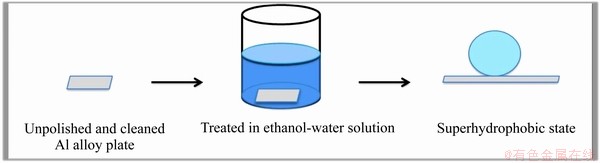

图1 超疏水铝合金表面制备过程

Fig. 1 Fabrication process of superhydrophobic aluminum alloy surface

本研究在不对铝合金试样进行打磨处理的情况下,采用简单方便的一步浸泡法处理工艺来制备超疏水铝合金表面,制备工艺如图1所示。将铝合金片依次用甲醇、丙酮和去离子水超声清洗 10 min,去除试样表面的油脂和杂质。然后,置于 25 mmol/L硬脂酸的乙醇/水溶液中(VCH2OH:VH2O=2:1)于60 ℃下浸泡处理60 h,最后,依次用无水乙醇和去离子水进行洗涤,室温晾干后即得到超疏水铝合金。

1.3 超疏水铝合金表面的表征

在室温下,用接触角测角仪(DSA100,Kruss)测试水滴在铝合金表面的接触角(CA)。采用场发射型扫描电子显微镜(FE-SEM,JSM-6701F)对铝合金试样表面的微观形貌进行表征。通过傅里叶变换红外光谱仪(FT-IR,VER-TEX 70,德国)对试样表面的化学组成进行表征。电化学性能用三电极电池系统(CHI660D, CH Instruments Inc.)测试,以3.5%(质量分数)的NaCl溶液中作为腐蚀溶液。

2 结果与讨论

2.1 铝合金表面的润湿性及微观形貌

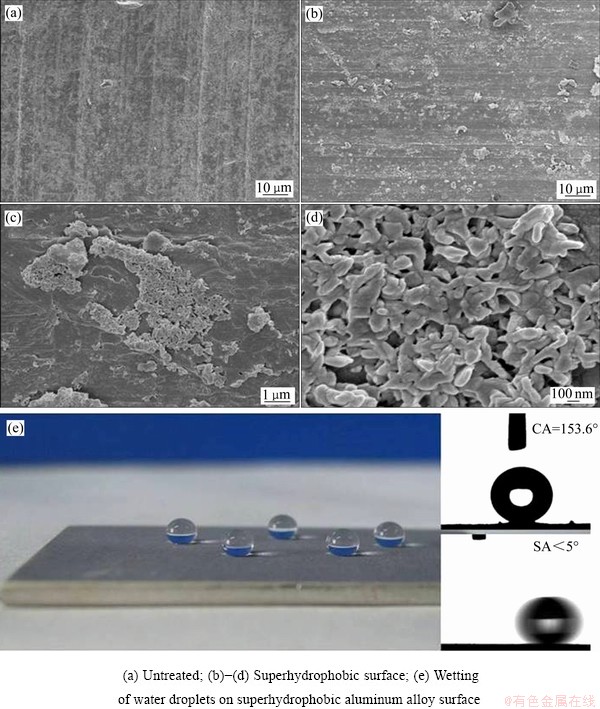

在不对铝合金表面进行打磨的情况下,将铝合金用硬脂酸的醇水溶液进行浸泡处理,制备超疏水铝合金表面。图2(a)所示为超声清洗后铝合金表面的SEM像。由图2(a)可以看出,清洗后的空白铝合金表面比较平整。相对而言,采用硬脂酸醇水溶液浸泡处理后(见图2(b)),铝合金表面出现大量的突起,从而使表面变得较粗糙。从图2(c)中进一步的放大照片可以发现,一方面铝合金基底变得不平整,另一方面在基底上出现许多堆积物,其尺寸可达微米级别。从图2(d)中进一步的放大照片可以看出,堆积物是由大量的蠕虫状物构成,这种蠕虫状结构的直径为50~60 nm,并且相互交织,使得铝合金表面产生大量的空隙,增大了铝合金表面的粗糙度。因此,可以看出:经硬脂酸的醇水溶液处理后,铝合金表面获得了纳米-微米二级粗糙结构,这种粗糙结构是由于铝合金中的铝元素在60 ℃下与水发生反应所形成的。并且硬脂酸长链接枝到了铝合金表面,形成了致密的疏水纳米膜层。水滴在该铝合金表面呈球形形态(见图2(e)),水滴的静态接触角达153.6°、滚动角小于5°,表明所制备的铝合金表面呈现出超疏水特性。

2.2 超疏水铝合金表面的化学结构

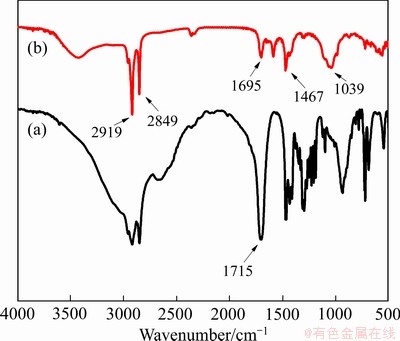

利用FT-IR对超疏水铝合金表面的化学结构进行分析,得到的超疏水铝合金及硬脂酸的红外光谱如图3所示。硬脂酸的红外谱图中1715 cm-1处是—COOH的吸收峰(见图3(a))。在超疏水铝合金表面的红外谱图中,2919 cm-1和2849 cm-1分别为—CH2—的对称和反对称伸缩振动峰(见图3(b)),1467 cm-1处和1039 cm-1分别出现了—CH2—和—CH3的吸收峰,而1695 cm-1处出现了—COO-的吸收峰,这表明硬脂酸中的自由—COOH与铝合金表面的Al—OH成功发生了化学反应,从而在铝合金表面形成了CH3(CH2)16COO—Al (STA—Al)薄膜,因而在红外光谱中产生了COO—Al基团的吸收峰(见图3(b))。因此,硬脂酸中疏水性烷基长链被成功接枝到粗糙化的铝合金表面上。正是凭借粗糙化的表面和接枝的疏水长链共同作用,使得铝合金表面获得了超疏水特性。

2.3 超疏水铝合金表面的疏水多样性和稳定性

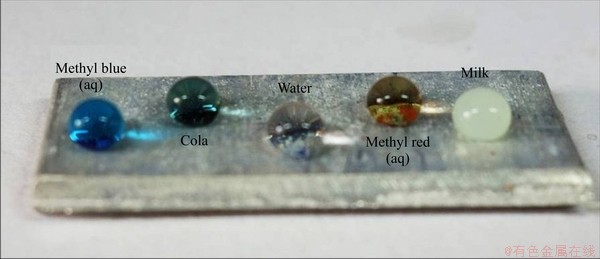

图4所示为不同液滴在超疏水铝合金表面的润湿性照片。其中从左到右依次是亚基蓝水溶液、可乐、去离子水、甲基红水溶液和牛奶的润湿效果。可以发现:各种水性液滴在超疏水铝合金表面都呈现出球形形态,接触角均大于150°而滚动角小于5°。这表明所构建的超疏水铝合金表面不仅对水呈现出强的疏水作用,而且对所使用的所有水性液滴均呈现出强的疏水作用。这表明经过疏水化处理后的铝合金表面具有疏水多样性和普适性。并且在室温环境下放置半年后,其表面仍然表现出优异的超疏水性能,表明所制得的超疏水表面具有良好的稳定性。

图2 铝合金表面SEM像及润湿性照片

Fig. 2 SEM images of aluminum alloy surface and wetting property

图3 硬脂酸及超疏水铝合金表面的红外光谱图

Fig. 3 FT-IR spectra of STA (a) and superhydrophobic aluminum alloy surface (b)

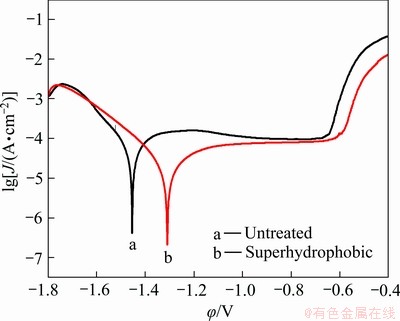

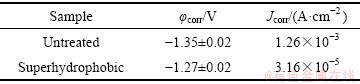

2.4 超疏水铝合金表面耐腐蚀性能

通过电化学测试对超疏水铝合金表面的耐腐蚀性能进行考察,得到的空白铝合金和超疏水铝合金在3.5% NaCl溶液中的极化曲线如图5所示。采用塔菲尔外推法分析铝合金表面的耐腐蚀性能,得到的腐蚀电压(φcorr)和腐蚀电流密度(Jcorr)如表1所示。

与空白铝合金比较,超疏水铝合金的腐蚀电压增大而腐蚀电流密度下降。一般来说,腐蚀电压升高或腐蚀电流密度降低意味着材料的耐腐蚀性能改善。因此,上述结果表明:相对于空白铝合金试样,超疏水铝合金具有较低的腐蚀速率,说明超疏水铝合金具有更好的耐腐蚀性能。这是由于铝合金表面被超疏水薄膜覆盖以后,Cl-等腐蚀介质难以靠近铝合金表面与铝合金表面进行有效接触,从而凭借超疏水表面的强疏水作用将腐蚀介质屏蔽和阻挡在铝合金表面之外,使腐蚀反应被抑制而难以发生,因此,超疏水铝合金获得了良好的耐腐蚀特性。

图4 不同液滴在超疏水铝合金表面的润湿性照片

Fig. 4 Wettability photos of different droplets on superhydrophobic aluminum alloy surface

图5 空白铝合金和超疏水铝合金的极化曲线

Fig. 5 Polarization curves of untreated and superhydrophobic aluminum alloy surfaces

表1 空白铝合金和超疏水铝合金在3.5% NaCl溶液中的腐蚀电位(φcorr)和腐蚀电流密度(Jcorr)

Table 1 Corrosion potential (φcorr) and corrosion current density (Jcorr) of untreated and superhydrophobic aluminum alloy in 3.5% NaCl solution

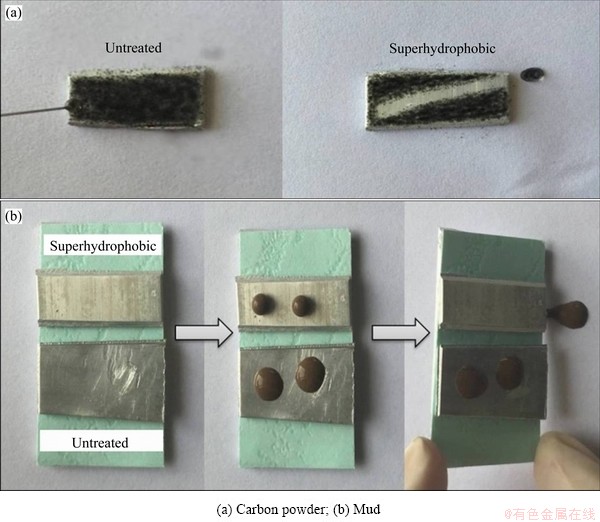

2.5 超疏水铝合金表面的防污特性

采用滚动水滴带走碳粉和泥浆滚落两种方法对超疏水铝合金的防污性能进行考察。首先以碳粉作为模拟污染物,将碳粉覆盖于空白和超疏水铝合金表面上。然后,将10 μL水滴分别滴加到倾斜角为4°的空白和超疏水铝合金表面,通过观察水滴能否带走碳粉来评价超疏水铝合金表面的防污特性,结果如图6(a)所示。当水滴到覆盖有碳粉的空白铝合金表面时,水滴呈铺展状态并黏附于试样表面,所以试样表面的碳粉无法得以清洁。然而,当水滴被滴加到超疏水铝合金表面时,水滴立即从超疏水铝合金表面滚离并将碳粉带离,使得超疏水铝合金表面得到有效清洁,因此,超疏水铝合金表面呈现出优异的自清洁防污性能。

图6(b)所示为空白和超疏水铝合金表面滴上泥浆时的对照图。可以看出:由于空白铝合金样品具有亲水性而超疏水铝合金表面具有极强的疏水性,因此,泥浆在超疏水铝合金表面呈球状而在空白铝合金表面呈铺展状态。当将两种铝合金试样进行倾斜时,超疏水铝合金表面的泥浆球滴迅速滚落而未留下任何痕迹,而泥浆不能从空白铝合金表面移开而仍然黏附于其表面。

以上两种实验表明碳粉、泥浆等模拟污染物与超疏水铝合金表面之间的黏附力很弱。因此,污染物在超疏水铝合金表面难以附着,即使有部分污染物黏附在超疏水铝合金表面,通过滴注水滴或轻微的扰动等就可以清除污染物,使超疏水铝合金能够保持干净的表面。由此说明超疏水铝合金表面具有防污自清洁特性。

图6 空白铝合金和超疏水铝合金表面的防污效果对比

Fig. 6 Comparison of antifouling effect untreated and superhydrophobic aluminum alloy surfaces

3 结论

1) 在无需对铝合金表面进行打磨处理的情况下,通过简单环保的醇水溶液一步浸泡法成功将烷基长链接枝到铝合金表面,从而制备得到超疏水铝合金,其接触角可达153.6°、滚动角低于 5°。

2) 采用SEM和FT-IR分别对超疏水铝合金的表面形貌和化学组成进行表征,发现超疏水铝合金表面呈现出大量粗糙结构,硬脂酸中的疏水长链成功接枝到铝合金表面。

3) 铝合金表面的超疏水特性具有多样性、普适性和良好的稳定性,相对于未经处理的铝合金,超疏水铝合金获得了优异的耐腐蚀和防污性能。

REFERENCES

[1] FENG L B, Yan Z N, QIANG X H, QIANG X H, LIU Y H, WANG Y P. Facile formation of superhydrophobic aluminum alloy surface and corrosion-resistant behavior[J]. Applied Physics A, 2016, 122(3): 165.

[2] Zuo Z P, Liao R J, Guo C, YUAN Y, ZHAO X T, ZHUANG A Y, ZHANG Y Y. Fabrication and anti-icing property of coral-like superhydrophobic aluminum surface [J]. Applied Surface Science, 2015, 331: 132-139.

[3] SHASHANK S, Yung C. S. Superhydrophobic contoured surfaces created on metal and polymer using a femtosecond laser[J]. Applied Surface Science, 2017, 405: 465-475.

[4] LI H, YU S R, HAN X X. Fabrication of CuO hierarchical flower-like structures with biomimetic superamphiphobic, self-cleaning and corrosion resistance properties[J]. Chemical Engineering Journal, 2016, 283: 1443-1454.

[5] 何家文. 追溯历史评表面形变纳米化[J]. 中国表面工程, 2014, 27(5): 1-13.

HE Jia-wen. Comments on nano-treatment of urface attrition via historical review[J]. China Surface Engineering, 2014, 27(5): 1-13.

[6] Zheng S L, LI C, FU Q T, LI M, HU W, WAGN Q, DU M P. Fabrication of self-cleaning superhydrophobic surface on aluminum alloys with excellent corrosion resistance[J]. Surface & Coatings Technology, 2015, 276: 341-348.

[7] LI J H, LIU Q, WANG L Y, CHEN R R, TAKAHASHI K, LI R M, LIU L H, WANG J. Formation of a corrosion-resistant and anti-icing superhydrophobic surface on magnesium alloy via a single-step Method[J]. Electrochemical Society, 2016, 163(5): 213-220.

[8] LI X, ZHANG Q, GUO Z, SHI T, YU J H, TANG M K, HUANG X J. Fabrication of superhydrophobic surface with improved corrosion inhibition on 6061 aluminum alloy substrate[J]. Applied Surface Science, 2015, 342: 76-83.

[9] NASER V M, ROUHOLLAH K, SAEED R. Super dewetting surfaces: Focusing on their design and fabrication[J]. Colloids and Surfaces A, 2015, 484: 528-546.

[10] 晏忠钠, 车彦慧, 冯利邦, 强小虎, 刘艳花. 超疏水铝合金表面的防结冰和防黏附行为[J]. 材料工程, 2015, 43(9): 25-29.

YAN Zhong-na, CHE Yan-hui, FENG Li-bang, QIANG Xiao-hu, LIU Yan-hua. Anti-icing and anti-adhesion behavior of superhydrophobic aluminum alloy surface[J]. Journal of Materials Engineering, 2015, 43(9): 25-29.

[11] 汪怀远, 孟 旸, 赵景岩, 朱艳吉. 双疏表面的制备及性能研究新进展[J]. 材料工程, 2014, 43(3): 90-96.

WANG Huai-yuan, MENG Yang, ZHAO Jing-yan, ZHU Yan-ji. New progress on preparation and properties of amphiphobic surface[J]. Journal of Materials Engineering, 2014, 43(3): 90-96.

[12] ZHENG S L, LI C, FU Q T, HU W, XIANG T F, WANG Q, DU M P, LIU X C, CHEN Z. Development of stable superhydrophobic coatings on aluminum surface for corrosion-resistant, self-cleaning, and anti-icing applications[J]. Materials and Design, 2015, 93: 261-270.

[13] GUPTA R, Vaikuntanathan V, SIVAKUMAR D. Superhydrophobic qualities of an aluminum surface coated with hydrophobic solution never wet[J]. Colloids and Surface, 2016, 500: 45-53.

[14] ZHAO T, KANG Z X. Simultaneously fabricating multifunctional superhydrophobic/superoleophilic coatings by one-step electrodeposition method on cathodic and anodic magnesium surfaces[J]. Electrochemical Society, 2016, 163(10): 628-635.

[15] ZHANG Z Z, GE B, MEN X H, LI Y. Mechanically durable, superhydrophobic coatings prepared by dual-layer method for anti-corrosion and self-cleaning[J]. Colloids and Surfaces A, 2016, 490: 182-188.

Fabrication, anti-corrosion and antifouling performance of superhydrophobic aluminum alloy surface

SULTONZODA Firdavs, WANG Jing, ZHOU Jin-xuan, FENG Li-bang

(School of Materials Science and Engineering, Lanzhou Jiaotong University, Lanzhou 730070, China)

Abstract: It is necessary of preparing superhydrophobic aluminum alloy surfaces by simple and environment-friendly method. Meanwhile, it is also quite important of endowing the aluminum alloys with excellent corrosion resistance and anti-fouling performance so that the application scope of aluminum alloys can be expanded. Herein, without pre-polishing, a facile and environment-friendly method was developed to fabricate the superhydrophobic aluminum alloy surface with a one-step immersion in alcohol-water solution. The water contact angle at the resultant aluminum alloy surface can reach 153.6° while the rolling angle is less than 5°. The surface wettability, microstructure, chemical structure, antifouling and anti-corrosion performance of the obtained superhydrophobic aluminum alloy surface were investigated by means of contact angle measurement, scanning electron microscope, infrared spectrum analysis, antifouling and anti-corrosion experiments, respectively. The results indicate that both micro- and nano-scaled binary structure form on the resultant aluminum alloy surface. Meanwhile, long alkyl chains are grafted chemically onto the rough aluminum alloy surface successfully. Consequently, the aluminum alloy obtains excellent superhydrophobicity. Moreover, the superhydrophobicity has variety, universality, and good stability. Then, just based on the superhydrophobicity, the aluminum alloy wins excellent corrosion resistance and antifouling performance.

Key words: aluminum alloy; one-step immersion; superhydrophobic; antifouling; anti-corrosion

Foundation item: Project(21161012) supported by the National Natural Science Foundation of China

Received date: 2019-05-29; Accepted date: 2020-08-29

Corresponding author: FENG Li-bang; Tel: +86-931-4955786; E-mail: fenglb@mail.lzjtu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(21161012)

收稿日期:2019-05-29;修订日期:2020-08-29

通信作者:冯利邦,教授,博士;电话:0931-4955786;E-mail:fenglb@mail.lzjtu.cn