DOI: 10.11817/j.issn.1672-7207.2018.08.002

脱气处理对微细白钨颗粒疏水聚团行为的影响

陈昊,欧乐明,周伟光

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:通过沉降试验、Zeta电位测定和显微镜观察试验,研究油酸钠体系下脱气处理对微细粒白钨矿疏水聚团行为的影响。研究结果表明:加热脱气能显著脱除水中溶解气核,且脱气后气体再次溶解速度缓慢,为后续试验稳定性和可靠性提供了保证;在脱气水中,微细白钨颗粒沉降行为与油酸钠浓度密切相关,当油酸钠浓度较低时,脱气处理后矿浆浊度增大,说明脱气处理促进白钨颗粒分散,当油酸钠浓度较高时,脱气水对应矿浆浊度较小;脱气水中白钨颗粒表面负电性增强,颗粒间静电排斥增强,不利于白钨颗粒间疏水聚团;脱气处理后,白钨颗粒间疏水聚团能力减弱;当油酸钠浓度较高时,未脱气矿浆溶液中固体颗粒由于气核的桥联作用可能形成链状或网状絮团结构,颗粒沉降时浮力增大,从而导致测定矿浆浊度反而较大。

关键词:脱气处理; 气核;疏水聚团; 微细粒白钨; 油酸钠

中图分类号:TD921 文献标志码:A 文章编号:1672-7207(2018)08-1851-06

Influence of degassing on aggregation of ultra-fine scheelite particles

CHEN Hao, OU Leming, ZHOU Weiguang

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: The influence of degassing on aggregation of ultra-fine scheelite was studied through sedimentation test, Zeta potential measurement and microscopic observation. The results show that gas nuclei in water can be removed by heating, and the dissolution rate of gas is slow after degassing, which provides guarantee for the stability and reliability of experiments. The settling behavior of ultra-fine scheelite particles is closely related to the concentration of sodium oleate (NaOl) in the degassing water. When the concentration of NaOl is low, the turbidity of the mineral suspension increases when water is degassed, which suggests that the degassing promotes the dispersion of the scheelite particles, while the turbidity of the degassing aqueous dispersion is low when the NaOl concentration is high. The surface of scheelite particles is more negatively charged in the degassing water, thus enhancing the electrostatic repulsion between the particles, which is not conducive to the aggregation. The ability of aggregation of particles is reduced in the degassing water. In the case of high NaOl concentration, solid particles in the non-degassing slurry may form aggregates with chain or network structure due to the bridging effect of the gas nuclei, and therefore the buoyancy of aggregates increases sharply, resulting in the high turbidity in the measurements.

Key words: degassing; gas nuclei; hydrophobic aggregation; ultra-fine scheelite; sodium oleate

浮选过程往往伴随着大量矿泥存在。例如,白钨性脆,且多为细粒嵌布,在磨矿过程中易过粉碎,从而产生大量钨细泥[1-2]。这些矿泥的存在给工业生产带来诸多问题,如降低浮选指标,导致后续沉降脱水困难等[3]。为实现细泥高效分选,国内外研究者提出了许多解决方案,主要包括疏水聚团分选、选择性絮凝和微泡浮选等[4-5]。与其他方案相比,疏水聚团调控操作简单,工艺成熟,在有色金属选矿过程中应用最广泛。在工业生产中,常常通过添加表面活性剂的方法扩大目的矿物和脉石矿物表面亲疏水性差异,促进目的矿物疏水聚团从而实现高效分选。但对于微细矿物颗粒,由于其比表面积较大,仅通过表面活性剂调控矿物表面疏水聚团,不但消耗大量药剂,增大药剂成本,而且会对后续回水利用带来诸多问题[6]。另一方面,溶液中存在大量微纳米气核(微纳米气泡),这些气核能够选择性地吸附在疏水矿物表面,增强矿物表面疏水性[7]。同时,大量微纳米直径的气核能够通过桥联作用促进矿物颗粒间疏水聚团[8]。当浮选气泡存在时,由于微纳米气核存在,颗粒和气泡间气泡/颗粒作用模式将被气泡/气核/颗粒作用模式取代,这有助于浮选气泡在矿物表面附着,实现微细矿物颗粒的高效捕收[9-10]。微纳米气核的这一作用在煤矿、磷矿、铁矿、闪锌矿和黄铜矿的浮选研究过程中得到了有效应用[10-12]。溶解气体含量是影响微纳米气核性质的重要影响因素之一[13]。ZHOU等[14]在研究水力空化过程中发现,增加充气量并不能降低空化发生阈值,但可以显著增加空化过程产生的微纳米气泡直径。ZHANG等[15]发现不同气体产生的微纳米气泡性质之间存在差异,与氧气和氮气相比,二氧化碳气体由于溶解度较大,能够产生更多的微纳米气泡,但稳定性较弱。在浮选体系中,矿浆溶解气体质量浓度是影响矿物颗粒疏水聚团的重要因素,也将影响最终浮选指标[16],但人们对其相关机理研究不多。研究溶解气体质量浓度对矿物疏水聚团行为的影响,有助于理解溶解气核与矿物颗粒间相互作用关系,对深入了解微纳米气核促进矿物颗粒疏水聚团、强化微细粒矿物颗粒浮选回收具有重要意义。实践中,主要通过外加通气和脱气的方法改变溶液中溶解气体质量浓度,人们通过外加通气的方法改变溶液中溶解气体质量浓度,而对脱气后矿物颗粒聚集/分散行为的研究较少。为此,本文作者采用加热处理的方式对溶液进行脱气处理,并通过沉降试验、Zeta电位测定和显微镜观察等手段,揭示脱气处理前后矿浆中微细白钨颗粒疏水聚团行为的变化,并对其机理进行分析。

1 实验

1.1 矿样与试剂

白钨矿取自湖南辰州矿业公司钨浮选摇床精矿。经过重选、磁选除去其中的黑钨矿及其他杂质,并反复用蒸馏水洗涤得到白钨单矿物。X线衍射和化学分析结果表明:样品中WO3质量分数为80.24%,纯度为99.64%。矿样经细磨、筛分、水析后得到粒度小于10 μm的样品。白钨矿样粒度检测结果如下:筛下累积体积分数为10%,50%和90%的粒度分别为0.991,3.685和9.699 μm,体积平均粒径为4.608 μm。试验所用NaOl,HCl和NaOH均为分析纯;试验用水为超纯水(电阻率为18.2 MΩ·cm,Smart-S15型超纯水机)。

1.2 脱气水的制备和表征

脱气水由超纯水经水浴加热至80 ℃,保温4 h后密封,冷却至室温制得[17]。试验水样含氧量通过CN61M便携式DO测定仪测定。二氧化碳质量浓度通过TOC-L型总有机碳分析仪测定。先将超纯水煮沸后测定无机碳质量浓度作为基底值,再测定试验水样的无机碳质量浓度,试验水样的无机碳质量浓度减去基底值换算后即为水中游离二氧化碳质量浓度。

1.3 沉降试验

取0.5 g白钨矿加入100 mL试验水样中,调节pH。加入一定量的NaOl溶液后,通过磁力搅拌器匀速搅拌3 min。在距离液面2 cm处移取5 mL悬浮液加入至沉降管中,加水稀释至50 mL,充分混匀后静置沉降3 min。沉降完毕后,在距离液面5 cm处吸取悬浊液2 mL移入标准比色瓶中,加水稀释至25 mL后,用WGZ-3型散射光浊度仪测量试样浊度。

1.4 动电位测试

将白钨矿纯矿物用玛瑙研钵细磨至粒径小于5 μm,每次称取30 mg矿物放入容量为100 mL的烧杯中,加入50 mL试验用水,调节pH后,加入NaOl溶液搅拌5 min。停止搅拌后,将矿浆静置5 min,随后取上清液进行动电位测试。试验采用Malvern Zetasizer Nano ZS90型Zeta电位分析仪,以浓度为 0.01 mol/L的硝酸钾溶液为背景电解质溶液,每次试样测定3次后取平均值。

1.5 显微镜观察试验

按照沉降试验条件对白钨矿样进行调浆处理后,移取少量矿浆滴在载玻片上,在Olympus CX31型透射光显微镜下观察矿物的分散/聚集状态。为了保证图片具有代表性,每次试样制备3份,每份拍取5张图片,利用图像分析软件Image Pro Plus对所有图片进行统计学分析,并选取代表性图片予以展示。

2 结果与讨论

2.1 脱气水表征试验

图1所示为脱气处理前后水中氧气、二氧化碳质量浓度的变化。由图1可知:脱气处理后水中溶解氧和二氧化碳质量浓度降低50%以上,说明该研究方法能够有效脱除水中溶解气体;但脱气处理后水中仍存在氧气和游离的二氧化碳,这说明单纯通过加热脱气手段很难完全脱除水中溶解气体。ZHANG等[18]的研究结果表明,脱气处理后,一些微纳米气核会发生兼并,然后在浮力的作用下上浮,而另一部分则不受影响。脱气处理是调控溶液中微纳米气核质量浓度的有效手段。

图1 脱气前后超纯水中氧气和二氧化碳质量深度

Fig. 1 Mass concentration of oxygen and carbon dioxide in ultra-pure water before and after degassing

2.2 白钨矿颗粒沉降试验

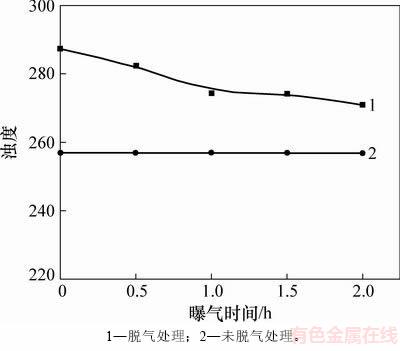

图2所示为曝气时间对白钨颗粒沉降行为的影响。从图2可知:随着曝气时间延长,脱气水制备白钨矿浆的浊度呈缓慢下降趋势,但在2 h内,矿浆浊度变化幅度不大,这说明脱气后气体再次溶解于水的速度较慢。因此,在浊度试验测量时间范围(30 min)内,可以忽略气体再溶解对脱气水性质的影响。同时,用脱气水制备的白钨矿浆的浊度始终高于未脱气水对应矿浆的浊度,说明此时白钨颗粒更加分散。由于在脱气前后,试样只有溶解气体质量浓度(微纳米气核)发生了变化,这说明溶液中原始微纳米气核对矿物颗粒聚集/分散行为具有重要影响。ZHOU等[19]发现了类似现象,并认为这与微纳米气核在矿物表面的吸附有关。同时,在试验过程中,矿浆中无表面活性剂加入,白钨矿天然疏水性并不强,在纯水中接触角为42°[20],这说明微纳米气核在矿物表面的吸附并不需要很强的疏水性。SIMONSEN等[21]的研究表明,微纳米气核在中等疏水度表面即能够有效吸附。

图2 曝气时间对白钨颗粒沉降行为的影响

Fig. 2 Effect of aeration time on turbidity of scheelite suspension

图3所示为油酸钠浓度对白钨颗粒沉降行为的影响。从图3可知:随着油酸钠浓度增大,矿浆浊度先迅速降低,并在油酸钠浓度达到(3~4)×10-4 mol/L时降至最低。这是因为随油酸钠浓度增大,白钨颗粒表面疏水性不断增强,疏水聚团能力增强,颗粒表观粒径增大,导致矿浆浊度降低。随着油酸钠浓度进一步增大,测定的矿浆浊度稍微增大并在5×10-4 mol/L后基本保持稳定。这是由于此时白钨颗粒表面药剂吸附达到饱和,疏水性不再增加。另一方面,当油酸钠浓度较低时,未脱气水制备矿浆的浊度显著低于脱气水制备矿浆的浊度。这是由于脱气处理后,溶液中微纳米气核数量急剧减少,使得附着在白钨颗粒表面的微纳米气核减少,颗粒表面疏水性降低。与此同时,微纳米气核对颗粒的桥联聚团作用减弱,从而导致矿浆中白钨颗粒更加分散。当油酸钠浓度较高(大于3.5×10-4 mol/L)时,由未脱气水制备的矿浆浊度更大,这是由于微纳米气核和油酸钠共同作用能够促进微细矿物颗粒间形成网状絮团结构[22],导致颗粒沉降时,浮力显著增大,从而测定的浊度更大。

图3 油酸钠浓度对白钨矿浆浊度的影响(pH=8)

Fig. 3 Effect of NaOl concentration on turbidity of scheelite suspension

图4所示为矿浆pH对白钨颗粒沉降行为的影响。从图4可知:当溶液中无油酸钠时,随pH增大,白钨矿浆浊度先缓慢降低,并在pH=8附近达到最低值;此后,随着pH继续增大,矿浆浊度变化幅度不大。矿浆浊度的变化可能是pH的改变影响了白钨表面电位和静电力,导致白钨颗粒聚集/分散行为发生改变。但整体而言,当不添加表面活性剂时,矿浆浊度随pH变化幅度不大。当溶液中添加油酸钠(浓度为5×10-4 mol/L)时,矿浆浊度显著降低。油酸钠在矿物表面的吸附导致颗粒疏水性增强,促进了矿物颗粒疏水聚团和微细颗粒沉降,从而降低了矿浆浊度。另一方面,矿浆浊度随pH变化更加明显,在酸性和弱碱性条件下,矿浆浊度较低(pH=7附近对应矿浆浊度最低);此后,随pH增大,矿浆浊度迅速增大,并在pH=10.5附近接近不添加油酸钠情况下矿浆浊度。刘旭等[20, 23]通过研究发现,在油酸钠体系中,白钨矿浆浊度随pH变化也呈现出类似规律,并认为矿浆浊度随pH的变化可能与不同pH下油酸钠溶液的溶解组分及其在矿物表面的吸附行为有关。经对比发现:当溶液中无表面活性剂时,利用脱气水制备矿浆对应浊度始终大于未脱气水样制备矿浆的浊度,再次证明水中溶解的微纳米气核对白钨矿浆浊度有显著影响。脱气后,水中微纳米气核数量减少,白钨颗粒更加分散。另一方面,当溶液中油酸钠浓度为5×10-4 mol/L时,脱气水和未脱气水对应矿浆浊度差值显著减小,这说明在该条件下,脱气处理对矿浆浊度的影响效果减弱。大量研究结果表明[23-24]:油酸钠自身具有一定聚团作用;在高油酸钠浓度条件下,油酸钠能够显著促进微细粒矿物颗粒疏水聚团。这可能是造成溶解气核对矿浆浊度影响效果减弱的原因。

图4 矿浆pH对白钨矿浆浊度的影响

Fig. 4 Effect of pH on turbidity of scheelite suspension

2.3 脱气处理影响白钨矿颗粒疏水聚团的机理分析

白钨颗粒在脱气水和未脱气水中表面电位与pH的关系见图5。从图5可知:随着pH增大,白钨颗粒表面电位呈现下降趋势。这是因为溶液中OH-浓度不断增大,矿物表面负电性不断增强。更重要的是,超纯水经过脱气之后,白钨表面电位绝对值增大,在碱性条件下尤为明显。一个可能的原因是:溶液中微纳米气核自身带负电[25],在碱性环境中更加稳定[26],且纳米气泡的存在使得矿浆中负电荷增加,压缩了白钨双电层,颗粒表面电位绝对值降低。微纳米气核和表面活性剂分子在矿物表面存在竞争吸附关系[7, 27],脱气后附着在矿物表面的微纳米气核数量减少,促进油酸钠在矿物表面的吸附,导致测定矿物表面电位绝对值增大。颗粒表面电位绝对值越大,颗粒间静电排斥力越大,越不利于颗粒间形成聚团。

图5 pH对白钨颗粒表面电位的影响(c(NaOl)=1×10-4 mol/L)

Fig. 5 Zeta potential of scheelite particles as function of pH when c(NaOl)=1×10-4 mol/L

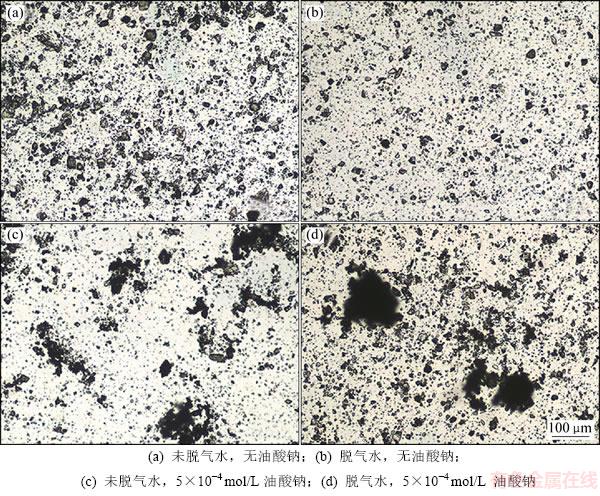

图6 矿浆悬浮液中白钨颗粒显微图片

Fig. 6 Micrographs of solids in scheelite suspension

为了更加直观地分析脱气处理对微细白钨颗粒疏水聚团行为的影响,进行显微镜观察试验(结果见图6),并对获取的显微照片图像进行统计学分析(结果见表1)。从图6和表1可知:在脱气水制备的矿浆中,白钨颗粒更加分散,颗粒的表观粒径更小,再次证明脱气处理有利于白钨颗粒更加分散;油酸钠的加入使得矿浆中白钨颗粒疏水聚团现象明显,絮团平均面积和粒径均显著增大,说明油酸钠自身能够显著促进微细白钨颗粒疏水聚团;当油酸钠浓度较高时,未脱气水中形成更大絮团,并部分呈现网络状和链状结构,但当有油酸钠存在时,脱气和未脱气矿浆中白钨絮团特性差异较无油酸钠时小,这也再次表明脱气处理对白钨颗粒疏水聚团的影响在低油酸钠浓度下更显著。

表1 显微照片统计学参数

Table 1 Statistical parameter of micrographs

3 结论

1) 加热脱气能有效减少水中的溶解气体质量浓度,但是不能完全脱除溶解气核。

2) 白钨颗粒在脱气水中更易分散,这在油酸钠浓度较低时更加明显;当油酸钠浓度较高时,其自身促絮团作用使水中溶解的微纳米气核对颗粒聚集/分散的影响减弱。

3) 白钨颗粒在脱气水中表面负电性增强,颗粒间静电排斥增强,不利于颗粒间疏水聚团。

参考文献:

[1] 周晓文, 陈江安, 袁宪强, 等. 微细粒级钨细泥选矿试验研究[J]. 有色金属科学与工程, 2010, 1(2): 64-68.

ZHOU Xiaowen, CHEN Jiangan, YUAN Xianqiang, et al. On the experimental processing of fine tungsten slime[J]. Nonferrous Metals Science and Engineering, 2010, 1(2): 64-68.

[2] YIN Wanzhong, WANG Jizhen. Effects of particle size and particle interactions on scheelite flotation[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3682-3687.

[3] MIETTINEN T, RALSTON J, FORNASIERO D. The limits of fine particle flotation[J]. Minerals Engineering, 2010, 23(5): 420-437.

[4] CALGAROTO S, AZEVEDO A, RUBIO J. Flotation of quartz particles assisted by nanobubbles[J]. International Journal of Mineral Processing, 2015, 137: 64-70.

[5] 王淀佐, 邱冠周, 胡岳华. 颗粒间相互作用与细粒浮选[M]. 长沙: 中南工业大学出版社, 1993: 234-345.

WANG Dianzuo, QIU Guanzhou, HU Yuehua. Interaction between particles and fine particle flotation[M]. Changsha: Central South University of Technology Press, 1993: 234-345.

[6] 常自勇, 冯其明, 欧乐明. 回水中絮凝剂对铝土矿浮选影响的研究[J]. 有色金属(选矿部分), 2014(6): 88-91.

CHANG Ziyong, FENG Qiming, OU Leming. Study on the impact of flocculants in backwater on bauxite flotation[J]. Nonferrous Metals (Mineral Processing Section), 2014(6): 88-91.

[7] AGARWAL A, NG W J, LIU Y. Principle and applications of microbubble and nanobubble technology for water treatment[J]. Chemosphere, 2011, 84(9): 1175-1180.

[8] SCHUBERT H. Nanobubbles, hydrophobic effect, heterocoagulation and hydrodynamics in flotation[J]. International Journal of Mineral Processing, 2005, 78(1): 11-21.

[9] 冯其明, 周伟光, 石晴. 纳米气泡的形成及其对微细粒矿物浮选的影响[J]. 中南大学学报(自然科学版), 2017, 48(1): 9-15.

FENG Qiming, ZHOU Weiguang, SHI Qing. Formation of nano-bubbles and their influences on ultrafine mineral flotation[J]. Journal of Central South University (Science and Technology), 2017, 48(1): 9-15.

[10] AHMADI R, KHODADADI D A, ABDOLLAHY M, et al. Nano-microbubble flotation of fine and ultrafine chalcopyrite particles[J]. International Journal of Mining Science and Technology, 2014, 24(4): 559-566.

[11] FAN Maoming, TAO D, HONAKER R, et al. Nanobubble generation and its applications in froth flotation (part II): fundamental study and theoretical analysis[J]. International Journal of Mining Science and Technology, 2010, 20(2): 159-177.

[12] ZHOU Zhiang, XU Zhenghe, FINCH J A, et al. Role of hydrodynamic cavitation in fine particle flotation[J]. International Journal of Mineral Processing, 1997, 51(1): 139-149.

[13] ZHOU Zhiang, XU Zhenghe, FINCH J A, et al. On the role of cavitation in particle collection in flotation–a critical review. II[J]. Minerals Engineering, 2009, 22(5): 419-433.

[14] ZHOU Zhiang. Gas nucleation and cavitation in flotation[D]. Montreal: McGill University, 1996: 87-107.

[15] ZHANG Xuehua, QUINN A, DUCKER W A. Nanobubbles at the interface between water and a hydrophobic solid[J]. Langmuir, 2008, 24(9): 4756-4764.

[16] 郭德, 张秀梅, 石常省, 等. 压强预处理对煤泥浮选效果的影响[J]. 煤炭学报, 2011, 36(8): 1365-1369.

GUO De, ZHANG Xiumei, SHI Changsheng, et al. The effect of pressure-based pre-treat on the flotation efficiency of coal slurry[J]. Journal of China Coal Society, 2011, 36(8): 1365-1369.

[17] LI Haipeng. Role of hydrodynamic cavitation in fine particle flotation[D]. Edmonton: University of Alberta, 2014: 40-41.

[18] ZHANG Xuehua, LI Gang, MAEDA N, et al. Removal of induced nanobubbles from water/graphite interfaces by partial degassing[J]. Langmuir, 2006, 22(22): 9238-9243.

[19] ZHOU Z A. Effect of gas nuclei on hydrophobic coagulation[J]. Journal of Colloid & Interface Science, 1996, 179(1): 311-314.

[20] 刘旭. 微细粒白钨矿浮选行为研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2010: 62-65.

LIU Xu. Study on the flotation of micro-grained scheelite[D]. Changsha: Central South University. School of Minerals Processing and Bioengieering, 2010: 62-65.

[21] SIMONSEN A C, HANSEN P L, KL SGEN B. Nanobubbles give evidence of incomplete wetting at a hydrophobic interface[J]. Journal of Colloid & Interface Science, 2004, 273(1): 291-299.

SGEN B. Nanobubbles give evidence of incomplete wetting at a hydrophobic interface[J]. Journal of Colloid & Interface Science, 2004, 273(1): 291-299.

[22] ZHOU Weiguang, CHEN Hao, OU Leming, et al. Aggregation of ultra-fine scheelite particles induced by hydrodynamic cavitation[J]. International Journal of Mineral Processing, 2016, 157: 236-240.

[23] 冯博, 王鹏程, 王金庆. 油酸钠在微细粒白钨矿浮选中的作用[J]. 有色金属工程, 2015, 5(4): 44-48.

FENG Bo, WANG Pengcheng, WANG Jinqing. Functions of sodium oleate in fine grain scheelite flotation[J]. Nonferrous Metals Engineering, 2015, 5(4): 44-48.

[24] 王军, 程宏伟, 赵红波, 等. 油酸钠作用下金红石的浮选行为及作用机理[J]. 中国有色金属学报, 2014, 24(3): 820-825.

WANG Jun, CHENG Hongwei, ZHAO Hongbo, et al. Flotation behavior and mechanism of rutile in presence of sodium oleate[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 820-825.

[25] KIM J Y, SONG M G, KIM J D. Zeta potential of nanobubbles generated by ultrasonication in aqueous alkyl polyglycoside solutions[J]. Journal of Colloid & Interface Science, 2000, 223(2): 285-291.

[26] CALGAROTO S, WILBERG K Q, RUBIO J. On the nanobubbles interfacial properties and future applications in flotation[J]. Minerals Engineering, 2014, 60(6): 33-40.

[27] WU Zhihua, ZHANG Xuehua, ZHANG Xiaodong, et al. Retracted: nanobubbles influence on BSA adsorption on mica surface[J]. Surface & Interface Analysis, 2005, 37(10): 797-801.

(编辑 陈灿华)

收稿日期:2017-07-13;修回日期:2017-09-15

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2014CB643402);国家自然科学基金资助项目(51674291)(Project (2014CB64340) supported by the National Basic Research Development Program(973 Program) of China; Project(51674291) supported by the National Natural Science Foundation of China)

通信作者:欧乐明,博士,教授,从事矿物加工理论研究;E-mail:olm@csu.edu.cn