DOI: 10.11817/j.issn.1672-7207.2020.10.011

TBM盘形滚刀切削力学模型分析

张桂菊1, 2, 3,谭青2,劳同炳2

(1. 高效动力系统智能制造湖南省重点实验室,湖南 邵阳,422004;

2. 中南大学 机电工程学院,湖南 长沙,410083;

3. 邵阳学院 机械与能源工程学院,湖南 邵阳,422004)

摘要:为了研究盘形滚刀掘进过程中的切削特性,对盘形滚刀侵入岩石过程进行受力分析。通过对盘形滚刀与岩石作用机理的研究,基于摩尔-库仑强度理论,分析岩石的脆性断裂过程,建立一种考虑密实核作用的刀具载荷计算模型,得到滚刀侵入破岩的力学表达式。采用颗粒离散元法建立岩石破碎全过程的二维颗粒离散元数值模型,在不同的侵入深度下,对TBM盘形滚刀的破岩过程进行数值分析。然后通过直线式盘形滚刀破岩实验台,对TBM盘形滚刀在不同侵入深度下的破岩过程进行实验研究。研究结果表明:垂直力的数学模型理论计算结果、数值模拟结果和实验结果平均误差较小,验证了所建立的受力预测力学模型的正确性和有效性。

关键词:岩石掘进机;盘形滚刀;力学模型;颗粒离散元;破岩实验

中图分类号:U455.3+1;TP391.9 文献标志码:A

文章编号:1672-7207(2020)10-2792-08

Analysis of rock breaking mechanics model for TBM disc cutter

ZHANG Guiju1, 2, 3, TAN Qing2, LAO Tongbing2

(1. Key Laboratory of Hunan Province for Efficient Power System and Intelligent Manufacturing,Shaoyang 422004, China;

2. College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

3. Department of Mechanical and Energy Engineering, Shaoyang University, Shaoyang 422004, China)

Abstract: In order to study the breaking characteristics of disc cutter, the force analysis of the disc cutter intruding into the rock was carried out during the tunneling process. Through studying the breaking mechanism of the action between disk cutter and rock, the brittle fracture process of rock was analyzed based on the theory of molar-Coulomb strength. Then a tool load calculation model considering the dense core was established, and thus the mechanical expression of disc cutter intruding into hard rock was obtained. The two-dimensional numerical model of particle discrete element in the whole process of rock breaking was established by using the particle flow code(PFC) method. At different invasion depths, the process of rock breaking of tunnel boring machine(TBM) disc cutter was numerically analyzed. Then, the rock breaking process of TBM disc cutter at different invasion depths was studied by using the straight-line disc cutter rock breaking experimental platform. The results show that the average errors of vertical force obtained from mathematical models, numerical simulations and experiments are small, which verifies the correctness and validity of the established mechanical model of stress prediction.

Key words: tunnel boring machine(TBM); disc cutter; mechanical model; particle flow code(PFC); rock breaking experiment

岩石掘进机(tunnel boring machine,TBM)是地下空间隧道掘进的主要工具,在其施工过程中,作为掘进机主要的刀具之一的盘形滚刀,直接参与掘进破岩的工作[1-2]。对盘形滚刀与岩石的作用机理进行研究,分析刀具的载荷规律,建立刀具破岩的力学模型,有利于研究分析刀盘推力、刀盘扭矩以及掘进机的掘进性能,对于提高破岩掘进效率意义重大[3-7]。对于硬岩掘进机的盘形滚刀破岩机理,国内外学者进行了大量的研究[8]。EVANS等[9]对盘形滚刀破岩过程进行了研究,认为岩石属于挤压破坏,在破岩过程中,滚刀的垂直推力与其滚压的岩石范围投影于岩石的面积呈正比。AKIYAMA[10]利用剪切破碎理论和挤压破碎理论,对TBM盘形滚刀破岩时的受力分布进行了分析。NISHIMATSU[11]认为岩石破坏面属于剪切破坏,岩石被破碎并压实而形成密实核,并根据摩尔强度理论,得出了岩石剪切破坏的刀具切削力表达式。谭青等[12]利用有限元软件建模分析得到滚刀切割岩石过程受到的三向力。屠昌峰[13]在接触应力模型的基础上建立了盘形滚刀侧向力预测模型。WANG等[14]准确预测了其复合地层土压平衡盾构机滚刀的磨损量与切削距离寿命,得到了适用于软硬不均复合地层的滚刀磨耗系数。SHI等[15]对盘形滚刀与岩石之间的接触载荷分布模型进行了分析,得出了不同贯入度下接触载荷分布曲线变化。上述研究对于理解盾构刀具破岩特性分析具有指导意义。然而,前人的研究没有从密实核角度出发,对刀具的载荷计算尚不够深入。本文作者以剪切应力强度理论为基础,分析密实核对岩体的作用,建立考虑密实核作用的摩尔-库仑强度理论滚刀刀具载荷计算模型,得出盘形滚刀侵入破岩的力学模型表达式,以期为滚刀刀具的设计研究提供参考。

1 TBM盘形滚刀切削机理

全断面岩石掘进机示意图如图1所示。掘进机中所使用的破岩滚刀主要有齿面滚刀、镶嵌硬质合金滚刀、单刃、双刃、三刃(或多刃)盘形滚刀,其中盘形滚刀是硬岩掘进机的主要破岩工具。美国罗宾斯公司最早开始使用盘形滚刀,与初期的切刀相比,盘形滚刀具有破岩效率高、刀具磨损量小、比能耗低等特点。在隧道开挖过程中,盘形滚刀由于岩石的摩擦作用在TBM刀盘的开挖面上不断滚动,同时,在刀盘的垂直推力作用下,TBM盘形滚刀做直线侵入运动,当滚刀作用的载荷超过岩石的强度时,岩石会发生破裂并出现剥落现象。

图1 全断面岩石掘进机

Fig. 1 Full-face tunnel boring machine

在刀盘上,滚刀的布置形式要以便于顺次破岩为主,也就是说,前一把滚刀接触岩石后形成较易切割的裂纹和轨迹,要为后一把滚刀破岩做好预破岩准备,使2把滚刀的裂纹能够贯通,形成破碎块岩片,达到破岩的目的。在满足顺次破岩这一点要求上,双刃和多刃滚刀不及单刃滚刀好,并且还极易造成刀刃的受力不均和不均匀磨损,从而导致刀具浪费。因此,在刀盘空间允许的情况下,布置刀具时,无论中心刀还是边刀,应尽可能选用单刃滚刀。

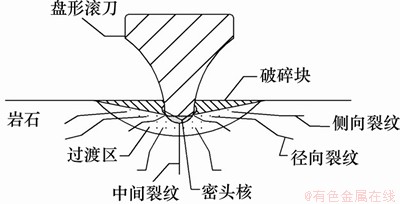

盘形滚刀侵入破岩时岩石的破碎体系如图2所示。通过研究滚刀侵入岩石过程发现:安装在刀盘上的盘形滚刀侵入岩石时,首先,在刀盘的推力和扭矩作用下,盘形滚刀在掌子面上形成一系列的同心圆形状的沟槽;而在岩石内部,滚刀刀刃下方则形成了高应力区,由于盘形滚刀的作用,岩石内部的微裂纹被压实,甚至闭合;当盘形滚刀侵入的总应力大于岩石强度时,岩石就发生失效,产生破坏。密实核的形成过程为:在破岩过程中,盘形滚刀不断对岩石进行剪切、挤压、拉裂等综合作用,从而导致在岩石的掌子面上不断剥离出细小的破碎颗粒;紧接着,这些细小的破碎颗粒又被连续工作的盘形滚刀碾压成细碎的粉末状,从而形成了密实核;岩石的内部能量通过密实核传递到附近区域,又会使岩石再次产生新的裂纹,按照裂纹在岩石内扩展路径的不同,又可以分为中间裂纹、侧向裂纹、径向裂纹等,其中,侧向裂纹可扩展至自由面,发展形成块岩,从而剥落;另一方面,径向裂纹和中间裂纹则会引起岩石更深部分的失效破裂[16];当滚刀刀间距满足一定条件时,相邻滚刀之间内侧向裂纹、横向裂纹以及径向裂纹便会相互贯通,从而形成岩石碎片并剥落,至此,盘形滚刀完成了1次破岩过程。

图2 滚刀作用下岩石失效示意图

Fig. 2 Diagram of rock failure under action of disc cutter

2 滚刀侵入破岩数学模型

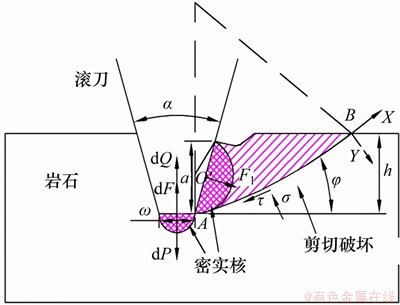

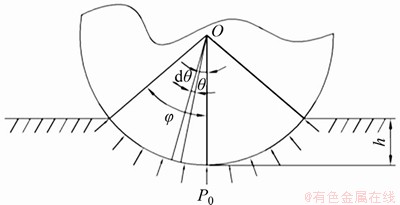

建立如图3所示的微元角度为dθ的滚刀压头侵入岩石的力学模型,滚刀剖面应力分布示意图如图4所示。硬岩掘进机盘形滚刀侵入岩石过程中,滚刀与岩石相互接触的区域在较小的体积之内产生了极大的接触应力,在滚刀下方及两侧附近形成密实核,滚刀两侧上方由于过早破碎剥落,忽略其对滚刀的作用力,根据摩尔-库仑破坏准则[16],假设岩石破碎是由剪切应力引起的,且遵守摩尔-库仑强度理论;破碎面受到压应力σ和剪切应力τ共同作用,如图3所示;同时还可看出密实核的形状由一段圆弧构成,圆弧段的圆心为O′,半径为r,圆弧最高点距离底部即密实核的长度为a。

图3 微元dθ滚刀压头破岩力学模型

Fig. 3 Mechanical model of micro-element dθ of disc cutter head invading into rock

图4 滚刀剖面应力分布示意图

Fig. 4 Diagram of stress distribution in section of disc cutter

假设微元滚刀压头侵入岩石深度为h,根据力学分析方法,滚刀在侵入时,必须要克服摩擦力dF和岩石的强度dQ。当dθ微元滚刀压头侵入岩石时,其受到的作用力 为

为

(1)

(1)

此时,岩石的强度dQ为

(2)

(2)

即岩石的抗破碎强度dQ为滚刀侵入刀刃在垂直方向上的投影面积与岩石抗压强度的乘积。其中, 为岩石单轴抗压强度,

为岩石单轴抗压强度, 为刀刃角,

为刀刃角, 为滚刀半径,

为滚刀半径, 为刀刃宽度。

为刀刃宽度。

根据图3所示的几何关系可得通过密实核作用于岩石破碎块的合力 为

为

(3)

(3)

式中: 为滚刀与岩石接触角。

为滚刀与岩石接触角。

当作用力足够大时,岩块在剪切应力的作用下,以破碎角2β沿着线AB破碎,极限剪切应力满足摩尔-库仑理论。

(4)

(4)

式中:τ为剪切面上的剪应力;σ为剪切面上的正应力; 为岩石的内摩擦角;c为岩石的内聚力。

为岩石的内摩擦角;c为岩石的内聚力。

对于破碎块进行受力平衡分析可得:

(5)

(5)

式中: 表示岩石破碎块在X方向上所受合力为0;

表示岩石破碎块在X方向上所受合力为0; 表示岩石破碎块在Y方向上所受合力为0;φ为剪切面与水平面的夹角,

表示岩石破碎块在Y方向上所受合力为0;φ为剪切面与水平面的夹角,

;2β取120°~150°[17]。

;2β取120°~150°[17]。

将式(3)和式(4)代入式(5)可得密实核的长度a为

(6)

(6)

另外,岩石抗破碎强度dQ滚刀两侧楔形面的分量与岩石正压力 相平衡,即

相平衡,即

(7)

(7)

所以,刀刃侵入总摩擦力 为

为

(8)

(8)

式中:μ为岩面与滚刀楔形面的摩擦因数,μ=0.40~0.55[18]。

因此,dθ微元滚刀压头侵入岩石受到作用力 为

为

(9)

(9)

ROSTAMI等[19]计算得到岩石压碎区的压力P沿着圆周方向上的分布应满足

(10)

(10)

式中:θ为某一具体圆周角(工程计算中,常常取为0~ );ψ为接触压力分布指数(通常取0.2~0.2),由经验可取ψ=0.1[20];

);ψ为接触压力分布指数(通常取0.2~0.2),由经验可取ψ=0.1[20]; 为位于滚刀刀刃正下方的基准应力,取值为单位长度下的dP,即

为位于滚刀刀刃正下方的基准应力,取值为单位长度下的dP,即

(11)

(11)

所以,滚刀接触区受到的合力F为

(12)

(12)

盘形滚刀侵入破岩受到的两侧侧向力大小相等,方向相反,滚动水平力为0,垂直力FV为

(13)

(13)

式中:β为垂直力和滚动力的合力与滚刀垂直方向之间的夹角,β≈ /2。

/2。

3 滚刀侵入岩石离散元建模

3.1 岩石宏观力学参数测试

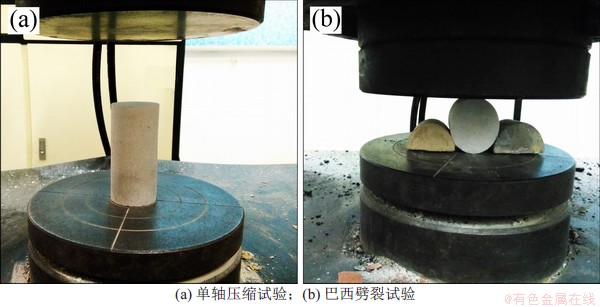

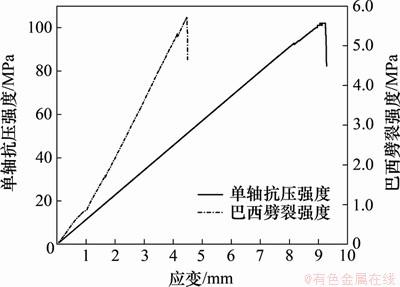

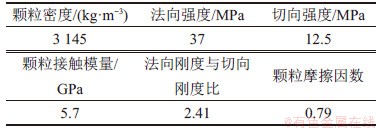

利用颗粒流离散元程序PFC2D对岩石进行数值模拟:首先应根据岩石力学性能测试的标准,分别制作直径×长度为50 mm×100 mm和50 mm×150 mm的2种标准圆柱岩石试件,然后通过电液伺服控制材料试验设备对岩石试件的力学参数进行巴西劈裂和单轴压缩试验,如图5所示,可以得到岩石材料的宏观力学参数,如表1所示。

图5 岩石试样力学参数测试

Fig. 5 Testing of mechanical parameters for rock samples

表1 岩石试件的宏观力学参数

Table 1 Macroscopical parameters of hard rocks samples

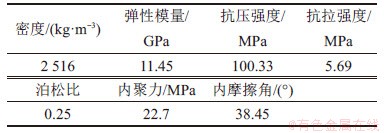

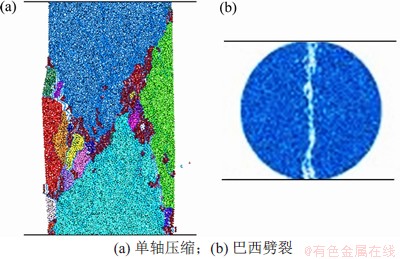

3.2 岩石细观参数标定

基于岩石试样的宏观力学试验参数对数值模型中的岩石样本进行巴西劈裂和单轴压缩的数值模拟[21],离散元模型细观参数标定实验及应力-应变曲线分别如图6~7所示。经过不断地调整细观参数,获得与岩石样本宏观性质一致的细观参数,如表2所示。

图6 离散元模型细观参数标定实验

Fig. 6 Calibration tests of mesoscopical parameters for discrete element model

图7 离散元模型标定应力-应变曲线

Fig. 7 Calibration of stress-strain curve by discrete element model

表2 岩石试件的细观力学参数

Table 2 Meso-mechanical parameters of hard rocks samples

3.3 滚刀数值模型的建立

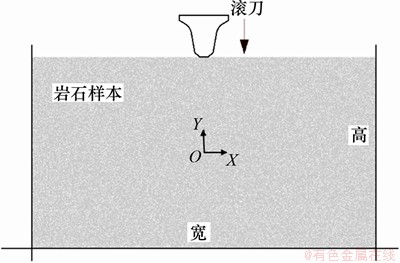

根据上述标定的细观力学参数,采用空隙比生成法生成岩石试件,颗粒最小半径为0.4 mm,颗粒最大和最小半径比值为1.66,空隙率为0.08,包含颗粒数为48 694个,岩石试件宽×高为300 mm×160 mm。滚刀模型根据实验中使用的直径为432 mm的滚刀参数进行建模,先借助AUTOCAD软件建立目标滚刀模型,再导入PFC2D中生成刚性墙体替代滚刀[22]。图8所示为滚刀破岩数值模型。

图8 盘形滚刀破岩数值模型

Fig. 8 Numerical model of disc cutter of breaking rock

3.4 数值模拟结果

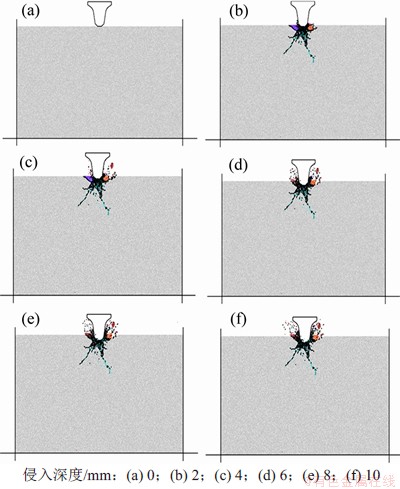

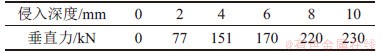

设滚刀侵入深度分别为2,4,6,8和10 mm,进行5组数值模拟分析,图9所示为不同侵入深度滚刀破岩情形。通过数值模拟之后得到滚刀侵入岩石的模拟结果如表3所示。

图9 不同侵入深度滚刀破岩情形

Fig . 9 Rock breaking shapes of different invasive depths of disc cutter

表3 垂直力数值模拟结果

Table 3 Numerical simulation results of vertical force

4 盘形滚刀侵入实验

图10所示为直线式盘形滚刀破岩实验台,本文利用其对盘形滚刀破岩过程实验进行验证。实验工作台主要由机架、破岩工作台、控制台、液压系统和数据采集系统等组成。实验时,通过液压系统对实验台统进行驱动,其中垂直液压缸对盘形滚刀的上下直线运动进行驱动,另一方面,纵向液压缸对岩石的纵向进给进行驱动。

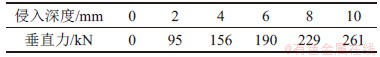

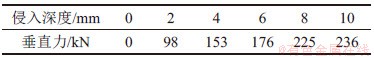

滚刀选用和数值模拟相同尺寸截面滚刀,直径为432 mm,刀刃宽为18 mm,刀刃为角20°,岩石长×宽×高为1 000 mm×500 mm×300 mm,力学参数如下:抗拉强度为5.69 MPa,抗压强度为100.33 MPa,弹性模量为11.45 GPa。在实验过程中,用带百分表的游标卡尺测量滚刀侵入深度,通过数据采集卡采集处理对应垂直力的数据。垂直液压油缸通过活动横梁不断向滚刀施压,使得滚刀贯入一定的深度,观察滚刀侵入岩石时的情形,量取侵入岩石深度。通过三向力传感器测量垂直力,表4所示为滚刀侵入深度对应垂直力的实验结果。通过实验结果可知,滚刀侵入深度越大,垂直力越大。

表4 垂直力实验测量结果

Table 4 Experimental results of vertical force

图10 直线式盘形滚刀破岩实验台

Fig. 10 Straight-line rock breaking experiment bench of disc cutter

5 结果对比

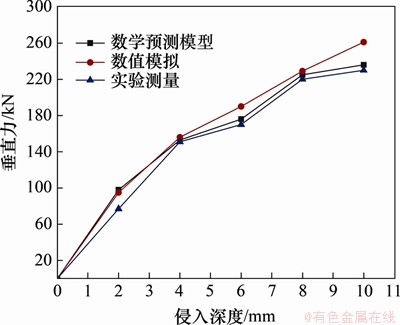

根据实验所用滚刀的尺寸参数以及岩石的宏观参数,可得数学预测模型计算结果,如表5所示。将岩石掘进机盘形滚刀侵入岩石的数学预测模型计算结果、数值模拟结果与实验结果进行对比,如图11所示。从图11可以看出,盘形滚刀侵入破岩垂直推进力随着侵入深度的增加而逐渐增大,数学预测模型计算结果与实验测量结果的误差随着侵入深度的增加而减小。这是由于在滚刀侵入岩石的初始阶段,岩石表面存在不平整性,进行滚刀侵入实验时,滚刀先是把岩石表面压平、压实,岩石内部的微裂隙被压紧或闭合,导致滚刀侵入深度较小时,实验测量的垂直力偏小,而数学预测模型没有考虑此因素,其计算结果偏大。滚刀侵入破岩的数学模型结果与数值模拟结果平均相对误差约为3.4 %,与实验测量结果平均相对误差约为8.3 %,数值模拟结果与实验结果平均相对误差约为12.1 %,3种方法所得的垂直力比较接近,验证了受力预测模型的正确性和有效性。

表5 垂直力数学预测模型计算结果

Table 5 Calculation results of mathematical prediction model of vertical force

图11 滚刀侵入破岩垂直力对比图

Fig. 11 Comparison of vertical force of invading breaking rock model with disc cutter

6 结论

1) 通过对滚刀侵入破岩机理进行研究,考虑密实核的性质,以摩尔-库仑理论为基础,建立了盘形滚刀侵入破岩的力学预测模型,得到了滚刀侵入破岩垂直推进力的表达式、滚刀侵入岩石垂直力的数学预测模型计算结果。

2) 将数学预测模型计算结果与数值模拟结果、实验结果进行对比分析,发现这3种方法所得的垂直力比较接近,验证了模型的正确性和有效性。

参考文献:

[1] FU Jie, XIA Yimin, ZHANG Ling, et al. Failure analysis on the fracture of disc cutter in EPB shield machine[J]. Engineering Failure Analysis, 2020, 108: 104341.

[2] 柳培蕾. 盘形滚刀刀圈磨损的建模方法与寿命预测[D]. 西安; 西安理工大学机械与精密仪器工程学院, 2019: 1-5.

LIU Peilei. Wear and life prediction of disc hob tools based on wear mechanism[D]. Xi'an: Xi'an University of Technology. College of Mechanical and Precision Instrument Engineering, 2019: 1-5.

[3] 陈思远. 硬岩掘进滚刀破岩力动态仿真与热分析[D]. 沈阳: 吉林大学机械与航空航天工程学院, 2019: 1-3.

CHEN Siyuan. Dynamic simulation and thermal analysis of rock breaking force on disc cutter of tunnel boring machine[D]. Shenyang: Jilin University. College of Mechanical and Aerospace Engineering, 2019: 1-3.

[4] 秦银平, 张竹清, 孙振川, 等. 基于现场试验的TBM滚刀磨损分析及预测[J]. 隧道建设(中英文), 2019, 39(11): 1914-1921.

QIN Yinping, ZHANG Zhuqing, SUN Zhenchuan, et al. Analysis and prediction of TBM disc cutter wear based on field test[J]. Tunnel Construction, 2019, 39(11): 1914-1921.

[5] 刘建琴, 刘蒙蒙, 郭伟. 硬岩掘进机盘型滚刀回转破岩仿真研究[J]. 机械工程学报, 2015, 51(9): 199-205.

LIU Jianqin, LIU Mengmeng, GUO Wei. Research on the simulation of cutting rock rotary by hard rock tunnel boring machine disc cutters[J]. Journal of Mechanical Engineering, 2015, 51(9): 199-205.

[6] 张桂菊, 谭青, 夏毅敏, 等. 岩石温度对盘形滚刀掘进参数破岩特性的影响[J]. 湖南大学学报(自然科学版), 2015, 42(4): 40-47.

ZHANG Guiju, TAN Qing, XIA Yimin, et al. Influence of different rock temperatures on rock breaking characteristics of disc cutter tunneling parameters[J]. Journal of Hunan University(Natural Sciences), 2015, 42(4): 40-47.

[7] 张桂菊, 谭青, 劳同炳. 不同动静载荷组合作用下盘形滚刀破岩机制[J]. 中南大学学报(自然科学版), 2019, 50(3): 540-549.

ZHANG Guiju, TAN Qing, LAO Tongbing. Disc cutter cutting mechanism under different combined dynamic and static loading conditions[J]. Journal of Central South University(Science and Technology), 2019, 50(3): 540-549.

[8] SUN Zhenchuan, YANG Yandong, CHEN Kui, et al. Disc cutter's rock breaking ability and wear resistance in extremely hard rock: a case study in Qinling tunnel of Han river to Wei river water diversion project[J]. Geotechnical and Geological Engineering, 2019, 37(6): 4901-4910.

[9] EVANS I, POMEROY C D. Wedge penetration into coal[C]// The Strength, Fracture and Workability of Coal. Amsterdam: Elsevier, 1966: 184-194.

[10] AKIYAMA T. A theory of the rock-breaking function of the disc cutter[J]. Komatsu Technology, 1970, 16(3): 56-61.

[11] NISHIMATSU Y. The mechanics of rock cutting[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1972, 9(2): 261-270.

[12] 谭青, 屠昌锋, 暨智勇, 等. 盘形滚刀切割岩石的数值仿真[J]. 现代制造工程, 2009(2): 62-64.

TAN Qing, TU Changfeng, JI Zhiyong, et al. Numerical simulation of rock cutting by disc cutter[J]. Modern Manufacturing Engineering, 2009(2): 62-64.

[13] 屠昌锋. 盾构机盘形滚刀垂直力和侧向力预测模型研究 [D]. 长沙: 中南大学 机电工程学院, 2009: 15-23.

TU Changfeng. Study on the prediction model of vertical force and lateral force of shield machine disc cutter[D]. Changsha: Central South University. College of Electrical Mechanical Engineering, 2009: 15-23.

[14] WANG Haojie, WANG Zhiyong, ZHOU Zhi et al. Analysis on wear law of Hob and prediction of cutting distance life of EPB shield in composite stratum[C]// Proceedings of the 2019 engineering geology. China Geological Society: Editorial Department of Journal of Engineering Geology, 2019: 104-112.

[15] SHI Yupeng, XIA Yimin, TAN Qing, et al. Distribution of contact loads in crushed zone between tunnel boring machine disc cutter and rock[J]. Journal of Central South University, 2019, 26(9): 2393-2403.

[16] 徐小荷, 余静. 岩石破碎学[M]. 北京: 煤炭工业出版社, 1984: 24-31.

XU Xiaohe, YU Jing. Rock crushing study[M]. Beijing: China Coal Industry Publishing House, 1984: 24-31.

[17] 朱晶晶, 李夕兵, 宫凤强, 等. 单轴循环冲击下岩石的动力学特性及其损伤模型研究[J]. 岩土工程学报, 2013, 35(3): 531-539.

ZHU Jingjing, LI Xibing, GONG Fengqiang, et al. Dynamic characteristics and damage model for rock under uniaxial cyclic impact compressive loads[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(3): 531-539.

[18] 谭青, 黎子兵, 夏毅敏, 等. 盘形滚刀刀圈轧制过程的数值模拟和试验验证[J]. 热加工工艺, 2017, 46(15): 129-133, 136.

TAN Qing, LI Zibing, XIA Yimin, et al. Numerical simulation and experimental verification of disc cutter ring in rolling process[J]. Hot Working Technology, 2017, 46(15): 129-133, 136.

[19] ROSTAMI J, OZDEMIR L, NILSON B. Comparison between CSM and NTH hard rock TBM performance prediction models[C]// Proceedings of Annual Technical Meeting of the Institute of Shaft Drilling Technology. Las Vegas. 1996: 1-10.

[20] 张厚美. TBM的掘进性能数值仿真研究[J]. 隧道建设, 2006, 26(S2): 1-7.

ZHANG Houmei. Study on numerical simulations of performance of tunnel boring machines(TBM)[J]. Tunnel Construction, 2006, 26(S2): 1-7.

[21] 谭青, 劳同炳, 张桂菊, 等. 静载与冲击加载方式下滚刀破岩特性[J]. 中南大学学报(自然科学版), 2018, 49(1): 101-108.

TAN Qing, LAO Tongbing, ZHANG Guiju, et al. Disc cutter cutting mechanism under static loading and impact dynamic loading conditions[J]. Journal of Central South University (Science and Technology), 2018, 49(1): 101-108.

[22] MOON T, NAKAGAWA M, BERGER J R. Measurement of fracture toughness using the distinct element method[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(3): 449-456.

(编辑 伍锦花)

收稿日期: 2020 -03 -26; 修回日期: 2020 -05 -26

基金项目(Foundation item):国家高技术研究发展计划(863 计划)项目(2012AA041803);国家重点基础研究发展计划(973计划)(2013CB035401);国家自然科学基金资助项目(51274252, 51475478);湖南省教育厅创新平台开放基金资助项目(16K080) (Project(2012AA041803) supported by the National High Technology Research and Development Program(863 Program) of China; Project(2013CB035401) supported by the National Basic Research Program of China(973 Program); Projects(51274252, 51475478) supported by the National Natural Science Foundation of China; Project(16K080) supported by the Innovation Platform Open Foundation of Education Department of Hunan Province)

通信作者:张桂菊,博士研究生,副教授,从事岩石切削机理、机电系统仿真理论与方法等研究;E-mail:zhangguiju1999@sina.cn