DOI: 10.11817/j.ysxb.1004.0609.2021-36702

粉末冶金共烧结制备90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料的组织与力学性能

朱文谭,蔡青山,王健宁,刘文胜,马运柱

(中南大学 轻质高强结构材料国家级重点实验室,长沙 410083)

摘 要:以90W-7Ni-3Fe预混粉末和30CrMnSiNi2A钢雾化粉末为原料,采用热等静压技术在1350 ℃、150 MPa、3 h烧结工艺下进行共烧结。利用SEM、XRD、TEM和万能力学试验机等研究了90W-7Ni-3Fe/ 30CrMnSiNi2A共烧结体的微观组织和力学性能特征。结果表明:采用共烧结方法成功制备了90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料,共烧结体组织均匀、致密度高、界面无孔洞和裂纹,结合良好;钨合金和钢基体的相对密度均大于99%,抗拉强度分别为920 MPa和1309 MPa。在钨合金和钢的界面区域发生强烈的元素扩散,形成了厚度为40~50 μm的Fe6W6C相,并分析了Fe6W6C相的形成;硬脆Fe6W6C相的存在恶化钨合金/钢界面的力学性能,界面的抗拉强度为85 MPa。断裂模式为Fe6W6C相和W相的混合断裂。

关键词:钨/钢结构复合材料;热等静压;粉末共烧结;微观组织;力学性能

文章编号:1004-0609(2021)-07-1737-10 中图分类号:TF841.1 文献标志码:A

引文格式:朱文谭, 蔡青山, 王健宁, 等. 粉末冶金共烧结制备90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料的组织与力学性能[J]. 中国有色金属学报, 2021, 31(7): 1737-1746. DOI: 10.11817/j.ysxb.1004.0609.2021-36702

ZHU Wen-tan, CAI Qing-shan, WANG Jian-ning, et al. Microstructure and mechanical properties of 90W-7Ni-3Fe/30CrMnSiNi2A structural composite materials prepared by powder metallurgy co-sintering[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(7): 1737-1746. DOI: 10.11817/j.ysxb.1004.0609.2021-36702

钨及其合金具有高密度(16.5~19.0 g/cm3)、高硬度、高强度、优异的抗腐蚀和氧化性以及良好的导电热性等性能,在航空航天、国防军工和核能源等领域得到应用广泛[1-2]。将钨合金与超高强韧低合金钢进行复合连接,相比单一合金,整体呈现出高密度、高硬度、超高强度和成型能力的匹配,在核聚变反应堆和穿甲武器中有着广泛的应用前景[3]。然而,由于钨与钢的物理性能差异较大,尤其是热膨胀系数(钨:4.5×10-6 K;钢:12×10-6~14×10-6 K)和弹性模量(钨:410 GPa; 钢:200 GPa)相差巨大,钨/钢高温复合后界面处出现热收缩不匹配现象,导致大的残余应力产生,同时连接界面极易形成FeW、Fe2W和Fe7W6等金属间化合物相,严重影响钨/钢结构复合材料性能[4-5]。

目前,钨/钢结构复合材料主要采用真空离子喷涂、钎焊、扩散焊和气相沉积等技术制备[6-9],其中扩散焊技术是制备钨/钢结构复合材料最有效的方法之一。在钨/钢扩散连接过程中,常需要添加一些中间层材料来改善钨/钢界面结合性能[10-12],这不可避免会引入新的杂质,且存在装配工差大、热裂纹等问题,材料性能及可靠性有待进一步提高。此外,扩散焊技术对待焊母材表面光洁度要求高,无法满足钨/钢复杂结构件的制备需求。

粉末冶金共烧结技术是将异种金属或合金材料粉末成形为一个整体后,在同一烧结制度下制备异种复合材料的方法,具有节约成本、近净成形、避免在界面处引入杂质以及避免焊接产生的热裂纹等独特优势[13-14],受到国内外学者的广泛关注。近年来,共烧结技术在陶瓷膜、电子封装、不锈钢等领域得到了广泛的应用[15-16],但关于钨/钢结构复合材料的共烧结制备研究却鲜有报道。鉴于此,本文提出采用粉末冶金共烧结技术来制备钨/钢结构复合材料。但由于钨合金和钢粉末形貌、松装密度及烧结特性存在差异,共烧结过程中会产生烧结收缩不均匀从而导致产生界面开裂、分层等缺陷,严重影响共烧结后材料的性能。热等静压技术具有结构适应性强、有效减小内应力的优势,在制备结构复合材料领域有很大的潜力。因此,本文借助热等静压技术来实现钨/钢结构复合材料的共烧结制备。

本文作者选择90W-7Ni-3Fe合金粉末与30CrMnSiNi2A低合金钢粉末进行共烧结探索,研究了钨/钢结构复合材料共烧结基体和界面的微观组织和力学性能,探讨了界面断裂失效的微观机制,为采用共烧结方法制备高性能钨/钢结构复合材料提供基础理论支撑。

1 实验

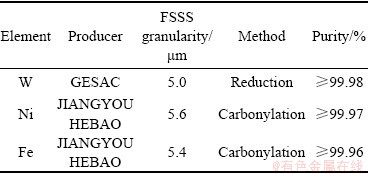

将W、Ni、Fe粉末按照90:7:3的质量分数比在三维混料机中均匀混合,混料在Ar气氛中进行以避免粉末氧化,球料比为1:1,混料时间为5 h。钢粉采用旋转电极雾化方法制备。实验所用的原始粉末性能如表1和2所示。图1(a)和(b)所示分别为90W-7Ni-3Fe混合粉末和30CrMnSiNi2A钢粉末形貌的扫描照片。90W-7Ni-3Fe粉末在预混之后各原始粉末的形貌没有发生明显变化,W粉和Ni粉呈现不规则形状,Fe粉为球形,如箭头标注所示。钢粉末则为球形颗粒。将90W-7Ni-3Fe粉末和钢粉按照上下两层分别装入钢包套中,随后进行封焊除气,最后在热等静压烧结炉中完成烧结实验,烧结温度、压力和保温时间分别为1350 ℃、150 MPa和3 h。将烧结完成的样品进行去包套加工。所有样品采用电火花线切割机进行切割,经过打磨、抛光后,对其微观组织和力学性能进行检测。其中钢采用4%(体积分数)硝酸酒精溶液进行腐蚀,腐蚀时间为8~10 s。

表1 钨合金原始粉末性能

Table 1 Properties of original tungsten alloy powders

表2 30CrMnSiNi2A钢化学成分

Table 2 Chemical composition of 30CrMnSiNi2A steel powder (mass fraction, %)

图1 粉末形貌

Fig. 1 Morphologies of powders

利用美国FIB公司生产的Nova Nano SEM230场发射电子显微镜对共烧结样品的微观组织、断口形貌进行观察,同时结合SEM自带的能谱装置(EDS)对界面物相成分、界面元素分布进行表征。采用RIGAKU-3104型X射线衍射仪(扫描角度为30°~90°,Cu靶)对共烧结界面物相结构进行表征。采用Tecnai G2 F20 S-TWIN TMP场发射透射电镜对共烧结界面物相晶体结构、界面物相取向关系进行分析。采用美国Instron 3369型力学试验机对共烧结基体及界面进行室温拉伸强度的测试,拉伸试样尺寸为狗骨头形状(L×W×T,25 mm×8.0 mm× 3.0 mm),加载速率为1 mm/min。

2 结果与讨论

2.1 共烧结基体的微观组织和力学性能

表3所列为90W-7Ni-3Fe/30CrMnSiNi2A共烧结样品的基体材料密度,共烧结后钨合金和钢的密度分别达到17.03 g/cm3和7.75 g/cm3,其相对密度均大于99%。可见在1350 ℃、150 MPa、3 h的热等静压条件下,钨合金和钢均实现了致密化烧结,这得益于热等静压独特的致密化机制。热等静压致密化过程分为3个阶段:粉末颗粒的流动和重排阶段(第一阶段),塑性变形阶段(第二阶段),蠕变和高温扩散阶段(第三阶段)[17]。在第一阶段,包含内部的粉末颗粒之间呈点接触状态,粉末中存在大量的孔隙。当加压时,钨合金和钢粉末发生平移或翻转,小颗粒被挤入到大颗粒孔隙中,钨合金粉末和钢粉末共同收缩,其相对致密度迅速提高。在第二阶段,粉末颗粒之间互相接触到一定程度后会相互抵触,因此,需要继续提高压力或温度来使粉末产生塑性流动的临界剪切应力降低。在该阶段,粉末颗粒产生一定的塑性变形流动后,颗粒之间互相扩散形成一个整体,其相对致密度接近理论致密度。因此,在该阶段,钨合金和钢的基体已经实现致密化烧结。在第三阶段,粉末的塑性流动机制不再起作用,而位错蠕变、晶格扩散和晶界扩散等被激活,原子或空位发生缓慢的扩散与蠕变,粉末原子缓慢进入残余孔隙,使得孔隙完全消除,该阶段可以显著促进钨合金和钢基体颗粒之间的冶金结合,有利于钨合金和钢基体的致密化烧结并获得优异的力学性能。

表3 共烧结90W-7Ni-3Fe合金和钢的密度

Table 3 Densities of 90W-7Ni-3Fe alloy and steel fabricated by co-sintering.

图2(a)和(b)所示分别为共烧结90W-7Ni-3Fe/ 30CrMnSiNi2A样品基体材料的显微组织。90W-7Ni-3Fe合金由灰白色的W相和黑色的γ-(Ni,Fe)黏结相组成。微观组织呈现典型的固相烧结特征:细小不规则的W颗粒聚集在一起,黏结相呈现片状分布。对于90W-7Ni-3Fe合金来说,其液相烧结温度通常在1477 ℃左右[18],而在1350 ℃下γ-(Ni,Fe)粘结相未熔化,因此合金呈现固相烧结组织。对于钢来说,样品表面没有明显的孔洞,同时没有观察到明显的钢颗粒边界,表明在该烧结状态下钢颗粒之间互相扩散并形成了良好的冶金结合。其组织由贝氏铁素体和大量粒状或条状的岛状组织(M-A岛)组成,这种组织通常被称为粒状贝氏体[19]。

图2 共烧结样品的微观组织

Fig. 2 Microstructures of co-sintered samples

对共烧结90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料的基体抗拉强度进行检测,结果如图3所示。钨合金抗拉强度为920 MPa,钢的抗拉强度为1309 MPa,同时其性能稳定波动小。对于粉末冶金制备的材料来说,通常高的致密度可以使合金获得优良的力学性能。根据文献[20]报道,传统90W-7Ni-3Fe合金在1300 ℃真空烧结状态下致密度仅为77%左右,而粉末冶金钢在1100~1350 ℃真空烧结状态下相对密度最高可以达到97%左右[21]。热等静压过程中施加了各向同性的静压力,相当于强化烧结,与传统的压制–烧结相比,采用热等静压技术所制备的钨合金和钢致密化程度更高(接近全致密),因此,可以获得更优异的抗拉强度。

图3 90W-7Ni-3Fe合金和30CrMnSiNi2A钢的抗拉强度

Fig. 3 Tensile strength of 90W-7Ni-3Fe alloy and 30CrMnSiNi2A steel

图4所示为共烧结90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料基体的拉伸断口形貌。从图4(a)中可以看出,90W-7Ni-3Fe合金断口形貌没有明显的孔洞,断口主要呈现W颗粒穿晶断裂和W-W界面失效的特征。一般来说,W穿晶断裂对应高的力学性能[22]。在固相烧结的状态下钨颗粒尺寸仅为5~8 μm,远远小于常规液相烧结状态下钨颗粒尺寸(40~60 μm),细小的钨颗粒起到了细晶强化的作用,这也是其获得高的抗拉强度的原因。对于30CrMnSiNi2A钢来说,如图4(b)所示,断口表面可以发现存在大量韧窝,同时还能观察到解理断裂,表现为混合断裂的方式。韧窝和解理断裂的出现也印证了通过热等静压制备的钢具有良好的强度和塑形。

图4 90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料样品的断口形貌

Fig. 4 Fracture morphologies of 90W-7Ni-3Fe/ 30CrMnSiNi2A structural composite materials

2.2 共烧结界面的微观组织和力学性能

图5所示为90W-7Ni-3Fe/30CrMnSiNi2A共烧结试样的界面显微组织。从图5(a)中可以看出,白色区域为90W-7Ni-3Fe合金,黑色区域为30CrMnSiNi2A钢。钨合金/钢界面区域没有发现明显的孔洞和裂纹,界面整体呈现曲折分布,同时,在靠近钢一侧的界面区域可以发现球形的钢颗粒的存在。两种材料在烧结过程中元素之间发生扩散反应,因此,在钨合金/钢界面连接区域可以发现一层新的灰色区域。从图5(b)中可以发现灰色相沿钨合金/钢界面呈连续分布,厚度约为40~50 μm左右。对界面区域进行元素线扫描和能谱分析,其结果如图5(c)和(d)所示。结合线扫和能谱的结果可知该灰色相主要富含W和Fe元素,还有少量的Ni和C元素。在共烧结过程中,界面附近的粉末会在压力的作用下实现共同收缩,克服了两种材料因收缩速率不同而导致界面应力的出现;同时,在界面区域的孔隙也会逐渐变少,钨颗粒与钢颗粒之间在高温高压下会发生一定的塑性变形和扩散反应。尤其在保温阶段,高的烧结温度和压力会促进钨颗粒和钢颗粒之间的剧烈扩散。根据Fe-W二元相图[23]可知,当Fe和W直接接触时原子会互相扩散形成脆的金属间化合物相,如FeW、Fe7W6和Fe2W相。为了进一步判定灰色相的晶体结构,采用透射电镜对其进行分析,其结果如图6所示。

图5 90W-7Ni-3Fe/30CrMnSiNi2A共烧结界面显微组织及线扫描和能谱分析

Fig. 5 Interface microstructures of 90W-7Ni-3Fe/30CrMnSiNi2A co-sintered samples and elemental scanning line, EDS spectra

图6(a)所示为灰色相和钨颗粒的界面区域的TEM像。区域A、B和C的选区电子衍射分别如图6(c)~(e)所示。根据选区电子衍射结果可知区域A为BCC结构的W相,区域B为复杂立方结构的Fe6W6C相。通过对灰色相的选区电子衍射结果标定可知其(220)、 和(602)的晶面间距分别为0.398 nm、0.254 nm和0.173 nm,这与Fe6W6C相标准PDF卡片(No.23-1127)相对应。W/Fe6W6C界面(区域C)的选区电子衍射结果表明,其界面位相关系为[111]W//[013]Fe6W6C,如图6(e)所示,表明该界面属于半共格关系。此外,在W/Fe6W6C相界面可以发现有明显裂纹(见图4(b)),裂纹一侧沿着Fe6W6C相的内部扩展,另一侧终止于W/Fe6W6C相界面,表明该半共格界面可以阻碍裂纹的扩展。根据文献[24]报道,Fe6W6C相本质属于脆性的碳化物,其键合方式为金属键和共价键的组合,其中C原子间隙固溶到W的八面体间隙中从而形成强的W—C共价键,这是导致其高脆性的本源。

和(602)的晶面间距分别为0.398 nm、0.254 nm和0.173 nm,这与Fe6W6C相标准PDF卡片(No.23-1127)相对应。W/Fe6W6C界面(区域C)的选区电子衍射结果表明,其界面位相关系为[111]W//[013]Fe6W6C,如图6(e)所示,表明该界面属于半共格关系。此外,在W/Fe6W6C相界面可以发现有明显裂纹(见图4(b)),裂纹一侧沿着Fe6W6C相的内部扩展,另一侧终止于W/Fe6W6C相界面,表明该半共格界面可以阻碍裂纹的扩展。根据文献[24]报道,Fe6W6C相本质属于脆性的碳化物,其键合方式为金属键和共价键的组合,其中C原子间隙固溶到W的八面体间隙中从而形成强的W—C共价键,这是导致其高脆性的本源。

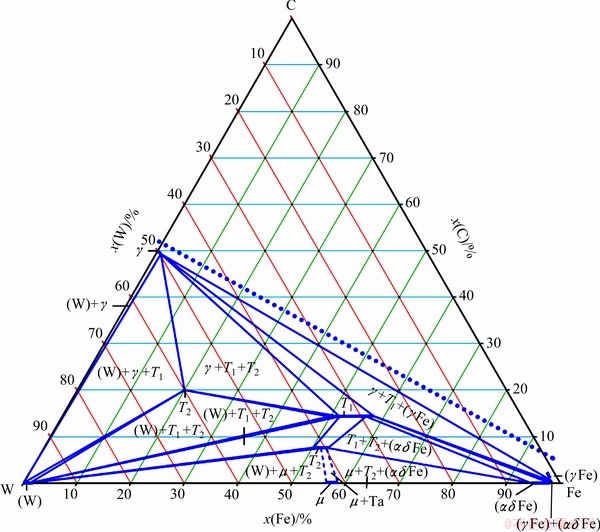

脆性Fe6W6C相的形成主要归因于90W-7Ni-3Fe合金和钢在界面区域固态扩散反应。90W-7Ni-3Fe合金和30CrMnSiNi2A钢的液相线分别为1477 ℃和1410 ℃,因此,在1350 ℃下,两者均属于固相烧结,界面物相的反应条件也属于固态扩散。高温高压加剧了Fe与W原子之间的扩散,因此在界面处发生剧烈的原子迁移形成FeW相。同时,钨合金中的Ni元素也会置换固溶部分Fe原子。而钢中的C原子由于其原子半径小,扩散更加剧烈,因此,在保温过程中界面元素互相扩散形成Fe6W6C相。该相的出现一方面可以实现钨合金与钢的冶金结合,但同时其高脆性也会弱化界面结合能力。根据W-Fe-C三元相图[25]也可以发现,富W和Fe区域存在T1(Fe3W3C)和T2(Fe6W6C)相,这与我们的实验结果相对应。

图6 90W-7Ni-3Fe/30CrMnSiNi2A共烧结界面TEM微观组织及选区电子衍射

Fig. 6 TEM images of 90W-7Ni-3Fe/30CrMnSiNi2A co-sintered sample and selected electron diffraction patterns

2.3 共烧结界面的力学性能

对共烧结90W-7Ni-3Fe/30CrMnSiNi2A界面的强度进行检测可知,其界面抗拉强度仅为85 MPa。这主要是硬脆Fe6W6C相的存在恶化了界面的力学性能。从图8(a)中可以判断,钨合金/钢结构复合样品失效路径主要是沿着Fe6W6C相脆断。对其断口进行观察,如图8(b)所示,可以发现界面处存在两种区域:一种为Fe6W6C的脆性断裂,同时,在Fe6W6C相的表面可以观察到一些二次裂纹的出现;另一种主要为不规则形状的W颗粒。结合XRD分析结果(见图8(c))可知,钨合金/钢样品的断口主要呈现Fe6W6C相的脆断和W颗粒间的断裂的特征,表明其失效路径沿W和Fe6W6C相界面扩展。对于异种材料连接界面,脆性金属间化合物的出现必然导致恶化界面性能,导致界面脆断。尤其当钨合金和钢界面处出现脆性Fe6W6C时,在拉伸载荷作用下,裂纹极易在W/Fe6W6C相界面萌生并高速扩展,导致界面发生脆性断裂。

图7 Fe-W-C在1250 ℃下等温截面图[25]

Fig. 7 Isothermal section of Fe-W-C at 1250 ℃[25]

图8 90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料共烧结界面断口形貌及XRD谱

Fig. 8 Fracture morphologies of 90W-7Ni- 3Fe/30CrMnSiNi2A structural composite material and XRD pattern of failure surface

3 结论

1) 采用粉末冶金共烧结方法成功制备了90W-7Ni-3Fe/30CrMnSiNi2A结构复合材料,其界面区域组织致密,无明显裂纹以及孔隙,形成了良好的冶金结合。

2) 在1350 ℃、150 MPa、3 h烧结工艺下钨合金和钢基体均实现了致密化烧结,其相对密度均大于99%,抗拉强度分别为920 MPa和1309 MPa。

3) 90W-7Ni-3Fe/30CrMnSiNi2A共烧结界面形成厚度为50 μm的金属间化合物层,TEM表征结果表明该相为复杂立方结构的Fe6W6C相。Fe6W6C相的出现显著降低了钨/钢结构复合材料的界面结合性能,其界面抗拉强度为85 MPa。

4) 90W-7Ni-3Fe/30CrMnSiNi2A共烧结界面断裂方式为沿着W/Fe6W6C相界面和Fe6W6C相内部混合断裂,断口呈现脆性断裂。

REFRTRENCES

[1] KUMARI A, SANKARANARAYANA M, NANDY T K. On structure property correlation in high strength tungsten heavy alloys[J]. International Journal of Refractory Metals & Hard Materials, 2017, 67: 18-31.

[2] GERO R, BORUKHIN L, PIKUS I. Some structural effects of plastic deformation on tungsten heavy metal alloys[J]. Materials science and Engineering A, 2001, 302: 162-167.

[3] 马运柱, 叶晓珊, 刘文胜, 等. 机械合金化制备钨基非晶合金的研究进展[J]. 粉末冶金技术, 2014, 32(2): 138-143.

MA Yun-zhu, YE Xiao-shan, LIU Wen-sheng, et al. Research process of the tungsten-based amorphous alloys by mechanical alloying[J]. Powder Metallurgy Technology, 2014, 32(2): 138-143.

[4] MA Yun-zhu, ZHU Wen-tan, CAI Qing-shan, et al. Microstructural evolution and mechanical properties in the partial transient liquid phase diffusion bonding of tungsten to steel[J]. International Journal of Refractory Metals And Hard Materials, 2018, 73: 91-98.

[5] LIU Dong-guang, ZHENG Liang, LUO Lai-ma, et al. An overview of oxidation resistant tungsten alloys for nuclear fusion[J]. Journal of Alloys and Compounds, 2018, 765: 299-312.

[6] WIDODO W B, JARIR A. Process optimization for diffusion bonding of tungsten with EUROFER97 using a vanadium interlayer[J]. Journal of Nuclear Materials, 2015, 459: 217-224.

[7] CAI Qing-shan, LIU Wen-sheng, MA Yun-zhu, et al. Microstructure, residual stresses and mechanical properties of diffusion bonded tungsten-steel joint using a V/Cu composite barrier interlayer[J]. International Journal of Refractory Metals and Hard Materials, 2015, 48: 312-317.

[8] KONURUS L K K, UMASANKAR V, SARKAR B, et al. Microstructure and mechanical properties of tungsten and tungsten-tantalum thin-film-deposited RAFM steel[J]. Materials Research Innovations, 2020, 24:97-103.

[9] QU D D, BASUKI W W, AKATTA J. Numerical assessment of functionally graded tungsten/EUROFER coating system for first wall applications[J]. Fusion Engineering and Technology, 2015, 98:1389-1393.

[10] ZHONG Zhi-hong, HINOKI T, KOHYAMA A, Effect of joining temperature on the microstructure and strength of tungsten/ferritic steel joints diffusion bonded with a nickel interlayer[J]. Journal of Materials Processing Technology, 2010, 210: 1805-1810.

[11] ZHONG Zhi-hong, HINOKI T, NOZAWA T, et al. Microstructure and mechanical properties of diffusion bonded joints between tungsten and F82H steel using a titanium interlayer[J]. Journal of Alloys and Compounds, 2010, 489: 545-551.

[12] BASUKI W W, AKTAA J. Diffusion bonding between W and EUROFER97 using V interlayer[J]. Journal of Nuclear Materials, 2012, 429: 335-340.

[13] 潘文强, 何 浩, 李益民. Fe-2Ni/Fe-2Ni-xCr梯度功能材料的共烧结致密化行为和界面强度[J]. 粉末冶金材料科学与工程, 2012, 17(5): 27-34.

PAN Wen-qiang, HE Hao, LI Yi-min. Co-sintering densification behaviors and interface strength of Fe-2Ni/Fe-2Ni-xCr functionally gradient materials[J]. Materials Science and Engineering of Powder Metallurgy, 2012, 17(5): 27-34.

[14] 刘剑敏, 李益民, 何 浩. Co-Cr-Mo合金和ZrO2共烧结及其制品性能[J]. 粉末冶金材料科学与工程, 2014, 19(4): 559-564.

LIU Jian-min, LI Yi-min, HE Hao. Behavior and product performance of co-sintering Co-Cr-Mo alloy and ZrO2[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(4): 559-564.

[15] DOURANDISH M, SIMCHI A, HOKAMOTO K. Interface formation and bond strength in 3Y-TZP/Cr composite bilayers produced by sinter-joining[J]. Materials Science and Engineering A, 2010, 527: 449-453.

[16] FIROUZDOR V, SIMCHI A, KOKABI A H. An investigation of the densification and microstructural evolution of M2/316L stepwise graded composite during co-sintering[J]. Journal of Materials Science, 2008, 43: 55-63.

[17] 郭瑞鹏. 粉末冶金钛合金力学性能与热等静压致密化研究[D]. 沈阳: 东北大学, 2014.

GUO Rui-peng. Mechanical properties of powder metallurgy titanium alloys and densification of titanium powders during HIPing[D]. Shenyang: Northeastern University, 2014.

[18] 于 洋, 王尔德, 胡连喜. 热液静挤压93W-4.9Ni-2.1Fe合金显微组织与力学性能[J]. 稀有金属材料与工程, 2007, 36(3): 408-411.

YU Yang, WANG Er-de, HU Lian-xi. Microstructure and mechanical properties of 93W-4.9Ni-2.1Fe alloy by hot hydrostatic extrusion[J]. Rare Metal Materials and Engineering, 2007, 36(3): 408-411.

[19] 王建平, 杨志刚, 白秉哲, 等. 奥氏体形变对仿晶界型铁素体/粒状贝氏体复相钢组织和强韧性能的影响[J]. 金属学报, 2004, 40(3): 263-269.

WANG Jian-ping, YANG Zhi-gang, BAI Bing-zhe, et al. Influence of austenite deformation on the microstructure strength and toughness of the grain boundary allotriomorphic ferrite/granular bainite duplex steel[J]. Acta Metallurgica Sinica, 2004, 40(3): 263-269.

[20] ZHU Wen-tan, MA Yun-zhu, LIU Weng-sheng, et al. Study on low-temperature sintering behavior of 90W-7Ni-3Fe alloys: The influence of Sn addition[J]. Journal of Materials Engineering and Performance, 2020, 29(9): 5894-5901.

[21] 杨 璐. DT300高强度钢粉末冶金法制备工艺研究[D]. 郑州: 河南科技大学, 2017.

YANG Lu. Research on the preparation of DT300 high- strength steel by powder metallurgy[D]. Zhengzhou: Henan University of Science and Technology, 2017.

[22] CHURN K S, GERMAN R M. Fracture behavior of W-Ni-Fe heavy alloys[J]. Metallurgical and Materials Transactions A, 1984, 15: 331-338.

[23] 张恒华. 金属二元系相图手册[M]. 北京: 化学工业出版社, 2009.

ZHANG Heng-hua. Handbook of phase diagrams for binary systems of metals[M]. Beijing: Chemical Industry Press, 2009.

[24] SUETIN D V, SHEIN I R, IVANOVSKII A L. Structural, electronic and magnetic properties of η carbides (Fe3W3C, Fe6W6C, Co3W3C and Co6W6C) from first principles calculations[J]. Physica B Condensed Matter, 2009, 404: 3544-3549.

[25] KORNIYENKO K. W-Fe-C ternary phase diagram evaluation (2007). https://materials.springer.com/msi/docs/ sm_msi_r_10_010004_01.

Microstructure and mechanical properties of 90W-7Ni-3Fe/30CrMnSiNi2A structural composite materials prepared by powder metallurgy co-sintering

ZHU Wen-tan, CAI Qing-shan, WANG Jian-ning, LIU Wen-sheng, MA Yun-zhu

(National Key Laboratory of Science and Technology for National Defence on High-strength Structural Materials, Central South University, Changsha 410083, China)

Abstract: 90W-7Ni-3Fe premixed powders and 30CrMnSiNi2A steel atomized powder were used as raw materials and co-sintered by HIP at (1350 ℃, 150 MPa, 3 h). The SEM, XRD, TEM and universal mechanical testing machine were used to evaluate the microstructure and mechanical properties of co-sintered samples. The results show that the 90W-7Ni-3Fe/30CrMnSiNi2A composite can be successfully fabricated by co-sintering method. The co-sintered samples shows high density and uniform microstructure, and the interface present good metallurgical bonding free from voids or cracks. The relative densities of 90W-7Ni-3Fe alloy and steel are more than 99%, and their tensile strengths are 920 MPa and 1309 MPa, respectively. The violent element reaction occurs at the interface between 90W-7Ni-3Fe alloy and 30CrMnSiNi2A steel and the Fe6W6C phase with thickness of 40-50 μm forms. In addition, the formation mechanism of Fe6W6C phase was discussed based on the phase diagram theory. The tensile strength of tungsten alloy/steel joint is 85 MPa, and the tungsten/steel composites failed mainly along the interface of tungsten alloy/Fe6W6C, which show Fe6W6C phase brittle fracture and W/W interfacial failure on the fracture.

Key words: tungsten/steel structural composite materials; hot isostatic pressing; co-sintering; microstructure; mechanical property

Foundation item: Project(51931012) supported by the National Natural Science Foundation of China

Received date: 2021-02-25; Accepted date: 2021-05-10

Corresponding authors: LIU Wen-sheng; Tel: +86-731-88877998; E-mail: liuwensheng@csu.edu.cn

MA Yun-zhu; Tel: +86-731-88877825; E-mail: zhuzipm@csu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51931012)

收稿日期:2021-02-25;修订日期:2021-05-10

通信作者:刘文胜,教授,博士;电话:0731-88877998;E-mail:liuwensheng@csu.edu.cn

马运柱,教授,博士;电话:0731-88877825;E-mail:zhuzipm@csu.edu.cn