Effect of additional element and heat treating temperature on micro-structure and mechanical behavior of Ag alloy thin film

JU Dong-ying1, ISHIGURO S1, ARIZONO T1, HASEGAWA K2

1.Department of Material Science and Engineering, Saitama Institute of Technology, Fusaiji 1690, Okabe, Saitama, Japan 369-0293;

2.Ishifuku Metal Industry Co Ltd, Kanda 3-20-7, Chiyoda-ku, Tokyo, Japan

Received 10 April 2006; accepted 25 April 2006

Abstract: For Ag alloy film used for the storage media, it is required to have heat-resistance, anti-constant temperature and anti-constant humidity characteristics, corrosion resistance, while high reflectivity over Al is maintained. An Ag alloy thin film (additive element Pd, Cu, P) was created on glass substrates, and various heat treatment was conducted. Then, fine structure was observed on this thin film using AFM, and fine structure evaluation of the inside was carried out by the in-plane diffractometry and X-ray diffractometry, and in addition, residual stress analysis was carried out. These results were compared and were examined, and fine structure and physical property in a metallic thin film were evaluated, and usefulness of evaluation method was verified.

Key words: Ag alloy; thin film; strage media; X-ray diffraction; DVD; Blu-ray

1 Introduction

Ag alloy film used for the storage media is required to have some advantages such as heat-resistance, anti-constant temperature, anti-constant humidity characteristics and corrosion resistance, while the high reflectivity over Al is maintained[1-3]. Various additive elements were tested, though good characteristics were obtained by adding Cu and P, mechanism of characteristic improvement had not sufficiently been clarified.

Then, Ag alloy thin film was created on glass substrates, and various heat treatment was conducted. It is considered that it becomes demonstration of usefulness of evaluation method, if this thin film is evaluated and it becomes aid of mechanism elucidation. On this thin film, fine structure was observed using AFM, and fine structure evaluation of the inside was carried out by X-ray diffraction, and in addition, mechanical characteristics such as hardness were also evaluated using nano indenter residual stress[4-6].

These results were compared and examined.

2 Evaluation method of thin film

2.1 Measurement of film thickness by X-ray reflection rate method

In low angle area, total reflection was generated, when X-ray was emitted in material. The vibration profile was extracted by subtracting average reflectivity from the data profile within generating total reflection. Fourier transformation was carried out, after angle compensation was carried out at refractive index of a film in respect of this, and after it was converted into the period pattern without contraction and the data were interpolated. From the peak of executed graph, film thickness was obtained.

2.2 Crystal structure analysis by in-plane diffraction

Analysis of crystal structure is very difficult when thickness of a film becomes nano level. In-plane diffraction is utilized[7] based on component of X-ray parallelly rans along the part in which sample which appears, when the X-ray is emitted to the sample surface used produced total reflection at critical angle of low angle. When X-ray is emitted in the material, it is very shallow along the sample surface. This would be able to do even in the equipment by the small-scale level crystal structure analysis of a thin film. Here fine crystal structure of a thin film was analyzed using this in-plane diffraction.

2.3 Residual stress measurement by synchrotron radiation

Spring-8 is a possible 8 GeV synchrotron radiation facility generating the best synchrotron radiation[8].

In this study, synchrotron radiation was taken out as an X-ray(X-ray strength is 10.25 keV, wavelength is 1.209 75×10-10 m), and X-ray diffraction measurement was carried out.

(1)

(1)

Stress σ is obtained according to Eqn.(1), when 2θ of the diffraction line is examined by changing normal line N of the sample plane and angle ψ which normal line N′ of lattice plane makes.

The relationship between sin2ψ and 2θ appears to be linear and the stress is required from the gradient of the straight line which approximates the least square.

2.4 Microstructure observation by SPM

Since observation of molecular level and atom becomes possible for nondestruction and resolution noncontacting scan in respect of observation sample surface, in this study, SPM(scanning probe microscope) such as AFM(atomic force microscopy) can be used to evalute fine structure of a thin film surface.

2.5 Evaluation method of hardness

Harness measurement pushes diamond indenter into the sample by electron actuator, it is possible to measure load and indentation depth from that time. Indentation load is detected by an electron balance, and it is pushed by the strength of the light which the mirror of the probe reflects, and the depth is detected. Then, the VICKERS hardness and depth can be calculated by the following Eqns.

(2)

(2)

(3)

(3)

where H is height, α is a constant, W(x) is the load in indentation depth x, ξ is the depth, H(ξ) is the hardness in depth ξ, and d is the displacement.

3 Estimated results of each materiality values

3.1 Observation and estimated results of Ag thin film

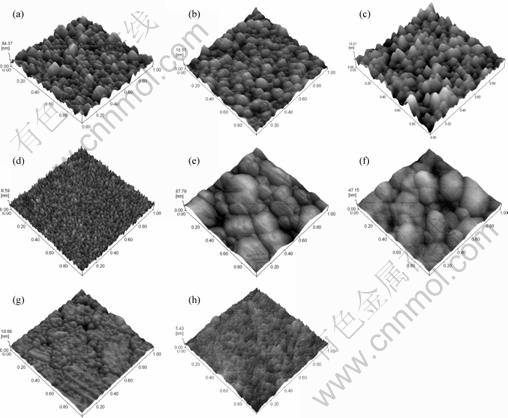

AFM image of Ag thin film is shown in Fig.1. It is proved that surface roughness of Ag alloy thin film

Fig.1 AFM images of Ag thin films: (a) Ag; (b) Ag0.5Pd; (c) Ag0.6Cu;(d) Ag 0.68Cu-0.12P; (e) Ag(250 ℃); (f) Ag 0.5Pb (250 ℃); (g) Ag0.6Cu (250 ℃); (h) Ag0.68Cu-0.12P (250 ℃)

added Cu , P , Pd is held low in comparison with Ag thin film.

Fig.1 AFM images of Ag thin films: (a) Ag; (b) Ag0.5Pd; (c) Ag0.6Cu;(d) Ag 0.68Cu-0.12P; (e) Ag(250 ℃); (f) Ag 0.5Pb (250 ℃); (g) Ag0.6Cu (250 ℃); (h) Ag0.68Cu-0.12P (250 ℃)

added Cu , P , Pd is held low in comparison with Ag thin film.

In case of the alloy film of the simple substance addition by Cu, P, Pd, it is confirmed that surface roughness of thin film increases with the increase of temperature.

It is confirmed that there is little effect to surface roughness by heat treatment on a Ag0.68Cu-0.12P alloy thin film and it maintains minutest surface structure. Additive element suppresses the transfer of the atom, and the growth of particle seems difficult to be generated. Profile measurement result of an Ag thin film by the in-plane diffraction is shown in Fig.2. Miller indexes of (111), (200), (220), (311) planes of cubic Ag are confirmed. Since additive is an ultratrace level, very small peak is detected on Ag alloy thin film. It is not possible to discuss the existence of the effect to a thin film, because very small peak is not detected.

Fig.2 In-plane profile of Ag thin film

In the measurement results by in-plane diffraction of an Ag thin film heat-treated at 80 ℃ and 95%RH(96 h), the confirmation is not possible for the peak. By condensing a thin film surface by heat and humidity, the reflectivity seems lowered. It is an Ag thin film that the reflectivity loweres most. The relationship between reflectivity and surface roughness is proportional. For this reason the lowering of reflectivity seems to be reflected diffusely by surface state changing when a thin film is heat-treated. The lowering of the reflectivity is about 2.3% on a Ag0.68Cu-0.12P thin film, and the effect of heat treatment is not most received.

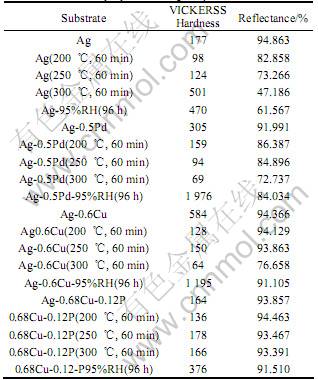

3.2 Hardness and reflectivity of an Ag thin film

The value of VICKERS hardness and reflectivity of an Ag thin film are shown in Table 1. The hardnesses of Ag0.68Cu-0.12P, Ag, Ag0.5Pd, Ag0.6Cu are high in order, when the hardnesses of the untreated samples are compared. Each sample is heat treated, and the hardness lowers temporarily. Afterwards, the hardness decreases with the rise of temperature. In 80 ℃ and 95%RH(96 h), the confirmation is not possible and the hardness and the regularity. And the correlation between surface state and reflectivity of a film can not be recognized either.

Table 1 Mechanical properties of Ag alloy film

Acknowledgment

The authors would like to thank Synchrotron Radiation Experimental Facility Spring-8 and Saitama University of Technology High Tech Research Center and professor HANABUSA T and assistant KUSAKA K who work in Factory of Engineering, University of Tokushima Science.

References

[1] SBIAA R, AHMAD E, SUZUKI T. Characterization of perpendicular recording media of coptcro granular thin films[J]. Journal of Magnetics Society of Japan, 2001, 25(3-2): 226-229.

[2] NISHIHARA T, KOJIMA R, MIYAGAWA N. High-transmittance phase-change media with TiO2 film for rewritable dual-layer blu-ray discs[J]. Japanese Journal of Applied Phys, 2005, 5: 3037-3041.

[3] MATSUE T, HANABUSA T, IKEUCHI Y. Residual stress and its thermal relaxation in TiN films[J]. Thin Solid Films, 1996, 281-282: 344-347.

[4] YANAGISAWA H, SHINKAI S, SASAKI K. Epitaxial growth of (001)ZrN thin films on (001)Si by low temperature process[J]. Japanese Journal of Applied Physics, 2005, 44(1A): 343-349.

[5] LIU Yu-xue, MASUMOTO H, GOTO T. Electrical and optical properties of IrO2 thin films prepared by laser-ablation[J]. Materials Transactions, 2004, 45(10): 3023-3027

[6] NOYAN I C, COHEN J B. Residual stress measurement by diffraction and interpretation[M]. New York: Springer, 1987.

[7] OFUJI M, INABA K, OMOTO K. Grazing incidence in-plane X-ray diffraction study on oriented copper phthalocyanine thin films[J]. Japanese Journal of Applied Phys Regular Papers, 2002, 41(8): 5467-5471.

[8] WITHERS P J, PREUSS M, WEBSTER P J, HUGHES D J, KORSUNSKY A M. Mater Sci Forum, 2002, 1: 404-407.

(Edited by CHEN Can-hua)

Corresponding author: JU Dong-ying; Tel: +81-48-595-6826; E-mail: dyju@sit.ac.jp