文章编号:1004-0609(2010)S1-s0207-04

热处理对Ti3Al基合金板材拉伸性能与微观组织的影响

曹京霞1,何书林2,石卫民2,王宏武2,王 新2

(1. 北京航空材料研究院,北京 100095;

2. 宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:研究固溶温度、时效温度以及多重时效处理对Ti-24Al-15Nb-1Mo合金热轧板材拉伸性能的影响,对不同热处理工艺下板材的微观组织和拉伸断口形貌进行观察。结果表明:当固溶处理温度从990 ℃升高到1 010 ℃时,Ti-24Al-15Nb-1Mo合金热轧板材的室、高温强度均有所提高,塑性略有降低;当时效温度从815 ℃升高到850 ℃时,板材的室温和高温强度降低,塑性变化不明显;Ti-24Al-15Nb-1Mo合金热轧板材经990 ℃固溶处理后再进行多次时效处理,其拉伸性能变化不明显;增加时效次数,拉伸强度略微降低。

关键词:Ti3Al基合金;板材;拉伸性能;微观组织

中图分类号:TG113.1; TG113.25; TG146.2+3 文献标志码:A

Effect of heat treatment on tensile properties and

microstructures of Ti3Al based alloy sheet

CAO Jing-xia1, HE Shu-lin2, SHI Wei-min2, WANG Hong-wu2, WANG Xin2

(1. Beijing Institute of Aeronautical Materials, Beijing 100095, China;

2. Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The effects of solution treatment temperature, aging treatment temperature, multiple aging treatments on the tensile properties of Ti-24Al-15Nb-1Mo alloy hot-rolled sheet were studied. The microstructure and tensile fracture morphologies with different heat treatment conditions were observed by SEM. The results show that the tensile strength of Ti-24Al-15Nb-1Mo alloy hot-rolled sheet is improved, but the tensile ductility decreases slightly both at room and elevate temperature with the increase of solution temperature from 990 ℃ to 1 010 ℃. The tensile strength decreases with aging temperature increasing from 815 ℃ to 850 ℃, but the tensile ductility does not change obviously. No significant differences of tensile properties are observed after solution treatment and multiple aging treatments. Additional aging treatments results in slightly decrease of tensile strength.

Key words: Ti3Al-based alloys; sheet; tensile property; microstructure

中等Nb含量的Ti3Al基合金及高Nb含量的Ti2AlNb基合金具有密度低、比强度高的特性,与高温钛合金相比其使用温度提高50~150 ℃以上。随着Ti3Al基合金及Ti2AlNb基合金的室温塑性和韧性的改善以及热加工技术的突破,使这些材料在航空航天等领域的高温结构件上的应用成为可能[1-5]。近年来,随着高性能飞行器的研发,对轻质耐高温的Ti-Al系合金板材及锻件的需求日益迫切,特别是由于Ti3Al基合金具有良好的热工艺性能,其板材和锻件的制备及其组织性能控制都受到关注[6-9]。本文作者主要研究一种中等Nb含量的Ti3Al基合金热轧板材经不同温度固溶和时效处理后的组织和拉伸性能,以及多重时效对这种合金板材拉伸性能的影响,以期了解中等Nb含量Ti3Al基合金板材的拉伸性能对固溶温度和时效温度变化的敏感程度,以便于实际应用中对板材的组织和性能进行控制。

1 实验

试验用Ti3Al基合金的名义成分为Ti-24Al-15Nb- 1Mo(摩尔分数,%),合金简称为TD3合金。TD3合

金铸锭采用真空自耗的工艺熔炼,成品铸锭尺寸为直径为600 mm,TD3合金铸锭经β单相区开坯锻造后,制成板坯。板坯经(α2+B2)两相区多火次轧制,轧制成7 mm和1.9 mm厚的热轧板材。

对7 mm板材进行不同固溶温度和时效温度的热处理试验,固溶温度选择990和1 010 ℃,时效温度选择为815和850 ℃。热处理后沿板材的轧向取样,并加工标距为d 3 mm×15 mm的圆棒拉伸试样;对1.9 mm板进行990 ℃固溶处理,然后对不同试样毛坯进行815 ℃时效处理,时效保温时间为30 min,时效次数为1~4次,均为空冷。热处理后,沿板材轧向取样加工成标距长为10 mm的片形拉伸试样。所有试样均测试室温及高温拉伸性能。板材的显微组织和部分拉伸断口形貌采用JSM 5600和Philips Quanta 600扫描电镜上进行观察。

2 结果与分析

2.1 固溶处理和时效处理对TD3合金板材拉伸性能的影响

表1所列为7 mm厚的TD3合金板材经不同温度固溶和时效处理后的拉伸性能。由表1可以看到,固溶处理温度从990 ℃升高到1 010 ℃后,板材的室、高温强度均有所提高,塑性略有降低;提高时效温度从815 ℃到850 ℃,板材的室温和高温强度均有所降低,塑性变化不明显,面缩率(ψ)略有提高。

2.2 多次时效对TD3合金板材拉伸性能的影响

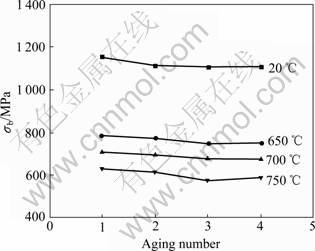

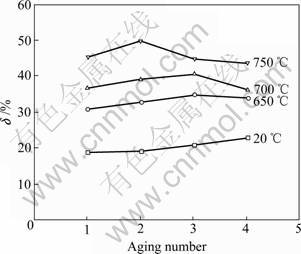

1.9 mm厚板材经固溶处理及不同次数815 ℃时效处理后的拉伸强度和塑性分别如图1和2所示。由图1和2可知,单次时效的拉伸试样强度最高,室温下的拉伸强度为1 165 MPa,750 ℃时的拉伸强度能够达到630 MPa;随时效次数增加,室温和高温强度都略有降低。不同时效次数对塑性有一定的影响,室温时,随时效次数的增加,塑性提高,高温下未呈现一致的变化规律,总体可以认为,在815 ℃多次时效对板材的拉伸性能影响不大。

表1 7 mm厚TD3合金板材经固溶时效处理后的拉伸性能

Table 1 Tensile properties of TD3 sheet with thickness of 7 mm sheet after solution and aging treatment

图1 不同温度时多次时效对TD3合金板材拉伸强度的影响

Fig.1 Effect of multiple aging treatment on tensile strength of TD3 alloy sheet at different temperatures

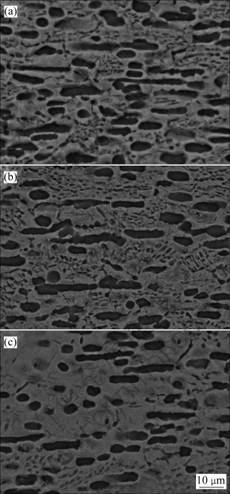

2.3 TD3合金板材的微观组织

图3所示为不同固溶温度和时效温度处理后7 mm厚TD3合金板材的微观组织。由图3可看出,固溶时效处理的板材组织呈现多个层次,较为粗大的拉长或等轴的初生α2相是锻造和轧制过程中保留下来的。由于固溶温度与轧制温度接近,在固溶处理时,初生α2相的体积分数基本保持轧态下的数量,在后续的时效处理中,初生α2相也具有高度的稳定性;基体中较为显著的小等轴相是轧制过程中产生的细小α2相和O相的混合相。在固溶处理时,一部分已经固溶,当时效温度从815 ℃升高到850 ℃,这部分细小的混合相出现一定程度的粗化,导致拉伸强度的略微降低和塑性的提高;第三个层次是基体组织,时效过程中析出二次的α2相和O相,随着时效温度的提高,二次相将进一步粗化。而固溶温度升高到1 010 ℃后,并未显著地造成拉长或等轴初生α2相的减少,但使轧制过程中产生的细小初生α2相和初生O相较多地固溶到基体中,从而使强度提高。

图2 不同温度时多次时效对TD3合金板材拉伸塑性的影响

Fig.2 Effect of multiple aging treatment on tensile ductility of TD3 alloy sheet at different temperatures

图3 固溶和时效处理后TD3合金板材的微观组织

Fig.3 Microstructures of TD3 alloy sheet after solution and aging treatment: (a) Solution treatment at 990 ℃+aging treatment at 815 ℃; (b) Solution treatment at 990 ℃+aging treatment at 850 ℃; (c) Solution treatment at 1 010 ℃+aging treatment 815 ℃

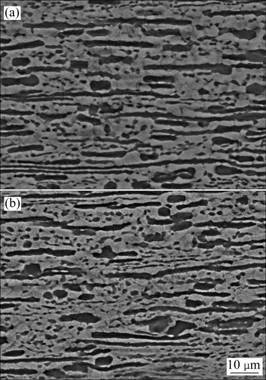

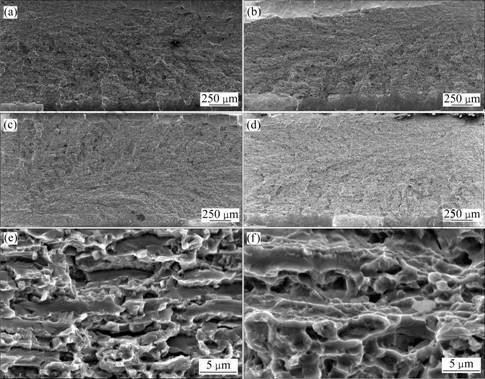

图4所示为1.9 mm厚板材固溶时效后的微观组织。由图4可看出,815 ℃时的时效次数增加仅引起基体组织中次生α2相和O相的略微粗化,从而使拉伸强度略微降低。多次时效后的室温拉伸断口如图5所示。由图5可知,断口的形貌相近,断裂起源于试样的近表面,裂纹快速扩展的放射区明显,断口边缘有明显、但不完整的剪切唇,表明 TD3合金板材具备较好的室温塑性。断口呈现准解理特征,扩展区域组织特征模糊;快断区可观察到较多的韧窝。

图4 多次时效处理后的TD3合金热轧板材的微观组织

Fig.4 Microstructures of TD3 alloy hot-rolled sheet after multiple aging treatment: (a) 815 ℃, 1st; (b) 815 ℃, 4th

3 结论

1) 当固溶处理温度从990 ℃升高到1 010 ℃时,Ti-24Al-15Nb-1Mo合金热轧板材的室、高温强度均有所提高,塑性略有降低;当时效温度从815 ℃升高到850 ℃时,板材的室温和高温强度降低,塑性变化不不明显。

图5 TD3合金热轧板材多次时效后试样的拉伸断口形貌

Fig.5 Tensile fracture morphologies of TD3 alloy hot-rolled sheet after multiple aging treatment: (a) 1st aging; (b) 2nd aging; (c) 3rd aging; (d) 4th aging; (e) Fracture initial area; (f) Final area

2) Ti-24Al-15Nb-1Mo合金热轧板材经990 ℃固溶处理后再进行多次时效处理,其拉伸性能变化大;增加时效次数,拉伸强度略微降低。

REFERENCES

[1] BANERJEE D, GOGIA A K, NANDY T K. A new phase in Ti3Al based alloy with high content of niobium[J]. Acta Metall Mater, 1988, 36: 871-882.

[2] WU Y T, YANG C T, KOO C H, SINGH A K. A study of texture and temperature dependence of mechanical properties in hot rolled Ti-25Al-xNb alloys[J]. Materials Chemistry and Physics, 2003, 80: 339-347.

[3] SUWAS S, RAY R K. Stability of rolling texture during heat treatment in a two-phase Ti3Al base intermetallic alloy[J]. Acta Materialia, 1999, 47(18): 4599-4614.

[4] BANERJEE D, BALIGIDAD R G, GOGIA A K. Engineering multiphase intermetallics[C]//HEMKER K J, DIMIDUK D M, et al. Third International Symposium on Structural Intermetallics, Warrendale, PA, USA, 2001: 43-47.

[5] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775-5799.

[6] ROWE R G. Tri-titanium aluminide alloys containing at least eighteen atom percent niobium: US 5032357[P]. 1991.

[7] 张建伟, 程云君, 梁晓波, 李世琼. (α2+B2+O)三相区温度变形的Ti3Al基合金板材组织和性能[J]. 稀有金属材料与工程, 2008(Supple 3): 561-564.

ZHANG Jian-wei,CHENG Yun-jun, LIANG Xiao-bo, LI Shi-qiong. Study on the microstructure and properties of hot rolling sheets of Ti3Al based alloy processed in (α2+B2+O) phase field[J]. Rare Metal Materials and Engineering, 2008(Supple 3): 561-564.

[8] 曹京霞, 孙育峰, 曹春晓, 全 旭. Ti3Al-Nb-Mo-(Si)合金的显微组织与力学性能[J]. 稀有金属, 1997, 21(1): 490-493.

CAO Jing-xia, SUN Yu-feng, CAO Chun-xiao, QUAN Xu. The microstructure and properties of Ti3Al-Nb-Mo-(Si) alloys[J]. Chinese Journal of Rare Metals, 1997, 21(1): 490-493.

[9] CAO Jing-xia, BAI Fang, LI Zhen-xi. High temperature low cycle fatigue behavior of titanium aluminide Ti-24Al-15Nb-1Mo alloy[J]. Materials Science and Engineering A, 2006, 424: 47-49.

(编辑 龙怀中)

收稿日期:2010-06-20;修订日期:2010-07-30

通信作者:曹京霞;电话:010-62496624;E-mail: caojingxia@sina.com