文章编号:1004-0609(2013)S1-s0101-04

电子束逐层熔化金属成型技术制备多孔Ti-6Ai-4V合金的力学性能

徐勤思1,程旭莹1,侯文韬1,王 哲 2,李述军1,郝玉琳1,杨 锐1

(1. 中国科学院 金属研究所,沈阳材料国家(联合)实验室,沈阳 110016;

2. 沈阳大学 机械工程学院,沈阳 110044)

摘 要:利用电子束逐层熔化(Additive manufacture-electron beam melting,AM-EBM)金属成型技术制备出菱形十二面体网格结构的多孔Ti-6Al-4V合金,并对其微观组织和力学性能进行了研究。研究结果表明:该多孔材料孔壁组织主要为针状α′马氏体相,同时含有极少量的β相;其弹性模量和压缩强度随孔隙率的增加而降低,相对模量、相对强度与相对密度的关系基本符合Gibson-Ashby模型。

关键词:多孔Ti-6Al-4V合金;电子束熔融;压缩性能;孔隙率;压缩强度

中图分类号:TG146.2+3 文献标志码:A

Mechanical properties of cellular-structure Ti-6Al-4V alloys fabricated by electron beam melting method

XU Qin-si1, CHENG Xu-ying1, HOU Wen-tao1, WANG Zhe2, LI Shu-jun1, HAO Yu-lin1, YANG Rui1

(1. Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. College of Mechanical Engineering, Shenyang University, Shenyang 110044, China)

Abstract: Cellular Ti-6Al-4V alloys with reticulated mesh structures were designed by computer aided design (CAD) and manufactured by the electron beam melting (EBM) technique using raw powders with extra low interstitials (ELI). The microstructures and mechanical properties of these cellular alloys were further characterized. The cellular Ti-6Al-4V alloys with acicular microstructures mainly consist of thin α′ martensite with a small amount of β phase. The elastic modulus and compressive strength of these Ti-6Al-4V alloys decrease with the increase of porosity of cellular structures. Moreover, the relationships between relative modulus and density, as well as between relative strength and density, were found to be consistent with the Gibson-Ashby model.

Key words: cellular Ti-6Al-4V; electron beam melting; compressive properties; porosity; compressive strength

Ti-6Al-4V合金是一种应用广泛的医用钛合金[1]。致密的Ti-6Al-4V块体材料作为植入体材料,其弹性模量与人体骨骼相比仍较高,且表面为生物惰性,无法与人体组织形成强有力的结合。因此,相对于致密块体材料,人们提出采用具有大量孔隙的多孔材料作为植入材料[2-3]。多孔的引入不仅可以降低致密体的弹性模量,减少植入体于人体骨组织之间的应力屏蔽现象,还能为新骨细胞的长入和水分养料的传输提供空间和渠道,增强植入体与人体组织之间的结合,从而延长金属植入体的使用寿命[4-6]。

本文作者研究利用电子束逐层熔化金属成型技术制备了一种以像晶格单胞一样可以在三维空间复制且密堆积的菱形十二面体为孔结构单元的规则多孔Ti-6Al-4V合金,并研究其力学行为。

1 实验

本实验采用的粉末原料为Ti-6Al-4V-ELI医疗用(外科植入)合金粉末,粉末颗粒呈近似球形,平均粒度约30 μm;Ti-6Al-4V粉末的元素成分(质量分数)为:6.04% Al,4.05% V,0.013% C,0.07% Fe,0.13% O,低于0.005% 的N和H,余量为Ti。

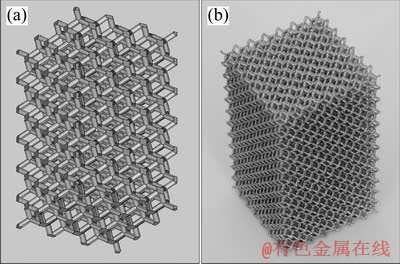

利用Arcam(A1)型电子束逐层熔化金属成型(EBM)实验设备[7-8] (瑞典曼德卡姆有限公司),通过调整制备工艺参数,制备出相对密度分别为0.73、0.91和1.18 g/cm3的菱形十二面体网格多孔Ti-6Al-4V合金,如图1所示。

图1 Ti-6Al-4V网格多孔结构设计模型图和实体图

Fig. 1 CellularTi-6Al-4V alloys model(a) and entity(b)

利用高低真空扫描电镜(Scanning electron microscope)观察孔壁形貌;采用RFDA-HTVP1750-C弹性模量仪测量其动态弹性模量。该弹性模量仪属于敲打接触式,共振频率范围为1~106 Hz,内耗(阻尼)测量范围10-5~10-1;金相组织观察采用德国Zeiss Axiovert200MAT金相显微镜;透射样品利用离子减薄的方法制得,采用能量为5 keV的氩离子源对试样进行减薄,入射角15°,无附加冷凝装置。采用TECNAI 20透射电子显微镜对减薄样品进行观察。室温压缩力学性能测试在电子万能试验机(Instron-5582)上进行,压缩应变速率为1×10-3 s-1。试样尺寸为15 mm×15 mm×30 mm。

2 结果与分析

2.1 AM-EBM法制备多孔Ti-6Al-4V合金的微观组织

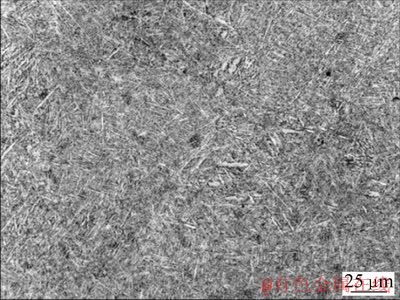

图2所示为由AM-EBM技术制备的Ti-6Al-4V网格多孔结构的孔棱横截面典型显微组织形貌。从图2可以看出:制备的多孔合金均为针状α′马氏体相。这种组织在采用电子束或激光熔化Ti-6Al-4V基体合金时常常出现,主要是由于熔化的合金在凝固过程中冷却速率较快,无法通过高温β相的扩散相变产生α相。

图2 多孔Ti-6Al-4V合金的孔棱横截面金相显微组织

Fig. 2 SEM images of EBM Ti-6Al-4V samples

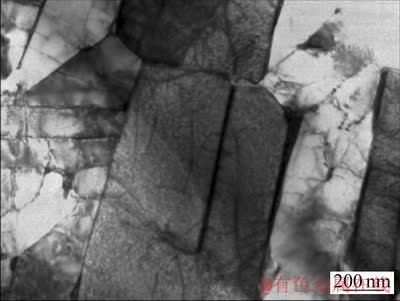

为了进一步观察多孔Ti-6Al-4V材料的微观结构,对多孔样品孔棱横截面取样进行透射电镜观察(图3)。由TEM像可观察到针状α′的片层厚度为1 μm左右,此外,还观察到α′片层组织之间存在片层很薄且极少量的β相。

图3 网格多孔Ti-6Al-4V合金的TEM形貌

Fig. 3 TEM image of EBM Ti-6Al-4V sample

2.2 AM-EBM法制备的多孔Ti-6Al-V合金的动态弹性模量

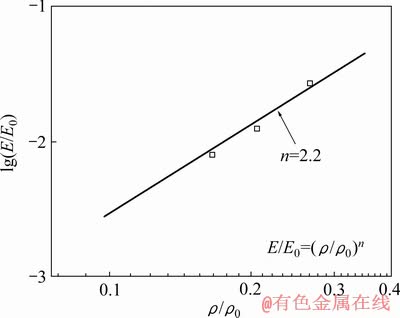

本研究制备的多孔样品的动态弹性模量值为0.2~6.3 GPa。GIBSON和ASHBY在文献[9]中给出了多孔材料的弹性模量和相对密度之间存在如下关系:

(1)

(1)

式中:E0和ρ0分别为实体金属的弹性模量(GPa)和理论密度(g/cm3)。由立方体孔结构模型的受力和几何关系可以推导出公式中的指数项n=2。对于本文中采用AM-EBM技术制备的Ti-6Al-4V多孔结构,通过线性回归计算得到n的值等于2.2(图4),这一结果与先前MURR等[4, 10]研究报道一致,基本符合Gibson-Ashby关系。且多孔材料的杨氏模量与孔隙率的变化趋势相反,即样品的相对密度越大,刚度越大。

图4 多孔Ti-6Al-4V合金的相对弹性模量(E/E0)与相对密度(ρ/ρ0)的理论关系

Fig. 4 Theoretical relationship between elastic modulus(E/E0) and relative density(ρ/ρ0)

2.3 AM-EBM法制备的多孔Ti-6Al-V合金的压缩力学行为

2.3.1 相对密度对AM-EBM法制备的多孔Ti-6Al-V合金力学性能的影响

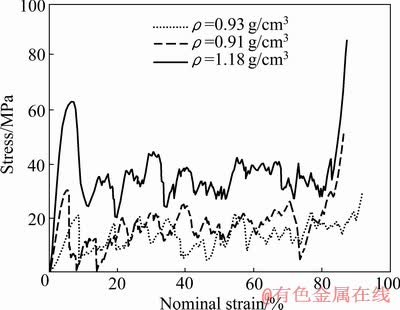

对AM-EBM技术制得的多孔Ti-6Al-4V样品进行了静态压缩测试,得到的名义应力—应变曲线,如图5所示。在曲线的起始段存在一个“弹性”区,名义应力—应变关系近似呈线性,在应力达到某一峰值后曲线中开始出现一段平台区,随着应变的增加应力围绕着一个恒定值上下波动,直到达到一个较大的名义应变值后应力急速上升,即达到致密化。然而,与大多数已报道的铝合金泡沫的变形特征相比,本文中的多孔Ti-6Al-4V样品的压缩曲线平台区的应力波动较大,类似于脆性泡沫典型的锯齿形平台,由此推断AM-EBM技术制备的多孔Ti-6Al-4V合金的压缩变形机制为孔棱的脆性断裂,这主要与快速冷却形成的马氏体相具有较低韧性相关联。

本研究中将压缩曲线弹性段结束时的应力最大值定义为样品的压缩强度,该应力最大值处对应的应变称为失效应变。从图5中可以看出:多孔样品的压缩强度随相对密度的升高而升高,而失效应变的变化趋势则正好相反。在静态压缩试验的过程中,观察网格结构的试样在压缩变形时产生的变形带与承载方向的夹角始终为45°。

图5 Ti-6Al-4V多孔结构的压缩名义应力—应变曲线

Fig. 5 Strain—stress curves of cellular Ti-6Al-4V alloys

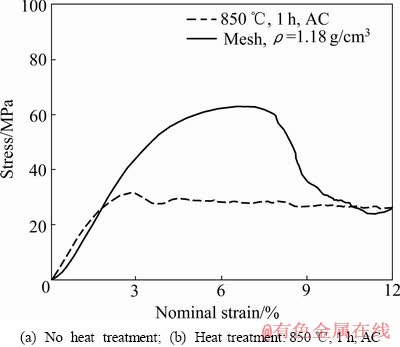

2.3.2 热处理对AM-EBM法制备的多孔Ti-6Al-4V合金力学性能的影响

根据前文对压缩变形行为的研究可以看出:AM-EBM技术制备的多孔Ti-6Al-4V合金的孔棱多表现为脆性断裂,这主要与快速冷却形成的马氏体相具有较低韧性相关联,通过热处理的方式析出韧性α相可能会提高合金的韧性,从而使多孔合金的力学性能得到改善。

图6 多孔Ti-6Al-4V合金850 ℃、1 h空冷热处理前后的压缩名义应力—应变曲线

Fig. 6 Comprehensive nominal strain—stress curves of cellular Ti-6Al-4V alloys

图6所示为AM-EBM技术制备的多孔Ti-6Al-4V合金经850 ℃、1 h热处理前后的静态压缩曲线。由图6可以看出:热处理后的多孔Ti-6Al-4V合金的压缩强度虽有所降低,但孔棱由脆性断裂变成了韧性断裂。这说明,通过热处理的方式有望改善多孔Ti-6Al-4V合金的压缩力学性能。

3 结论

1) 采用EBM法制备的多孔Ti-6Al-4V合金的孔棱微观组织主要为针状α马氏体,此外还有极少量的β相存在。

2) 多孔Ti-6Al-4V合金的压缩变形特征为典型的脆性断裂。断裂优先发生于孔棱结点处。

3) 多孔Ti-6Al-4V合金的弹性模量和压缩强度随孔隙率的增加而降低,相对模量、相对强度与相对密度的关系基本符合Gibson-Ashby模型。

REFERENCES

[1] NIINOMI M. Recent metallic materials for biomedical applications[J]. Metallurgical and Materials Transactions A, 2002, 33(3): 477-486.

[2] HEINL P, ROTTMAIR A, KORNER C, SINER R F. Cellular titanium by selective electron beam melting[J]. Advanced Engineering Materials, 2007, 9: 360-364.

[3] MURR L E, GAUTAN S M, MEDINA F, MARTINEZ E, MARTINEZ J L, HEMANDEZ D H, MACHADO B I, RAMIREZ D A, WICKER R B. Characterization of Ti-6Al-4V open cellular foams fabricated by additive manufacturing using electron beam melting[J]. Materials Science and Engineering A, 2010, 527: 1861-1868.

[4] MURR L E, GAYTAN S M, MEDINA F, MARINEZ E, MARTINEZ J L, HEMANDEZ D H, MACHADO B I, RAMIREZ D A, WICKER R B. Microstructure evolution associated with adiabatic shear bands and shear band failure in ballistic plug formation in Ti-6Al-4V targets[J]. Materials Science and Engineering A, 2009, 516: 205-216.

[5] HEINL P, MULLER L, KOMER C, SINGER R F, MULLER F A. Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting[J]. Acta Biomaterialia, 2008, 4: 1536-1544.

[6] RAMIREZ D A, MURR L E, LI Shu-jun, TIAN Yu-xing, MARTINEZ E, MARTINEZ J L, MACHADO B I, GAYTAN S M, MEDINA F, WICKER R B. Open-cellular copper structures fabricated by additive manufacturing using electron beam melting[J]. Materials Science and Engineering A, 2011, 528: 5379-5386.

[7] WOHLER T. Rapid prototyping, tooling and manufacturing state of the industry annual worldwide progress report[R]. Colorado: Wohlers Associates, Inc., 2005.

[8] MURR L E, AMATO K N, LI Shu-jun, TIAN Yu-xing, GAYTAN S M, MARTINEZ E S H, MEDINA F, WICKER R B. Microstructure and mechanical properties of open cellular biomaterials prototypes for total knee replacement implants fabricated by electron beam melting[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2011, 4: 1396-1411.

[9] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties[M]. 2nd ed. Cambridge: Cambridge University Press, 1997.

[10] MURR L E, GAUTAN S M, MEDINA F, MARTINEZ E, MARTINEZ J L, HEMANDEZ D H, MACHADO B I, RAMIREZ D A, WICKER R B. Microstructure evolution associated with Adiabatic shear bands and shear band failure in ballistic plug formation in Ti-6Al-4V targets[J]. Materials Science and Engineering A, 2009, 516: 205-216.

(编辑 何运斌)

基金项目:国家自然科学基金资助项目(51071152,51271182);国家重点基础研究发展计划项目(2012CB619103,2012CB933901,2012CB933902)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:郝玉琳,研究员,博士;电话:024-83978841;E-mail: ylhao@imr.ac.cn