文章编号:1004-0609(2013)05-1173-09

预时效温度及回归加热速率对7150铝合金显微组织及性能的影响

冯 迪1, 2,张新明1, 2,刘胜胆1, 2,陈 祺1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料与工程教育部重点实验室,长沙 410083)

摘 要:采用硬度、电导率、室温拉伸测试、差示扫描量热分析(DSC)、极化曲线及透射电镜(TEM)观察研究预时效温度及回归加热速率对7150铝合金显微组织及性能的影响。结果表明:合金的抗拉强度对预时效温度敏感,耐腐蚀性能对回归加热速率敏感。再时效后合金的抗拉强度随预时效温度的升高而增加,耐腐蚀性能随回归加热速率的提高而降低。经(65 ℃,24 h)+(4.25 ℃/min)(190 ℃,50 min)+(120 ℃,24 h)的三级时效处理后,7150 铝合金的电导率(IACS)大于36%,抗拉强度损失小于峰时效态(T6)合金强度的3%。

关键词:7150铝合金;回归;预时效温度;力学性能

中图分类号:TG146.2 文献标志码:A

Effect of pre-aging temperature and retrogression heating rate on microstructure and properties of 7150 alloy

FENG Di1, 2, ZHANG Xin-ming1, 2, LIU Sheng-dan1, 2, CHEN Qi1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: Hardness, electrical conductivity, room temperature tensile properties testing, differential scanning calorimetry (DSC), polarization curve and transmission electron microscope (TEM) observation were used to investigate the effect of pre-aging temperature and retrogression heating rate on the microstructure and properties of 7150 aluminum alloy. The results reveal that the tensile strength is sensitive to the pre-ageing temperature, while the corrosion resistance is sensitive to the retrogression heating rate. The tensile strength of the re-aging treated alloy increases with the rise of pre-aging temperature, and the corrosion resistance deteriorates with the increase of retrogression heating rate. After (65 ℃, 24 h)+(4.25 ℃/min)(190 ℃, 50 min)+(120 ℃, 24 h) aging treatment,the electrical conductivity (IACS) of the 7150 aluminum alloy exceeds 36%, and the reduction of ultimate strength is less than 3% of the strength of T6 treatment alloy.

Key words: 7150 aluminum alloy; retrogression; pre-aging temperature; mechanical properties

CINA等[1-2]针对7000系铝合金提出回归再时效(RRA)工艺,经RRA处理后,合金晶内、晶界组织分别与T6、T7态的相似,使合金在保证较高强度的同时具有良好的抗应力腐蚀性能。1989年,SRIVATSAN等[3]在RRA的研究基础上以T77为名注册了世界上第一个三级时效热处理工艺实用规范,回归再时效工艺开始走向实用化阶段。目前,欧美已在航空航天领域广泛使用7150-T7751厚板和挤压件[4],T7751态铝合金不但具有很好的力学和腐蚀性能匹配度,而且厚板性能均匀,各向异性低。在国内RRA的研究起步较晚,虽然针对回归处理时间和温度方面进行了大量的研究工作,但是至今未见RRA工艺在7000系铝合金中厚板方面的工业化应用,而超强高韧铝合金中厚板是具有代表性的航空高性能铝合金制品之一,该类制品力学和抗腐蚀性能的提高及性能均匀性的改善对大飞机工程起着关键作用。

李国峰等[5-6]在预时效为T6状态的条件下研究了回归加热过程中7050铝合金微观组织的演变规律,得出了57 ℃/min的回归升温速率可保证合金的力学和抗应力腐蚀性能的结论。在此基础上,XU等[7]的研究进一步表明:较低的回归加热速率可使厚板表层和心部的升温速率趋于一致,降低升温过程中的温度梯度,从而有利于铝合金中厚板均匀性的提高。韩小磊等[8]认为预时效为欠时效态的回归再时效制度可使7150合金获得强度和抗腐蚀性能的良好匹配。上述研究成果为Al-Zn-Mg-Cu合金T77制度的探索和工业化应用提供了理论基础,但是Al-Zn-Mg-Cu系中厚板性能均匀性的研究应综合考虑以下两个方面:1) 保证中厚板依然具有较优的力学性能和抗腐蚀性能;2) 降低性能的各向异性,特别是降低各向性能的不均匀性。因此,应探索更为合适的预时效处理规范及其与回归加热速率的匹配制度。本文作者针对7150铝合金中厚板回归过程中第二相的回溶与析出不均匀所造成的材料显微组织性能各向异性这一高性能铝合金热处理的难题,研究预时效温度及其与回归加热速率的匹配对该系合金显微组织及性能的影响,为改善Al-Zn-Mg-Cu合金厚板的性能均匀性提供实验及理论基础。

1 实验

1.1 材料及热处理

实验材料为东北轻合金有限公司提供的7150铝合金80 mm厚板(6.22 Zn,1.9 Mg,2.54 Cu,0.08 Zr,0.01 Fe,0.01 Si,余量Al;质量分数,%),已经工业固溶、淬火及预拉伸。在LTD-RD面切取20 mm×15 mm×2 mm片状试样在473 ℃、30 min条件下进行重固溶处理以消除自然时效的影响[9-10],室温水淬后立即进行预时效,预时效制度分别为65 ℃、24 h欠时效和120 ℃、24 h峰时效;由随空气炉缓慢升温及盐浴加热控制回归升温时间,升温速率分别为4.25 ℃/min及1 024 ℃/min,回归制度为190 ℃、0~120 min;再时效制度为120 ℃、24 h峰时效;65 ℃、24 h欠时效慢和快速回归再时效分别标记为HT-1和HT-2,120 ℃、24 h峰时效慢和快速回归再时效分别标记为HT-3和HT-4。取相同回归时间且具有代表性的回归再时效样品进行力学性能及抗腐蚀性能比较,回归及再时效状态分别标记为R-xmin和RRA-xmin,其中,xmin代表回归时间。

1.2 显微组织观察

采用TecnaiG2 20型透射电镜观察典型再时效样品的显微组织,加速电压为200 kV,透射电镜样品直径为3 mm,厚度为0.08 mm,在含20%HNO3(体积分数)的甲醇溶液中进行双喷减薄,温度控制在-25 ℃以下,电压为15~20 V。

1.3 性能检测

在HV-10B小负荷维氏硬度计上测试试样的硬度,载荷为30 N,加载时间为15 s;采用7501涡流导电仪测量试样的电导率;在CSS-44100型试验机上测量合金的室温拉伸性能,按GB/T228—2002标准进行,取样方向为L向。

在NETZSCH STA 449C型热分析仪上对合金进行差示扫描热分析,试样为d 5 mm的圆片,质量约为30 mg。用纯铝作参比样品,试样升温速度为10 ℃/min,温度范围为50~470 ℃。

在 CHI66C 电化学工作站上进行极化曲线扫描,实验在质量分数为3.5%的NaCl溶液中进行,采用Pt作为辅助电极、饱和甘汞电极为参比电极的三电极体系。试样暴露面积为1 cm2。极化曲线测试的动电位扫描速度为2 mV/s,扫描范围为(开路电位±0.3) V。

2 实验结果

2.1 预时效态合金的显微组织和力学性能

图1所示为7150铝合金经65 ℃、24 h和120 ℃、24 h预时效处理后晶内、晶界析出相的显微组织。欠时效态合金的晶内可观察到大量Al3Zr质点, 尺寸为10~20 nm,晶内析出相细小弥散,晶界析出相呈连续分布,未见晶界无沉淀析出带;峰时效态合金晶内、晶界析出相都较欠时效态的粗大,晶界析出相也呈链状连续分布(图1(b)),无沉淀析出带不明显。

由[112]Al晶带轴衍射斑点可知,欠时效态合金在2/3{311}处出现GP区的衍射斑点;在1/3{220}处沿{111}方向出现与η′相相关的微弱芒线。峰时效态下,在1/3{220}和2/3{220}处沿{111}方向出现明锐的衍射斑点[11]。由形貌及衍射斑点可以判断欠时效态晶内析出相为GP区,因此对应较低的硬度(163.43HV);而峰时效态下晶内析出相主要为η′相 η′,硬度较高(195.09HV)。两种预时效状态下的电导率都较低,分别为26.38%(IACS)和28.11%(IACS)。

2.2 硬度和电导率

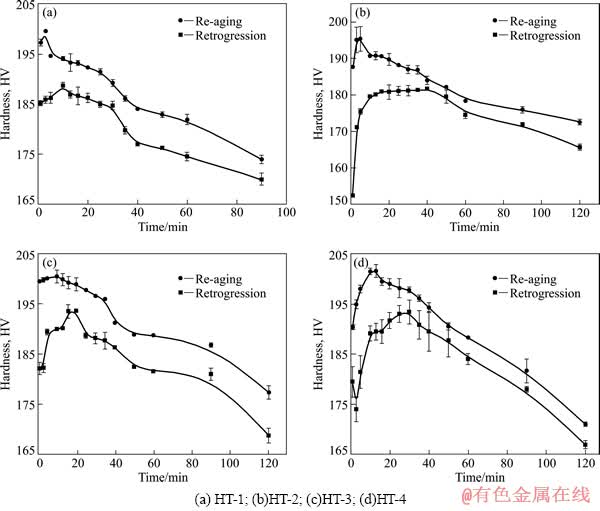

各回归再时效制度下7150铝合金的硬度和电导率曲线分别如图2和3所示。

图1 预时效合金的TEM像

Fig. 1 TEM images of pre-aged alloy

图2 不同预时效及升温速率下7150铝合金的回归及再时效硬度曲线

Fig. 2 Hardness curves of RRA-treated 7150 aluminum alloys under different pre-aging and retrogression heating rate conditions

由图2可知,HT-4的回归态合金硬度曲线随回归时间的延长经历了先下降后上升再下降的过程,各阶段的微观组织演变分别对应于小于临界尺寸预时效析出相的回溶、亚稳相η′相的析出、η′相的粗化及向η相的转变;再时效硬度曲线则经历了先上升再下降的过程,分别对应于η′相的再析出、η′相的粗化及向η相的转变[12-13]。HT-1、HT-2和HT-3的回归硬度曲线则只存在上升→下降两个阶段。其中,HT-1和HT-2样品预时效析出相体积分数较小、尺寸小(图1(a)),HT-1样品在40 min的回归升温过程中就发生了预析出相的继续析出、长大以及回溶,而HT-2样品几乎在瞬时升至回归温度,因此在回归开始的极短时间内就可以回溶完全,HT-3样品虽然预析出完全(图1(b)),但是由于回归加热速率慢、时间长,预时效析出相在升温过程中也发生了回溶、η′相的析出及长大,因而HT-1、HT-2和HT-3样品都未表现出硬度谷值。合金各再时效硬度曲线则具有相同的演变趋势。

为描述方便,将HT-1、HT-2和HT-3样品回归硬度谷值点对应的时间都规定为1 min,各阶段关键点的硬度值及对应时间见表1。

表1 不同处理条件下合金的典型硬度值及对应时间

Table 1 Typical hardness and corresponding time of alloys under different treatment conditions

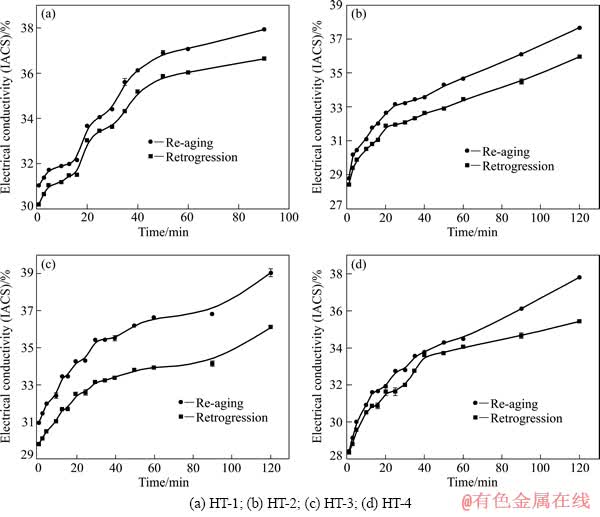

图 3 不同预时效及升温速率下7150铝合金的回归及再时效电导率曲线

Fig. 3 Electrical conductivity curves of RRA-treated 7150 aluminum alloys under different pre-aging and retrogression heating rate conditions

由表1可知,在相同预时效温度下,慢速回归条件下样品达到回归态硬度峰值的时间较快速回归达到回归态硬度峰值的时间较短,且再时效硬度峰值对应的时间也较短。HT-3,HT-4样品的回归及再时效硬度都高于HT-1和HT-2样品的回归及再时效硬度,这说明硬度响应速率对回归加热速率敏感,而硬度对预时效温度敏感。

图3所示为7150铝合金电导率随回归时间的演变曲线。由图3可知,各制度下的回归及再时效态合金的电导率随回归时间的延长单调增加。对于时效态合金,其电导率与析出相对电子的散射作用相关,不同RRA制度下晶界析出相尺寸及分布的差异使电子在晶界附近传导时所受阻碍作用大小不同,从而导致电导率的大小和响应速率不同[14-15]。HT-1和HT-3样品的电导率响应较快,按照美铝7150-T77制度规定合金的电导率(IACS)不低于36%[16]的标准,HT-1和HT-3样品分别在回归40 min及50 min后再时效就能达到标准,而HT-2和HT-4样品的电导率(IACS)则在90 min才达到36%。当回归时间为50 min时,HT-1、HT-2、HT-3和HT-4样品的电导率(IACS)分别为36.90%、34.31%、36.21%和34.31%。由此推断,电导率敏感于回归加热速率,慢速加热有利于电导率的升高。

2.3 室温拉伸性能

考虑回归50 min再时效条件下HT-1和HT-3样品的电导率都达到36%,对各预时效及回归加热速率下RRA-50 min样品进行室温拉伸测试,结果见图4。

图4 不同预时效及回归升温速率下RRA-50 min样品的拉伸性能

Fig. 4 Tensile properties of RRA-50 min samples under different pre-aging and retrogression heating rates conditions

由图4可知:T6态合金的抗拉强度和屈服强度最高,分别为622和598.2 MPa;RRA态合金强度均低于T6态合金强度,其中,HT-4样品的抗拉强度和屈服强度较高,分别为609.4和572.4 MPa,HT-1样品的抗拉强度略低于HT-3的,这两种状态合金的抗拉强度分别为602和605.2 MPa,但是,HT-3样品的屈服强度只有548.9 MPa,远远低于HT-1的屈服强度(572.4 MPa),HT-2样品的抗拉强度最低。各热处理状态下样品的伸长率相差不大,在13%~13.67%之间。力学性能测试表明:抗拉强度对预时效温度敏感,预时效为峰时效的RRA处理样品的抗拉强度高于预时效为欠时效态RRA样品的抗拉强度,这与硬度测试的结果是一致的。

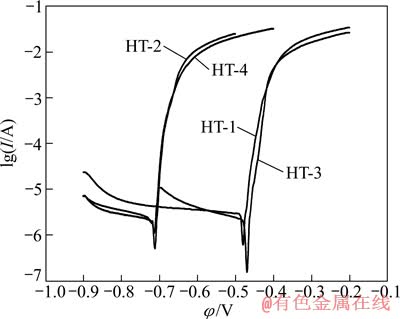

2.4 电化学测试

不同预时效及回归加热速率条件下,RRA-50 min试样的极化曲线如图5所示。其中,慢速回归加热条件下试样的自腐蚀电位(>-0.5 V)高于快速回归加热条件试样的自腐蚀电位 (<-0.7 V),自腐蚀电位越低,腐蚀倾向越大[17]。

图5 不同预时效及回归升温速率下RRA-50 min样品的极化曲线

Fig. 5 Polarization curves of RRA-50 min samples under different pre-aging and retrogression heating rates conditions

对图5所示极化曲线进行分析可知,各状态试样的腐蚀电流密度J(电流除以试样暴露面积)的关系如下:JHT-2(5.187 μA/cm2)>JHT-4 (3.975 μA/cm2)>JHT-3 (3.592 μA/cm2)>JHT-1(2.278 μA/cm2),腐蚀电流密度越高,腐蚀越快,因此,快速回归加热条件下的腐蚀速率较快。这从动力学方面进一步验证了电导率的测试结果。电化学测试结果表明,7150铝合金的抗腐蚀性能对回归加热速率敏感,慢速回归加热有利于合金抗腐蚀性能的提高。

2.5 DSC分析

图6所示为不同预时效和回归加热速率下RRA-50 min样品的DSC曲线。190~210 ℃温度范围内的A峰代表GP区和η′亚稳相的回溶;220~280 ℃温度区间内的B峰对应η′相的再次析出,C峰对应η平衡相的析出及 Ostwald熟化。吸热峰D对应η相的回溶;高温放热峰E则代表S相的析出[18]。

图6 不同预时效及回归速率下RRA-50 min样品的DSC曲线

Fig. 6 DSC curves of RRA-50min sample under different pre-aging and retrogression rate conditions

由于加热过程中可同时发生多个反应,因此,部分峰之间发生了重叠,导致峰形不明显。反应峰面积对应沉淀相析出或溶解的体积分数,对A峰进行峰面积(A)拟合得到:A4>A3>A1、A2,其中A1、A2相差不大,因此,可半定量地推测,预时效为峰时效状态试样经再时效后,其组织中的GP区及η′相的总体积分数相对较大,且快速升温回归处理样品的GP区及η′相体积分数也较慢速升温回归处理样品的GP区及η′相体积分数大;预时效为欠时效状态试样经不同回归加热速率及再时效后,GP区及η′相的总体积分数相差不大。再对D峰(η相的回溶峰)进行峰面积(D)拟合得到:D3>D2>D4>D1, 这说明HT-2和HT-3样品的η相体积分数大于HT-1和HT-4样品的体积分数。η′相为Al-Zn-Mg-Cu系的主强化相,η′相体积分数越大,则材料的强度相应越高,而η相与基体不共格,其强化作用较η′相的弱,因此对应较低的力学性能。综合A、D反应峰面积拟合结果可知:HT-3和HT-4样品由于GP区及η′相体积分数较大,因此对应较高的强度和硬度,而虽然HT-1和HT-2样品非平衡相体积分数差别不大,但是由于HT-2样品中η相体积分数较大,因此,其抗拉强度低于HT-1样品的抗拉强度。DSC分析结果与硬度及力学性能测试结果一致。

2.6 显微组织观察

图7所示为不同RRA制度下晶内、晶界析出相形貌TEM明场像及选区衍射斑点。对晶内析出相进行统计得到HT-1、HT-2、HT-3和HT-4制度下析出相尺寸分别为12.3、12.8、13.5和12.3 nm。虽然预时效温度及回归速率不同,但各制度样品都经相同的回归时间和峰值再时效,因此各状态下晶内析出相比T6态晶内析出相(图1(b))尺寸稍大,但彼此差别不大。

预时效为欠时效处理的回归再时效样品(图7(a),(b))对应[ 12]Al晶带轴选区衍射斑点,HT-1和HT-2样品在1/3{311}和2/3{311}处出现GP区的模糊斑点,其中HT-1样品在1/3{220}和2/3{220}处沿{111}方向出现η′相的明锐斑点,而HT-2样品(图7(b))在1/3{220}处的η′相斑点较模糊,只在{111}方向出现对应η′相的芒线[19];预时效为峰时效的回归再时效样品对应[011]Al晶带轴选区衍射斑点,在1/3{31

12]Al晶带轴选区衍射斑点,HT-1和HT-2样品在1/3{311}和2/3{311}处出现GP区的模糊斑点,其中HT-1样品在1/3{220}和2/3{220}处沿{111}方向出现η′相的明锐斑点,而HT-2样品(图7(b))在1/3{220}处的η′相斑点较模糊,只在{111}方向出现对应η′相的芒线[19];预时效为峰时效的回归再时效样品对应[011]Al晶带轴选区衍射斑点,在1/3{31 }和2/3{31

}和2/3{31 }处均出现η′相的明锐斑点[20]。衍射斑点的强弱可间接反映析出相的体积分数,因此,HT-1、HT-3和HT-4样品中η′相体积分数较大,HT-2样品中GP区的体积分数相对较大,而GP区的强化效果低于η′相的强化效果,这解释了DSC曲线中虽然HT-2样品的A峰面积与HT-1样品的A峰面积相似但强度较低的原因。

}处均出现η′相的明锐斑点[20]。衍射斑点的强弱可间接反映析出相的体积分数,因此,HT-1、HT-3和HT-4样品中η′相体积分数较大,HT-2样品中GP区的体积分数相对较大,而GP区的强化效果低于η′相的强化效果,这解释了DSC曲线中虽然HT-2样品的A峰面积与HT-1样品的A峰面积相似但强度较低的原因。

经65 ℃、24 h和120 ℃、24 h慢回归再时效,晶界析出相呈粗大、不连续分布(HT-1和HT-3),晶界无沉淀析出带较宽,分别约为65.68和57.58 nm(图7(e),(g))。其中,65 ℃、24 h慢回归再时效样品的晶界析出相完全断开;经65 ℃、24 h和120 ℃、24 h快回归再时效后,晶界析出相尺寸相对较小,HT-4样品的晶界析出相呈断续分布,而HT-2样品的晶界析出相则呈连续分布状态,晶界完全被析出相覆盖,且快速回归再时效试样的无沉淀析出带明显变窄,约为40 nm。研究表明[21]:完全断开的晶界析出相在应力腐蚀开裂过程中能有效阻碍阳极通道的形成,有利于提高合金的抗应力腐蚀性能。

图7 7150铝合金RRA-50 min试样晶内、晶界析出相的TEM明场像及选区衍射斑点

Fig. 7 Bright field TEM images and selected area diffraction spots of precipitates in matrix and grain boundary of 7150 aluminum alloy of RRA-50 min samples

3 分析与讨论

等[22]的研究表明:在20~70 ℃的时效温度范围内,Al-Zn-Mg-Cu合金的主要析出反应是GP区的形核和长大,其体积分数与时间呈对数增长关系。当时效温度在80~100 ℃时,GP区体积分数与时间呈线性增长关系,而η′相在100~160 ℃范围内才开始形成。结合TEM明场像和衍射斑点可知,65 ℃、24 h预时效样品的晶内析出相基本为细小的GP区 (图1(a)),在快速升温过程中,绝大部分GP区来不及回溶或长大转变为η′相的形核核心。回归过程中,小于临界尺寸的预析出GP区大量溶解,这极大地提高了溶质原子固溶度,为回归过程中η′ 相的大量析出以及η相的直接析出提供条件。由于回归过程中溶质原子被消耗,且缺乏足够的η′相形核核心,导致再时效过程中η′强化相的再次析出动力下降,因此,HT-2样品的η′体积分数较小,而GP区和η相体积分数较大,粗化程度高,因此,HT-2样品的硬度和强度较低。慢速回归升温条件下,GP区有足够的时间形核和长大,在回归处理时,只有一部分小于临界尺寸的GP区回溶,而大尺寸GP区粗化,由于GP区的存在降低了溶质原子的过饱和度,η′ 相及η相不会在回归过程中大量析出,回归结束后的组织既为再时效提供了大量η′ 相的形核核心,又保证了溶质原子饱和程度,使得HT-1样品中η′ 相的体积分数大于HT-2样品中η′相的体积分数,且η相较少,因此其硬度及强度高于HT-2样品的硬度及强度。120 ℃、24 h预时效样品晶内析出完全,存在大量η′相及一小部分GP区,在快速加热条件下,其回归初始组织与预时效基本相同,小尺寸析出相在回归过程中回溶,其回归结束组织与65 ℃、24 h预时效慢速回归结束相类似,但是由于预时效产生大量的η′相部分可能仍存在于再时效组织中,因此,HT-4样品的硬度和强度更高。峰时效后慢速回归则导致析出相粗化的程度增大,再时效后溶质浓度的下降及缺乏有效的形核核心,导致HT-3样品中η′相的体积分数较小,η相增多,因此,其硬度和强度低于HT-4样品的硬度和强度。

等[22]的研究表明:在20~70 ℃的时效温度范围内,Al-Zn-Mg-Cu合金的主要析出反应是GP区的形核和长大,其体积分数与时间呈对数增长关系。当时效温度在80~100 ℃时,GP区体积分数与时间呈线性增长关系,而η′相在100~160 ℃范围内才开始形成。结合TEM明场像和衍射斑点可知,65 ℃、24 h预时效样品的晶内析出相基本为细小的GP区 (图1(a)),在快速升温过程中,绝大部分GP区来不及回溶或长大转变为η′相的形核核心。回归过程中,小于临界尺寸的预析出GP区大量溶解,这极大地提高了溶质原子固溶度,为回归过程中η′ 相的大量析出以及η相的直接析出提供条件。由于回归过程中溶质原子被消耗,且缺乏足够的η′相形核核心,导致再时效过程中η′强化相的再次析出动力下降,因此,HT-2样品的η′体积分数较小,而GP区和η相体积分数较大,粗化程度高,因此,HT-2样品的硬度和强度较低。慢速回归升温条件下,GP区有足够的时间形核和长大,在回归处理时,只有一部分小于临界尺寸的GP区回溶,而大尺寸GP区粗化,由于GP区的存在降低了溶质原子的过饱和度,η′ 相及η相不会在回归过程中大量析出,回归结束后的组织既为再时效提供了大量η′ 相的形核核心,又保证了溶质原子饱和程度,使得HT-1样品中η′ 相的体积分数大于HT-2样品中η′相的体积分数,且η相较少,因此其硬度及强度高于HT-2样品的硬度及强度。120 ℃、24 h预时效样品晶内析出完全,存在大量η′相及一小部分GP区,在快速加热条件下,其回归初始组织与预时效基本相同,小尺寸析出相在回归过程中回溶,其回归结束组织与65 ℃、24 h预时效慢速回归结束相类似,但是由于预时效产生大量的η′相部分可能仍存在于再时效组织中,因此,HT-4样品的硬度和强度更高。峰时效后慢速回归则导致析出相粗化的程度增大,再时效后溶质浓度的下降及缺乏有效的形核核心,导致HT-3样品中η′相的体积分数较小,η相增多,因此,其硬度和强度低于HT-4样品的硬度和强度。

由于Al-Zn-Mg-Cu系合金具有晶界优先析出倾向,因此,低温长时间的欠时效处理以及峰时效状态下其晶界析出都较为充分(图1),与快速加热相比,慢速回归加热实际上延长了回归时间,更多的溶质原子有足够的时间向晶界扩散,使得晶界析出相在回归过程中的粗化及不连续程度大大增加,同时增加了PFZ的宽度。此外,Al-Zn-Mg-Cu合金晶界析出相Cu元素含量的增加将降低晶界析出相的电化学活性,提高其自腐蚀电位(图5中HT-1和HT-3样品),从而降低阳极反应速率,提高抗SCC腐蚀性[23-26]。由于Al基体中Cu元素在150 ℃时才开始向晶界沉淀相扩散[19],当回归加热速率为4.25 ℃/min时,Cu元素向晶界沉淀相扩散的时间是9.4 min,这极大地增加了Cu向晶界析出相的扩散量。由阳极溶解理论可知,由于慢速升温回归有效降低了晶界阳极相的电化学活性,降低阳极溶解速率、粗化、断开的晶界析出相有利于阻断腐蚀通道,从而使合金的抗腐蚀性能大幅提高,因此,HT-1和HT-3样品表现出比HT-2和HT-4样品更高的电导率及更低的腐蚀电流密度。

由以上分析可知,预时效温度对再时效后合金的抗拉强度有明显的影响,再时效后抗拉强度随预时效温度的升高而提高;回归加热速率对晶界析出相的形貌及分布影响更大,晶界析出相的粗化程度和分布的不连续性随加热速率的降低而增大。

4 结论

1) 预时效温度和回归加热速率对回归再时效合金的力学和抗腐蚀性能影响显著。再时效态合金的抗拉强度对预时效温度敏感,而其抗腐蚀性能对回归加热速率敏感。合金的抗拉强度随着预时效温度的提高而增高,抗腐蚀性能随着回归加热速率的降低而提高。预时效温度与回归加热速率的优化组合,可使合金获得强度与抗腐蚀性能的良好匹配。

2) 经欠时效/峰时效+(4.25 ℃/min)190 ℃回归+峰时效的三级时效处理后,合金的抗拉强度损失均小于峰时效态(T6)合金强度的3%,电导率(IACS)大于36%。其中,经(65 ℃,24 h)+(4.25 ℃/min)(190 ℃,50 min)+(120 ℃,24 h)的回归再时效处理后,合金的抗拉强度、屈服强度、伸长率和电导率(IACS)分别为601.9 MPa、573.1 MPa、13.3%和36.9%。此回归再时效制度在保证强度和电 导率的同时,由于慢速回归加热延长了的回归处理时间,减小了厚板高向温度梯度,因此,有利于7150铝合金厚板均匀性的改善,适用于工业化生产。

REFERENCES

[1] CINA B. Reducing the susceptility of alloys, particularly aluminium alloys, to stress cracking: USA, 3856584[P]. 1974-12-24.

[2] TALIANKER M, CINA B. Retrogression and reaging and the role of dislocations in the stress corrosion of 7000-type aluminum alloys[J]. Metallurgical and Materials Transactions A, 1989, 20(10): 2087-2092.

[3] SRIVATSAN T S, GURUPRASAD G, VASUDEVAN V K. The quasi static deformation and fracture behavior of aluminum alloy 7150[J]. Materials and Design, 2008, 29(4): 742-751.

[4] SRIVATSAN T S. The low cycle fatigue and cyclic fracture behaviour of 7150 aluminium alloy[J]. International Journal of Fatigue, 1991, 13(4): 313-321.

[5] 李国峰, 张新明, 李鹏辉. 7055合金在回归加热过程中组织演变[J]. 稀有金属材料与工程, 2011, 40(7): 1295-1299.

LI Guo-feng, ZHANG Xin-ming, LI Peng-hui. Microstructure evolution rules for aluminum alloy 7050 during retrogression heating up[J]. Rare Metal Materials and Engineering, 2011, 40(7): 1295-1299.

[6] LI Guo-feng, ZHANG Xin-ming, LI Peng-hui, YOU Jiang-hai. Effects of retrogression heating rate on microstructures and mechanical properties of aluminum alloy 7050[J]. Transactions of Nonferrous Metals Society of China, 2010, 40(7): 935-941.

[7] XU D K, BIRBILIS N, ROMETSCH P A. The effect of pre-ageing temperature and retrogression heating rate on the strength and corrosion behaviour of AA7150[J]. Corrosion Science, 2012, 54(1): 17-25.

[8] 韩小磊, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋. 欠时效态7150合金的高温回归时效行为[J]. 中国有色金属学报, 2011, 21(1): 80-87.

HAN Xiao-lei,XIONG Bai-qing,ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng. High-temperature retrogression behavior of under-aged 7150 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 80-87.

[9] OLIVEIRA Jr A F, de BARROS M C, CARDOSO K R, TRAVESSA D N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys[J]. Materials Science and Engineering A, 2004, 379(1/2): 321-326.

[10] SALAZAR-GUAPURICHE M, ZHAO Y Y, PITMAN A, GREENE A. Variations of properties across plate thickness for Al alloy 7010[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(6): 1258-1263.

[11] BERG L K,  J, HANSEN V, LI X Z, KNUTSON W M, WATERLOO G, SCHRYVERS D, WALLENBERG L R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49(17): 3443-3451.

J, HANSEN V, LI X Z, KNUTSON W M, WATERLOO G, SCHRYVERS D, WALLENBERG L R. GP-zones in Al-Zn-Mg alloys and their role in artificial aging[J]. Acta Materialia, 2001, 49(17): 3443-3451.

[12] LI X Z, HANSEE L,  J, WALLENBERG L R. HREM study and structure modeling of the η′ phase—The hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materialia, 1999, 47(9): 2651-2659.

J, WALLENBERG L R. HREM study and structure modeling of the η′ phase—The hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materialia, 1999, 47(9): 2651-2659.

[13] PARK J K, ARDELL A J. Effect of retrogression and reaging treatments on the microstructure of Al-7075-T651[J]. Metallurgical and Materials Transactions A, 1984, 15(8): 1531-1543.

[14] TADAKAZU O,YOSHIAKI T.Improvement of fracture toughness in 7475 aluminum alloy by the RRA(Retrogression and re-aging) process[J].Materials Transactions, 1989, 30(8): 601-607.

[15] 曹明盛. 物理冶金基础[M]. 北京: 冶金工业出版社, 1985: 158-159.

CAO Ming-sheng. Foundations of physical metallurgy[M]. Beijing: Metallurgical Industry Press, 1985: 158-159.

[16] AMS 4252B. Aluminum alloy, plate 6.4Zn-2.4Mg-2.2Cu-0.12Zr (7150-T7751) solution heating treated, stress relieved, and over aged[S]. 2005.

[17] MANSFELD F. Tafel slopes and corrosion rates obtained in the pre-Tafel region of polarization curves[J]. Corrosion Science, 2005, 47(12): 3178-3186.

[18] VIANA F, PINTO A M P, SANTOS H M C, LOPES A B. Retrogression and re-aging of 7075 aluminium alloy: Microstructural characterization[J]. Journal of Materials Processing Technology, 1999, 92/93: 54-59.

[19] CHEN J Z, ZHEN L Z, YANG S J, SHAO W Z, DAI S L Investigation of precipitation behavior and related hardening in AA7055 aluminum alloy[J]. Materials Science and Engineering A, 2009, 500(1/2): 34-42.

[20] SHA G, CEREZO A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050)[J]. Acta Materialia, 2004, 52(15): 4503-4516.

[21] LI J F, BIRBILISC N, LI C X, JIA Z Q, CAI B, ZHENG Z Q. Influence of retrogression temperature and time on the mechanical properties and exfoliation corrosion behavior of aluminium alloy AA7150[J]. Materials Characterization, 2009, 6(11): 1334-1341.

[22]  T, LENDVAI J, KOVACS I, GROMA G,

T, LENDVAI J, KOVACS I, GROMA G,  E. The decomposition of the solid solution state in the temperature range 20-200 ℃ in an Al-Zn-Mg alloy[J]. Journal of Materials Science, 1979, 14: 671-679.

E. The decomposition of the solid solution state in the temperature range 20-200 ℃ in an Al-Zn-Mg alloy[J]. Journal of Materials Science, 1979, 14: 671-679.

[23] HARDWICK D A, THOMPSON A W, BERNSTEIN I M. The effect of copper content and heat-treatment on the hydrogen embrittlement of 7050-type alloys[J]. Corrosion Science, 1988, 28(12):1127-1137.

[24] WLOKA J, HACK T, VIRTANEN S. Influence of temper and surface condition on the exfoliation behaviour of high strength Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2007, 49(3): 1437-1449.

[25] MARLAUD T, MALKI B, HENON C, DESCHAMPS A, BAROUX B. Relationship between alloy composition, microstructure and exfoliation corrosion in Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2011, 53(10): 3139-3149.

[26] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划项目 (2012CB619505)

收稿日期:2012-06-19;修订日期:2012-11-26

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail:xmzhang@csu.edu.cn