improvement of visible light-induced photocatalytic performance by Cr-doped SrTiO3-carbon nitride intercalation compound (CNIC) composite

来源期刊:中南大学学报(英文版)2016年第2期

论文作者:杨明 金效齐

文章页码:310 - 316

Key words:photocatalysis; carbon nitride intercalation compound (CNIC); Cr-doped SrTiO3; composite

Abstract: Novel organic-inorganic composite photocatalyst offers new opportunities in the practical applications of photocatalysis. novel visible light-induced Cr-doped SrTiO3–carbon nitride intercalation compound (CNIC) composite photocatalysts were synthesized. The composite photocatalyst was characterized by X-ray diffraction (XRD), field-emission scanning electron microscopy (FESEM), high-resolution transmission electron microscopy (HRTEM), Fourier transform infrared (FT-IR) spectroscopy, UV-vis diffuse reflection spectroscopy, photoluminescence (PL) spectroscopy, and BET surface area analyzer. The photocatalytic oxidation ability of the novel composite photocatalyst was evaluated using methyl orange (MO) as a target pollutant. The photocatalysts exhibited a significantly enhanced photocatalytic performance in degrading MO. For maximizing the photodegradation activity of the composite photocatalysts, the optimal CNIC content was determined. The improved photocatalytic activity of the as-prepared Cr-doped SrTiO3–CNIC composite photocatalyst may be attributed to the enhancement of photo-generated electron–hole separations at the interface.

J. Cent. South Univ. (2016) 23: 310-316

DOI: 10.1007/s11771-016-3075-3

YANG Ming(杨明)1, JIN Xiao-qi(金效齐)2

1. School of Transportation, Southeast University, Nanjing 210096, China;

2. Bio-Chemistry Department, Wenshan University, Wenshan 663000, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Abstract: Novel organic-inorganic composite photocatalyst offers new opportunities in the practical applications of photocatalysis. novel visible light-induced Cr-doped SrTiO3–carbon nitride intercalation compound (CNIC) composite photocatalysts were synthesized. The composite photocatalyst was characterized by X-ray diffraction (XRD), field-emission scanning electron microscopy (FESEM), high-resolution transmission electron microscopy (HRTEM), Fourier transform infrared (FT-IR) spectroscopy, UV-vis diffuse reflection spectroscopy, photoluminescence (PL) spectroscopy, and BET surface area analyzer. The photocatalytic oxidation ability of the novel composite photocatalyst was evaluated using methyl orange (MO) as a target pollutant. The photocatalysts exhibited a significantly enhanced photocatalytic performance in degrading MO. For maximizing the photodegradation activity of the composite photocatalysts, the optimal CNIC content was determined. The improved photocatalytic activity of the as-prepared Cr-doped SrTiO3–CNIC composite photocatalyst may be attributed to the enhancement of photo-generated electron–hole separations at the interface.

Key words: photocatalysis; carbon nitride intercalation compound (CNIC); Cr-doped SrTiO3; composite

1 Introduction

In recent years, photocatalysis has attracted considerable interest for its potential applications in the remediation of water containing organic pollutants and in water splitting for hydrogen or oxygen generation as renewable energy by using solar energy; however, highly efficient photocatalysts are still most important to realize the photocatalysis technique for large-scale applications [1-4]. Usually, to increase the separation efficiency of photogenerated electron–hole pairs is a good method to improve the photocatalytic activities, such as the use of co-catalysts [5], and a composite photocatalyst formed between two kinds of semiconductors [6].

Graphitic carbon nitride (g-C3N4), a metal-free visible-light responded semiconductor photocatalyst used for hydrogen or oxygen generation from photocatalytic water splitting reported by Wang et al [7], has attracted vast attention [7]. However, due to the large optical band gap of 2.7 eV and the inefficiency in separation and transport of photogenerated carriers, the photoactivity of g-C3N4 is low [8]. narrowing the band gap for more light absorption by doping Zn, S, B, P [9-12] and etc, to enhance the efficiency in separation and transport of photogenerated holes and electrons is another method to modify the photocatalytic activity of g-C3N4. Recently, a carbon nitride intercalation compound (CNIC), an organic polymer semiconductor material, has been formed by a simple molten salt route, coordinating alkali metals into the C-N plane of carbon nitride and thus significantly improving the electrical conductivity of g-C3N4, which is beneficial to improve the separation and transport efficiency of the photogenerated electron- hole pairs exhibiting such high quantum yield for solar hydrogen production and the alluring prospect for solar energy conversion [13]. Also, it has been well demonstrated that to build g-C3N4-based hybrids photocatalysts with various materials, such as TiO2 [14], Bi2MoO6 [15], graphene [16], SrTiO3:Rh [17], BiOBr [18], TaON [19] and AgX/g-C3N4 (X = Br, I) [20], can efficiently promote the separation and transfer of the photogenerated carriers. Here, to combine a proper material with CNIC is expected to make an efficient photocatalyst to improve the photocatalytic activity for photocatalytic degradation of organic pollutants over carbon nitride. A carbon black/carbon nitride intercalation compound (CNIC) composite photocatalyst has been synthesized [8]; however, the composite photocatalyst composed of CNIC and inorganic semiconductor photocatalyst has not been reported.

SrTiO3, as the promising perovskite-type photocatalyst, has attracted much more attention due to its excellent photocatalytic performance [21]. However, SrTiO3 with the relatively wide band gap (3.2 eV) only responds to the ultraviolet light, which accounts for only 4% of the incoming solar energy. To broaden the light absorption into the visible light region which possesses 43% of the solar energy, doping of foreign elements into SrTiO3 has been reported by many research groups [22]. The strong hybridization of orbital of the doping elements, such as some three-valence metal ions (Rh3+, Ir3+ and Ru3+) with the O 2p states, leads to the band gap narrowing of SrTiO3. In particular, the visible light response can be achieved through the Cr doping into the Sr2+ sites of SrTiO3 due to the formation of new valence band by the occupied Cr3+ level and also the occupied Cr3+ level is about 1.0 eV higher than the valence band top formed by O 2p [23]. To the best of our knowledge, there has been no report regarding the introduction of carbon nitride intercalation compound to Cr-doped SrTiO3 to enhance the photocatalytic performance.

In the present work, considering the synergic effect between Cr-doped SrTiO3 and carbon nitride intercalation compound (CNIC), the novel heterostructured Cr-doped SrTiO3–CNIC photocatalyst was prepared via mixing and heating methods. The characteristics of the organic-inorganic heterogeneous composite powders with various amounts of CNIC were analyzed, and also the amount of CNIC was optimized in terms of maximizing the photocatalytic activity for enhancing the photodegradation of methyl orange (MO) under visible light irradiation. The results demonstrated that the Cr-doped SrTiO3–CNIC heterojunction photocatalyst showed an improved MO photodegradation activity due to the improvement of separation efficiency of photogenerated electron–hole pairs.

2 Experimental

2.1 Materials

The starting materials utilized were Sr(NO3)2, Ti(C4H9O)4, Cr(NO3)3·9H2O, NaOH, ethylene glycol (EG), LiCl·H2O, KCl, NaCl and melamine (C3H6N6) (analysis purity grade, Sinopharm Chemical Reagent Co. Ltd.).

2.2 Synthesis of Cr-doped SrTiO3–CNIC composite

The Cr-doped SrTiO3 was prepared through a sol-gel hydrothermal route [23]. In a typical process, Sr(NO3)2, Cr(NO3)3·9H2O and Ti(C4H9O)4 were weighed according to the stoichiometry of Sr0.95Cr0.05TiO3. Cr(NO3)3·9H2O and Sr(NO3)2 were dissolved in ethylene glycol (EG) and the solution was stirred at 80 °C. Ti(C4H9O)4 was dropped into the solution to obtain a sol. Then, a gel was prepared with the evaporation of EG. Then, 30 ml NaOH solution (5 mol/L) was added to the gel. It was transferred into Teflon-lined stainless steel autoclave after stirring for a certain time, and heated at 200 °C for 24 h. The product was washed with distilled water until the pH value was 7-8, then it was dried at 80 °C for 12 h. The carbon nitride intercalation compound (CNIC) was synthesized by a simple molten salt route [13]. The mixture of eutectic salts (LiCl·H2O–KCl–NaCl with 1:1:1 mass ratio) and melamine with a mass ratio of 15:1 for eutectic salts to melamine was prepared and finely ground in a mortar. The obtained mixture was transferred into a quartz glass beaker, and then the powder mixture was heated at 500 °C for 1 h with a ramp rate of 5 °C/min under semiclosed environment. After it was cooled to room temperature, the obtained yellow powder product was washed thoroughly with deionized water several times, and then the final product was collected by centrifugation and dried at 60 °C for 10 h. Then, the mixture of Cr-doped SrTiO3 and CNIC powder was ground together with 20%, 40% and 60% CNIC (denoted as 20%, 40% and 60% Cr-doped SrTiO3-CNIC respectively). Then, the mixture was calcined at 300 °C for 1 h in a tubular furnace under N2 atmosphere. A mechanically mixed CNIC and Cr-doped SrTiO3 with 40% CNIC and no heat treatment was also prepared as a reference (denoted as 40% Cr-doped SrTiO3/CNIC). The g-C3N4 photocatalyst was prepared as a reference by directly heating melamine at 500 °C (heating rate: 20 °C/min) for 2 h, and the further deammonation treatment was performed at 520 °C for 2 h [24] in the semiclosed system to prevent sublimation of melamine.

2.3 Characterization

The as-prepared samples were characterized by X-ray diffraction (XRD) for phase identification on a Rigaku Ultima III diffractometer with Cu Kα radiation (λ=0.154 nm, 40 kV, 40 mA) and a scan rate of 10 (°)/min. The specific surface area was determined by an adsorption apparatus (Micromeritics TriStar 3000, USA) at 77 K based on the Brunauer–Emmett–Teller (BET) method, calculated from the linear part of the BET plot ranging from p/p0=0.05 to p/p0=0.15. Fourier transformed infrared (FTIR) spectra were measured using a Nicolet Nexus 870 FTIR spectrometer using KBr pellet technique. Ultraviolet visible (UV-vis) diffuse reflection spectra were measured using a UV-vis spectrophotometer (Shimadzu UV-2550, Japan) and converted from reflection to absorbance by the Kubelka-Munk method. Their band gaps were calculated by equation of αhv = A(hv-Eg)n/2, in which α, v, A and Eg signify the absorption coefficient, light frequency, proportionality constant, and band gap respectively, and n equals 1 or 4, depending on whether the transition is direct or indirect. Here, n=1 because these materials are direct-gap semiconductors. The microstructure of the sample was observed by a field emission scanning electron microscope (FE-SEM; NOVA230, FEI Ltd.) with accelerating voltage 15 kV, and a high resolution transmission electron microscope (HR-TEM; JEM-2100, 200 kV, JEOL Ltd.). The photoluminescence (PL) spectroscopy was obtained with a spectrofluorometer (VARIAN, Cary Eclipse, USA) at room temperature.

2.4 Photocatalytic activity tests

The methyl orange (MO) dye was used to test the photocatalytic activities of as-prepared samples and the photocatalytic reaction was preformed in a Pyrex reactor. The catalyst (0.1 g) was dispersed in 100 mL MO aqueous solution (4.2 mg/L). The light irradiation system contains a 300 W Xe lamp with cut-off filter L42 for visible light and a water filter to remove heating effects. The reaction solutions of the MO photodegradation for all experiments were first stirred in the dark for 1 h to reach the adsorption–desorption equilibrium of MO on catalysts. The MO degradation efficiency was evaluated using the UV-vis absorption spectra to measure the peak value of a maximum absorption of MO solution at wavelength of 463 nm.

3 Results and discussion

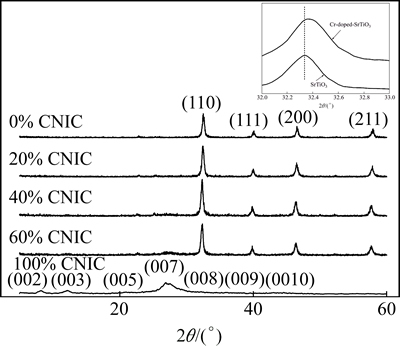

The powder XRD patterns for the as-prepared CNIC, Cr-doped SrTiO3 and Cr-doped SrTiO3–CNIC composites are shown in Fig. 1. For the sample with 100% CNIC, it can be seen that there are the series of diffraction peaks at 8.3°, 12.1°, 21.5°, 27.8°, 32.6° and 36.4°, which can be assigned to the (00l) reflections by analogy to graphite intercalation compounds [25], suggesting that a carbon nitride intercalation compound was successfully synthesized. The XRD pattern (Fig. 1) indicates that the Cr-doped SrTiO3 sample is very similar to the cubic SrTiO3, and all Bragg diffraction peaks which can be indexed as (110), (111), (200) and (211) are in good agreement with JPCDS No. 89-4934. A magnified image of the diffraction peak for the (110) plane is shown in the inset of Fig. 1, and it can be seen that the peak is shifted toward a higher angle, which confirms the incorporation of the Cr ions into the SrTiO3 crystal lattice for the smaller ionic radius of the Cr3+ (0.0615 nm) compared with the ionic radius of Sr2+ (0.118 nm) [23]. The Cr-doped SrTiO3–CNIC composite samples present two-compositions: CNIC and Cr-doped SrTiO3, and the intensity of the (007) peak of CNIC becomes stronger with the increase of the content of CNIC.

Fig. 1 XRD patterns of Cr-doped SrTiO3 and CNIC composites with different proportions (Inset shows diffraction peak positions of (110) plane in range of 2θ = 32°-33°)

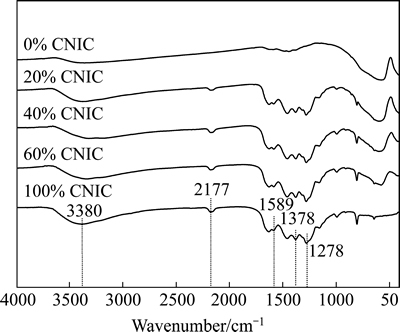

Figure 2 shows the Fourier transform infrared (FTIR) spectra for CNIC, Cr-doped SrTiO3 and Cr-doped SrTiO3–CNIC composites. The FTIR spectrum of the as-prepared CNIC shows the features very similar to the published results [13]. From Fig. 2, a band at 2177 cm-1 corresponds to a cyano group stretch, which can be attributed to loss of ammonia. The FTIR spectrum shows that, after forming CNIC, several stretching peaks at 1589, 1408 and 1238 cm-1 of CN heterocycles of g-C3N4 [26], shift to 1560, 1378 and 1278 cm-1, respectively. The position shift indicates the strong interaction between insertions and the s-triazine ring [13]. The strong hydroxyl stretching at 3380 cm-1 in the FTIR spectrum, indicates that the CNIC has a hydrophilic surface, which is beneficial to obtain a highly dispersed state and provide a sufficient surface area forphotocatalytic organic pollutant degradation. The FTIR spectra of Cr-doped SrTiO3–CNIC composites show that the characteristic bands for CNIC still remain. Broad absorption in the range of 500-800 cm-1 for the pure Cr-doped SrTiO3, may be attributed to TiO6 octahedron stretching vibration [27], while for the composite, the intensity of the broad band decreases with the increase of the content of CNIC, which may be due to the existence of the organic component.

Fig. 2 FTIR spectra of Cr-doped SrTiO3 and CNIC composites with different proportions

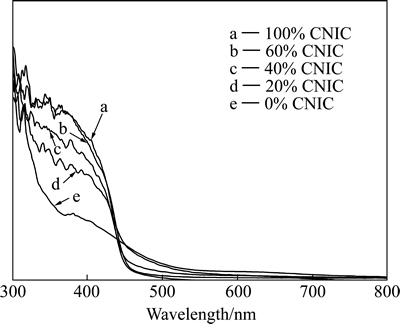

The optical absorption of the as-prepared samples was investigated using UV-vis diffuse reflectance spectroscopy. Figure 3 shows the UV-vis absorption spectra of CNIC, Cr-doped SrTiO3 and Cr-dopedSrTiO3–CNIC composites. It can be observed that the absorption edge of the Cr-doped SrTiO3 sample occurs at ca. 540 nm, and the band gap energy is estimated to be 2.30 eV. After being coupled with CNIC, the absorption edge shifts to the higher energy region. It can be seen from Fig. 3 that the absorption edges of the composite samples shift remarkably to shorter wavelength with increasing the amount of CNIC. The band gap of the samples increases from 2.30 eV of Cr-doped SrTiO3 to 2.71 eV of CNIC when the content of CNIC is increased from 0 to 100 %.

Fig. 3 UV-vis diffuse reflectance spectra of Cr-doped SrTiO3 and CNIC composites with different proportions

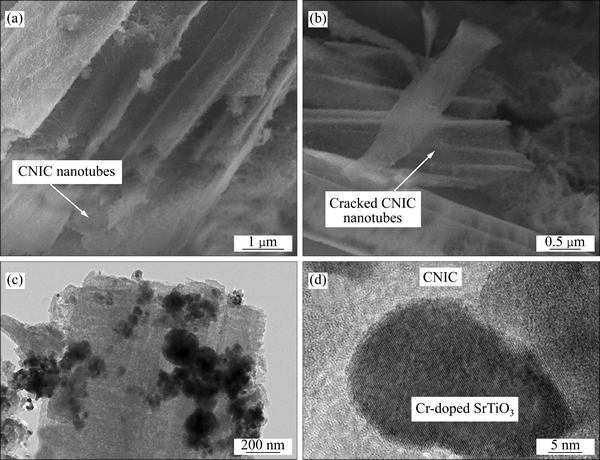

The morphology of CNIC and 40% (mass fraction) Cr-doped SrTiO3-CNIC composite material was investigated using SEM, TEM and high-resolution TEM (HRTEM) respectively, which is shown in Fig. 4. Scanning electron microscopy (SEM) observations (Figs. 4(a) and (b)) show that the CNIC has tubular morphology (several hundreds of nanometers in width and several micrometers in length) with a square cross-section. The specific surface area of CNIC reaches 118.4 m2/g, much higher than 10 m2/g for bulk g-C3N4 [7, 10, 24], owing to the small thickness of nanoplates (corresponding to seven repeating identity periods) and the porous structure, and the walls of CNIC nanotubes are formed by agglomeration of nanoplates [13]. From Fig. 4(c), the particle size of the Cr-doped SrTiO3 was estimated to be in the range of 20-30 nm. The HRTEM image (Fig. 4(d)) shows that the lattice fringes have a spacing of 0.27 nm corresponding to interplanar spacing of (110) plane of Cr-doped SrTiO3, which is consistent with the XRD result.

Fig. 4 SEM images of CNIC nanotube (a, b) and TEM (c) and HRTEM (d) images of 40% (mass fraction) Cr-doped SrTiO3-CNIC composite

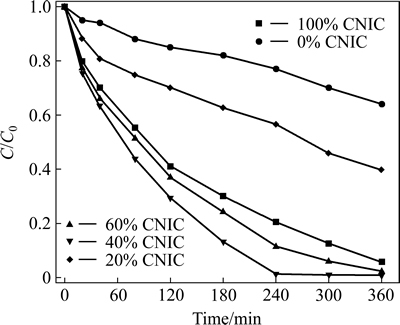

MO photodegradation is used to evaluate the photocatalytic activity for the investigated samples and the results are shown in Fig. 5. In the blank experiment, MO photodegradation is not observable in the absence of catalyst, which indicates that MO is stable under visible light irradiation. From Fig. 5, it can be seen that, after 6 h of visible light illumination, MO removal over CNIC is 94% and Cr-doped SrTiO3 shows a degradation ratio as low as 35% for MO. The as-prepared composite photocatalysts with 40% or 60% CNIC show better photocatalytic activity than single-phase CNIC and Cr-doped SrTiO3. Significantly, the 40% Cr-doped SrTiO3-CNIC composite presents a sharp increase in the catalytic activity for MO decomposition, which induced 100% degradation within 4 h light irradiation. 11.4%, 12.3%, 12.7%, 12.9% and 13.2% MO before the photoreaction were adsorbed on the surface of CNIC, Cr-doped SrTiO3 and 20%, 40%, 60% Cr-doped SrTiO3–CNIC composites, respectively. From Fig. 5, 79.5%, 23.0%, 43.4%, 100%, 88.5% MO were photocatalytically degraded over CNIC, Cr-doped SrTiO3 and 20%, 40%, 60% Cr-doped SrTiO3-CNIC composites after 4 h light irradiation, respectively. For the Cr-doped SrTiO3-CNIC composite, the content of CNIC was important to achieve the high photocatalytic activity. The suitable content of CNIC caused the better dispersion of the Cr-doped SrTiO3, and may promote the transfer and separation of photogenerated electrons and holes. However, at content higher than 40%, the heterojunction structures and interfaces between the CNIC and Cr-doped SrTiO3 particles decreased and thus the interfacial charge transfer was suppressed, which reduced the photocatalytic activity.

Fig. 5 MO photodegradation over Cr-doped SrTiO3 and CNIC composites with different proportions

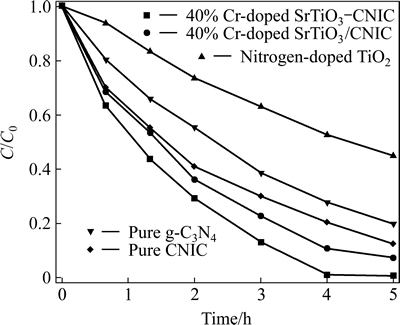

For comparison, the mixed material of CNIC and Cr-doped SrTiO3 without heat treatment (40% Cr-doped SrTiO3/CNIC), pure g-C3N4, and the commercial nitrogen-doped-TiO2 with a specific surface area about 65 m2/g (TPS201, Sumitomo Corp. Japan) were also used as photocatalysts for the degradation of MO. Figure 6 shows the degradation activities of MO with different photocatalysts under visible light irradiation. As shown in Fig. 6, the 40% Cr-doped SrTiO3-CNIC composite shows much higher activity than pure g-C3N4, pure CNIC, nitrogen-doped TiO2, and 40% Cr-doped SrTiO3/CNIC photocatalysts. This clearly indicates that the advantage of heating treatment is the formation of chemically bonded interfaces between the two materials, and the Cr-doped SrTiO3-CNIC composite was determined as an efficient visible-light-driven photocatalyst for the degradation of MO.

Fig. 6 Comparison of MO degradation with different photocatalysts under visible light irradiation

In general, during the photocatalytic degradation reaction, hydroxyl radicals (·OH) and superoxide (O2· or HOO·) reactive oxidation species are formed [10]. Hydroxyl radical (·OH) may be the active species for the composite system [28]. ·OH is generated via the photogenerated hole oxidation [29] or multistep reduction of O2 induced by photogenerated electron (O2+e O2·-, O2·-+e+2H+

O2·-, O2·-+e+2H+ H2O2, H2O2+e

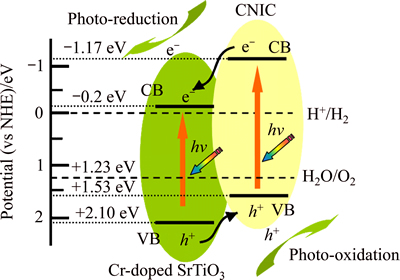

H2O2, H2O2+e ·OH+OH-) [30]. The photodegradation activity of photocatalysts is generally associated with oxidation ability of photogenerated holes in valence band and reduction ability of photogenerated electrons in conduction band [10]. The oxidation potential of CNIC is 1.53 V [13], which means that the photogenerated holes are incapable of directly oxidizing adsorbed hydroxyl groups to generate hydroxyl radicals (2.7 V vs NHE) [10]. Therefore, a reliable speculation may be that the ·OH in the composite photocatalysis system is formed from the multistep reduction of O2 under light irradiation.

·OH+OH-) [30]. The photodegradation activity of photocatalysts is generally associated with oxidation ability of photogenerated holes in valence band and reduction ability of photogenerated electrons in conduction band [10]. The oxidation potential of CNIC is 1.53 V [13], which means that the photogenerated holes are incapable of directly oxidizing adsorbed hydroxyl groups to generate hydroxyl radicals (2.7 V vs NHE) [10]. Therefore, a reliable speculation may be that the ·OH in the composite photocatalysis system is formed from the multistep reduction of O2 under light irradiation.

The BET specific surface area of the as-prepared samples was investigated by nitrogen adsorption. The BET specific surface areas of CNIC, Cr-doped SrTiO3, 20%, 40% and 60% Cr-doped SrTiO3-CNIC samples are 118.4, 22.9, 42.5, 55.2 and 68.4 m2/g, respectively. Thus, the change in photocatalytic degradation activity is not linked with the difference in specific surface area. The enhancement of photocatalytic performance for the composite materials is supposed to be attributed to the more effective separation and transport of the photogenerated electron–hole pairs. Based on the band gap positions, the CB and VB edge potentials of polymeric CNIC were determined to be -1.17 and 1.53 eV at pH 7 (versus the normal hydrogen electrode) [13], respectively. The conduction band level of SrTiO3 is -0.2 eV [31]. Therefore, the occupied Cr3+ level in Cr-doped SrTiO3 is estimated to be 2.1 eV according to the band gap of 2.3 eV which was determined from the UV-vis absorption spectrum (Fig. 3). Since the CB edge potential of CNIC (-1.17 eV) is more negative than that of Cr-doped SrTiO3 (-0.2 eV), the photo-induced electrons on CNIC particle surfaces transfer more easily to Cr-doped SrTiO3 via the well developed interface. Similarly, the photo-induced holes on the Cr-doped SrTiO3 surface move to CNIC due to the large difference in VB edge potentials. The scheme for electron–hole separation and transport at the visible-light-driven Cr-doped SrTiO3–CNIC composite photocatalyst interface is shown in Fig. 7. This reduces the probability of electron–hole recombination and leads to a larger number of electrons on the Cr-doped SrTiO3 surface and holes on the CNIC surface, respectively, which promotes the photocatalytic reactions to decompose MO.

Fig. 7 schematic illustration for electron-hole separation and transport at visible light-driven Cr-doped SrTiO3-CNIC composite photocatalyst interface

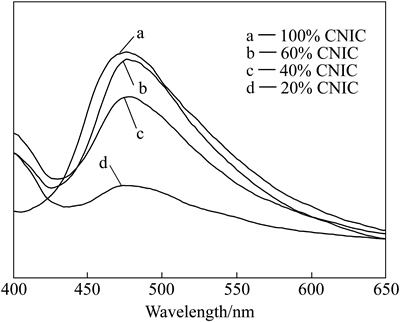

Photoluminescence (PL) analysis is an effective method to investigate the migration and recombination efficiency of photo-generated carriers in semiconductors because PL emission probably results from the band edge recombination mechanism [16, 32]. To further confirm the above-proposed mechanism, the PL spectra of the Cr-doped SrTiO3-CNIC composite photocatalysts are investigated with an excitation wavelength of 330 nm and shown in Fig. 8. The emission band for pure CNIC is centered at about 460 nm, which is close to the band gap energy of 2.7 eV for carbon nitride intercalation compound, which is indicative of the band edge recombination of electron–hole pairs [8]. The positions of the emission peaks of Cr-doped SrTiO3–CNIC composites are similar to those of pure CNIC. Obviously, compared with pure CNIC, the emission intensity of the Cr-doped SrTiO3-CNIC composite samples is much lower. This indicates that the composite sample has a lower recombination rate of electrons and holes under visible light irradiation. The process can be assumed that the electrons were excited from the valence band to the conduction band of CNIC and then transferred to Cr-doped SrTiO3 nanoparticles, preventing a direct recombination of electrons and holes, thus effectively increasing the separation of photogenerated electron-hole pairs, which conforms to the discussion about the separation of charge carriers and photocatalytic experiments.

Fig. 8 Photoluminescence spectra of Cr-doped SrTiO3-CNIC composite photocatalysts

4 Conclusions

1) A series of Cr-doped SrTiO3-CNIC composite photocatalysts are prepared by introducing carbon nitride intercalation compound via a mixing and heating method.

2) Compared with single-phase CNIC or Cr-doped SrTiO3, the Cr-doped SrTiO3–CNIC composite photocatalysts exhibit a significantly enhanced photocatalytic performance in degrading MO, and the highest efficiency is observed with 40% Cr-doped SrTiO3-CNIC composite.

3) Our results clearly indicated that the suitably matching conduction and valance band levels improved the separation and transport of photogenerated electron-hole pairs, thus enhancing the visible-light- driven photo-oxidation performance of the Cr-doped SrTiO3-CNIC composite photocatalysts.

References

[1] PELAEZ M, NOLAN N T, PILLAI S C, SEERY M K, FALARAS P, KONTOS A G, DUNLOP P S M, HAMILTON J W J, BYRNE J A, O’SHEA K, ENTEZARI M H, DIONYSIOU D D. A review on the visible light active titanium dioxide photocatalysts for environmental applications [J]. Appl Catal B: Environ, 2012, 125: 331-349.

[2] DHOLAM R, PATEL N, ADAMI M, MIOTELLO A. Hydrogen production by photocatalytic water-splitting using Cr- or Fe-doped TiO2 composite thin films photocatalyst [J]. Int J Hydrogen Energy, 2009, 34(13): 5337-5346.

[3] CHEN Chun-cheng, MA Wan-hong, ZHAO Jin-cai. Semiconductor-mediated photodegradation of pollutants under visible-light irradiation [J]. Chem Soc Rev, 2010, 39(11): 4206-4219.

[4] TANK C M, SAKHARE Y S, KANHE N S, NAWALE A B, DAS A K, BHORASKAR S V, MATHE V L. Electric field enhanced photocatalytic properties of TiO2 nanoparticles immobilized in porous silicon template [J]. Solid State Sci, 2011, 13(8): 1500-1504.

[5] OSTERLOH F E. Inorganic materials as catalysts for photochemical splitting of water [J]. Chem Mater, 2008, 20(1): 35-54.

[6] LIN Xin-ping, XING Jing-cheng, WANG Wen-deng, SHAN Zhi-chao, XU Fang-fang, HUANG Fu-qiang. Photocatalytic activities of heterojunction semiconductors Bi2O3/BaTiO3: a strategy for the design of efficient combined photocatalysts [J]. J Phys Chem C, 2007, 111(49): 18288-18293.

[7] WANG Xin-chen, MAEDA K, THOMAS A, TAKANABE K, XIN Gang, CARLSSON J M, DOMEN K, ANTONIETTI M. A metal-free polymeric photocatalyst for hydrogen production from water under visible light [J]. Nat Mater, 2009, 8(1): 76-80.

[8] WU Zhao-chun, GAO Hong-lin, YAN Shi-cheng, ZOU Zhi-gang, Synthesis of carbon black/carbon nitride intercalation compound composite for efficient hydrogen production [J]. Dalton Trans, 2014, 43(31): 12013-12017.

[9] LIU Gang, NIU Ping, SUn Cheng-hua, SMITH S C, CHEN Zhi-gang, LU Gao-qing (Max), CHENG Hui-ming. Unique electronic structure induced high photoreactivity of sulfur-doped graphitic C3N4 [J]. J Am Chem Soc, 2010, 132(33): 11642-11648.

[10] YAN Shi-cheng, LI Zhao-sheng, ZOU Zhi-gang. Photodegradation of rhodamine b and methyl orange over boron-doped g-C3N4 under visible light irradiation [J]. Langmuir, 2010, 26(6): 3894-3901.

[11] ZHANG Yuan-jian, MORI T, Ye Jin-hua, ANTONIETTI M. Phosphorus-doped carbon nitride solid: enhanced electrical conductivity and photocurrent generation [J]. J Am Chem Soc, 2010, 132(18): 6294-6295.

[12] YUE Bing, LI Qiu-ye, IWAI H, KAKO T, YE Jin-hua. Hydrogen production using zinc-doped carbon nitride catalyst irradiated with visible light [J]. Sci Technol Adv Mater, 2011, 12(3): 034401.

[13] GAO Hong-lin, YAN Shi-cheng, WANG Jia-jia, HUANG Yu-an, WANG Peng, LI Zhao-sheng, ZOU Zhi-gang. Towards efficient solar hydrogen production by intercalated carbon nitride photocatalyst [J]. Phys Chem Chem Phys, 2013, 15(41): 18077-18084.

[14] YAN Hong-jian, YANG Hao-xin. TiO2–g-C3N4 composite materials for photocatalytic H2 evolution under visible light irradiation [J]. J Alloys Compd, 2011, 509(4): L26-L29.

[15] LI Hai-ping, LIU Jing-yi, HOU Wan-guo, DU Na, ZHANG Ren-jie, TAO Xu-tang. Synthesis and characterization of g-C3N4/Bi2MoO6 heterojunctions with enhanced visible light photocatalytic activity [J]. Appl Catal B: Environ, 2014, 160/161: 89-97.

[16] Xiang Quan-jun, Yu Jia-guo, Jaroniec M. Preparation and enhanced visible-light photocatalytic H2-production activity of graphene/C3N4 composites [J]. J Phys Chem C, 2011, 115(15): 7355-7363.

[17] KANG H W, LIM S N, SONG Dong-su, PARK S B. Organic-inorganic composite of g-C3N4–SrTiO3: Rh photocatalyst for improved H2 evolution under visible light irradiation [J]. Int J Hydrogen Energy, 2012, 37(16): 11602-11610.

[18] FU Jie, TIAN Yan-long, CHANG Bin-bin, XI Feng-na, DONG Xiao-ping. BiOBr–carbon nitride heterojunctions: synthesis, enhanced activity and photocatalytic mechanism [J]. J Mater Chem, 2012, 22(39): 21159-21166.

[19] YAN Shi-cheng, LV Shu-bai, LI Zhao-sheng, ZOU Zhi-gang. Organic–inorganic composite photocatalyst of g-C3N4 and TaON with improved visible light photocatalytic activities [J]. Dalton Trans, 2010, 39(6): 1488-1491.

[20] XU Hui, YAN Jia, XU Yuan-guo, SONG Yan-hua, LI Hua-ming, XIA Jie-xiang, HUANG Chuan-jing, WAN Hui-lin. Novel visible-light-driven AgX/graphite-like C3N4 (X=Br, I) hybrid materials with synergistic photocatalytic activity [J]. Appl Catal B: Environ, 2013, 129: 182-193.

[21] Domen K, Kudo A, Onishi T, Kosugi N, Kuroda H. Photocatalytic decomposition of water into hydrogen and oxygen over nickel(II) oxide-strontium titanate (SrTiO3) powder. 1. Structure of the catalysts [J]. J Phys Chem, 1986, 90(2): 292-295.

[22] Wang Jin-shu, Yin Shu, Komatsu M, Zhang Qi-wu, Saito F, Sato T. Preparation and characterization of nitrogen doped SrTiO3 photocatalyst [J]. J Photochem Photobiol A, 2004, 165(1/2/3): 149-156.

[23] YU He, OUYANG Shu-xin, YAN Shi-cheng, LI Zhao-sheng, YU Tao, ZOU Zhi-gang. Sol–gel hydrothermal synthesis of visible-light-driven Cr-doped SrTiO3 for efficient hydrogen production [J]. J Mater Chem, 2011, 21(30): 11347-11351.

[24] YAN Shi-cheng, LI Zhao-sheng, YU Tao, ZOU Zhi-gang. Photodegradation performance of g-C3N4 fabricated by directly heating melamine [J]. Langmuir, 2009, 25(17): 10397-10401.

[25] Dresselhaus M S, Dresselhaus G. Intercalation compounds of graphite [J]. Adv Phys, 2002, 51(1): 1-186.

[26] Lin-Vien D, Colthup N B, Fatelley W G, Grasselli J G. The handbook of infrared and Raman characteristic frequencies of organic molecules [M]. San Diego, CA: Academic Press Inc., 1991.

[27] CHEN G, LI Z H, ZHANG Z G. Electronic structure and visible light photocatalysis water splitting property of chromium-doped SrTiO3 [J]. J Solid State Chem, 2006, 179(12): 3704-3708.

[28] Yang Ming, Huang Qiao, Jin Xiao-qi. ZnGaNO solid solution-C3N4 composite for improved visible light photocatalytic performance [J]. Mater Sci and Eng B, 2012, 177(8): 600-605.

[29] Yoon S H, Lee J H. Oxidation mechanism of As(III) in the UV/TiO2 system: evidence for a direct hole oxidation mechanism [J]. Environ Sci Technol, 2005, 39(24): 9695-9701.

[30] LIU Guang-ming, LI Xiang-zhong, ZHAO Jin-cai, HORIKOSHI S, HIDAKA H. Photooxidation mechanism of dye alizarin red in TiO2 dispersions under visible illumination: an experimental and theoretical examination [J]. J Mol Catal A: Chem, 2000, 153(1/2): 221-229.

[31] KATO H, KUDO A. Visible-light-response and photocatalytic activities of TiO2 and SrTiO3 photocatalysts codoped with antimony and chromium [J]. J Phys Chem B, 2002, 106(19): 5029-5034.

[32] GE Lei, HAN Chang-cun, LIU Jing. Novel visible light-induced g-C3N4/Bi2WO6 Composite photocatalysts for efficient degradation of methyl orange [J]. Appl Catal B: Environ, 2011, 108/109: 100-107.

(Edited by YANG Hua)

Foundation item: Project(51208102) supported by the National Natural Science Foundation of China

Received date: 2014-12-15; Accepted date: 2015-04-15

Corresponding author: YANG Ming, Associate Professor, PhD; Tel: +86-25-83794100; Fax: +86-25-83795406; E-mail: bartty_ym@sina.com