文章编号:1004-0609(2010)03-0488-08

方形管分流模双孔挤压过程中金属的流动行为

黄东男1,2,李静媛1,张志豪1,谢建新1

(1. 北京科技大学 新材料技术研究院,北京 100083;

2. 内蒙古工业大学 材料科学与工程学院,呼和浩特 010051)

摘要:采用Deform-3D有限元软件,结合基于逆向工程的焊合面网格修复技术,建立方形管分流模双孔挤压时包括焊合过程在内的全过程的三维有限元数值模拟方法,分析分流孔的配置方案对金属流动行为、挤压力、挤压温度及成形质量的影响。结果表明:中间分流孔与位于两侧分流孔的面积比值Q1/Q2是影响金属流动均匀性、焊缝位置和制品平直度的重要因素,比值Q1/Q2为0.93~1.03时,挤出的方管平直度好;分流孔外接圆直径和挤压筒直径的比值对挤压过程中温升的影响较小,而对挤压力有一定的影响,当该比值为0.82时挤压力最小,该比值超过0.82时挤压力明显增加。

关键词:分流模挤压;有限元模拟;分流孔面积;金属流动行为

中图分类号:TG379 文献标识码:A

Metal flowing behaviors during diplopore extrusion of

square tube with porthole die

HUANG Dong-dan1, 2, LI Jing-yuan1, ZHANG Zhi-hao1, XIE Jian-xin1

(1. Institute of Advanced Materials and Technologies, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, Inner Mongolia University of Technology, Hohhot 010051, China)

Abstract: Applying welding plane meshes repairing technology based on reverse engineering and commercial FEM soft Deform-3D, a three dimensions finite element method for simulating the whole diplopore extrusion process of square tube with porthole die, including bonding stage, were developed. The effects of the portholes configuration scheme on the metal flowing behaviors, extrusion load, tube temperature and forming quality were analyzed. The results show that, the area ratio of the center to the side porthole (Q1/Q2) is an important factor affecting the flow uniformity, seam position and straightness of the tube. When the area ratio (Q1/Q2) ranges in 0.93?1.03, the straightness of the extrusion tube is satisfied. The diameter ratio of the porthole circumcircle to the extrusion container (Dc/D) has little effect on the temperature-rising, but has great effect on the extrusion load. When the diameter ratio is 0.82, the extrusion load is at minimum. When the diameter ratio is larger than 0.82, the extrusion load increases obviously.

Key words: porthole die extrusion; finite element simulation; porthole area; metal flowing behavior

分流模挤压是生产铝及铝合金空心型材的主要方法[1?2]。与一次挤压生产一根制品的单孔模挤压相比,一次挤压生产两根或多根制品的多孔模挤压法,在非对称复杂断面型材挤压成形时平衡金属流动、在大吨位挤压机上生产小规格型材和提高型材生产效率等方面具有重要应用前景。

在分流挤压过程中,正确的模具设计是获得高表面质量和高形状尺寸精度挤压制品、提高挤压生产效率、提高模具使用寿命的关键[3?4]。分析分流、焊合过程的金属流动行为,了解模具结构和尺寸因素等对金属流动变形的影响规律,是正确设计模具的前提[5?6]。

由于多孔模挤压时金属流动均匀性控制难度较大,常导致挤出型材产生刀弯、扭拧及各制品间流速不等缺陷,依靠源于实践的经验规律和模具设计者个人经验的传统的设计方法很难解决此类模具设计所面临的问题[7?8]。采用有限元数值模拟技术对变形金属内部的应力场、应变场、温度场和速度场等物理量进行分析,可预测制品成形质量,为合理设计模具结构和制定挤压工艺提供理论依据[9?10]。

现有的有限元模拟方法只能对焊合面与对称面位置一致的对称断面空心型材的分流模挤压焊合过程进行模拟分析[11?13](此时,通过假定焊合面为刚性面,可使焊合接触面上不产生网格穿透现象),而对于焊合面与对称面不一致断面空心型材,由于无法处理焊合面上网格穿透问题,无法模拟其焊合过程,只能对其分流过程及稳态成形过程进行分析,因而难以获得模具结构尺寸对挤压制品的形状和尺寸的影响规律。

谢建新等[14]提出了一种基于逆向工程技术的焊合面网格修复技术,对分流模挤压过程中焊合面相互穿透的网格进行修复,实现对空心型材分流模挤压全过程的数值模拟分析。在此基础上,本文作者重点研究分流孔配置对铝合金A6005方管型材分流模双孔挤压过程中金属流动行为、挤压力及挤压温度的影响,并在650 t挤压机上进行实验验证。

1 计算条件及焊合面穿透网格处理

1.1 计算条件

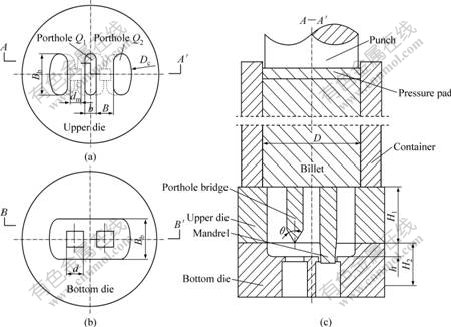

生产中一般采用如图1(a)和(b)所示的双孔分流模挤压方管,模具名称及组装如图1(c)所示。为了改善金属流动的均匀性,两侧分流孔的外壁设计成圆弧形。分流孔外接圆直径Dc与挤压筒直径D之比通常为0.7~0.9[3]。焊合角为30?。

由图1可知,流经中间分流孔(以下简称Q1孔)内的金属同时向两个模孔供料,两侧分流孔(以下简称Q2孔)各向一个模孔供料。因此,分流孔面积比(Q1/Q2)及分流孔位置(可用分流孔外接圆直径与挤压筒直径比Dc/D来描述)是影响金属流动均匀性及方管成形质量的关键因素。

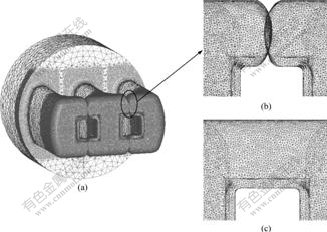

采用有限元软件Deform-3D对图1所示方管分流模双孔挤压过程进行模拟。考虑到模具结构的对称性,为减少单元网格数量及计算时间,并获得较高的仿真精度,取如图2所示的1/4模型进行过程模拟。网格划分采用绝对网格法,计算单元为四面体网格单元,并对塑性变形较剧烈的分流孔入口及模孔入口处进行网格单元细化。设定模拟过程中单元最小尺寸为0.5 mm,单元最大尺寸为15 mm。为了减少焊缝位置的网格穿透量,将相对冲突干涉系数设为0.4。

图1 双孔分流模结构及挤压模具装配示意图

Fig.1 Schematic diagrams of structure of porthole die and die assembling: (a) Upper die; (b) Bottom die; (c) Die assembling

图2 几何模型及网格划分

Fig.2 Geometry model and meshes of FEM simulation

挤压的初始工艺条件如下:坯料温度480 ℃,挤压筒温度400 ℃,模具温度450 ℃,挤压垫温度30 ℃,挤压垫速度4 mm/s。

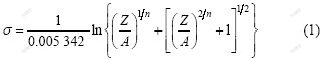

将变形温度下的A6005铝合金坯料设为粘塑性材料,采用等温热压缩实验,通过最小残差平方和回归分析方法,建立了合金本构关系模型,为几何模型提供材料流动变形行为。

式中:σ为流变应力, 为应变速率,T为变形温度,

为应变速率,T为变形温度,

R为摩尔气体常数,A、α和n均为与材料状态有关的系数,Q为热变形激活能,Z为温度补偿的应变速率因子,其中:

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

模具设为刚性材料,坯料和模具之间选用剪切摩擦模型, 摩擦因数 (τ为接触摩擦切应力,σ为材料的流动应力)[15]。本研究根据A6005铝合金的圆环压缩实验结果,取m=1,施加在坯料与模具表面和挤压筒内表面。

(τ为接触摩擦切应力,σ为材料的流动应力)[15]。本研究根据A6005铝合金的圆环压缩实验结果,取m=1,施加在坯料与模具表面和挤压筒内表面。

1.2 焊合面穿透网格处理

模拟过程中,当焊合面网格单元相互穿透时,依据塑性成形过程中体积不变原理,当焊合面网格穿透体积和未穿透体积相等时,将此时的有限元网格模型转化成由小三角形面为基本描述单元的三维模型,即STL(Stereo lithography)模型,通过三维实体设计软件Pro/ENGINEER中的基于逆向工程技术的小平面特征技术,对STL模型中相互穿透的焊合面三角网格进行修复,删除产生穿透及畸变的三角形网格,然后依次选取3个相邻的顶点重新构建三角形网格,对其表面进行填充。同时将焊合面尚未充满区域的表面用三角形面片单元进行填充,使得原始穿透区和未充满区重新形成一个由三角形面片单元构成的三维模型[14]。焊合面穿透网格修复前后的有限元模型如图3所示,其中图3(a)所示为焊合面网格相互穿透时的有限元模型,图3(b) 所示为焊合面网格修复前的有限元模型局部放大,图3(c) 所示为修复后的有限元模型。

图3 焊合面穿透网格修复前后的有限元模型

Fig.3 FEM model of penetration mesh on welding surface before and after mesh repairing: (a) Mutual penetration meshes on welding surfaces; (b) Before mesh repairing; (c) After mesh repairing

在有限元软件Deform-3D中对如图3所示的修复模型添加单元节点数据,继续计算,从而完成分流模挤压焊合阶段及挤压全过程的模拟分析。

2 模拟结果与讨论

2.1 挤压各阶段金属的流动行为分析

为便于与在650 t挤压机上进行实验的结果相比较,本研究首先以L15 mm×t2 mm(其中L表示边长,t表示厚度,下同)的方管为例,分析分流模双孔挤压过程中各个阶段金属的流动行为。

挤压筒直径D为95 mm,分流孔外接圆直径Dc为84 mm;上模高H1为50 mm,下模高H2为50 mm,焊合室高度h为13 mm;模孔d为15 mm,模芯dm为11 mm;Q1孔的宽度b为12 mm,相应的Q1和Q2的面积比为0.71;焊合压缩比K(俗称分流比,即分流孔总面积与制品总断面积之比)为8.6,挤压比R 为34.1。

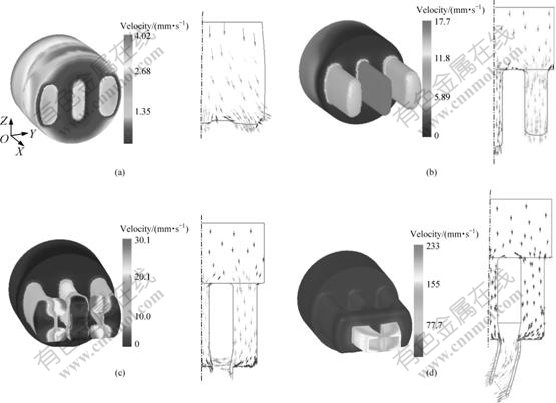

图4所示为挤压不同阶段的金属流动行为及速度场分布,各分图中右图所示为沿x轴方向(挤压方向)对称面上的速度场矢量图。

图4 挤压过程金属流动行为及速度场

Fig.4 Metal flowing behaviors and velocity fields(Dc/D =0.88, Q1/Q2=0.71): (a) Upsetting stage (with stroke of 6 mm); (b) Dividing stage (with stroke of 20.5 mm); (c)Filling welding chamber stage (with stroke of 24.8mm) ; (d) Welding and forming stage (with stroke of 26.2mm)

由图4(a)可知,在镦粗阶段的后期,坯料开始进入分流孔,但分流孔内金属流速小于挤压轴速度,主要由于镦粗和分流同时进行,导致分流速度减小。

由图4(b)可知,在分流阶段,金属在分流桥的作用下被拆分为3股进入分流孔,分流孔内金属流速远高于挤压轴速度。同时,由于挤压筒中心附近金属流动阻力小,受挤压筒内壁摩擦力影响也小,使得Q1孔内金属流速明显大于Q2孔的金属流速,因此Q1孔所挤压出的金属长度比Q2孔的长。

由图4(c)可知,在填充焊合阶段,3股金属相继与焊合室底面接触,形成径向流动开始填充焊合室。在填充焊合室过程中,Q2孔内的金属只向模具中心侧流动填充,而Q1孔的金属进入焊合室后向两侧分流填充,使得金属从分流孔内进入焊合室后,其速度被分解,导致填充过程中焊合面端部速度小于由Q2孔内流入焊合室的焊合面端部速度。同时,由于Q1/Q2=0.71,即Q1孔面积相对较小,即从Q1孔流出的金属量较少,因此从Q2孔流出的金属成为填充焊合室的主要来源,从而最终导致焊缝偏向模具中心位置,并使焊缝两侧方管表面流速不等。

图4(c)还表明,在金属坯料填充焊合室过程中,即焊缝尚未完全焊合前,已有部分金属先期被挤出模孔形成了方管的料头。

由图4(d)可知,在焊合及成形阶段,延续了填充焊合阶段的金属不均匀流动,Q2孔对应的方管外侧金属流量大、速度快,导致焊缝位置偏离方管的对称中心,型材离开模孔后向模具中心侧弯曲,形成刀弯,并产生碰触。

上述对分流模双孔挤压方管时金属流动行为的分析表明,方管向中心侧弯曲的主要因素是Q1孔的金属流量过小,因此为消除方管产生的内侧弯曲缺陷,应该增大Q1孔的面积。

2.2 分流孔面积比Q1/Q2对金属流动行为的影响

将Q1孔宽度b从12 mm增加至16、18和20 mm,而Q2孔面积保持不变,即Q1/Q2由上述的0.71增加至0.93、1.03和1.13。

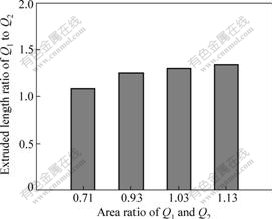

图5所示为挤压行程为20.5 mm时,不同分流孔面积比时各分流孔内流出金属长度比。由图5可见,随Q1/Q2的增加,Q1与Q2孔内金属的长度比值增加,即Q1和Q2孔流出金属的长度差增加,使得由Q1孔流出并充填焊合室的金属量增大。

图5 挤压行程为20.5 mm时金属分流长度比与分流孔面积比的关系

Fig.5 Relationship of portholes metal length ratio and porthole area ratio with stroke of 20.5 mm

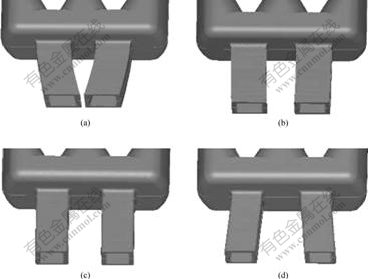

图6所示为不同分流孔面积比条件下,稳态成形阶段方管分流模挤压成形模拟结果。由图6可以看出,当Q1/Q2=0.71和Q1/Q2=1.13时(见图6(a)和(d)),挤出方管各部位流速不均匀,方管向内侧和外侧产生刀弯,说明分流孔Q1面积过小和过大。当Q1/Q2=1.03时(见图6 (c)),挤出方管各部位流速最均匀,外形最佳。当Q1/Q2=0.93时(见图6(b)),只是方管的料头略有弯曲,而随着挤压行程的增加,方管各部位流速逐渐趋于均匀,外形较好。

图6 稳态挤压时方管成形情况

Fig.6 Simulation results of square tube extrusion at steady stage (Dc/D=0.88): (a) Q1/Q2=0.71(L15 mm×t2 mm) ; (b) Q1/Q2= 0.93(L15 mm×t2 mm); (c) Q1/Q2=1.03(L15 mm×t2 mm); (d) Q1/Q2=1.13(L15 mm×t2 mm)

因此可以认为,当分流孔外接圆直径和挤压筒直径比为Dc/D=0.88时,分流孔Q1/Q2=0.93~1.03时,挤出方管流出速度均匀,外形平直。

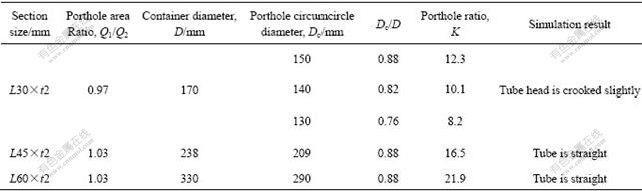

以上合适的分流孔面积比(Q1/Q2=0.93~1.03)是在挤压筒直径D为95 mm、分流孔外接圆直径Dc为84 mm(即Dc/D=0.88)的条件下确定的。为了验证其普遍性,本研究计算了不同Dc/D、不同断面尺寸方管的分流模双孔挤压时的成形情况,结果如表1所列。由表1模拟结果可知,对于此类分流模双孔挤压方管时,当分流孔面积Q1/Q2为0.93~1.03时,挤出的方管外形平直。

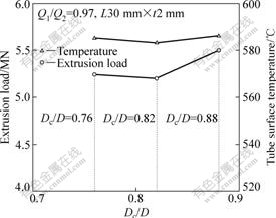

2.3分流孔位置对最大挤压力及温度的影响

模拟结果表明,在其它结构参数相同的条件下, Dc /D对金属流动行为的影响较小,但对挤压力的影响较大。方管(L30 mm×t2 mm)挤压时的挤压力及稳态挤压时模口出口处,由热变形及摩擦生热所得的方管表面温度随Dc/D的变化如图7所示。由图7可知,分流孔外接圆直径和挤压筒直径比对挤压过程中的金属温度变化影响很小,而对挤压力有一定的影响,即随着比值的增加,挤压力呈先略有减小然后增大。当比值Dc/D为0.82时最大挤压力最小,比值超过0.82时最大挤压力明显增加。因此,Dc/D存在一个最佳值,使得挤压力最小。

图7 分流孔外接圆直径和挤压筒直径之比对挤压力及方管表面温度的影响

Fig.7 Effects of Dc/D on extrusion load and tube surface temperature

3 实验验证

为验证模拟结果,以方管(L15 mm×t2 mm)为例,设计加工了Q1/Q2=0.93的双孔分流模,并在650 t卧式挤压机上进行挤压实验。挤压工艺参数和上述模拟参数相同。为了便于从模具中取出坯料,以及观测分流孔内金属的流动情况和焊合室内焊缝的位置,挤压前在模具内表面涂敷少量石墨乳。

当挤压行程为20 mm,即挤压处于分流阶段末期时,实验结果如图8(a)所示,Q1孔内流出金属长度为55 mm,Q2孔内金属长度为42 mm。同一行程时的模拟结果如图8(b)所示,Q1孔内流出金属长度为57 mm,Q2孔内金属长度为45 mm。金属长度的模拟结果比实测结果长2~3 mm,误差小于7%。

表1 不同Dc/D、断面尺寸的方管成形情况

Table 1 Simulation results of square tube extrusion with various Dc/D and section sizes

图8 分流阶段及焊缝位置的实验和模拟结果对比

Fig.8 Comparison of simulation and experimental results at welding line position and dividing stage: (a) Experimental result of flowing behavior; (b) Simulation result of flowing behavior; (c) Experimental result of welding line position; (d) Simulation result of welding line position

当金属充满焊合室并从模孔流出时,实验结果与模拟结果如图8(c)、(d)所示。从图8中可以看出,模拟与实际结果在外形和焊缝位置上皆吻合,焊缝位置偏向Q1孔,挤压实验的焊缝位置偏移了1.2 mm,模拟结果为1.1 mm,误差小于10%。

4 结论

1)采用Deform-3D有限元计算软件,结合基于逆向工程的焊合面网格修复技术,建立了方形管分流模双孔挤压时包括焊合过程在内的全过程的三维有限元数值模拟技术。

2) 中间分流孔和两侧分流孔面积的比值Q1/Q2是影响金属流速、焊缝位置的重要因素,比值Q1/Q2为0.93~1.03时,挤出方管外形平直。

3) 分流孔外接圆和挤压筒直径的比值对挤压过程中的温升影响很小,而对挤压力有一定的影响;随着该比值的增大,挤压力先呈减小趋势,然后有明显增大;在本研究条件下,当该比值为0.82时挤压力最小,该比值超过0.82时挤压力明显增大。

REFERENCES

[1] MURAKAMI S. Adoption of aluminum extrusion and its technology[J]. Journal of the Japan Society for Technology of plasticity, 2008, 49(567): 25?30.

[2] 谢建新, 刘静安. 金属挤压理论与技术[M]. 北京: 冶金工业出版社, 2001.

XIE Jian-xin, LIU Jing-an. Theory and technology for metal extrusion[M]. Beijing: Metallurgical Industry Press, 2001.

[3] XIE J X, MURAKAMI T, IKEDA K. Experimental simulation of metal flow in porthole-die extrusion[J]. Journal of Materials Processing Technology, 1995, 49(1/2): 1?11.

[4] CHANDA T, ZHOU J, KOWALSKI L. 3D FEM simulation of the thermal events during AA6061 aluminum extrusion[J]. Scripta Materialia, 1999, 41(2): 195?202.

[5] YANG D Y, PARK K, KANG Y S. Integrated finite element simulation for the hot extrusion of complicated Al alloy profile[J]. Journal of Materials Processing Technology, 2001, 111(1/3): 25?30.

[6] JO H H, LEE S K, JUNG S C. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die[J]. Journal of Materials Processing Technology, 2006, 173(2): 223?231.

[7] YANG D Y, KIM K J. Design of processes and products through simulation of three-dimensional extrusion[J]. Journal of Materials Processing Technology, 2007, 191(1/3): 2?6.

[8] 程 磊, 谢水生, 黄国杰, 吴鹏越, 和优锋. 分流组合模挤压过程的有限元分步模拟[J].系统仿真学报, 2008, 20(24): 6603?6608.

CHEN Lei, XIE Shui-sheng, HUANG Guo-jie, WU Peng-yue, HE You-feng. Multi-stage finite element simulation of porthole die extrusion process[J]. Journal of System Simulation, 2008, 20(24): 6603?6608.

[9] 邸利青, 张士宏. 分流组合模挤压过程数值模拟及模具优化设计[J]. 塑性工程学报, 2009, 16(2): 123?127.

DI Li-qing, ZHANG Shi-hong. Porthole die extrusion process numerical simulation and optimal die design[J]. Journal of Plasticity Engineering, 2009, 16(2): 123?127.

[10] JUNG M L, BYUNG M K, CHUNG G K. Effects of chamber shapes of porthole die on elastic deformation and extrusion process in condenser tube extrusion[J]. Materials and Design, 2005, 26(4): 327?336.

[11] LI L, ZHANG H, ZHOU J. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials and Design, 2008, 29(6): 1190-1198.

[12] JO H H, LEE S K, LEE S B. Prediction of welding pressure in the non-steady state porthole die extrusion of Al7003 tubes[J]. International Journal of Machine Tools and Manufacture, 2002, 42(6): 753-759.

[13] DONATI L, TOMESANI L. The prediction of seam welds quality in aluminum extrusion[J]. Journal of Materials Processing Technology, 2004, 153: 366?373.

[14] 谢建新, 黄东男, 李静媛, 张志豪. 一种空心型材分流模挤压焊合过程数值模拟技术: CN101604350A[P].2009?12?16.

XIE Jian-xin, HUANG Dong-nan, LI Jing-yuan, ZHANG Zhi-hao. A numerical simulation technology for hollow profile extrusion by porthole die: CN101604350A[P].2009?12?16.

[15] LIU G, ZHOU J, DUSZCZYK J. FE analysis of metal flow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength[J]. Journal of Materials Processing Technology, 2008, 200(1/3):185-198.

基金项目:国家重点基础研究发展计划资助项目(2007CB613703);国家“十一五”科技支撑计划资助项目(2007BAE38B00)

收稿日期:2009-06-20;修订日期:2009-12-04

通信作者:谢建新,教授,博士;电话:010-62332254;E-mail:jxxie@mater.ustb.edu.cn

(编辑 何学锋)