液体黏性传动装置摩擦副瞬态热应力耦合

谢方伟,侯友夫

(中国矿业大学 机电工程学院,江苏 徐州,221008)

摘 要:结合热流密度和边界条件,根据热传导理论建立液体黏性传动装置对偶钢片瞬态热应力耦合理论模型,并采用有限元法求解。根据带式输送机实际工况,对摩擦副边界摩擦阶段的瞬态热应力耦合场进行理论和试验研究。研究结果表明:对偶钢片表面温度随对偶钢片半径r增大而升高,但是最高温度出现在r =170 mm处,并不在外径r =180 mm处,原因是外径处对偶钢片与工作油存在对流换热;径向各点的表面温度随边界摩擦时间呈指数关系增长;当边界摩擦时间15 s时,最高温度可达465.9 ℃,表面发生烧伤甚至胶合现象;同时,径向温度分布不均导致内应力的产生,最大热应力达832 MPa,大于材料屈服应力,对偶钢片产生塑性变形。因此,在研究液体黏性传动特性时必须考虑对偶钢片变形,以便为液黏传动装置的设计提供更可靠的理论依据。

关键词:液体黏性;对偶钢片;热应力;边界摩擦;耦合

中图分类号:TB131 文献标志码:A 文章编号:1672-7207(2010)06-2201-06

Transient thermal-stress coupling of friction pair of

hydro-viscous drive device

XIE Fang-wei, HOU You-fu

(School of Mechanical and Electrical Engineering, China University of Mining and Technology, Xuzhou 221008, China)

Abstract: Combining heat flux and boundary conditions of steel disk of hydro-viscous drive (HVD) device, a theory model of transient thermal stress coupling was established based on heat conduction theory. The theory model was solved using finite element method. According to the belt conveyor’s actual conditions, the transient thermal stress coupling field of the steel disk was studied during the stage of boundary friction. The results show that the surface temperature of the steel disk increases with the increase of radius, while the highest temperature appears at r=170 mm, not at outer radius r=180 mm, for there is convection heat transfer between steel disk and working oil at outer radius. The surface temperatures of radial points increase with the increase of boundary friction time exponentially. Simultaneously, uneven radial temperature causes thermal stress. When the boundary friction time is 15 s, the highest temperature reaches 465.9 ℃, and there is burn even scuffing on the steel disk surface. And the thermal stress reaches 832 MPa, which is larger than the material’s yield stress, which causes steel disk’s plastic deformation. Therefore, in order to provide a reliable theoretical basis for the HVD device’s design, steel disk’s deformation must be considered while studying the characteristics of the HVD.

Key words: hydro-viscous; steel disk; thermal-stress; boundary friction; coupling

液体黏性(简称液黏)传动装置是利用摩擦副间油膜的剪切力传递动力,并通过改变油膜的厚度实现无级调速。该装置广泛应用于风机、水泵、带式输送机等大功率重载设备,是节能降耗的优选产品[1-2]。在启动过程中,摩擦副经历液黏摩擦、混合摩擦和边界摩擦3个阶段。通过研究发现:摩擦副在边界摩擦阶段产生大量的热量,表面温度急剧升高,致使摩擦副出现变形、烧伤甚至胶合的现象,最终导致液黏传动装置不能正常运行。因此,有必要开展边界摩擦阶段摩擦副热应力耦合研究,以便准确掌握接合过程中摩擦副瞬态热应力分布规律,为液黏传动装置摩擦副的设计提供可靠的理论依据。

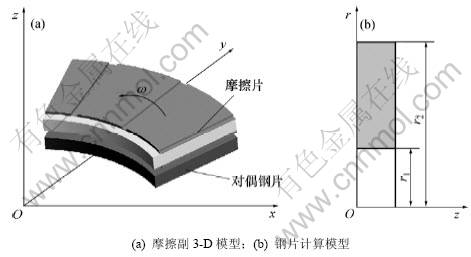

1 理论模型

摩擦副是液黏传动装置传递动力的主要部件,由摩擦片和对偶钢片组成。图1所示为摩擦副1/8几何模型。由于摩擦片上有油槽,油液可以通过油槽流动并带走热量,因此,摩擦片的温度为对偶钢片温度的一半左右。本文作者在研究摩擦副热应力耦合时,仅对对偶钢片进行研究。

液黏传动装置启动时,摩擦副逐渐压紧直至完全接合,此阶段摩擦副间存在滑差,导致热量产生[3-6]。其热流密度为:

(1)

(1)

式中:p为对偶钢片沿径向的分布;ω为摩擦副转速差,r/min;μ为摩擦因数;t为接合过程的时间,s;r和z分别为对偶钢片径向和轴向半径。

摩擦副在小转速差时处于边界摩擦阶段,此时,以表面微凸体接触为主,其间只有极薄的不连续油膜,因此,可忽略工作油吸收的热量,认为摩擦产生的热量全部传递给了摩擦副。对偶钢片的热流密度为:

(2)

(2)

式中: 和

和 分别为对偶钢片和摩擦衬片的密度,kg/m3;c1和c2分别为对偶钢片和摩擦衬片的比热容,J/(kg?℃);k1和k2分别为对偶钢片和摩擦衬片的导热系数,W/(m?℃);q1和q2分别为对偶钢片和摩擦衬片表面的热流密度,W/m2。

分别为对偶钢片和摩擦衬片的密度,kg/m3;c1和c2分别为对偶钢片和摩擦衬片的比热容,J/(kg?℃);k1和k2分别为对偶钢片和摩擦衬片的导热系数,W/(m?℃);q1和q2分别为对偶钢片和摩擦衬片表面的热流密度,W/m2。

对偶钢片接触区是轴对称结构,且旋转轴没有内热源,基于热传导理论,构建圆柱坐标系中对偶钢片的瞬态热传导微分方程:

(3)

(3)

式中: 为对偶钢片的温度。

为对偶钢片的温度。

边界摩擦阶段摩擦副的边界条件为:

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

式中: 和

和 为对偶钢片内、外表面与工作油的换热系数,W/(m2?℃);θe为边界摩擦开始时工作油的温度,℃;h为对偶钢片厚度,mm。

为对偶钢片内、外表面与工作油的换热系数,W/(m2?℃);θe为边界摩擦开始时工作油的温度,℃;h为对偶钢片厚度,mm。

图1 摩擦副几何模型

Fig.1 Geometrical model of friction pair

2 理论求解

采用有限元加权余量法求解对偶钢片非线性瞬态温度场,则微分方程(1)可转化为一个等价泛函求极值问题:

(8)

(8)

根据Galerkin法,可得:

,

,

l=1, 2, 3, …, n (9)

式中: 为温度场的定义域。

为温度场的定义域。

应用Green公式得:

,

,

l=1, 2, 3, …, n (10)

式(10)为对偶钢片瞬态温度场有限元法计算的基本方程。利用已求得的温度场θ(x, r, t),可求得对偶钢片周向应力 和径向应力

和径向应力 :

:

(11)

(11)

(12)

(12)

式中:r1和r2分别为摩擦副内径和外径,mm;E为对偶钢片的弹性模量,K-1; 为对偶钢片的线膨胀系数,GPa。

为对偶钢片的线膨胀系数,GPa。

3 数值计算

3.1 工况分析

以矿用大功率带式输送机实际工况为例,对对偶钢片瞬态热应力耦合行为进行研究。大功率带式输送机启动曲线为Harrision曲线,启动时间为80,120和180 s。根据Harrision曲线的特点和理论分析,得出启动时间与边界摩擦时间和转速差之间的关系如表1所示。受控制策略和摩擦副结构特点的影响,边界摩擦阶段速度波动严重,瞬间产生大量的热量,影响液黏传动装置的正常工作。

表1 启动时间与边界摩擦时间和转速差的关系

Table 1 Relationship between time and speed difference and boundary friction time

3.2 计算参数

以400 kW某液黏传动装置为例,对偶钢片材料为65Mn,弹性模量为210 GPa,泊松比为0.3,热膨胀系数为1.1×10-5 K-1,表面摩擦因数为0.09;其几何参数为:内径130 mm,外径180 mm,厚度6 mm。对偶钢片的热物理性能参数如表2所示。

表2 对偶钢片的热物理性能参数

Table 2 Thermophysical parameters of steel disk

4 计算结果与分析

4.1 温度场分析

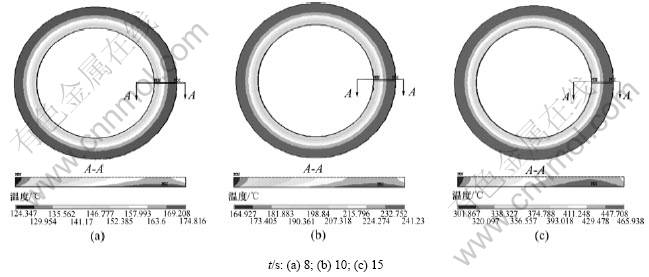

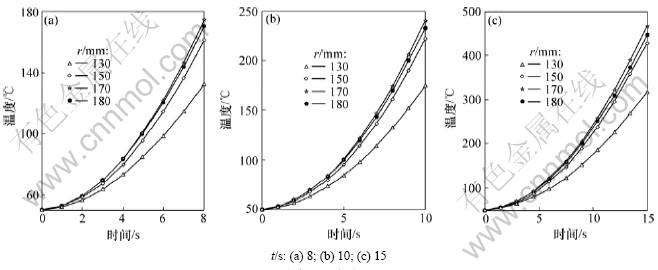

根据带式输送机液黏传动装置实际工况,结合物理模型、热传导模型和边界条件,对对偶钢片瞬态温度场进行数值模拟。图2和图3所示为3种工况下对偶钢片表面温度分布规律。在对偶钢片表面取4点,径向位置r=130,150,170和180 mm,径向各点表面温度随时间的变化曲线如图4所示。

边界摩擦阶段,对偶钢片表面温度最高,随着厚度增加,温度逐渐减小。原因是摩擦副存在转速差,且由于热阻的存在,对偶钢片内部的温度小于表面温度,因此,对偶钢片表面易出现烧伤的现象。

虽然摩擦副在边界摩擦阶段的时间不同,但对偶钢片表面的温度分布规律基本相同:表面温度随半径的增大而升高,但是,最高温度并没有出现在外径r=180 mm处,而是在半径r=170 mm处,原因是外径处对偶钢片与工作油存在对流换热;在内径r=130 mm处,对偶钢片与润滑油的对流换热系数大,所以,内径处温度最低。

图2 3种工况下对偶钢片的表面温度

Fig.2 Surface temperature of steel disk under three conditions

65Mn许用温度为400 ℃。由图2和图3可知:当边界摩擦时间为8 s和10 s时,对偶钢片表面最高温度分别为174.8 ℃和233.2 ℃;当边界摩擦时间15 s时,最高温度可达465.9 ℃,此时,对偶钢片表面温度超过其许用温度,容易产生局部烧伤甚至胶合现象。

径向表面温度随时间呈指数关系增长,原因是边界摩擦阶段摩擦副以表面微凸体接触为主,摩擦副摩擦产生的热量约70%被对偶钢片所吸收。

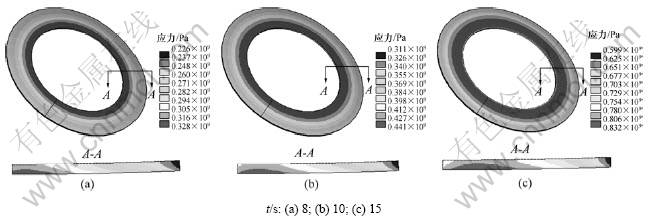

4.2 应力场与变形分析

由热力学可知,温度变化不均匀将导致热应力产生[7-11]。图5所示为3种工况下表面与截面应力场。可以看出:当边界摩擦时间为8 s和10 s时,对偶钢片表面最大热应力均小于许用屈服应力(430 MPa),对偶钢片发生热弹性变形;当边界摩擦时间达到15 s时,表面最大热应力达832 MPa,超过材料屈服应力,对偶钢片产生塑性变形。

由流体动力学可知:对偶钢片变形以后,摩擦副间油膜的动力学行为发生改变,影响液黏传动性能。故目前研究摩擦副时均假设其为刚性平面是不全面的,应对其变形效应及变形对传动性能的影响进行深入研究。

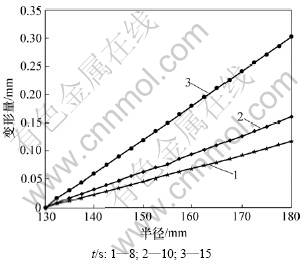

图6所示为3种工况下对偶钢片的变形量。由图6可知:变形量随接合时间的加长而增大,当接合时间为15 s时,最大变形量0.32 mm;变形量与半径近似呈线性关系。因此,实际启动过程中,应尽量减小边界摩擦阶段的时间,以减小对偶钢片的发热量和变形量。

图3 3种工况下的对偶钢片表面与截面温度场

Fig.3 Surface and section temperature field of steel disk under three conditions

图4 径向各点温度随时间的变化

Fig.4 Variation of temperature along radial direction with time

图5 3种工况下的对偶钢片表面与截面应力场

Fig.5 Surface and section stress field of steel disk under three conditions

图6 3种工况下的对偶钢片的变形量

Fig.6 Deformation of steel disk under three conditions

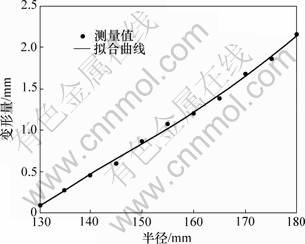

该液黏传动装置现场使用1月后,取出摩擦副,对偶钢片已发生明显的翘曲变形(如图7所示)。图8所示为对偶钢片变形量的实测值与拟合曲线。从图8可以看出:对偶钢片变形量的实测曲线与仿真曲线(图6)变化规律基本相同。

图7 试验变形形貌

Fig.7 Morphology of experimental deformation

图8 对偶钢片变形量的实测值与拟合曲线

Fig.8 Measured data and fitting curve of deformation for steel disk

5 结论

(1) 综合考虑热流密度和边界条件,基于热传导理论建立了对偶钢片瞬态热应力耦合理论模型,并利用有限元法对瞬态温度场进行求解。

(2) 对偶钢片表面温度随半径的增大而升高,但最高温度并没有出现在外径处,而是在半径r=170 mm处,原因是外径处对偶钢片与工作油之间存在对流换热。

(3) 对偶钢片表面温度随边界摩擦时间呈指数关系增长,当边界摩擦时间15 s时,最高温度可达465.9 ℃;对偶钢片热应力达832 MPa,大于屈服应力,对偶钢片发生翘曲变形,因此,在液黏传动装置启动过程中,应尽量减少边界摩擦时间。

(4) 对偶钢片理论变形与实验研究基本一致,变形后摩擦副间油膜的动力学行为发生改变,影响液黏传动装置的传动性能。因此,应对其变形效应及变形对传动性能的影响进行深入研究,为液黏传动装置的设计和控制策略的制定提供可靠的理论依据。

参考文献:

[1] MENG Qing-rui, HOU You-fu. Mechanism of hydro-viscous soft start of belt conveyor[J]. Journal of China University of Mining & Technology, 2008, 18(3): 459-564.

[2] 魏宸官, 赵家象. 液体黏性传动技术[M]. 北京: 国防工业出版社, 1996: 1-3.

WEI Chen-guan, ZHAO Jia-xiang. Hydro-viscous drive technology[M]. Beijing: Defense Industry Press, 1996: 1-3.

[3] Zagrodzki P. Numerical analysis of temperature fields and thermal stresses in the friction discs of a multidisc wet clutch[J]. Wear, 1985, 101(3): 255-271.

[4] ZHOU Man-shan, ZHANG Yuan. Theoretical research on hydroviscous speed-adjusting clutch in soft-start of belt conveyor[J]. Journal of Coal Science & Engineering, 2005, 11(1): 79-82.

[5] 孙冬野, 秦大同, 杨亚联, 等. 湿式多片制动器瞬态温度场有限元分析[J]. 中国公路学报, 1998, 11(4): 116-120.

SUN Dong-ye, QIN Da-tong, YANG Ya-lian, et al. Finite element analysis of transient temperature fields in multiple disc wet brakes[J]. China Journal of Highway and Transport, 1998, 11(4): 116-120.

[6] 洪跃, 刘谨, 金士良. 液体调速离合器中摩擦副热效应的简化分析[J]. 润滑与密封, 2003(5): 6-11.

HONG Yue, LIU Jin, JIN Shi-liang. Simplified thermal effect analysis of frictional disk in speeding wet clutch[J]. Lubrication Engineering, 2003(5): 6-11.

[7] ZHU Zhen-cai, PENG Yu-xing, SHI Zhi-yuan, et al. Three-dimensional transient temperature field of brake shoe during hoist’s emergency braking[J]. Applied Thermal Engineering, 2009, 29: 932-937.

[8] 朱真才, 史志远, 彭玉兴, 等. 提升机盘形制动器闸瓦三维瞬态温度场仿真与试验研究[J]. 摩擦学报, 2008, 23(4): 356-360.

ZHU Zhen-cai, SHI Zhi-yuan, PENG Yu-xing, et al. Simulation and experiment research on three dimensional transient temperature field of brake shoe for winder disc brake[J]. Tribology, 2008, 23(4): 356-360.

[9] 彭玉兴, 朱真才, 陈国安, 等. 摩擦衬垫动态热物性能及其对瞬态温度场的影响[J]. 中南大学学报: 自然科学版, 2009, 40(2): 436-440.

PENG Yu-xing, ZHU Zhen-cai, CHEN Guo-an, et al. Dynamic thermolphysical properties of friction lining and their effect on transient temperature field[J]. Journal of Central South University: Science and Technology, 2009, 40(2): 436-440.

[10] CHEN Ning, YUAN Bin. Study on the soft start-up steadiness of hydro-viscous drive[C]//Proceedings of the Fifth International Symposium on Fluid Power Transmission and Control. Hangzhou, 2007: 652-655.

[11] 庄光山, 王成国, 王海庆, 等. 盘形制动摩擦表面温升研究[J]. 机械工程学报, 2003, 39(2): 150-154.

ZHUANG Guang-shan, WANG Cheng-guo, WANG Hai-qing, et al. Study on temperature rise of friction surface in disc-braking[J]. Chinese Journal of Mechanical Engineering, 2003, 39(2): 150-154.

(编辑 赵俊)

收稿日期:2010-01-18;修回日期:2010-04-15

基金项目:国家自然科学基金资助项目(50975275)

通信作者:谢方伟(1983-),男,安徽萧县人,博士研究生,从事液体黏性传动技术及摩擦副温度-应力耦合行为研究;电话:13813290337;E-mail: cumtxfw@126.com