文章编号:1004-0609(2008)09-1628-06

超声振动对过共晶Al-Si合金半固态浆料凝固组织的影响

赵君文,吴树森,毛有武,安 萍

(华中科技大学 材料成形及模具技术国家重点实验室,武汉 430074)

摘 要:研究超声振动制备过共晶Al-Si合金半固态浆料中工艺参数对半固态浆料组织的影响规律。利用A390铝合金熔体,超声振动至液固相线温度区内制浆,研究超声振动时间、振动后保温及空振比等不同条件下半固态浆料的组织变化。结果表明:超声振动后初晶Si可细化到20 ?m左右;浆料在保温过程中,初晶Si粒以8 ?m/min的平均速度快速长大,2 min内初生Si晶粒仍保持较好的圆整度;2 min后初生Si晶粒慢慢恶化;在1℃/min的冷却速度下,在0.5~10 min的振动时间范围内,初生Si以小于2.5 ?m/min的速度缓慢长大;当超声振动的空振比为0.5时,初生晶粒的细化效果最好。

关键词:Al-Si合金;超声振动;过共晶;半固态浆料;空振比

中图分类号:TG 249.9;TG 146.2+1;O 426.9 文献标识码:A

Effect of ultrasonic vibration on microstructure of

semi-solid hypereutectic Al-Si alloy slurry

ZHAO Jun-wen, WU Shu-sen, MAO You-wu, AN Ping

(State Key Laboratory of Material Processing and Die and Mould Technology,

Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: The effects of process parameters on microstructures of hypereutectic Al-Si semi-solid slurry were investigated. The A390 melt was imposed with ultrasonic vibration once it was poured into the metal cup and controlled in the liquid-solid temperature range, and the effects of ultrasonic vibration time, isothermal holding time, rest-work ratio on the semisolid slurry were studied. The results show that the primary Si phase is refined to about 20 ?m. And with the increase of the isothermal holding time after ultrasonic vibration period, the primary Si particles grow up rapidly at the velocity of 8 ?m/min, and the primary Si particles remain globular in 2 min while the morphologies deteriorate after 2 min. The primary Si particles grow slowly at the speed below 2.5 ?m/min with relative stable morphology under ultrasonic vibration within 0.5?10 min. Ultrasonic vibration with rest-work ratio of 0.5 other than continuous ultrasonic vibration achieves the best refinement result.

Key words: Al-Si alloy; ultrasonic vibration; hypereutectic; semisolid slurry; rest-work ratio

过共晶Al-Si合金具有良好的耐磨性、耐热耐蚀性和体积稳定性等特点,常用于制造活塞、缸体、泵体和空调压缩机等[1?2]。但采用传统铸造方法生产过共晶Al-Si合金零件的组织中存在着与基体无共格界面的粗大初生Si块和针状共晶Si,不仅使零件的切削加工性能变差,还降低了零件的耐磨性及强度,并增大零件表面的粗糙度[3?4]。

金属半固态成形技术自20世纪70年代问世后,亚共晶Al-Si合金的半固态成形随即得到研究和应用。近年来过共晶Al-Si合金的半固态成形也得到广泛关注,但研究主要集中在半固态触变成形方面。由此产生了一些坯料制备方法,如机械搅拌法[5?6]、粉末冶金法[7]、喷射沉积法[8]和电磁搅拌法[9?11]等。也有学者进行了超声振动制备过共晶Al-Si合金半固态坯料的研究[12?14],如连铸坯料用以触变成形。但半固态流变成形采用超声波制浆的报道却很少,对超声振动制浆工艺及机理也还缺乏研究。

半固态流变成形不需制坯和重熔,与触变成形相比具有生产效率高及生产成本低等优点,成为目前的研究热点[15]。一般流变成形制浆过程中,为方便熔体均匀形核和初生晶粒缓慢长大,常将熔体从液相线温度缓慢冷却到半固态成形温度。但对过共晶Al-Si合金来说,一般的缓慢冷却不但难以阻碍初生Si粒的迅速长大[16] ,还会造成初生Si粒的偏析。目前的一些方法也很难以经济方式制备出理想的过共晶Al-Si合金流变浆料。因此,本课题进行超声振动制备过共晶Al-Si合金A390流变浆料的探索并研究相关工艺参数对浆料组织的影响。研究表明:超声振动设备成本低,能产生强烈的熔体对流,可以同时保证初生Si均匀形核、缓慢长大及避免Si相偏析,并提高制浆效率,最终制得初生Si晶粒细小、均匀分布的流变浆料。

1 实验

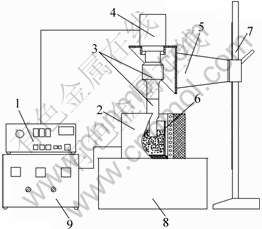

图1所示为本研究超声振动制备半固态流变浆料实验所用装置的示意图。它主要由超声发生控制器、超声换能器、超声变幅杆、电炉温度控制仪、加热电炉和浇杯等部分组成。其中,超声发生控制器的最大功率为1.2 kW,发振频率为20 kHz。为叙述方便,本研究将换能器和变幅杆构成的部分称为超声振动头。

图1 实验装置示意图

Fig.1 Schematic diagram of experimental set-up: 1—Ultrasonic generator; 2—Heating furnace; 3—Amplitude transforming rod; 4—Transducer; 5—Vibrator holder; 6—Metal cup; 7—Slide bar; 8—Holding table; 9—PID temperature controller

超声发生控制器1可以对超声振动头进行振动时间、振动间歇时间及振动次数进行预设,电炉温度控制仪9可以通过加热电炉2对浇杯6的预热温度和浇入熔体的温度进行控制。超声振动头可以通过升降杆7上下移动。浇杯盛液区的尺寸为d 68 mm×90 mm,浇注时一般浇入60 mm深的金属熔体。

本研究所用合金材料A390采用Al-22Si中间合金、纯Al、纯Cu和纯Mg配置而成,其成分为:17%Si,4.5%Cu,0.6%Mg,其余为Al。A390合金的固相线温度为505 ℃,液相线温度为650 ℃[17]。

将按一定比例配好的原材料放入铸铁坩埚中,用5 kW电阻炉加热至750~780 ℃熔化,然后加入纯Mg,静置10 min后用高纯氩气旋转除气15 min。 除气完毕后再静置并调温至680 ℃,同时预设好超声发生控制器的参数,并将超声振动头放入加热电炉内与浇杯一并预热到530 ℃。5 min左右后升起振动头,将一定量的金属熔体舀入浇杯中,随即放下振动头并浸入熔体15~20 mm,开启振动。振动或振后保温一定时间后,用内径为d 6 mm的石英管抽取少量熔体水淬制备试棒。

从水淬成的试棒上切取长度为10 mm的棒料作为金相试样,嵌样后进行粗磨、细磨、精磨和抛光,然后用质量分数为0.5%的HF溶液浸蚀,然后在光学显微镜下观察其显微组织并拍摄金相照片,用本课题组开发的半固态组织定量金相分析软件系统通过这些金相照片对不同条件下的半固态组织进行分析。

在所用半固态组织定量金相分析软件系统中,采用平均晶粒直径(AGD)来衡量初生Si晶粒大小,其具体定义及计算公式见文献[18]。软件分析中,将粒径小于15 ?m的Si粒视为淬冷时析出的,将其过滤掉。

由于超声振动设备可实现间歇振动,本研究引入空振比Rt来描述,其定义为超声作用的一个周期内间歇时间与振动时间的比值,设间歇时间与振动时间分别为Tr和Tw,则

本研究中除专门研究空振比的情况外,其余实验中空振比均为1。

2 结果及分析

2.1 保温时间对半固态A390铝合金微观组织的影响

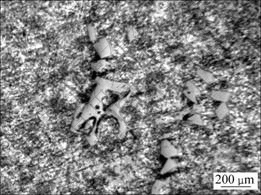

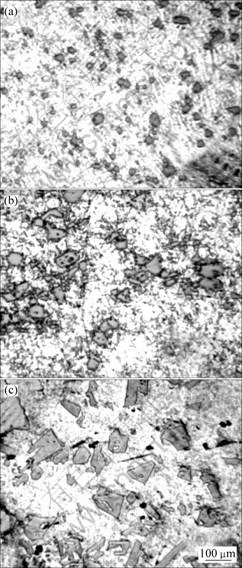

由于在实际生产过程中,通过超声振动制备好的浆料在随后的转移输送和成形等过程中,会有一段时间不受超声振动,而该段时间中浆料组织的变化对最终半固态成形零件的微观组织有极大影响。因此,有必要对振动一段时间后进行保温的浆料初生Si平均晶粒直径的变化进行研究,以便为今后的实际生产提供指导。在本组实验中,对熔体振动0.6 min后开始在590 ℃下进行保温。为了比较超声振动的效果,在不施加超声振动的情况下,降温至590 ℃并保温2 min后抽取一个试样,其微观组织如图2所示。由图2可以看出,未施加超声振动时,初生Si粒呈现多角状或块状,且有些晶粒甚至还出现分枝;初生Si粒的分布也非常不均匀,聚集严重,最大的Si粒长达350 ?m,平均晶粒大小为80 ?m。图3所示为超声振动后不同保温时间半固态A390铝合金的金相组织。由图3可看出,当振动0.6 min后(见图3(a)),初生Si粒分布均匀,并呈现近球状;无振动保温2 min后(见图3(b)),晶粒增大并开始聚集,但大部分晶粒形状仍近于椭圆状,与先前无超声振动的情况(见图2)相比,其在2 min后仍可保持较好的初始形貌;超声振动后保温5 min后(见图3(c)),晶粒长大很多,其形状也不规则,呈现多角块状。图4所示为超声振动后平均晶粒直径随保温时间变化。由图4可看出,在停止超声振动后的保温过程中,晶粒一直增大,且随着保温时间的延长,初生Si从20 ?m增大到60 ?m,前2 min增加了7 ?m,随后的3 min增加了33 ?m,平均增大速率为8 ?m/min,且随着时间的延长,长大速度有加快的趋势。

图2 无超声振动时半固态A390铝合金保温2 min的 显微组织

Fig.2 Microstructure of semi-solid A390 Al alloy after isothermal holding for 2 min without ultrasonic vibration

图3 超声振动后保温不同时间半固态A390铝合金的 微观组织

Fig.3 Microstructures of semi-solid A390 Al alloys with different isothermal holding times after ultrasonic vibration: (a) 0 min; (b) 2 min; (c) 5 min

无超声振动作用时,熔体浇入浇杯后,在较冷的杯壁形核和长大,由于对流微弱,初生Si粒发生宏观偏析[1]和微观偏析,溶质场和温度场分布也不均匀,因此,初生Si长成多角状或块状,甚至出现分枝。超声振动产生强烈的对流作用,使熔体的温度场和浓度场均匀化,使得初生Si各个方向的生长速度基本一致,呈现颗粒状。但停止施振后,一方面浆料中对流减弱,原本均匀的溶质场和温度场一段时间后变得不均匀,初生Si则沿一定方向生长,生成尖锐棱角;另一方面,由于初生固相和液相之间存在密度差,原本分散的晶粒开始聚集,初生Si的分布也不均匀。

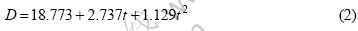

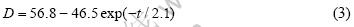

为了进一步探索超声振动一段时间后保温对初生Si的影响规律,将实验所得初生Si晶粒平均直径D随保温时间t(t≥0)变化的数据进行了拟合(见图4)。拟合曲线的数学模型如下:

图4 超声振动后A390铝合金平均晶粒直径随保温时间的变化

Fig.4 Change of average grain size of A390 Al alloy with isothermal holding time after ultrasonic vibration

经过检验,上式的相关性为98.5%。

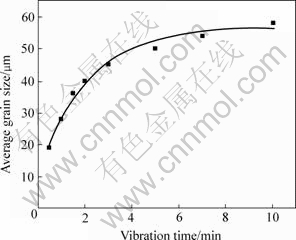

2.2 超声振动时间对半固态A390铝合金微观组织的影响

本研究中,浇入的熔体在超声作用下与浇杯和超声头达到热平衡,降温至590 ℃后,继续以1 ℃/min

的速度缓慢冷却。图5所示为不同超声振动时间半固态A390铝合金的微观组织。由图5可以看出,超声振动下初生Si最先细化(图5(a)),分布也均匀,但固相率比较低;随着时间的延长,晶粒增大,但增大速度较慢,并呈现越来越慢的趋势;初生Si平均长大速度在2.5 ?m/min以下,而硅粒形貌和分布变化不大。通过上述金相分析软件系统对它们的晶粒平均直径进行分析,结果如图6所示。从图6中可看出,在前2 min内,晶粒平均直径迅速增大;随后平均晶粒直径相对稳定地缓慢长大。经统计分析发现,初生Si的平均形状系数均为0.5~0.6。

图5 不同超声振动时间半固态A390铝合金的显微组织

Fig.5 Microstructures of semi-solid A390 Al alloys after ultrasonic vibration for different times: (a) 0.5 min; (b) 2 min; (c) 5 min; (d) 10 min

由于平均晶粒直径D随振动时间t(t≥0)变化的实验数据似乎具有明显的函数的关系,因此将实验数据进行了拟合,如图6所示。拟合曲线的数学模型为

图6 平均晶粒直径随振动时间的变化

Fig.6 Change of average grain size with ultrasonic vibration time

经过检验,上式的相关性为98%。

微观非均匀的过共晶al-si合金熔体中存在着若干Si原子团,超声在熔体中形成的空化泡的破灭,产生巨大的瞬时压力(109 Pa),使Si原子团转变为初晶晶核,较低的熔体温度将使这些晶核保存下来,从而增大了形核率。本研究中浇杯和超声振动头的预热温度都低于浇入熔体的温度,熔体浇入后被迅速过冷到固液温度区间,同时晶核在有利于形核的杯壁和浸入熔体的振动头上生成,并以较快的速度长大。超声振动产生的声空化和声流效应引起熔体宏观和微观紊流,一方面将在杯壁和振动头上形成的晶核带入到整个熔体中;另一方面使熔体的整个温度场和溶质场趋于均匀,使初生Si粒各向均匀生长,使其形状圆整[19],从而避免了多角状和长条状初生Si的生成,且由于紊流作用减小了初生晶粒的边界层,使晶粒生长前沿的温度梯度增大,从而减小了初生Si的生长速度。超声空化效应形成的空化泡的生成、长大和破灭使初生Si粒作不规则运动,在不同位置受不同大小和方向的作用力,从而使其难以聚集成团。

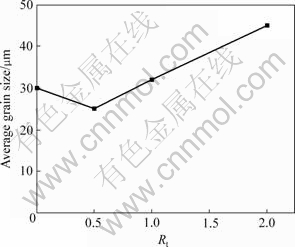

2.3 空振比对A390铝合金微观组织的影响

本研究中,振动总时间为1 min。图7所示为空振比(Rt)对初生Si粒大小的影响。由图7可知,当 Rt=0时,即连续振动时,初生Si粒平均直径为30 ?m;而当Rt=0.5时,初生Si粒平均直径只有25 ?m,相比于无间歇振动(Rt=0)时减小了15%以上。统计分析还发现,Rt=0.5时的平均形状系数比Rt=0时的增大了近40%;且随着Rt的近一步增大,初生Si平均直径一直增大。

图7 超声振动下平均晶粒直径随空振比的变化

Fig.7 Change of average grain size with rest-work ratio under ultrasonic vibration

适当的间歇振动使超声产生的空化作用和声流作用得到了更好地发挥,增大了熔体的紊乱度。一方面,由于短暂的间歇可以使空化产生的微小气泡完全破裂;另一方面,由于熔体中初生Si粒在周期间歇声流作用下,一直处于以极大加速度加速运动或减速运动中,增大了Si粒与熔体以及Si粒间的相互作用力和作用几率。因此,适当的周期间歇振动可以获得更细小的初晶Si颗粒。但当空振比大于等于1时,由于过长的间歇时间,在相同的时间内减少了超声作用的总时间,因而对初晶Si的细化效果变差。

同时间歇(脉冲)振动也降低了振动设备的能耗。更重要的是,超声振动设备中最易损坏的元件——振荡管和超声换能器晶片,由于间歇的休息,使其寿命大大延长并降低了故障率,从而节约了设备维修费用和设备成本。

3 结论

1) 过共晶Al-Si合金超声振动后,初晶Si粒可细化到20?m左右,浆料受超声振动后保温,初生Si晶粒以8 ?m/min的平均速度快速长大,2 min内初生Si晶粒仍保持较好的圆整度;2 min后,初生Si晶粒慢慢恶化,且初生晶粒随保温时间延长发生聚集。

2) 在1 ℃/min的冷却速度下,在超声振动0.5~ 10 min以内,初生Si粒以小于2.5 ?m/min的速度缓慢长大,形状系数保持在0.5~0.6,晶粒分布均匀。

3) 适当的间歇振动使初生Si晶粒细化的效果比连续振动的更优,当空振比为0.5时,效果最好。

REFERENCES

[1] [1]LIANG D, BAYRAKTAR Y, MOIR S A, BARKHUDAROV M, JONES H. Primary silicon segregation during isothermal holding of hypereutectic Al-18.3wt%Si alloy in the freezing range[J]. Scripta Metall Mater, 1994, 31(4): 363?367.

[2] [1]CRIADO A J, MARTINEZ J A, CALABRES R. Growth of eutectic silicon from primary silicon crystals in aluminium- silicon alloys[J]. Scripta Mater, 1997, 36(1): 47?54.

[3] [1]吴树森, 涂小林, 吴广忠. 冷却速度对过共晶Al-Si合金的初晶Si微细化的影响[J]. 材料科学与工艺, 2001, 9(2): 141?145.

WU Shu-sen, TU Xiao-lin, WU Guang-zhong. Effect of cooling rate on refining of primary silicon of hypereutectic Al-Si alloy[J]. Material Science and Technology, 2001, 9(2): 141?145.

[4] [1]KAPRANOS P, KIRKWOOD D H, ATKINSON H V, RHEINLANDER J T, BENTZEN J J, TOFT P T, DEBEL C P, LASLAZ G, MAENNER L, BLAIS S, RODRIGUEZ-IBABE J M, LASA L, GIORDANO P, CHIARMETTA, G, GIESE A. Thixoforming of an automotive part in A390 hypereutectic Al-Si alloy[J]. J Mater Process Tech, 2003, 135(2/3): 271?277.

[5] [1]LEE J I, LEE H I, KIM M I. Formation of spherical primary silicon crystals during semisolid processing of hypereutectic Al-15.5%Si alloy[J]. Script Metall, 1995, 32(12): 1945?1949.

[6] [1]叶春生, 张新平, 潘 治. 机械搅拌对过共晶Al-Si合金半固态组织的影响[J]. 热加工工艺, 2002, 31(1): 27?29.

YE Chun-sheng, ZHANG Xin-ping, PAN Ye. The influence of mechanical stirring on semi-solid microstructures of hypereutectic Al-Si alloy[J]. Hot Working Technology, 2002, 31(1): 27?29.

[7] [1]KIM Y J, WANG L F, CHUNG I S, KIM J C, JANG T S. Fabrication and characteristics of hypereutectic prealloyed Al-Si powders by gas atomization process[J]. Science of Engineering Ceramics Ⅲ, 2006, 317/318: 61?64.

[8] [1]WARD P J, ATKINSON H V, ANDERSON P R G, ELIAS L G, GARCIA B, KAHLEN L, RODRIGUEZ-IBABE J M. Semi-solid processing of novel MMCs based on hypereutectic aluminum-silicon alloys[J]. Acter Mater, 1996, 44(5): 1717?1727.

[9] [1]毛卫民, 李树索, 赵爱民, 崔成林, 钟雪友. 电磁搅拌对过共晶Al-Si合金初生Si长大过程和形貌的影响[J]. 材料科学与工艺, 2001, 9(2): 117?121.

MAO Wei-min, LI Shu-suo, ZHAO Ai-min, CUI Cheng-lin, ZHONG Xue-you. Effect of electromagnetic stirring on growth and morphology of primary silicon crystals of hypereutectic Al-Si alloys[J]. Material Science and Technology, 2001, 9(2): 117?121.

[10] [1] 晋芳伟, 任忠鸣, 任维丽, 邓 康, 钟云波, 余建波. 强磁场下过共晶铝硅合金凝固过程中初晶硅的迁移行为[J]. 中国有色金属学报, 2007, 17(2): 313?319.

JIN Fang-wei, REN Zhong-ming, REN Wei-li, DENG Kang, ZHONG Yun-bo, YU Jian-bo. Migratory behaviors of primary crystal silicon in hypereutectic Al-Si alloy under high magnetic field[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 313?319

[11] [1]毛卫民, 李树索, 赵爱民, 崔成林, 王德仁, 钟雪友. 电磁搅拌Al-24%Si合金的显微组织[J]. 中国有色金属学报, 2001, 11(5): 819?823.

MAO Wei-min, LI Shu-suo, ZHAO Ai-min, CUI Cheng-lin,WANG De-ren, ZHONG Xue-you. Microstructures of hypereutectic Al-24%Si alloy stirred by electromagnetic field[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 819?823.

[12] [1]GABATHULER J P, BUXMANN K. Process for producing a liquid-solid metal alloy phase for further processing as material in the thixotropic state. US Patent, 5186236[P]. 1993?02?16.

[13] [1] ABRAMOV V O, ABRAMOV O V, STRAUMAL B B, GUST W. Hypereutectic Al-Si based alloys with thixotropic microstructure produced by ultrasonic treatment[J]. Materials & Design, 1997, 18(4/6): 323?326.

[14] [1]ESKIN G I. Broad prospects for commercial application of the ultrasonic (Cavitation) melt treatment of light alloys[J]. Ultrasonics Sonochemistry, 2001, 8(3): 319?325.

[15] [1]康永林, 毛卫民, 胡壮麒. 金属材料半固态加工理论与技术[M]. 北京: 科学出版社, 2004.

KANG Yong-lin, MAO Wei-min, HU Zhuang-qi. Theories and techniques of semi-solid metal processing[M]. Beijing: Science Press, 2004.

[16] [1] DEEPAK S, DIRAN A, RATHINDRA D G. SSM processing of hypereutectic Al-Si alloys-An overview[C]// Proceedings of the 8th international S2P conference. Cyprus: Limassol, 2004: 855?864.

[17] [1]中国机械工程学会铸造专业学会. 铸造手册[M]. 第3卷. 北京: 机械工业出版社, 1995.

The Foundry Institution of the CMES. Handbook for casting[M]. Vol. 3. Beijing: China Machine Press, 1995.

[18] [1]赵君文, 吴树森, 谢礼志, 毛有武. 机械振动对半固态ZL101铝合金组织的影响[J]. 中国机械工程, 2006, 17(S1): 201?205.

ZHAO Jun-wen, WU Shu-sen, XIE Li-zhi, MAO You-wu. Study on preparing Al alloy ZL101 semi-solid slurry by mechanical vibration method[J]. China Mechanical Engineering, 2006, 17(S1): 201?205.

[19] [1]WU S S, WU X P, XIAO Z H. A model of growth morphology for semi-solid metals[J]. Acta Materialia, 2004, 52(12): 3519?3524.

基金项目:国家自然科学基金资助项目(50775086);国家高技术研究发展计划资助项目(2007AA03Z557)

收稿日期:2008-01-06;修订日期:2008-06-10

通讯作者:吴树森,教授,博士;电话/传真:027-87556262;E-mail: ssw636@hotmail.com

(编辑 李艳红)