文章编号:1004-0609(2013)12-3282-07

7050-T7451铝合金预拉伸板材热膨胀系数变化规律及机理

黄晓明1,孙 杰1,李剑峰1,罗育果2

(1. 山东大学 机械工程学院 高效洁净机械制造教育部重点实验室,济南 250061;

2. 中航工业集团成都飞机制造有限责任公司,成都 610092)

摘 要:针对平均热膨胀系数(CTE)对航空整体结构件热变形准确预测带来较大误差这一问题,利用热机械分析仪在25~500 ℃范围内对7050-T7451铝合金热膨胀系数进行准确测量,采用数值拟合方法获得铝合金7050-T7451热膨胀系数随温度升高的非线性变化规律。从铝合金7050-T7451材料的合金成分和金相结构变化角度,揭示铝合金7050-T7451热膨胀系数变化的材料学内在本质;分别采用平均热膨胀系数和准确热膨胀系数模型对工件变形进行预测分析。结果表明,与平均热膨胀系数模型相比,采用准确热膨胀系数模型时热变形最大相对计算误差由17.4%降为9.5%。

关键词:7050-T7451铝合金;热膨胀系数;微观结构;热处理;模型误差

中图分类号:TG146.2 文献标志码:A

Varying rules and mechanism of thermal expansion coefficient for pre-stretched 7050-T7451 aluminum alloy plate

HUANG Xiao-ming1, SUN Jie1, LI Jian-feng1, LUO Yu-guo2

(1. Key Laboratory of High Efficiency and Clean Mechanical Manufacture, Ministry of Education,

School of Mechanical Engineering, Shandong University, Ji’nan 250061, China;

2. CAC Chengdu Aircraft Industrial (Group) Co., Ltd., Chengdu 610092, China)

Abstract: Data for the coefficient of thermal expansion (CTE) of pre-stretched 7050-T7451 aluminum alloy are usually given in average values. This may bring a comparatively large error for predicting distortion of aeronautic monolithic components. To solve this problem, accurate measurements of the CTE of 7050-T7451 aluminum alloy were conducted. The measurement was carried out with the help of thermo mechanical analysis (TMA) with temperature varying from 25 to 500 ℃. Numerical fitting method was adopted to obtain the nonlinear variation rules of CTE of the alloy with temperatures. The inherent nature of CTE variation was revealed based on 7050-T7451 composition and metallography. At the end, the deformation prediction analysis of the workpiece was carried out using the average CTE and accurate CTE models, respectively. The results show that the maximum relative error obtained by the accurate CTE drops from 17.4% to 9.5% compared with that of the average CTE.

Key words: 7050-T7451 aluminum alloy; thermal expansion coefficient; microstructure; heat treatment; model error

现代航空工业中,铝合金是与钛合金和复合材料并重的三大主要结构件材料之一。铝合金广泛应用于现代飞机整体框、梁、壁板和长缘条等整体结构件[1-2]。7050-T7451铝合金属于Al-Zn-Mg-Cu系列合金,具有强度高、断裂韧度大和抗应力腐蚀性能好等优点,是航空航天工业应用最广泛的铝合金材料之一。铝合金具有较大的热膨胀系数,在航空整体结构件制造过程中,由于加工现场与测量、装配现场存在一定的温度差,加工现场的合格零件在装配、测量现场出现超差问题,给生产带来困扰[3]。另外,铝合金工件在使用过程中存在很大的季节性和地域性环境温度差异,当温度变化时产生较大的热变形和热应力,使零件的制造及装配精度降低,甚至造成零件报废[4]。铝合金热膨胀系数的准确测量和建模是航空结构件温度变化引起变形精确计算的基础和前提。国内外学者对航空材料的热膨胀特性进行了广泛的研究。ENYA等[5]研究了C/SiC航空复合材料在低温时的热膨胀系数,认为通过增加碳纤维可以有效减小该材料的热膨胀变形的各向异性。为了减小不同材料热膨胀系数差异引起的航空光学仪表测量差异,OLIVA等[6]研究了Al-6061和Al-6082的低温热膨胀特性,二者在77 K下的热膨胀系数误差仅为0.28%。BENAL等[7]分析了热处理时间对玻璃纤维增强6061铝合金复合材料的热膨胀系数的影响规律。孙建强等[8]通过假定合金膨胀系数与化学成分存在线性关系,计算了11种共晶铝合金的热膨胀系数。武玉英等[9]研究了硅相形态及含量对Al-Si 合金热膨胀系数的影响,指出Al-Si合金中硅含量越高,其热膨胀系数越小。王新宇等[10]研究了镀TiC金刚石/铝复合材料的热膨胀性能,认为TiC镀层能有效地降低复合材料的热膨胀系数,在体积分数相同的情况下,热膨胀系数随金刚石颗粒尺寸的减小而减小。上述研究主要集中在不同材料一定温度范围内的热膨胀系数平均值的比较,忽略了热膨胀系数随温度的动态变化,也缺乏金相组织结构对热膨胀系数影响的内在机制研究。

本文作者采用热机械分析仪对7050-T7451合金不同方向的热膨胀变形量进行准确测量,分析铝合金预拉伸板材不同方向热膨胀系数变化规律,采用多项式拟合获得热膨胀系数随温度变化的函数关系,借助于材料金相组织结构分析,揭示热膨胀系数变化的材料学内在机制。比较平均热膨胀系数和温度函数表达精确热膨胀系数对工件变形预测精度的影响,为因温度变化引起航空整体结构件变形的预测提供支持。

1 热膨胀系数计算模型

热膨胀特性是物体的基本属性,是原子在热作用下振动产生的效应。在双原子模型中,原子作用势能u(r)是原子间距离r的函数,当发生热振动时,两原子间距由r0变为r0+x,则相互作用势能变为[11]

(1)

(1)

将式(1)在r0处泰勒级数展开:

(2)

(2)

根据波尔兹曼热力学统计原理,偏离r0的平均位移x为

(3)

(3)

式中:u、K和T分别为两原子间的相互作用能、玻尔兹曼常数和热力学温度。由热膨胀系数定义,得到任意时刻的热膨胀系数( ):

):

(4)

(4)

其中: ;

; ;

; ;

; , …。

, …。

从式(4)看出,材料的热膨胀系数随着温度的不同而发生变化,由于铝合金的热膨胀系数受合金成分、相变、晶体缺陷、晶体各向异性和工艺等因素影响,难以利用理论计算热膨胀系数[12-13]。在实际工程中,通常采用在一定温度范围内的平均热膨胀系数,

(5)

(5)

温度升高T后物体长度变为

(6)

(6)

铝合金预拉伸板材金相组织结构在不同方向上存在差异[14],导致其热膨胀系数随着温度和材料方向的不同而发生变化,而不是一个恒定值。因此,采用平均热膨胀系数会造成一定的计算误差。当△t趋于零时,式(5)变为

(T1<T<T2) (7)

(T1<T<T2) (7)

为瞬时热膨胀系数。根据式(7),温度从T0变为T后材料长度变为

为瞬时热膨胀系数。根据式(7),温度从T0变为T后材料长度变为

(8)

(8)

两种计算模型产生的差异为

(9)

(9)

2 实验

为研究7050-T7451铝合金的热膨胀特性,采用热机械分析仪对铝合金试样温度变化引起特定尺寸方向伸长量进行测试,绘制关系曲线,进而对不同温度时材料金相组织结构进行分析。

2.1 实验材料

选取美国Kaiser Aluminum & Chemical Corp公司生产的7050-T7451预拉伸毛坯件试样,化学成分如表1所列。试样尺寸9.065 2 mm×7.995 1 mm×6.581 5 mm(长(x)×宽(y)×高(z))的方向分别对应板材预拉伸、宽度和厚度方向。

表1 7050-T7451铝合金的化学成分

Table 1 Chemical composition of 7050-T7451 Al alloy (mass fraction, %)

2.2 实验过程

试样通过线切割从200 mm×100 mm×58 mm毛坯件中心部取出,采用研磨纸对表面进行打磨处理,分别对试样的3个方向各测量热膨胀系数3次。

热膨胀测量在热机械分析仪(TMA)上进行,温度变化率为2 ℃/min,测量范围为25~500 ℃。实测之前,试样在25 ℃预热5 min。测量试样随温度升高的热膨胀量,借助TMA数据分析软件对测得数据进行分析,计算温度每升高1 ℃后的热膨胀系数。

利用Rigaku D/max-rc型X射线衍射仪进行材料物相分析,电压为40 kV,电流为100 mA,扫描速度为4 (°)/ min。

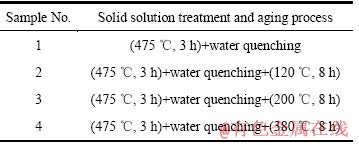

为了观察不同温度下材料组织结构的变化,取4块试样进行固溶和时效处理,工艺如表2所示。将所有试样进行抛光和金相腐蚀,腐蚀液为0.5%HF+ 1.5%HCl+2.5%HNO3+95.5%H2O(质量分数),最后利用Olympus光学金相显微镜观察原始试样和处理后试样的组织结构变化。

表2 7050-T7451铝合金固溶时效处理工艺

Table 2 Solid solution and aging treatment process of 7050-T7451 Al alloy

2.3 数据处理

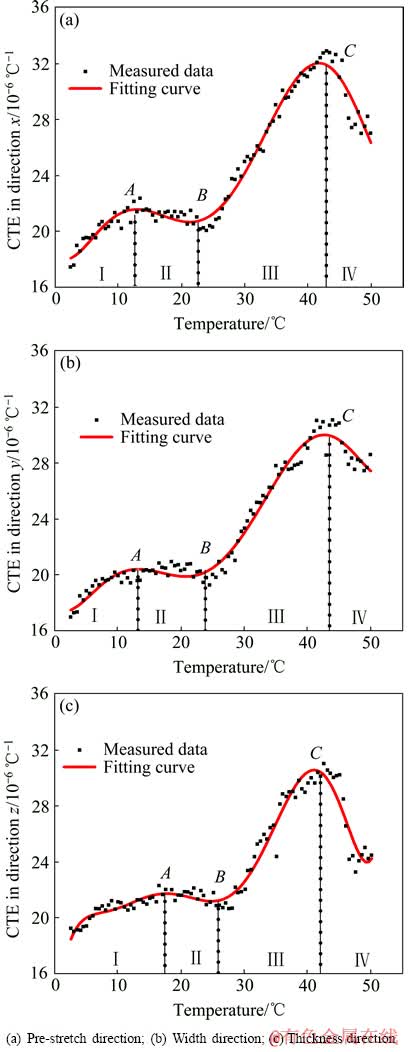

图1所示为通过TMA测量获得的不同温度下的热膨胀系数。从图1中可以看出,随着温度的升高,7050-T7451合金的热膨胀系数发生了非线性变化。考虑到工程应用的准确性和实用性,根据最小方差原则将测量的热膨胀系数离散数值进行6阶多项式拟合:

(10)

(10)

式中:i、aj和T分别为试样测量方向、拟合系数和对应的变化温度,拟合曲线如图1中实线所示。x、y和z方向6阶多项式拟合系数如表3所列。

根据变化规律,在温度升高过程中将图1中的热膨胀系数拟合曲线通过关键点A、B和C分为4个区域。

在第Ⅰ区域,随着温度的升高,预拉伸方向的热膨胀系数从1.746×10-5 ℃-1逐渐增加到2.231×10-5 ℃-1(142 ℃),宽度方向的热膨胀系数从1.699×10-5 ℃-1增加到2.025×10-5 ℃-1(138 ℃)、厚度方向热膨胀系数从1.921×10-5 ℃-1增加到2.218×10-5 ℃-1(166 ℃)。x和y方向近似呈线性增加,而厚度z方向变化率小,波动性增大。

表3 7050-T7451铝合金6阶热膨胀系数多项式拟合系数

Table 3 Coefficients of six-order polynomials of CTE for 7050-T7451 Al alloy

图1 7050-T7451铝合金热膨胀系数随温度的变化曲线

Fig. 1 CTE—temperature curves of 7050-T7451 Al alloy along different directions

在第Ⅱ区域热膨胀系数的变化不明显,x、y和z方向的Ⅱ和Ⅲ区域分界点为249、240和253 ℃,在分界点x、y和z方向的热膨胀系数分别为2.005×10-5、1.924×10-5和2.051×10-5 ℃-1。热膨胀系数随温度的升高出现略微下降的变化。

在第Ⅲ区域热膨胀系数快速增加并达到最大值。预拉伸方向的热膨胀系数峰值为3.293×10-5 ℃-1 (435 ℃),宽度方向热膨胀系数峰值次之,为3.117×10-5 ℃-1(441 ℃),厚度方向热膨胀系数峰值最小,为3.125×10-5 ℃-1(427 ℃),该方向热膨胀系数峰值温度分别低于x和y方向峰值温度8 ℃和14 ℃。

在第Ⅳ区域随着温度升高而呈现热膨胀系数减小的趋势。预拉伸方向、宽度方向和厚度方向的热膨胀系数分别减小至2.693×10-5、2.717×10-5和2.335× 10-5 ℃-1。

3 7050-T7451铝合金热膨胀系数的变化机理

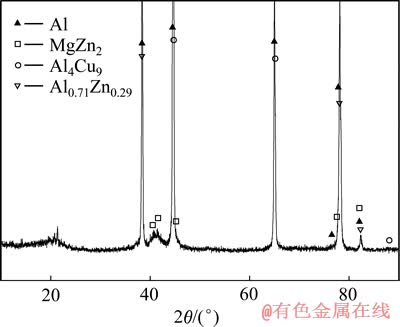

图2所示为室温下7050-T7451铝合金的X射线衍射谱。主相为α(Al)基体,含有MgZn2和Al4Cu9等多相混合物。在升温过程中,热膨胀系数的变化主要受两方面的影响:一方面是温度升高引起的原子热振动增加,另一方面是温度变化引起的合金元素的溶解、析出以及物相转变等相关。

图2 7050-T7451铝合金的XRD谱

Fig. 2 XRD pattern of 7050-T7451 Al alloy

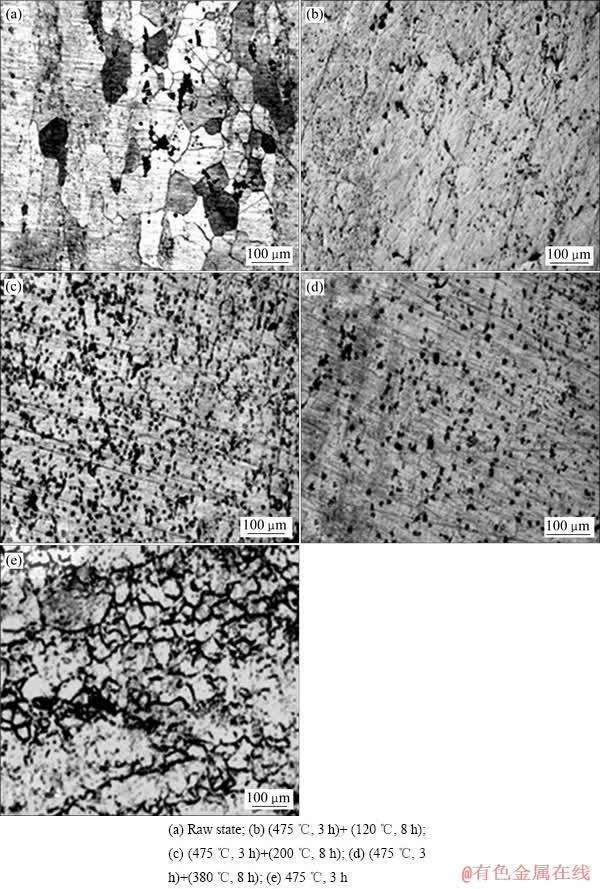

为研究材料热膨胀系数变化的原因,对不同热处理状态下试样的微观组织结构进行观察,结果如图3所示。从图3(a)可以看出,原始状态下晶粒大小为150 μm左右,经腐蚀后呈白色,结晶区约占40%。结晶区域含有大量亚晶组织,经试剂腐蚀后在光学显微镜下呈灰色。未固溶的富铁相等粗大金属化合物散落在 晶粒中间,难溶相粒子呈较短互且不相连的条状[15-16]。

图3 经不同热处理后7050-T7451铝合金的金相组织

Fig. 3 Optical micrographs of 7050-T7451 Al alloy after different heat treatments

从图3(b)可以看出,在温度升高的初始阶段,晶界上的相发生溶解,晶界不明显。晶粒内部析出GP区,根据文献[17-18],作为析出相的GP区不断长大,直径从2 nm增大至4.7 nm,晶界相的溶解和新的GP区不断析出长大,导致第一区域热膨胀系数近乎线性增加。

在温度升高的第Ⅱ区域,合金中的η相不断增多,这是因为合金为过饱和固溶体,合金中的Zn和Mg等原子不断从饱和固溶体中析出,形成η相,如图3(c)所示。在该过程中,首先生成η′相,该相是一种非平衡相,存在的温度区间较窄。η′和η相都为六方结构,η′相的点阵常数为a=0.496 nm,c=1.403 nm,η相点阵常数为a=0.521 nm,c=0.860 nm[18-19],大量η相析出造成基体点阵常数的负增长,减缓了热膨胀系数的增大,热膨胀系数曲线中的第Ⅱ区域变化主要是上述相变产生的结果。

随着温度的继续升高,溶质原子的固溶作用(见图3(d))对热膨胀系数的影响又开始占主导作用,合金原子的溶入使得铝合金体积增大,对应第Ⅲ区域的热膨胀系数快速增长,当温度达到450 ℃时,固溶已趋饱和[15],固溶的影响逐渐消除。

研究表明[20-21],当温度低于450 ℃时,合金在固溶时基体发生再结晶的过程十分缓慢,但温度从450 ℃逐渐升高后,再结晶启动速度加快,从图3(e)可以看出,在475 ℃下形成大量再结晶颗粒,晶粒大小为50 μm左右。再结晶颗粒的形成减小了材料的体积,从而使得第Ⅳ区域的热膨胀系数曲线呈下降趋势。

4 不同热膨胀系数模型精确度验证

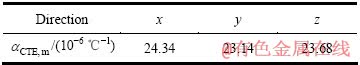

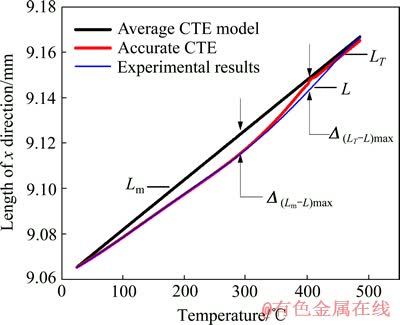

根据热膨胀测量结果,利用式(7)计算7075-T7451铝合金试样在不同方向25~500 ℃之间的平均热膨胀系数,结果列于表4。从表4可以看出,试样沿预拉伸x方向、厚度z方向和宽度y方向的平均热膨胀系数依次减小。由式(5)~(9)分析可知,不同的计算模型会导致计算误差,为了验证瞬时热膨胀系数的精确性,利用式(6)和(8)计算升温过程中试样x方向热膨胀后的长度Lm和LT,并与实验结果L相比较,求出计算误差 和

和 。不同温度下两种模型的计算结果如图5所示。

。不同温度下两种模型的计算结果如图5所示。

表4 7050-T7451铝合金在不同方向的平均热膨胀系数

Table 4 Average  of 7050-T7451 Al alloy on different orientations

of 7050-T7451 Al alloy on different orientations

图4 平均和瞬时热膨胀系数计算误差对比

Fig. 4 Computation of comparison of average and precision CTE models

从图4可以看出,平均热膨胀系数计算所得热变形伸长量大于实验测量值,误差为正值,这是由于在升温初始阶段,平均热膨胀系数2.434×10-5 ℃-1大于实际瞬时热膨胀系数,随温度升高,误差值逐渐增大,然后又开始减小。当温度由25 ℃升高到292 ℃时实验测得的伸长量为51.9 μm,平均热膨胀系数模型计算的伸长量为60.9 μm,最大误差为17.4%。利用精确热膨胀系数模型计算结果与实验值之间的误差在温度变化前期非常一致,温度升高到435 ℃时产生最大误 差,实验伸长量为78.7 μm,精确热膨胀系数模型计算量为86.3 μm,最大误差为9.5%。随后误差又逐渐减小并变为负值,这说明利用精确热膨胀系数函数有一定的误差纠正能力,利用瞬时精确热膨胀系数,能够得到更好的热膨胀变形预测。

5 结论

1) 采用热分析仪对7050-T7451铝合金热膨胀量随温度变化进行精确测量,获得材料在25~500 ℃之间的热膨胀系数变化规律,将热膨胀系数随温度变化特性划分为4个区域:增大-持平-增大-减小。

2) 根据最小方差原理,建立了7050-T7451铝合金预拉伸板不同方向热膨胀系数非线性变化精确表达式。

3) 根据不同温度下铝合金金相的特征,从材料组织结构角度揭示了热膨胀系数变化规律的本质,7050-T7451铝合金中晶界相的溶解,GP区、η相形成析出和固溶以及再结晶的发生是非线性变化的主要原因。

4) 采用研究中所建立的精确热膨胀系数模型可以显著提高变形预测精度。25~500 ℃间的平均热膨胀系数模型计算变形量大于实测结果,最大计算误差率达到17.4%,而精确热膨胀系数函数模型最大计算误差则为9.5%。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小峰, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] 林 纲, 林慧国, 赵玉涛. 铝合金应用手册[M]. 北京: 机械工业出版社, 2006: 280-290.

LIN Gang, LIN Hui-guo, ZHAO Yu-tao. Manual for application of aluminium alloys[M]. Beijing: China Machine Press, 2006: 280-290.

[3] YANG Y P, DONG P. Buckling distortions and mitigation techniques for thin-section structures[J]. Journal of Materials Engineering and Performance, 2012, 21(2): 153-160.

[4] 郭加林, 尹志民, 沈 凯, 彭小芒, 王 华. 使役条件下热暴露对2124-T851铝合金显微组织与性能的影响[J]. 中南大学学报: 自然科学版, 2009, 40(4): 921-925.

GUO Jia-lin, YIN Zhi-min, SHEN Kai, PENG Xiao-mang, WANG Hua. Effect of thermal exposure during application on microstructure and mechanical properties of 2124-T851 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2009, 40(4): 921-925.

[5] ENYA K, YAMADA N, IMAIL T. High-precision CTE measurement of hybrid C/SiC composite for cryogenic space telescopes[J]. Cryogenics, 2012, 52(4): 86-89.

[6] OLIVA E, GONZALEZ M. High-precision CTE measurement of aluminum-alloy for cryogenic astronomical instrumentation[J]. Exp Astron, 2009, 27(1): 1-7.

[7] BENAL M M, SHIVANAND H K. Influence of heat treatment on the coefficient of thermal expansion of Al (6061) based hybrid composites[J]. Materials Science and Engineering A, 2006, 435(5): 745-749.

[8] 孙建强, 张仁远, 卢国辉, 沈学忠. 共晶铝合金热膨胀系数的测定与回归分析[J]. 广东工业大学学报, 2006, 23(2): 12-17.

SUN Jian-qiang, ZHANG Ren-yuan, LU Guo-hui, SHEN Xue-zhong. Regression analysis and measurement for the coefficient of thermal expansion of eutectic Al-based alloy at solidus[J]. Journal of Guangdong University of Technology, 2006, 23(2): 12-17.

[9] 武玉英, 刘相法, 戴 勇, 姜炳刚, 边秀房. 硅相形态及含量对Al-Si合金热膨胀系数的影响[J]. 中国有色金属学报, 2007, 17(5): 688-692.

WU Yu-ying, LIU Xiang-fa, DAI Yong, JIANG Bing-gang, BIAN Xiu-fang. Influence of morphology and content of silicon phase on CTE of Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 688-692.

[10] 王新宇, 于家康, 朱晓敏. 镀TiC金刚石/铝复合材料的界面及热膨胀性能[J]. 中国有色金属学报, 2012, 22(6): 1718-1724.

WANG Xin-yu, YU Jia-kang, ZHU Xiao-min. Interface and thermal expansion properties of TiC-coated diamond/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1718-1724.

[11] 丁鸿章. 工程金属材料热膨胀系数的计算[J]. 浙江工业大学学报, 2000, 28(4): 358-366.

DING Hong-zhang. Calculation of linear expansion coefficient of metallic materials[J]. Journal of Zhejiang University of Technology, 2008, 28(4): 358-366.

[12] KIMA B G, DONG S L, PARKA S D. Effects of thermal processing on thermal expansion coefficient of a 50vol.% SiCp/Al composite[J]. Materials Chemistry and Physics, 2001, 72(1): 42-47.

[13] 黄继武, 尹志民, 聂 波, 陈继强, 何振波. 7A52铝合金原位加热过程中的物相转变与热膨胀系数测量[J]. 兵器材料科学与工程, 2007, 30(4): 9-12.

HUANG Ji-wu, YIN Zhi-min, NIE Bo, CHEN Ji-qiang, HE Zhen-bo. Investigation of phases and thermal expansivity of 7A52 alloy in in-situ heating[J]. Ordnance Material Science and Engineering, 2007, 30(4): 9-12.

[14] 张新明, 韩念梅, 刘胜胆, 宋丰轩, 曾瑞林, 黄乐瑜. 7050 铝合金厚板织构、拉伸性能及断裂韧性的不均匀性[J]. 中国有色金属学报, 2010, 20(2): 202-208.

ZHANG Xin-ming, HAN Nian-mei, LIU Sheng-dan, SONG Feng-xuan, ZENG Rui-lin, HUANG Le-yu. Inhomogeneity of texture, tensile property and fracture toughness of 7050 aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 202-208.

[15] LI X M, STARINK M J. DSC study on phase transitions and their correlation with properties of overaged Al-Zn-Mg-Cu alloys[J]. Journal of Materials Engineering and Performance, 2012, 21(6): 977-984.

[16] 李学朝. 铝合金材料组织与金相图谱[M]. 北京: 冶金工业出版社, 2010.

LI Xue-chao. Material organization and metallographic map of aluminium alloy[M]. Beijing: Metallurgical Industry Press, 2010.

[17] 李培跃, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 7050铝合金淬火特性与微观组织[J]. 中国有色金属学报, 2011, 21(3): 514-521.

LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Hardenability characteristic and microstructure of 7050 Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 514-521.

[18] YANG Ji-gang, OU Bin-lung. Influence of microstructure on the mechanical properties and stress corrosion susceptibility of 7050 Al-alloy[J]. Scandinavian Journal of Metallurgy, 2001, 30(3): 158-167.

[19] 万彩云, 陈江华, 杨修波, 刘吉梓, 伍翠兰, 赵新奇. 7XXX系AlZnMgCu 铝合金早中期时效强化析出相的研究[J]. 电子显微学报, 2010, 29(5): 455-460.

WAN Cai-yun, CHEN Jiang-hua, YANG Xiu-bo, LIU Ji-zi, WU Cui-lan, ZHAO Xin-qin. Study of the early & mid-stage hardening precipitates in a 7XXX AlZnMgCu aluminium alloy[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(5): 455-460.

[20] 熊创贤, 邓运来, 万 里, 张新明. 7050 铝合金板在固溶过程中微结构与织构的演变[J]. 中国有色金属学报, 2010, 20(3): 427-434.

XIONG Chuang-xian, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Evolutions of microstructures and textures of 7050 Al alloy plate during solution heat treatment[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 427-434.

[21] LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui. Temperature variation and solution treatment of high strength AA7050[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 546-554.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51275277)

收稿日期:2013-02-02;修订日期:2013-08-20

通信作者:孙 杰,教授,博士;电话:0531-88394593;E-mail: sunjie@sdu.edu.cn