AA6061管件颗粒介质内高压成形性能及强化机制

来源期刊:中国有色金属学报(英文版)2018年第2期

论文作者:毕江 赵长财 杜冰 国庆波 董国疆

文章页码:226 - 234

关键词:AA6061合金;内高压成形;热处理;强化机制

Key words:AA6061 alloy; internal high pressure forming; heat treatment; strengthening mechanism

摘 要:提出一种管材成形新工艺:固溶处理→颗粒介质内高压成形→人工时效。通过热处理工艺调整合金变形前后的力学性能,应用颗粒介质内高压成形技术实现管件塑性成形,以期建立一种工艺实施简便、设备要求较低、产品设计灵活的高强铝合金管件加工方法。结果表明,固溶温度560 °C且保温时间120 min时,合金伸长率提高了313%,但强度和硬度大幅减低;对合金进行固溶后时效处理,当人工时效温度180 °C且保温360 min时,合金塑性下降,强度和硬度等性能指标恢复至固溶前状态,确保成形零件具备母材力学性能。此工艺方法使AA6061挤压管材的最大胀形率提高了25.5%,管件材料性能达到了原材料的性能指标。

Abstract: A new technological process of tube forming was developed, namely solution treatment → granule medium internal high pressure forming → artificial aging. During this process, the mechanical properties of AA6061 tube can be adjusted by heat treatment to satisfy the process requirements and the processing method can also be realized by granule medium internal high pressure forming technology with the features of convenient implementation, low requirement to equipment and flexible design in product. Results show that, at a solution temperature of 560 °C and time of 120 min, the elongation of AA6061 increases by 313%, but the strength and the hardness dramatically decrease. At an aging temperature of 180 °C and time of 360 min, the strength and hardness of AA6061 alloy are recovered to the values of the as-received alloy. The maximum expansion ratio (MER) of AA6061 tube increases by 25.5% and the material properties of formed tube reach the performances of raw material.

Trans. Nonferrous Met. Soc. China 28(2018) 226-234

Jiang BI1,2, Chang-cai ZHAO1, Bing DU1, Qin-bo GUO3, Guo-jiang DONG4

1. Key Laboratory of Advanced Forging & Stamping Technology and Science of Ministry of Education, Yanshan University, Qinhuangdao 066004, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China;

3. Qinhuangdao North Metal Hose Co., Ltd., Qinhuangdao 066004, China;

4. School of Vehicles and Energy, Yanshan University, Qinhuangdao 066004, China

Received 14 November 2016; accepted 5 June 2017

Abstract: A new technological process of tube forming was developed, namely solution treatment → granule medium internal high pressure forming → artificial aging. During this process, the mechanical properties of AA6061 tube can be adjusted by heat treatment to satisfy the process requirements and the processing method can also be realized by granule medium internal high pressure forming technology with the features of convenient implementation, low requirement to equipment and flexible design in product. Results show that, at a solution temperature of 560 °C and time of 120 min, the elongation of AA6061 increases by 313%, but the strength and the hardness dramatically decrease. At an aging temperature of 180 °C and time of 360 min, the strength and hardness of AA6061 alloy are recovered to the values of the as-received alloy. The maximum expansion ratio (MER) of AA6061 tube increases by 25.5% and the material properties of formed tube reach the performances of raw material.

Key words: AA6061 alloy; internal high pressure forming; heat treatment; strengthening mechanism

1 Introduction

AA6061 is one of the most widely used Al-Mg-Si alloys [1]. It is applied in extreme conditions such as aerospace, transportation and petrochemical for low density, high impact toughness, excellent machinability and good corrosion resistance [2,3]. For example, the use of aluminum alloys for typical automobile body parts can provide a mass reduction of up to 50% compared with current steel component [4]. This kind of material can not be formed into complex parts for its high strength and poor plasticity at room temperature. So, the application range of AA6061 is restricted seriously. However, its elongation increases and deformation resistance decreases with the elevating of deformation temperature. Therefore, warm forming technology is becoming the main research direction in manufacturing complex parts of aluminum alloy. HE et al [5] studied the free bulging test carried out at different temperatures to evaluate the formability of AA6061 extruded tube, which revealed that the maximum expansion ratio (MER) reaches the maximum valve of 86% at 425 °C, namely the MER at high temperature increases significantly. WANG et al [6] studied the warm forming process of AA2024 sheet, which revealed that the formability increased as temperature increased. DONG et al [7] carried out the uniaxial tensile test on AA7075 sheet and found that its elongation is optimal at 250 °C under the condition that the strain rate is 0.001 s-1. KWON et al [8] studied the high temperature deformation behavior of Al-Mg-Si alloy, which exhibited enhanced formability at elevated temperatures. Although the formability of AA6061 can be improved by warm forming technology, high requirements of die set and temperature control system are the main problems. Unfortunately, hot forming at temperature higher than 300 °C tends to destroy the desirable microstructure, leading to softening of the formed parts [9]. Studies show that the mechanical properties of 2xxx [10], 6xxx [11] and 7xxx [12] aluminum alloy can be changed significantly through heat treatment with the content of precipitates controlled. After solution treatment, the formability of aluminum alloy tube increases significantly, and the complex parts can be formed at room temperature. Unfortunately, its strength and hardness are so low that it cannot meet the requirement of engineering application. However, the defects can be made up through aging treatment. The second phase particles precipitate again in grain inner, causing precipitation strengthening [13]. Due to the double effects of work hardening and precipitation strengthening, the strength and hardness of tube are increased remarkably, making the application require- ments satisfied. Heated tube after enough SHT (solution heat treatment) is quenched immediately, aiming to freeze the microstructure as supersaturated solid solution (SSSS), and then formed with solid granule medium internal high pressure forming. Aging is finally followed to obtained full strength. In this respect, FAN et al [14] studied the hot stamping technology of AA6A02 sheet and found that solution treatment before stamping makes its formability improved significantly, and subsequent aging treatment after stamping makes its strength high. Therefore, a new technological process of tube forming was developed, namely solution treatment → granule medium internal high pressure forming → artificial aging. With the new technological process, the internal high pressure forming of 6xxx aluminum alloy at room temperature can be realized by changing mechanical properties with the method of solution treatment before manufacturing and aging treatment after forming.

Therefore, in this work, the technological process of solution treatment → granule medium internal high pressure forming → artificial aging will be investigated to indicate the effect of heat treatment on formability and strengthening behavior. The formability is characterized by uniaxial tensile test and bulging test. The corresponding strength is measured with Vickers hardness test. The microstructure evolution and strengthening mechanism are analyzed by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The typical parts of AA6061 tube are trial-produced by the combination of heat treatment and granule medium internal high pressure forming. This study lays a basis on the preparation of high strength aluminum alloy tube.

2 Experimental

2.1 Materials

The experimental material is AA6061 extruded tube with 2 mm in thickness and 100 mm in diameter. The status of the original extruded tube is T6 (solution treatment + artificial aging). The alloy sample was tested by ADVANT X’P-381 type X-ray fluorescence spectrometer. The main chemical composition is given in Table 1.

Table 1 Chemical composition of as-received material (mass fraction, %)

2.2 Mechanical property measurement

The size of axial tensile specimen was determined by the international standard of tensile specimen (GB T228—2002) and the accuracy of experimental equipment (Fig. 1). A kind of fixture, which was designed for tube with 96 mm in inner diameter, was applied to this work to ensure the integrity of the specimen. Three or more samples were performed in one state and the values were averaged. AA6061 tubes were cut into uniaxial tensile specimens along the axial direction. In order to get SSSS at room temperature, the solution treatment was carried out in SX-G16103 type heat furnace. Solution temperatures (TS) were 530, 540, 550, 560 and 570 °C and holding time (tS) was 30, 60, 90, 120 and 150 min, respectively. Quenching was carried out in HH-2 type constant temperature water bath pot. In this process, the transfer time was less than 5 s and the water temperature was lower than 25 °C. After solution treatment, all the AA6061 specimens were kept in a freezer and its temperature is controlled at 0 °C. This is very important to avoid the natural aging of the alloy at room temperature.

Fig. 1 Axial tensile specimen size and experimental set-up

Following the solution treatment (TS=560 °C and tS=120 min), the specimens were artificially age- hardened in DHG-9070A type thermostatic air-blower- driven drying closet and subsequently cooled in air. Aging temperature (TA) was 180 °C. Aging time (tA) was 30, 60, 120, 240, 360 and 480 min.

Tensile test was performed at room temperature with an initial strain rate of 0.001 s-1. Vickers hardness test was performed in the deformation area of the stepped shaft tube to evaluate the strengthening effect of the process on AA6061 aluminum alloy tube. Samples for hardness were prepared by standard grinding and mechanical polishing. Vickers hardness instrument with a load of 1 N and a dwell time of 15 s was used. Five hardness readings were performed on every sample and they were averaged.

2.3 Microstructure examination

Microstructure characterization was performed with SEM and TEM. Samples for metallographic analysis were prepared by mechanical grinding and further by electropolishing in an electrolyte (ethanol to perchloric acid ratio of 9:1) at about -20 °C. SEM investigations were performed on a Hitachi S3400 operated at 20 kV. TEM investigations were used to characterize the strengthening precipitates by being performed on a JOEL2010. The samples were mechanically polished until the thickness was reduced to 50 μm. Disks (3 mm in diameter) were punched from the central position of the thin foils. Twin-jet thinning was further carried out in electrolyte (methanol to nitric acid ratio of 7:3) at a temperature of about -30 °C and a voltage of 12 V.

2.4 Experimental procedures

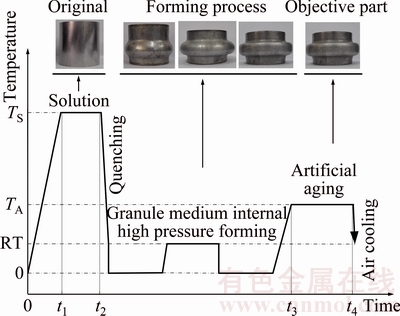

The schematic diagram in stepped shaft tube forming process is shown in Fig. 2. The original tube with 100 mm in length was solution-treated at 560 °C for 120 min followed by quenching at room temperature. After quenching and granule medium internal high pressure forming, the tubular components were kept in a freezer and its temperature is controlled at 0 °C to avoid the natural aging at room temperature.

Fig. 2 Process flow diagram of forming process of AA6061

Solution treatment enabled the precipitates to be dissolved within Al matrix. Following the solution treatment, the tube was formed by granule medium internal high pressure forming. The formed tubular components were artificially age-hardened at 180 °C for 360 min and subsequently cooled in air.

3 Results and discussion

The MER of AA6061 tube changes greatly before and after the solution treatment, as shown in Fig. 3. The processing test shows that the plasticity of AA6061 tube is very poor in the state of no solution treatment (NST), and the forming property is extremely poor. The tube fractures easily when the bulging diameter is 107 mm; namely the MER is 7%. The crack is perpendicular to circle orientation of tube and the fracture mode is brittle fracture, as shown in Fig. 3(a).

Fig. 3 Parts formed by different processes

However, at a solution temperature of 560 °C and time of 120 min, the forming property of AA6061 tube increases significantly, namely the MER is 32.5%. The tube fractures when the expansion ratio is 35%. The crack is also perpendicular to circle orientation of tube and the fracture appearance reflects the feature of part ductile fracture.

In processing test, we know that the deformation model of the stepped shaft tube before contact moulding is free bulging, which is similar to hydro-bulging. After contact moulding, the tube fits completely with the die corner. Due to the friction between tube and die, the relative motion between the un-deformed areas of tube and die is zero, namely the height of the tube is fixed [15]. The length of bulging area is 30 mm. Therefore, the tube is extremely difficult to fracture after contact moulding. The MER of stepped shaft tube can similarly evaluate the formability by hydro-bulging test.

3.1 Effect of solution treatment process parameters on mechanical properties of AA6061

3.1.1 True stress-strain curves

Through uniaxial tensile test, it is concluded that the strain rate has little effect on mechanical properties of AA6061 extruded tube at room temperature. The constitutive equation of AA6061 was assumed to conform to power-exponent function model with the influence of strain rate ignored:

σ=Kεn (1)

where K is strain strength coefficient, and n is strain hardening index. The true stress-strain curves of AA6061 tube in different solution treatment processes were obtained by uniaxial tensile tests, as shown in Figs. 4(a) and (b). In true stress-strain curve, the interval from yield point to the peak point was selected as fitting range. Multiple linear regression statistics of the test data were conducted, and constitutive equation parameters of this model were obtained, as given in Table 2. Through comparing true stress-strain curves of AA6061 before and after solution treatment, it is found that the strength is relatively high (the yield strength is 289.9 MPa and the tensile strength is 321.2 MPa) and the elongation Agt at the maximum force is lower than 4.8% under the condition of NST. However, after solution treatment, the strength drops dramatically and Agt is significantly improved. The results show that the strength and Agt of AA6061 tube are sensitive to solution treatment.

The axial tensile specimens were solution-treated at 560 °C for 120 min followed by quenching in water at room temperature. Following the solution treatment, the specimens were artificially age-hardened at 180 °C for a period of 30, 60, 120, 240, 360 and 480 min in a furnace and subsequently cooled in air. The true stress-strain curves of AA6061 under different aging treatment conditions were measured, as shown in Fig. 4(c). The strength increases and Agt decreases gradually with aging time extending. At an aging temperature of 180 °C and time of 360 min, the true stress-strain curve is in good agreement with NST. The strength even decreases in some degree when the aging time exceeds 360 min; namely the tube is over-aged.

Fig. 4 Effect of heat treatment on true stress-strain curves of AA6061

3.1.2 Material properties

The material properties of AA6061 extruded tube in different solution treatment processes are shown in Fig. 5. The strength of AA6061 tube is very high before solution treatment; namely the tensile strength is 321.2 MPa. The tensile strength decreases by 60% after solution treatment. The decrease of strength, which is beneficial to decreasing the requirement of forming equipment, makes deformation resistance reduced. At a solution temperature of 560 °C, the strength of AA6061 goes up after dropping with solution time prolonging. The minimum value is obtained when holding time is 120 min, namely the tensile strength is 189.9 MPa. At a holding time of 120 min, the strength of AA6061 increases first and then decreases with the elevating of solution treatment temperature. The maximum value is obtained when solution temperature is 560 °C.

Table 2 Related parameters of different solution treatment processes

At room temperature, the elongation Agt at the maximum force of the original tube is very low under the condition that the strain rate is 0.001 s-1, namely the Agt is 4.798%. Therefore, the alloy tube fractures easily in internal high pressure forming. However, the Agt of AA6061 extruded tube increases significantly after solution treatment. The Agt is 19.8% when the sample is solution-treated at 560 °C for 120 min. The Agt increases by 313%. The increase of Agt in AA6061 tube makes it possible to be formed by internal high pressure forming. At a solution temperature of 560 °C, the Agt of AA6061 increases first and then decreases with solution time prolonging. The maximum value is reached when holding time is 120 min. At a holding time of 120 min, the Agt of AA6061 increases first and then decreases with the elevating of solution temperature. The maximum value is reached when the solution temperature is 560 °C. The experimental results show that the plastic deformation capacity of AA6061 extruded tube nearly reaches the maximum value when it is solution-treated at 560 °C for 120 min.

Fig. 5 Effect of solution treatment on material properties of AA6061

Hardness is tested to evaluate the capacity of material resisting deformation. The smaller the hardness is, the easier the plastic deformation occurs. Figures 5(c), (d) and (e) show the dependence of Vickers hardness on heat treatment parameters. The changing rule of hardness is the same as that of the strength. The hardness of origin tube is as high as HV 123. However, the hardness decreases by nearly 50% after solution treatment. The hardness can decrease to an average value of HV 68, and the maximum hardness can arrive at HV 71. At a solution temperature of 560 °C, the hardness of AA6061 decreases first and then increases with solution time prolonging. The minimum value is reached when holding time is 120 min. At a holding time of 120 min, the hardness of AA6061 increases first and then decreases with the elevating of solution temperature. The maximum value is reached when solution temperature is 560 °C, namely the hardness is HV 71.

The hardness reflects the double effects of working hardening and precipitation strengthening when it is aging treated at 180 °C. The hardness of AA6061 rises sharply in the early stage of aging treatment and reaches the maximum value when aging time is 360 min, namely the hardness is HV 109. As observed, a significant agreement with the strength measurement can be obtained comparatively. The hardness of original tube is HV 123. By comparison, the difference between them is less than 12%. The hardness declines slightly with further increase of aging time, which is similar to the research result. DEMIR et al [16] studied the solution treatment of AA6061 ingot at 530 °C for 240 min followed by aging treatment at 180 °C and found that the hardness reaches the maximum value at an aging time of 660 min.

3.2 Softening and strengthening mechanism

Figure 6 shows the fracture surface morphology of AA6061 under different heat treatment conditions. For the condition of NST, some shallow dimples and cleavage steps can be seen on fracture surface. This indicates that the plasticity of the original tube is very poor. Also, the work hardening is obvious in deformation process. Under high magnification, a lot of tearing ridges are observed and the tearing ridge of dimple is very sharp. The fracture mode of the original tube, which belongs to brittle fracture, is quasi cleavage. At a solution temperature of 560 °C and time of 120 min, the number of dimples increases and their depth becomes deep (Fig. 6(b)). The strength of AA6061 decreases and its Agt increases. At an aging temperature of 180 °C and time of 360 min, the dimples are elongated along the same direction and the shape is parabolic (Fig. 6(c)).

By comparing the three images in Fig. 6, it is obvious that two conclusions can be drawn: firstly, the plastic characteristics of AA6061 are strengthened and the fracture mode of AA6061 is changed from brittleness fracture to ductile fracture after solution treatment. Secondly, the dimple, which reflects slipping characteristic, is torn after aging treatment. The second phase particles can be seen in the dimple, which makes the strength increase and the Agt decrease.

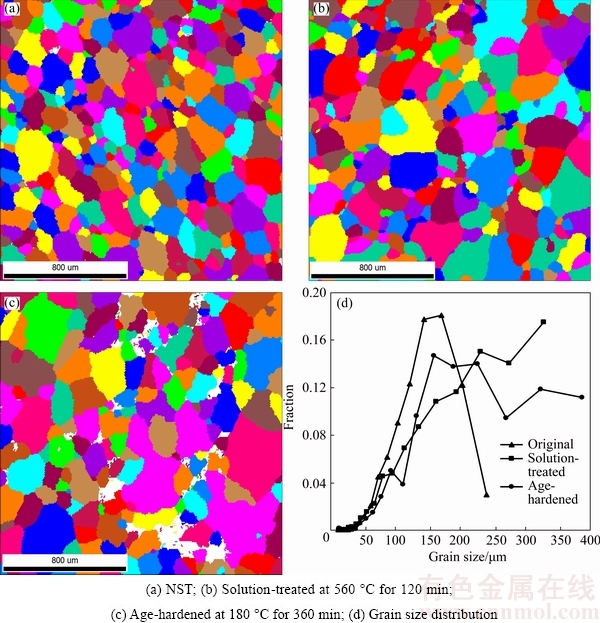

Figure 7 shows the grain structure of AA6061 tube in various conditions of treatment. The AA6061 tube is prepared by extrusion process. The microstructure of original tube is composed of equiaxed grain rather than fibrous structure because recrystallization occurs in preparation process, as shown in Fig. 7(a). It is clear that the grain sizes distribute heterogeneously in all cases. The average grain size is 123.7 μm. At a solution temperature of 560 °C and time of 120 min, the grains grow up and the average grain size is 202.1 μm. The grain structure is almost the same as the slightly annealed grain structure presented by FAN et al [14]. No obvious recrystallization grains are found around the grain boundaries of large grains. Only recovery takes place in solution treatment process. At an aging temperature of 180 °C and time of 360 min, there is almost no diversification appearing in grain structure. No abnormal grain growth appears in this situation. The recovery is carried out more thoroughly in the heating process [17-19].

Fig. 6 Effect of heat treatment on fracture morphology of AA6061

Fig. 7 Effect of solution and aging treatment on grain structure of tested alloy

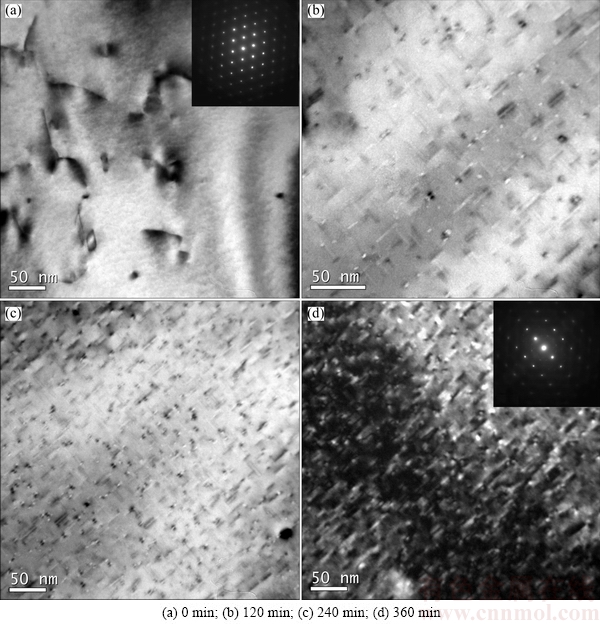

Figure 8 shows a series of TEM bright field images obtained form the samples aged for different time, as well as selected area diffraction patterns of samples aged at 180 °C for 0 and 360 min. Age hardening is the main strengthening mechanism in the whole process of tube bulging. The effect of solution treatment is to improve the forming capacity and ensure that the object parts have a high mechanical strength. From Fig. 8(a), it can be seen that no precipitate occurs in the Al matrix, making the strength and hardness decrease and the formability improved. At an aging temperature of 180 °C and time of 120 min, lots of fine needle-shaped precipitates occur with the size of 10-50 nm in the Al matrix. These particles distribute homogeneously throughout the matrix. The strain field contrast can be clearly observed around the needle-shaped precipitates. This indicates that these precipitates are coherent with the matrix. When the aging time is extended to 240 min, similar observation is acquired, as shown in Fig. 8(c). The needle-shaped precipitates still distribute homogeneously in the matrix. The number of precipitates increases with the extending of aging time. In general, the precipitation sequence for 6xxx aluminum alloy is accepted as: supersaturated solid solution (SSSS) → atomic clusters → GP zone → β" precipitates → β' precipitates → β Mg2Si precipitates [20,21]. Also, it has been shown that the GP zone, β", β' and β precipitates have typical morphologies of near-spherical shape (1-2 nm), needles (up to 40  × 40

× 40  × 350

× 350  ), ribbons (several microns long) and plates or cubes (up to 10-20 μm), respectively [22]. Therefore, the needle- shaped precipitates should be designated as β". At an aging temperature of 180 °C and time of 360 min, the number of needle-shaped precipitates is further increased. The strength and hardness of AA6061 alloy are recovered to the values of the as-received alloy.

), ribbons (several microns long) and plates or cubes (up to 10-20 μm), respectively [22]. Therefore, the needle- shaped precipitates should be designated as β". At an aging temperature of 180 °C and time of 360 min, the number of needle-shaped precipitates is further increased. The strength and hardness of AA6061 alloy are recovered to the values of the as-received alloy.

Among these precipitates, both the particles themselves and stress fields caused by lattice distortion around the particles could impede the progress of dislocation movement, which plays a dominant role in strengthening effect. The β" precipitates are considered to give the effective strengthening contribution because these particles generate more strain. The number density of strengthening precipitates determines the final hardness. When the aging time is short, the precipitates can not precipitate sufficiently. The number of precipitates increases with aging time prolonging. At an aging temperature of 180 °C and time of 360 min, the hardness of the tested alloy achieves the maximum value. The TEM micrographs are consistent with the results of the strength measurement.

Fig. 8 TEM images of precipitates for different aging time

4 Conclusions

1) The Agt, the tensile and yield strengths of the original tube are 4.798%, 288.9 MPa and 321.2 MPa, respectively. After solution treatment, the Agt increases significantly, but both the Vickers hardness and strength drop quickly. At a solution temperature of 560 °C and time of 120 min, the fracture mode of AA6061 is changed from brittleness fracture to ductile fracture. The Agt increases to 19.8%, but the tensile and yield strength drop to 189.9 MPa and 53.7 MPa, being 41% and 81% lower than the strength of the original tube, respectively.

2) At an aging temperature of 180 °C and time of 360 min, the hardness of AA6061 reaches the maximum value, namely HV 109. The hardness of original tube is HV 123. By comparison, the difference between them is less than 12%. The strengthening phase is the dispersal needle-shaped β" precipitates with size of 10-50 nm in Al matrix.

3) The technological process of AA6061 alloy tube, solution treatment → granule medium internal high pressure forming → artificial aging, is applied to trial- produced typical tubes. The MER is increased by 25.5% and the material properties can reach the performances of raw material.

References

[1] ZHENG Y S, TANG G Y, KUANG J, ZHENG X P. Effect of electropulse on solid solution treatment of 6061 aluminum alloy [J]. Journal of Alloys and Compounds, 2014, 615: 849-853.

[2] NIRANJANI V L, KUMAR K H, SUBRAMANYA V S. Development of high strength Al-Mg-Si AA6061 alloy through cold rolling and aging [J]. Materials Science and Engineering A, 2009, 515(1): 169-174.

[3] EI-MENSHAWY K, EI-SAYED A W A, EI-BEDAWY M E, AHMED H A, EI-RAGHY S M. Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061 [J]. Corrosion Science, 2012, 54: 167-173.

[4] GHOSH M, MIROUX A, WERKHOVEN R J, BOLT P J, KESTENS L A I. Warm deep-drawing and post drawing analysis of two Al-Mg-Si alloys [J]. Journal of Materials Processing Technology, 2014, 214(4): 756-766.

[5] HE Zhu-bin, FAN Xiao-bo, SHAO Fei, ZHENG Kai-lun, WANG Zhi-biao, YUAN Shi-jiang. Formability and microstructure of AA6061 Al alloy tube for hot metal gas forming at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s364-s369.

[6] WANG L, STRANGWOOD M, BALINT D, LIN J, DEAN T A. Formability and failure mechanisms of AA2024 under hot forming conditions [J]. Material Science and Engineering A, 2011, 528(6): 2648-2656.

[7] DONG Guo-jiang, ZHAO Chang-cai, CAO Miao-yan. Flexible-die forming process with solid granule medium on sheet metal [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2666-2677.

[8] KWON Y N, LEE Y S, LEE J H. Deformation behavior of Al-Mg-Si alloy at the elevated temperature [J]. Journal of Materials Processing Technology, 2007, 187-188(S3): s533-s536.

[9] LI Dao-ming, GHOSH A K. Biaxial warm forming behavior of aluminum sheet alloys [J]. Journal of Materials Processing Technology, 2004, 145(3): 281-293.

[10] KOK M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminum alloy composites [J]. Journal of Materials Processing Technology, 2005, 161(3): 381-387.

[11] FAN Xiao-bo, HE Zhu-bin, YUAN Shi-jian, LIN Peng. Investigation on strengthening of 6A02 aluminum alloy sheet in hot forming- quenching integrated process with warm forming dies [J]. Materials Science and Engineering A, 2013, 587(18): 221-227.

[12] XU Xiao-feng, ZHAO Yu-guang, WANG Xu-dong, ZHAN Yang-yang, NING Yu-heng. Effect of rapid solid-solution induced by electropulsing on the microstructure and mechanical properties in 7075 Al alloy [J]. Materials Science and Engineering A, 2016, 654(27): 278-281.

[13] RISANTI D D, YIN M, ZWAAG S V D. A systematic study of the effect of interrupted ageing conditions on the strength and toughness development of AA6061 [J]. Materials Science and Engineering A, 2009, 523(1): 99-111.

[14] FAN Xiao-bo, HE Zhu-bin, YUAN Shi-jian, ZHENG Kai-lun. Experimental investigation on hot forming–quenching integrated process of 6A02 aluminum alloy sheet [J]. Materials Science and Engineering A, 2013, 587(18): 221-227.

[15] DONG Guo-jiang, BI Jiang, DU Bing, CHEN Xiao-hua, ZHAO Chang-cai. Research on AA6061 tubular components prepared by conbined technology of heat treatment and internal high pressure forming [J]. Journal of Materials Processing Technology, 2017, 242: 126-138.

[16] DEMIR H,  S. The effects of aging on machinability of 6061 aluminium alloy [J]. Materials & Design, 2009, 30(5): 1480-1483.

S. The effects of aging on machinability of 6061 aluminium alloy [J]. Materials & Design, 2009, 30(5): 1480-1483.

[17] MANSOURINEJAD M, MIRZAKHANI B. Influence of sequence of cold working and aging treatment on mechanical behaviour of 6061 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2072-2079.

[18] FARSHIDI M H, KAZEMINEZHAD M, MIYAMOTO H. Severe plastic deformation of 6061 aluminum alloy tube with pre and post heat treatments [J]. Materials Science and Engineering A, 2013, 563: 60-67.

[19] DADBAKHSH S, TAHERI A K, SMITH C W. Strengthening study on 6082 Al alloy after combination of aging treatment and ECAP process [J]. Materials Science and Engineering A, 2010, 527(18-19): 4758-4766.

[20] EDWARDS G A, STILLER K, DUNLOP G L, COUPER M J. The precipitation sequence in Al-Mg-Si alloys [J]. Acta Materialia, 1998, 46(11): 3893-3904.

[21] MARIOARA C D, ANDERSEN S J, JANSEN J, ZANDBERGEN H W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al-Mg-Si alloy [J]. Acta Materialia, 2003, 51(3): 789-796.

[22] MARIOARA C D, ANDERSEN S J, JANSEN J, ZANDBERGEN H W. Atomic model for GP-zones in a 6082 Al-Mg-Si system [J]. Acta Materialia, 2001, 49(2): 321-328.

毕 江1,2,赵长财1,杜 冰1,国庆波3,董国疆4

1. 燕山大学 先进锻压成形技术与科学教育部重点实验室,秦皇岛 066004;

2. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001;

3. 秦皇岛北方管业有限公司,秦皇岛 066004;4. 燕山大学 车辆与能源学院,秦皇岛 066004

摘 要:提出一种管材成形新工艺:固溶处理→颗粒介质内高压成形→人工时效。通过热处理工艺调整合金变形前后的力学性能,应用颗粒介质内高压成形技术实现管件塑性成形,以期建立一种工艺实施简便、设备要求较低、产品设计灵活的高强铝合金管件加工方法。结果表明,固溶温度560 °C且保温时间120 min时,合金伸长率提高了313%,但强度和硬度大幅减低;对合金进行固溶后时效处理,当人工时效温度180 °C且保温360 min时,合金塑性下降,强度和硬度等性能指标恢复至固溶前状态,确保成形零件具备母材力学性能。此工艺方法使AA6061挤压管材的最大胀形率提高了25.5%,管件材料性能达到了原材料的性能指标。

关键词:AA6061合金;内高压成形;热处理;强化机制

(Edited by Bing YANG)

Foundation item: Project (51775481) supported by the National Natural Science Foundation of China; Project (A2016002017) supported by the High-level Talents Program of Heibei Province, China

Corresponding author: Guo-jiang DONG; Tel: +86-335-8043036; E-mail: dgj@ysu.edu.cn

DOI: 10.1016/S1003-6326(18)64655-2