磁力螺旋溜槽及其对细粒磁性物料的回收

伍喜庆,黄志华

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘 要:在普通螺旋溜槽的槽面上附加磁场,得到磁力螺旋溜槽(MSC)。与普通螺旋溜槽相比,MSC使磁性物料能够得到更有效的回收。其选矿的原理是:当磁性矿物经过磁场时,在磁场力的作用下,磁性成分被吸引(不要吸住)到溜槽的底部从而进入二次环流,利用二次环流将磁性物料运到溜槽内部,进入精矿中。对纯的磁铁矿试验的结果表明:磁场强度、溜槽螺旋圈数和给矿浓度等因素都对磁力螺旋溜槽的性能产生影响;尤其是磁场能够有效地减少尾矿中磁性成分的含量,提高磁性成分的回收率,增大磁性铁的回收率,且精矿中锌的品位从5.9%降低到1.8%。

关键词:磁力螺旋溜槽;细粒磁性物料;高炉瓦斯泥;铁矿石;回收

中图分类号:TD922; TD951 文献标识码:A 文章编号:1672-7207(2007)06-1083-05

Magnetic spiral chute and its application in recovery of

fine magnetic materials

WU Xi-qing, HUANG Zhi-hua

(School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Magnetic spiral chute (MSC) made by attaching a proper magnetic field to traditional spiral chute is able to efficiently increase the recovery of magnetic components. The main mechanism of the MSC’s recovery of magnetic materials is that magnetic particles are drawn to the bottom of spiral trough because of the presence of magnetic force, and they join in the secondary circumfluence while they pass through the magnetic fields, and consequently they are carried by the secondary circumfluence to the inner side of the trough and enter the magnetic concentrate outlet. The test result of pure magnetic iron ores shows that these factors such as magnetic field intensity, spiral number and feed concentration affect the result. The separation of blast furnace dust indicates that it not only increases the recovery of magnetic iron, but also reduces the grade of zinc in the magnetic concentrate from 5.9% to 1.8 %.

Key words: magnetic spiral chute; fine magnetic materials; blast sludge; iron ores; recycling

螺旋溜槽结构简单,无运动部件,操作维护方便,单位面积处理量大,是一种较为有效的细粒重选设备。这种设备处理量大、能耗低,但是,富集比小、回收率低,尤其是难以回收微细粒级粒子。为克服这些弱点,对螺旋溜槽结构进行了许多改造。使螺旋槽螺距h与螺旋槽外径D的比小于0.36,形成超极限距径比(h/D)螺旋溜槽,解决了非金属矿红柱石的脱泥及初步富集的问题[1]。组合式螺旋溜槽的结构特点为粗选溜槽设置在上部,而精选、扫选溜槽内外相套设置在粗选溜槽下部,对磁铁矿和石英的人工混合矿分离效率比普通的高7.1%,精矿品位高2.38%和回收率高5.47%[2]。旋转螺旋溜槽与一般螺旋溜槽的区别在于螺旋槽绕竖轴旋转,使颗粒受到更大的离心力作用,缩短分选过程必需的路程,提高了生产力;此外,还研究了不同槽面对分选的影响,试验表明刻槽旋转溜槽的效果更好;旋转螺旋溜槽能在钽铌、钨、锡、黄金、海滨砂矿和钛铁矿等重选工艺中的应用,提高回收 率[3-4]。采用多条立方抛物线复合而成的螺旋槽断面曲线,直径大、槽面宽,单位占地面积处理能力大,这种新型螺旋溜槽特别适用于铁矿、钛铁矿、硫酸烧渣、海滨砂矿、锡矿、砂金、钨矿和钽铌矿等金属矿及煤等非金属矿的选别及脱泥[5-6]。楔形刻槽螺旋溜槽,改善了叶片断面上浓度分布和增强水流的脉动作用,还可以借助导向槽使重矿物沿沟槽向内侧移动,提高重矿物的回收率[7]。此外,还可利用多段、多作业新型螺旋溜槽[8-9]、振摆螺旋选矿机[10]、防止块煤破碎的外螺旋溜槽[11-12]等提高采矿物的回收率。

为了克服现有螺旋溜槽选别磁性物料时,回收磁性微细粒级的不足,本文作者针对强化螺旋溜槽回收磁性微细粒子而研制了磁力螺旋溜槽,以期在复合力场中提高磁性微细粒子的回收率。

1 磁力螺旋溜槽中颗粒受力分析及其结构设计

1.1 磁力螺旋溜槽中磁性颗粒在复合力场中的受力分析

在普通螺旋溜槽中,颗粒在螺旋槽面上受到流体推动力、本身的重力、惯性离心力以及摩擦力的作用。假设颗粒为球形,则影响因素的表达式如下。

那些未与螺旋槽面接触的颗粒,则不受摩擦力的作用。磁力螺旋溜槽中,加上磁场后,磁性颗粒还会受到一个磁力的作用。

可见,与传统的螺旋溜槽相比,磁力螺旋溜槽由于磁力的作用,强化了磁性颗粒向槽底运动的作用力(FG?cos β+Fm)。这样,磁性颗粒在螺旋槽面上的“二次环流”中处于低部或小半径二次环流上,二次环流不断地将矿粒沿槽底输送到槽的内缘。根据螺旋溜槽的原理,综合作用的结果就是能更有效地回收矿浆中磁性颗粒。

至于所加磁场强度H的极限(或合适)值,与水流速度、颗粒磁性大小、粒度等因素有关。

1.2 磁力螺旋溜槽的结构设计

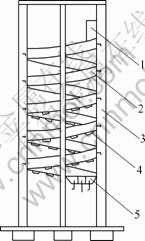

根据上述原理,所设计的磁力螺旋溜槽[14]如图1所示。主要结构参数为:溜槽共5圈,溜槽直径D为42 cm,螺距h为23.5 cm,h/D=0.56,倾斜角为10°。溜槽的材质以不严重衰减磁场的透磁材料为最好;磁系为永磁磁体均匀布置在槽的下沿(如图1和图2所示);在螺旋溜槽的下端,其形状为矩形斗状,设有磁性精矿、中矿和尾矿3个排放孔。

1—给矿口;2—螺旋溜槽;3—周边支撑架;

4—磁系;5—接矿槽

图1 磁力螺旋溜槽示意图

Fig.1 Schematic diagram of magnetic spiral chute

图2 螺旋槽面磁系分布

Fig.2 Distribution of magnetic slides

2 分选试验物料和方法

2.1 试验物料

a. 纯磁铁矿,粒度小于0.074 mm的矿物含量占84.0%。

b. 高炉瓦斯泥,含全铁25.4%,含锌5.9%。

c. 实际铁精矿,含全铁64.5%的铁矿。

2.2 试验方法

2.2.1 给矿条件

取300 g磁性物料,装入盛有4 L水的给矿斗中,以950 r/min搅拌给矿,补加水200 L/h。

2.2.2 分选过程

矿浆给入到螺旋槽上,在重力分力作用下沿槽向下流动,矿浆在离心惯性力的作用下向螺旋槽外缘扩展,于是,形成了内缘流层薄、流速低,外缘流层厚、流速高的流动特性。内缘液流呈层流状态,外缘液流呈明显的紊流状态。液流除了沿槽的纵向流动外,还存在着内缘流体与外缘流体间的横向循环运动,称作二次环流。由于这种环流运动,使得在槽的内圈出现上升分速度,外圈则有下降分速度。位于矿浆内的固体颗粒既受到流体运动特性的支配,同时也受到重力、惯性离心力、磁场力以及槽底摩擦力的作用。由于受到磁场力的作用,一方面那些磁性颗粒发生磁团聚;一方面那些磁性颗粒被吸引到液流下层,进入二次环流,二次环流不断地将矿粒沿槽底输送到槽的内缘,而同时又将内缘分出的轻矿物转移到外缘,促进分带的发展。磁(重)矿物靠近内圈,非磁性轻矿物移向外圈,矿粒运动趋于平衡,分带完成,非磁性颗粒被甩到最外缘的边流中,进入尾矿。

试验完毕后分别过滤精矿、中矿和尾矿,再烘干、称量和化验,计算回收率。

3 分选试验结果

3.1 磁场强度的影响

增加磁场是本设备的主要特征,且磁场强度的大小可以明显影响磁性矿物的回收,由式(6)可以看出:随着磁场强度H的增加,动摩擦力也随之增加,减少了颗粒甩到边缘的可能性,从而增加回收。表1所示为磁场强度对螺旋溜槽选别磁铁矿的结果。在粒度小于0.074 mm的矿物含量占90%时,磁力螺旋溜槽的精矿的回收率较普通螺旋溜槽(磁场强度为0)增加了3.6%,尾矿的损失率降低了4.9%。说明增加磁场可以增加磁性矿物的回收率,与当初设计的构想相吻合。

表1 磁力螺旋溜槽与普通螺旋溜槽的对比

Table 1 Comparison of magnetic spiral chute with traditional one

同时,比较J-3和J-32,在操作条件相同的情况下,粗粒级矿石相对细粒矿容易进入精矿中,尾矿损失少。表1中的二个粒度级别矿石,细粒尾矿比粗粒尾矿多6.2%,细粒级的颗粒易于跑到尾矿中,造成损失,这正是磁力螺旋溜槽设计的目的,加大对细粒级的磁性颗粒的回收。

3.2 磁力螺旋溜槽影响因素

影响磁力螺旋选矿机的因素可从螺旋的结构参数和操作条件[15]两方面来讨论,前面讨论了磁场强度的影响,这里主要讨论结构参数(圈数)和操作参数(给料浓度、补加水)的影响。

用螺旋选矿设备回收矿物的程度,取决于螺旋槽的长度。螺旋槽的长度由矿石分层和分带所需运行的距离决定,在结构参数上,它取决于螺圈的直径和圈数,当螺旋槽直径一定时,圈数对矿物的回收有着重要的影响。经过观察,液流在螺旋槽内(补加水为200 L/h)的移动轨迹,内外缘的移动行程为1.5圈左右。螺旋槽所必需的圈数,应根据入选矿石物理性质而定。表2所示为螺旋圈数对磁铁矿回收的影响。螺圈圈数越少,溜槽长度越短,矿石在槽面上分带不完全,精矿回收磁铁矿的程度就越低。尾矿中磁铁矿的损失率随着圈数由5圈变成3圈而增加3.5%,造成磁铁矿的损失。

表2 螺旋圈数对回收的影响

Table 2 Effect of spiral number on recovery

表3所示为给矿浓度(质量分数)对磁铁矿回收的影响。当矿浆中固体含量过高时,液流中的固相粘结成团流动,会破坏颗粒按密度分层的过程,降低液流

表3 给矿浓度对回收的影响

Table 3 Effect of feed concentration on recovery

的环流对矿物颗粒的作用;当矿浆很稀时,螺旋槽冲水过多,固相形成薄层移动,不具备矿物颗粒按密度分层和颗粒在流体压力下沿高低分离所必须的条件,指标也很低。当给矿浓度从2.5%增加到10%时,尾矿的损失率从10.4%下降到7.8%,减小2.6%。同时,给矿浓度还影响溜槽的处理量。应根据试验决定合适的给矿浓度。

冲洗水流量对Fe回收率的影响见表4。可见,对于纯磁性铁矿物,冲洗水的流量在保证磁性颗粒不被吸住的前提下,小流量冲洗水有利于磁性粒子的回收。精矿在100 L/h的补加水情况下回收率较250 L/h的回收率高4.2%,尾矿少5.1%,减少了磁性粒子的损失,增加了回收率。冲洗水流量小,液体流速小。由式(2)和式(3)可以看出,流体的推动力FW和惯性离心力FD都变小,即造成颗粒甩向外缘的力减小,尾矿损失 减少。

表4 补加水流量的影响

Table 4 Effect of addition of water

3.3 实际磁性物料的分选试验结果

在对磁铁矿纯矿物分选试验的基础上,确定了最佳的磁力螺旋溜槽的结构参数(场强和圈数)和操作参数(给料浓度和冲洗水流量)。对实际的铁矿石(含全铁64.5%铁精矿)矿浆从磁力螺旋溜槽的上部给矿口加入,然后分别得到磁性精矿、中矿和尾矿。经与同样非磁力螺旋溜槽比较,从磁力螺旋溜槽得到的尾矿比从非磁力螺旋溜槽得到的尾矿少12%。对高炉瓦斯泥(含全铁25.4%,含锌5.9%),经与相同非磁力螺旋 溜槽比较,从磁力螺旋溜槽得到的磁性精矿比从非磁力螺旋溜槽得到的磁性精矿高7%, 且其中锌含量降至1.8%。

4 结 论

a. 磁力螺旋溜槽是一种新型的具有复合力场的重选设备,磁力螺旋溜槽没有增加动力,只在槽面上附加磁场,保持了螺旋设备简单的特点,且能够提高磁性矿物的回收率。

b. 磁力螺旋溜槽强化磁性物回收的机理是:将磁性矿石吸引到水流底部,转而进入二次环流,提高磁性精矿的产率,减少其在尾矿的损失。对纯磁铁矿石,可使精矿回收率提高3.6%。

c. 磁力螺旋溜槽能够强化处理含磁性物的各种物料,如铁矿石、高炉尘泥等。对含Fe 25.4%、含Zn 5.9%的高炉瓦斯泥进行处理,磁性精矿回收率增加7%,且其中锌含量降至1.8%。

参考文献:

[1] 张一敏, 刘惠中. 超极限h/D螺旋溜槽的研究及应[J]. 矿产综合利用, 2000(5): 43-46.

ZHANG Yi-ming, LIU Hui-zhong. Development and application of out-limited h/D helical chute[J]. Multipurpose Utilization of Mineral Resources, 2000(5): 43-46.

[2] 马龙秋, 李书会. 组合式螺旋溜槽的研究[J]. 中国矿业, 1998, 7(3): 54-57.

MA Long-qiu, LI Shu-hui. Development of a new combined spiral chute[J]. China Mining, 1998, 7(3): 54-57.

[3] 封国富. 旋转螺旋溜槽选矿试验与实践[J]. 有色矿山, 2002, 31(4): 27-31.

FENG Guo-fu. Separation test and practice of rotary spiral chute[J]. Nonferrous Mines, 2002, 31(4): 27-31.

[4] 刘仁梁. 旋转螺旋溜槽选别机理与选型[J]. 矿山机械, 1998(10): 44-48.

LIU Ren-liang. Separation mechanism and typing of spiral chute[J]. Mining and Processing Equipment, 1998(10): 44-48.

[5] 刘惠中. BL1500-A型螺旋溜槽的研制及其在尾矿再选中的应用[J]. 矿冶, 2001, 10(4): 24-28.

LIU Hui-zhong. Development of BL1500-A spiral chute and its application in tailings retreatment[J]. Mining and Metallurgy, 2001, 10(4): 24-28.

[6] 刘惠中, 郑荣田. BL1500螺旋溜槽选别硫酸渣的应用研究[J]. 有色金属: 选矿部分, 2006(1): 26-28.

LIU Hui-zhong, ZHENG Rong-tian. The research of sulfate processing by BL1500 spiral chute[J]. Nonferrous Metals: Mineral Processing, 2006(1): 26-28.

[7] 金仁国, 陆庆秋, 于克旭. Φ1 200 mm×720 mm楔形刻槽螺旋溜槽的研制及试验研究[J]. 金属矿山, 2000(1): 46-49.

JIN Ren-guo, LU Qing-qiu, YU Ke-xu. Development of Φ 1 200 mm×720 mm wedge groove spiral sluice and its test research[J]. Metal Mine, 2000(1): 46-49.

[8] 刘学海, 李 斌. 多段螺旋溜槽的研究[J]. 矿冶, 1995, 4(1): 31-36.

LIU Xue-hai, LI Bin. Research on multi-stage spiral chute[J]. Mining and Metallurgy, 1995, 4(1): 31-36.

[9] 马龙秋, 楚海滨, 张淑敏. 多段、多作业新型螺旋溜槽的研制[J]. 沈阳黄金学院学报, 1995, 14(2): 152-157.

MA Long-qiu, CHU Hai-bing, ZHANG Shu-min. Research on multi-stage and function spiral chute[J]. Journal of Shenyang Gold College, 1995, 14(2): 152-157.

[10] 包莉娜. 对振摆螺旋选矿机结构的改进[J]. 有色金属: 选矿部分, 2000(1): 29-30.

BAO Li-na. Structure development of vibrate spiral chute[J]. Nonferrous Metals: Mineral Processing, 2000(1): 29-30.

[11] 聂其英. 外螺旋溜槽块煤防破碎技术在古汉山矿的应用[J]. 选煤技术, 2006(3): 36-38.

NIE Qi-ying. Crash prevented technology of lump coal with outside spiral chute used in Gu Han Shan mines[J]. Coal Preparation Technology, 2006(3): 36-38.

[12] 曹书卿. 外螺旋煤仓螺旋溜槽的设计与安装[J]. 煤炭工程, 2006(10): 100-101.

CAO Shu-qing. Design and installment of outside spiral chute[J]. Coal Engineering, 2006(10): 100-101.

[13] 孙玉波. 重力选矿[M]. 北京: 冶金工业出版社, 1981.

SUN Yu-bo. Gravity beneficiation[M]. Beijing: Metallurgical Industry Press, 1981.

[14] 伍喜庆. 磁力螺旋溜槽分选机: 中国, 200520050885[P]. 2006-07-19.

WU Xi-qing. Magnetic spiral chute separator: China, 200520050885[P]. 2006-07-19.

[15] 胡岳华, 冯其明. 矿物资源加工技术与设备[M]. 北京: 科学出版社, 2006.

HU Yue-hua, FENG Qi-ming. Technology and equipment of mineral resources processing[M]. Beijing: Science Press, 2006.

收稿日期:2007-01-22;修回日期:2007-03-25

基金项目:教育部留学回国人员基金资助项目(2005)

作者简介:伍喜庆(1962-),男,湖南新邵人,博士,副教授,从事矿物资源加工研究

通信作者:伍喜庆,男,博士,副教授;电话:0731-8830548;E-mail: xiqingwu@hotmail.com