文章编号:1004-0609(2015)-07-1867-09

CNTs/Cu复合超细粉末及其复合材料的制备

胡柏新1,陈小华1,许龙山2,汪次荣1,林承润2

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 厦门理工大学 材料科学与工程学院,厦门 361024)

摘 要:以硝酸铜和预处理碳纳米管(CNTs)为原料,采用喷雾干燥-煅烧-还原工艺获得超细CNTs/ Cu复合粉体。将复合粉体分别利用模压成形(MP)和冷等静压成形(CIP)两种工艺分别制备出CNTs/ Cu复合材料。比较两种工艺下得到的复合材料的致密度、硬度、导电率和导热性能。结果表明:喷雾干燥法制备的复合粉体纯度高,CNTs分散均匀。冷等静压成形优于模压工艺,冷等静压工艺制备的复合材料中CNTs含量为0.5%(质量分数)时,硬度和热导率分别达到105.24 HV和407.84W/(m·K)。

关键词:铜基复合材料;碳纳米管;喷雾干燥;模压;冷等静压

中图分类号:TB333 文献标志码:A

Fabrication of CNTs/Cu ultrafine powders and composite materials

HU Bai-xin1, CHEN Xiao-hua1, XU Long-shan2, WANG Ci-rong1, LIN Chen-run2

(1. College of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. College of Materials Science and Engineering, Xiamen University of Technology, Xiamen 361024, China)

Abstract: CNTs/Cu ultrafine powders were prepared from copper nitrate and pre-treated carbon nanotubes via spraying drying-calcination-hydrogen reduction method. CNTs/Cu composites with different CNTs contents were prepared by mould pressing (MP) and cold isostatic pressing(CIP) of the CNTs/Cu ultrafine powders. The relative density, microhardness, eletrical conductivity and thermal conductivity of the CNTs/ Cu composites were compared. The results indicate that the CNTs powders is high pury and distributes homogeneously, the cold isostatic pressing method is superior to the mould pressing method, especially for the 0.5% (mass fraction) CNTs composite formed by cold isostatic pressing, the microhardness and thermal conductivity increase to 105.24 HV and 407.84 W/(m·K), respectively.

Key words: copper-based composite material; carbon nanotube; spraying drying; mould pressing; cold isostatic pressing

铜作为应用最广泛的金属材料之一,具有优异导电导热性能和良好加工特性,随着现代工业的发展,对其性能提出了更高的要求[1-2]。如何保持在铜的高 导电、高导热情况下,大幅度提高其力学性能已成为铜材料研究领域的重要问题。目前,学者们主要通过铜基体中添加硬质材料(钢颗粒、钨颗粒、钼纤维等)和陶瓷颗粒(Al2O3等)的方法来提高铜及其合金的力学性能[3-7]。但硬质材料的密度远大于铜的,不利于复合材料密度的降低和致密度的提高,且烧结时很容易发生偏析。陶瓷颗粒一般为绝缘体,将对铜基复合材料的导电率产生很大影响,寻找一种比强度比模量大且导电导热优异的增强相取代以上两种增强体成为了铜基复合材料研究热点。

自碳纳米管(CNTs)发现以来,由于其独特的结构、极低的密度、超强的力学性能及优异的导电导热性能,引起了国内外材料学界的广泛关注[8-12]。大量研究结果表明[13-16]:将CNTs作为增强相加入金属、陶瓷和聚合物基体中能够获得综合性能优异的复合材料。然而,CNTs均匀分散于金属基体以及二者的界面结合这两个难题一直阻碍着该类复合材料的发展。为此,科研工作者们做了大量工作,如添加分散剂、表面嫁接特定官能团、表面镀层预处理、碳纳米管上的原位聚合等。在混合方法上采用过机械混合法[17-21]、熔融混合法[22-23]、溶液混合法[24-25]等,但这些方法对于碳纳米管来说效果并不理想:1) 由于碳纳米管直径仅为纳米级,在其表面进行金属层镀覆难以达到均匀、致密的效果[26-28],而大规模的镀覆更难保证包覆层的连续和致密,团聚现象仍无法避免;2) 由于直径小、密度低,碳纳米管与基体的混合和烧结成型面临更大困难。对于固相混合,尺寸和密度的差异将使得碳纳米管团聚和偏聚难以避免。烧结成型时,由于两者较差的相容性和铜的塑性流变,导致更严重的偏聚。对于液相混合,液体铜与碳增强体相互之间难以润湿也不会反应生成化合物,更易造成碳纳米管偏聚甚至上浮等问题。

喷雾干燥法是利用混合均匀的溶液经过高压雾化成小液滴,然后经高温快速干燥去除小液滴中的水分,最终得到物理和化学性质均一的前驱体粉末的一类方法[29],通过该方法不仅能得到粒度分布均匀、粒径细小、纯度高的复合粉体,而且能有效地实现增强体和基体的均匀混合,并且工艺简单、易于实现工业化生产。目前,利用喷雾干燥法制备超细钨粉、钨铜粉工艺日趋成熟,特别是范景莲等[30-32]对此进行了系统性研究,而采用该方法制备CNTs/Cu复合材料的研究鲜见报道。本文作者以硝酸铜盐和预处理CNTs为原料,经喷雾干燥-煅烧-氢还原的方法制备CNTs/Cu超细复合粉体,同时采用模压(MP)和冷等静压(CIP)两种工艺制备CNTs/Cu复合材料,并对其基本性能进行了分析和研究。

1 实验

1.1 CNTs的预处理

将3 g CNTs、3 g分散剂(乙二胺四乙酸,EDTA)与100 mL去离子水配成溶液,再加入240 mL配置好的混酸溶液(浓硫酸和浓硝酸的体积比为1:3),超声混合处理30 min,然后倒入三口瓶并置于微波炉中。在机械搅拌同时采取微波辅助加热(微波功率600 W),微波从物质内部快速均匀地加热,很大程度上促进CNTs的纯化及功能化,并冷凝回流30 min,待冷却后稀释抽滤,再用去离子水洗涤至pH为7,干燥48 h,得到预处理CNTs。采用日立JEOL-1230型透射电镜(TEM)和NICOLET FT-IR380傅里叶红外光谱仪对处理后的CNTs进行观察与分析,比较处理前后CNTs结构变化。

1.2 CNTs/Cu复合粉体的制备

按制备0.05%、0.1%、0.25%、0.5%、0.75%(质量分数)不同含量的CNTs/Cu复合材料,分别取5种比例的预处理后CNTs超声分散于去离子水配成溶液;将一定量的硝酸铜溶于去离子水中,待其完全溶解制备得到硝酸铜溶液;将两者水溶液混合超声30min,使其混合均匀。最后将5种混合溶液在YC-015型喷雾干燥机(进风温度200 ℃,蠕动泵40,通风60Hz)的作用下得到5种不同CNTs含量的超细CNTs/Cu (NO3)2复合粉体。

将得到的CNTs/Cu(NO3)2复合粉体置于OTF-1200X石英管式炉中,在650 ℃、纯氮气流量为100 mL/min下煅烧2 h,得到5种不同CNTs含量的CNTs/CuO超细复合粉体。然后将CNTs/CuO复合粉体在350 ℃,氢气与氮气体积比为1:1(流量均为300 mL/min)的气氛下还原3 h,最后随炉降温得到5种不同CNTs含量的CNTs/Cu复合粉体。利用ZEISSEVO18型扫描电镜(SEM)及X’Pert PRO X射线衍射仪对复合粉体进行形貌和物相进行分析。

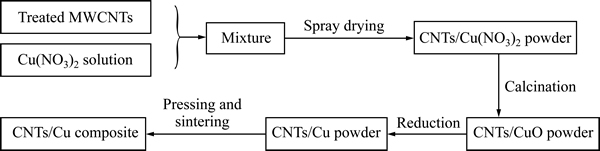

图1 CNTs/Cu复合材料制备流程

Fig. 1 Preparation process chart of CNTs/Cu composite

1.3 CNTs/Cu复合材料制备

称取一定量的CNTs/Cu粉体,分别装入内径为20 mm的钢模模具和20 mm的橡胶模具套中,采用模压和冷等静压两种工艺都在200 MPa的压力下进行压制,保压15 min,得到复合压坯。将所得到得两种压坯在950 ℃,纯氢气流量为450 mL/min烧结2.5 h,随炉降温,得到CNTs/Cu复合材料,制备流程图如图1所示。为进行对比,采用同样的工艺制备纯铜样。对得到的两系列复合材料,采用阿基米德排水法测试密度,复合材料计算公式计算出理论密度并通过二者比得到材料的相对密度;利用ZEISS EVO18型扫描电镜(SEM)对复合材料的断面进行形貌和元素含量能谱分析(EDS);HVST-1000ZD显微硬度测试仪金刚石压头进行维氏硬度测定,选择自动模式,加载载荷为4.903 N,加载时间为3 s,随机在上下表面选取6处进行测试后取平均值作为结果;以FD-102涡流式电导仪对复合材料进行电导率测试,d 12.7 mm探头,精确在0.3%(IACS),电导率结果自动补偿到20 ℃的模式进行测量,对每个复合材料样品上下表面分别进行6次测量,将等得到平均值作为该复合材料电导率的最终结果;采用NETZSCH-LFA-457 激光热导仪对复合材料的导热性能进行测试,通过测试出复合材料块体的热熔结合复合块体的密度,最终根据热导计算公式得到复合材料的热导率。

2 结果与讨论

2.1 CNTs预处理前后的结构分析

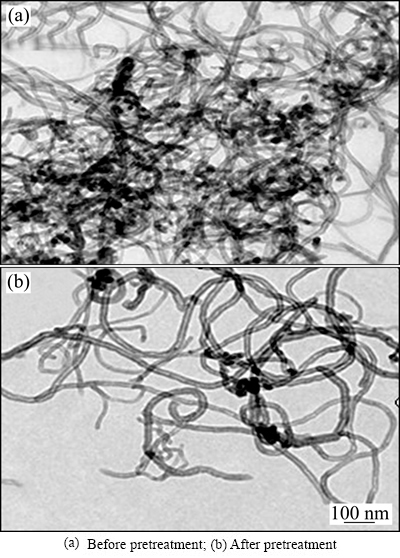

图2所示为处理前后CNTs的TEM像。从图2中可以看出,原始CNTs团聚严重、有许多端口附着催化剂金属颗粒,且CNTs表面分散着大量的无定形碳。而处理后的透镜照片(见图2(b))显示附着的大部分催化剂颗粒和无定形碳通过混酸预处理均被有效地去除。

图3所示为预处理前后CNTs红外光谱。从图3所示红外吸收谱可以看出,混酸处理后的CNTs不仅在1576 cm-1处出现了—C=C—伸缩振动吸收峰,在1074、1700和3853 cm-1等处也出现了较强的振动吸收峰,表明通过酸化处理后的CNTs成功引入C—N、C=O和O—H等活性官能团,改善了CNTs的亲水性,提高了其在溶液中的分散能力。

2.2 复合粉体及复合材料结构和形貌分析

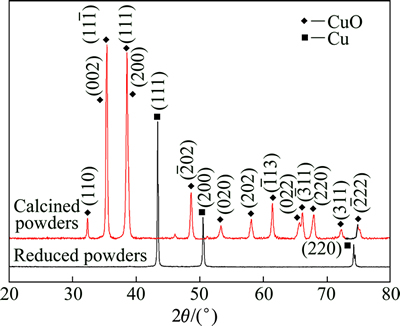

图4所示为0.75%(质量分数)复合粉体煅烧和还原后的XRD谱。由图4可以看出,煅烧后的粉体除了单一相的氧化亚铜外,未出现其他物相衍射峰,表明该方法制备的复合粉体纯度高。还原后复合粉体的XRD谱显示,除了铜相外,没有其他物相,证明粉体经350 ℃、3 h还原充分,没有氧化铜和氧化亚铜相的残留。由于CNTs在复合材料中的含量较低,X射线难以检测出来,故在XRD中没有出现与之相对应的峰位角。

图2 预处理前后CNTs的TEM像

Fig. 2 TEM images of CNTs before and after pretreatment

图3 预处理前后CNTs红外光谱

Fig. 3 IR patterns of CNTs before (a) and after (b) pretreatment

图4 0.75%复合粉体煅烧与还原后XRD谱

Fig. 4 XRD patterns of calcined and reduced composite 0.75% powders

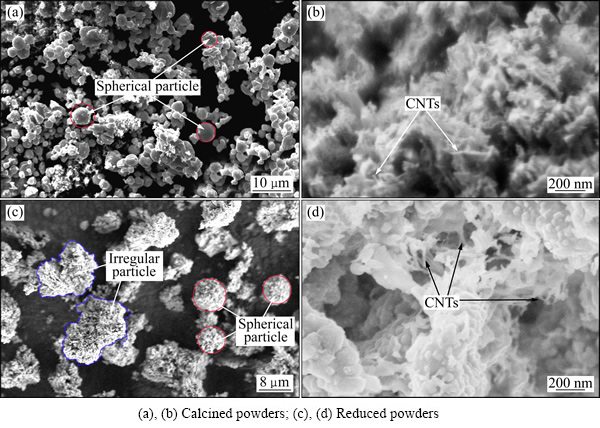

图5所示为0.5%复合粉体煅烧和还原后的显微形貌。从图5(a)和(c)中可以看出,复合粉体粒径在几十纳米到几微米之间,粒径呈连续梯度分布,大颗粒在压制时产生塑性变形,形成较致密的骨架,而小颗粒粉体表面能高,在烧结时会首先发生原子迁移填充大颗粒形成骨架空隙,这种粒度分散粉体对复合材料的致密化有一定的促进作用。煅烧后粉体为类球状颗粒,而还原后部分粉体颗粒呈现出了不规则形状且表面附着许多小颗粒金属铜,可能是由于粉体粒径较小,还原时间太长,类球状颗粒表面铜原子在还原过程中发生迁移,形成了不规则形状的颗粒,而有的铜原子在迁移过程中未能及时成核长大聚集成为小颗粒附着在了复合大颗粒表面。从图5(b)和(d)中可以看出,大量CNTs镶嵌于粉体之中,提高了CNTs与铜基体的结合强度。

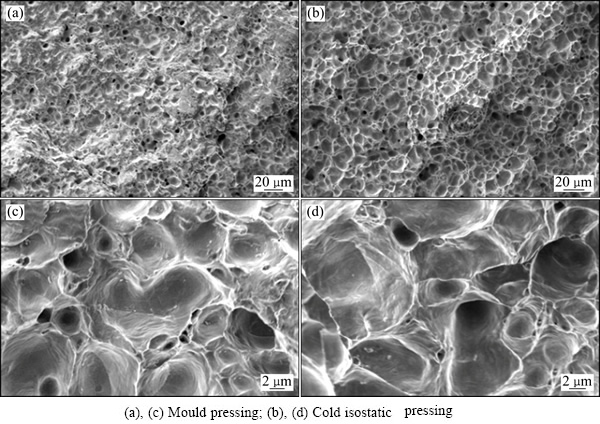

图6所示为0.5CNTs复合材料的断口SEM像。从图6(a)和(b)中可以看出,采用模压工艺制备复合材料的微孔远多于冷等静压成形得到复合材料的,且孔径大小不一,造成这样结果的原因是:一方面,CNTs的加入阻碍了铜颗粒的塑性变形,在复合材料中留下孔洞;另一方面,模压工艺中粉体与模具的摩擦减少了成形压力。而采用冷等静压压制时,粉体各方向所受压力相等,能有效避免压力的损耗,得到的复合材料的结构和性能更趋近各向同性。从图6(c)和(d)中还可以看出,复合材料断口有许多的韧窝,平均直径在5 μm左右,说明复合材料断裂形式为塑性断裂。图7所示为冷等静压成形不同CNTs含量的复合材料断面形貌。由图7可以看出,随着CNTs含量的增加,韧窝直径减小,空穴率增加。主要随着CNTs含量不断增加,对铜颗粒的塑性变形阻力增大,烧结时铜原子迁移困难,得到复合块体晶粒尺寸减小,导致断裂时韧窝直径减小。由于CNTs含量增加,部分发生团聚。同时,CNTs刚性较大压制烧结后会回弹,将导致复合材料空穴率增加。

为探测经过烧结后复合材料的成分,对断口进行了EDS分析。图8所示为冷等静压工艺下CNT含量为0.5% 时复合材料的能谱分析图。从图8中可以看出,复合材料中除了大部分为铜元素外,还含有一定量的碳元素,表明含有少量的CNTs。由于得到的复合粉体粒径细小,表面活化能较大,容易被氧化,故在能谱中显示少量的氧元素。

2.3 CNTs/Cu复合材料的性能测试和分析

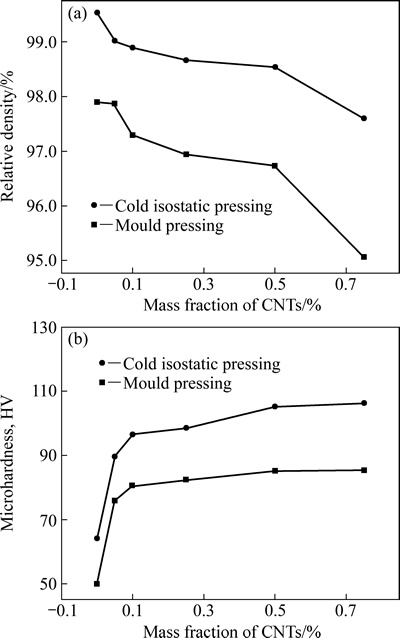

复合材料的相对密度直接影响材料的各方面性能,特别是铜基复合材料的导电、导热性能,为此,测试了两种成形工艺下所制备复合材料的相对密度和显微硬度,如图9 所示。从图9(a)中可看出,随着 CNTs含量的增加,复合材料的密度和致密度不断下降,这与断面形貌的结果相一致,特别是CNTs含量较高时(0.75%)复合材料的密度和致密度急剧下降。这主要是由于:1) CNTs本身密度为2.1 g/cm3,远低于纯铜密度(8.9 g/cm3),复合材料的密度必然随着CNTs含量的增加而降低;2) CNTs的硬度较大,作为增强相,在压制过程中基本不变形,对铜粉在压制过程中的塑性变形起到阻碍作用,随着含量的增加这种阻碍作用越明显;3) CNTs拥有很好的柔韧性,压制压力撤去后,变形的CNTs发生回弹,产生孔隙,降低复合材料致密度;4) 铜的熔点1083 ℃,烧结温度为950 ℃,采用固相烧结,过程中不发生相的改变,故烧结机制主要是铜原子的扩散和流动,CNTs的存在对扩散起到一定的阻碍作用,CNTs含量越大,这种阻碍越大,难以实现致密烧结。同时,从图9(a)还可知,冷等静压成形复合材料的相对密度比模压成形复合材料的约为2%,这主要是冷等静压成形压力利用率远高于模压成形结果。粉末冶金模压成形和冷等静压成形过程实质上是金属粉体冷焊接的过程,金属颗粒产生塑性变形,颗粒与颗粒之间相互靠近、挤压,焊接成为大颗粒。在冷等静压的过程中,外压损失少,颗粒之间焊接更牢固,且单位体积内焊接接触面更大,从而得到的压坯相对密度更高。而模压成形,压力不断损耗,铜颗粒总体塑性变形较小,空穴填充不够,很难得到高致密度压坯。由此可以看出,采用冷等静压成形有利于获得高致密度复合材料。

图5 0.5%复合粉体的SEM像

Fig. 5 SEM image of 0.5% composite powders

图6 0.5%CNTs复合材料的断口SEM像

Fig. 6 Cross-sectional SEM images of composites with 0.5% (mass fraction) CNTs

图7 冷等静压成形不同CNTs含量复合材料断口的SEM像

Fig. 7 Cross-sectional SEM images of composite with different CNTs contents prepared by cold isostatic pressing

图8 0.5% CNTs/Cu复合材料的EDS谱

Fig. 8 EDS spectrum of 0.5% CNTs/Cu composite

由图9(b)可看出,冷等静压得到的复合材料硬度高于模压成形复合材料的硬度,这主要归结为冷等静压压坯所受各个方向压力一致。在冷等静压过程中,冷焊接得到颗粒更趋于一致,烧结后得到复合材料的晶粒粒径较均匀,复合材料硬度较高。而模压成形过程由于坯体表面压力远大于内部压力,冷焊接压坯表面颗粒粗大,烧结得到复合材料表面晶粒较大,硬度偏小。而两种工艺下硬度值随CNTs含量的变化趋势基本一致,在低CNTs含量时,随着CNTs含量的增加复合材料硬度呈增大趋势,据复合材料增强理论和Hall-Petch理论,一方面是CNTs的本身硬度远大于铜基体的,作为增强体加入必然会使硬度有很大提高;另一方面是CNTs的存在抑制了铜晶粒的长大,从而起到了细晶强化的效果。当CNTs含量高于0.5%时,这种趋势有所减缓,主要是由复合材料致密度的下降以及孔隙率的增大所致,这与刘贵民等[33]的研究结果相一致,而硬度值远高于文献[33]中的,这主要得益于喷雾工艺对碳纳米管的有效分散作用。

图9 不同CNTs含量复合材料的相对密度和硬度

Fig. 9 Relatively density (a) and microhardness (b) of composites with different CNTs contents

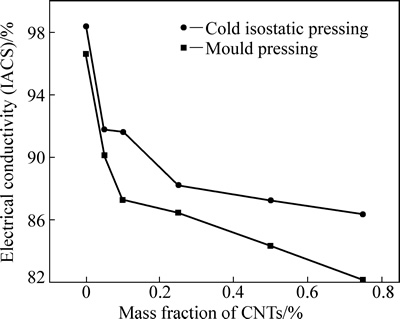

图10所示为复合材料电导率随CNTs含量的变化。由图10可以看出,复合材料电导率随CNTs含量增加有一定程度的下降,这主要由于CNTs阻碍了晶粒的长大,导致晶界密度增加,对电子散射增大,不利于电子定向移动。同时,CNTs含量的增加使复合材料的孔隙率和缺陷增加,这也是导致电导率下降的另一原因。但比较两种成形方式,冷等静压成形样品的电导率高于模压成形样品的,这与前述的冷等静压成形样品致密度较高的结果相符合。

图10 不同CNTs含量复合材料的电导率

Fig. 10 Electrical conductivity of composites with different CNTs contents

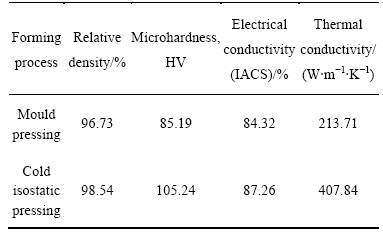

为进一步研究两种工艺对CNTs/Cu复合材料热导性能的影响,综合图8~10的结果,选取了致密度和显微硬度均较高、而电导率降低较少的0.5% CNTs/Cu复合材料进行了热导测试,其结果如表1所列。从表1中可以看出,当CNTs含量为0.5%时,冷等静压样各方面的性能均优于模压成形样的,特别是显微硬度和热导率分别达到了105.24 HV和407.84 W/(m·K),基本可以满足电子封装材料的应用要求;CNTs/Cu复合材料的性能与材料的致密度有着直接的关系,相同成分时下,致密度越高,材料各方面性能就越优异。

表1 不同成形工艺条件下0.5% CNTs/Cu复合材料性能的比较

Table 1 Properties comparison of 0.5% CNTs/Cu composites prepared by cold pressing and isostatic pressing

影响热导率的因素很多,诸如CNTs与铜基体的界面热阻、复合材料的孔隙率、CNTs在基体中的分散程度以及固化烧结程度都对复合材料的热导率起到了至关重要的作用[34]。CHU等[35]采用特殊颗粒复合系统(Particles composite system, PCS)得到CNTs增强铜基复合材料(5.0%CNTs(体积分数))的热导率为325 W/(m·K)左右,而本研究中制备工艺获得的0.5%CNTs/Cu复合材料热导率高达407.84 W/(m·K),归结主要原因:1) CNTs的热导率远高于铜的热导率;2) 喷雾方法获得复合粉体纯度较高,无杂质引入;3) 喷雾制粉使CNTs分散更均匀,与基体结合更牢固,降低了热能传递阻力;4) 冷等静压成形大大降低了复合材料的孔隙率,为发挥铜基体的高导电性能提供了基础。

3 结论

1) 利用喷雾干燥-煅烧-还原法将预处理后CNTs均匀分散于铜基体之中,获得了平均粒径在纳米级别的CNTs/Cu复合粉体,为制备细晶复合材料提供了基础。

2) 随着CNTs含量的增加,CNTs/Cu复合材料的显微硬度有了很大提高,而电导率和致密度均有所下降,但下降幅度不大。

3) 分析比较两种成形工艺对复合材料性能的影响,结果表明冷等静压成形明显优于模压成形。

4) 对CNTs含量为0.5%的冷等静压复合材料进行热性能分析,当复合材料电导率为87.26%(IACS)时,材料硬度和热导率分别提高到了105.24HV和407.84 W/(m·K),可望成为一类对散热性能要求较高的电子封装材料和热沉材料领域。

REFERENCES

[1] 张 兵, 王快社, 孙院军, 王 莎. Cu/Mo/Cu 轧制复合界面的结合特性[J]. 中国有色金属学报, 2011, 21(9): 2163-2163.

ZHANG Bing, WANG Kuai-she, SUN Yuan-jun, WANG Sha. Bonding property of Cu/Mo/Cu cladding metal materials by hot rolling[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2163-2163.

[2] 李红霞, 田保红, 林阳明, 李士凯, 刘 平. 内氧化法制备 Al2O3/Cu 复合材料的再结晶行为[J]. 稀有金属材料与工程, 2005, 34(7): 1039-1042.

LI Hong-xia, TIAN Bao-hong, LIN Yang-ming, LI Shi-kai, LIU Ping. Recrystallization behavior of Al2O3/Cu composite produced by internal oxidation[J]. Rare Metal Materials and Engineering, 2005, 34(7): 1039-1042.

[3] WANG X, LIANG S, YANG P, FAN Z. Effect of Al2O3 content on electrical breakdown properties of Al2O3/Cu composite [J]. Journal of Materials Engineering and Performance, 2010, 19(9): 1330-1336.

[4] 高 翔, 罗丰华, 谭永菊, 付晓虎, 陈春辉, 崔建民. 内氧化-冷轧制备Al2O3弥散强化铜合金的组织与性能[J]. 中国有色金属学报, 2010, 20(10): 2019-2024.

GAO Xiang, LUO Feng-hua, TAN Yong-ju, FU Xiao-hu, CHEN Chun-hui, CUI Jian-min. Microstructure and properties of Al2O3 dispersion strengthened copper alloys prepared by internal oxidation and cold rolling[J]. The Chinese Journal of Nonferrous Metals, 2010,20(10): 2019-2024.

[5] GUOBIN L, QUANMEI G, RU W. Fabrication of the nanometer Al2O3/Cu composite by internal oxidation[J]. Journal of Materials Processing Technology, 2005, 170(1): 336-340.

[6] ZHAN Y, ZHANG G. The effect of interfacial modifying on the mechanical and wear properties of SiC/Cu composites[J]. Materials Letters, 2003, 57(29): 4583-4591.

[7] 王婕丽, 林文松, 姜自旺, 杨国良, 段丽慧. 纤维结构钼铜复合材料的制备及组织性能[J]. 中国有色金属学报, 2014, 24(1): 174-178.

WANG Jie-li, LIN Wen-song, JIANG Zi-wang, YANG Guo-liang, DUAN Li-hui. Fabrication and structure properties of fiber-structured MoCu composites[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 174-178.

[8] 任 冲, 王 特, 巩前明, 梁 吉. 基于原位生长 CNTs/CFF/EP 层状复合材料的成型工艺[J]. 中国有色金属学报, 2013, 23(5): 1275-1281.

REN Chong, WANG Te, GONG Qian-ming, LIANG Ji. Forming process of in-situ growing CNTs/CFF/EP lamellar composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 13(5): 1275-1281.

[9] CHU K, JIA C, JIANG L, LI W S. Improvement of interface and mechanical properties in carbon nanotube reinforced Cu-Cr matrix composites[J]. Materials & Design, 2013, 45: 407-411.

[10] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes[J]. Materials Science and Engineering A, 2001, 313(1): 83-87.

[11] TSAI P C, JENG Y R. Experimental and numerical investigation into the effect of carbon nanotube buckling on the reinforcement of CNT/Cu composites[J]. Composites Science and Technology, 2013, 79: 28-34.

[12] 许龙山, 陈小华, 陈传盛, 李文华, 杨 植. 铜粉复合粉体的制备[J]. 无机材料学报, 2006, 21(2): 309-314.

XU Long-shan, CHEN Xiao-hua, CHEN Chuan-sheng, LI Wen-hua, YANG Zhi. Preparation of CNTs and Superfine Cu Compound Powder[J]. Journal of Inorganic Materials, 2006, 21(2): 309-314.

[13] ZHOU S,ZHANG X,DING Z, MIN C Y, XU G L, ZHU W M. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressureless infiltration technique[J]. Composites Part A: Applied Science and Manufacturing, 2007, 38(2): 301-306.

[14] SONG Y S,YOUN J R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites[J]. Carbon, 2005, 43(7): 1378-1385.

[15] MUSSO S, TULLIANI J M, FERRO G, TAGLIAFERRO A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites[J]. Composites Science and Technology, 2009, 69(11): 1985-1990.

[16] NAM D H,CHA S I,LIM B K, PARK H M, HAN D S, HONG S H. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al-Cu composites[J]. Carbon, 2012, 50(7): 2417-2423.

[17] KUZUMAKI T, MIYAZAWA K, ICHINOSE H, ITO K. Processing of carbon nanotube reinforced aluminum composite[J]. Journal of Materials Research, 1998, 13(9): 2445-2449.

[18] MANEET L, SINGHAL S K, INDU S. An alternative improved method for the homogeneous dispersion of CNTs in Cu matrix for the fabrication of Cu/CNTs composites[J]. Applied Nanoscience, 2013(3): 25-29.

[19] TANG Y, CONG H, ZHONG R, CHENG H M. Thermal expansion of a composite of single-walled carbon nanotubes and nanocrystalline aluminum[J]. Carbon, 2004, 42(15): 3260-3262.

[20] YOO S J, HAN S H, KIM WJ. A combination of ball milling and high-ratio differential speed rolling for synthesizing carbon nanotube/copper composites[J]. Carbon, 2013, 61: 487-500.

[21] WEI X U, RUI H U, LI J S, ZHANG Y Z, FU H Z. Tribological behavior of CNTs-Cu and graphite-Cu composites with electric current[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 78-84.

[22] QIAN M, GOH C S, SUN Y H. Effects of CNTs on microstructure and hardness of laser welds of the CNT-reinforced magnesium composite[J]. Composites A: Applied Science and Manufacturing, 2013, 48: 67-72.

[23] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes[J]. Mater Sci Eng A, 2001, 313(1/2): 83-87.

[24] 许龙山, 陈小华, 吴玉蓉, 潘伟英, 徐海洋, 张 华. 碳纳米管铜基复合材料的制备[J]. 中国有色金属学报, 2006, 16(3): 406-411.

XU Long-shan, CHEN Xiao-hua, WU Yu-rong, PAN Wei-ying, XU Hai-yang, ZHANG Hua. Preparation of CNTs/Cu composite[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 406-411.

[25] CHEN X H, ZHANG G, CHEN C S, ZHOU L P, LI S, LI X. Carbon nanotube composite deposits with high hardness and high wear resistance[J]. Advanced Eng Materials, 2003, 5(7): 514-518.

[26] CHEN X H, XIA J T, PENGT J C. Carbon-nanotube metal-matrix composites prepared by electroless plating[J]. Composites Science and Technology, 2000, 60(2): 301-306.

[27] XU L S, CHEN X H, PAN W Y. Electrostatic-assembly carbon nanotube-implanted copper composite spheres[J]. Nanotechnology, 2007, 18(43): 435607.

[28] 许龙山, 陈小华, 陈传盛, 李文华, 杨 植. 碳纳米管一超细铜粉复合粉体的制备[J]. 无机材料学报, 2006, 21(2): 309-314.

XU Long-shan, CHEN Xiao-hua, CHEN Chuan-sheng, LI Wen-hua, YANG Zhi. Preparation of CNTs and superfine Cu compound powder[J]. Journal of Inorganic Materials, 2006, 21(2): 309-314.

[29] FAN J, LIU T, ZHU S, ZHU S, HAN Y. Synthesis of ultrafine/nanocrystalline W-(30–50) Cu composite powders and microstructure characteristics of the sintered alloys[J]. International Journal of Refractory Metals and Hard Materials, 2012, 30(1): 33-37.

[30] 游 峰, 范景莲, 田家敏, 成会朝. 喷雾干燥和一步氢还原制备超细钨粉工艺的研究[J]. 中国钨业, 2008, 23(6): 15-18.

YOU Feng, FAN Jing-lian, TIAN Jia-min, CHENG Hui-chao. Fabrication of ultra-fine tungsten powder by spray-drying and one step hydrogen reduction[J]. China Tungsten Industry, 2008, 23(6): 15-18.

[31] 范景莲, 刘 涛, 田家敏, 成会朝, 黄伯云. 喷雾干燥-氢还原制备W-50Cu纳米复合粉膜过程中的相转变[J]. 稀有金属材料与工程, 2008, 37(11): 1919-1923.

FAN Jing-lian, LIU Tao, TIAN Jia-min, CHENG Hui-chao, HUANG Bai-yun. Phase transformation during synthesis of W-50Cu nanocomposite powder by spray-drying and hydrogen reduction process[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1919-1923.

[32] 刘 涛, 范景莲, 成会朝, 田家敏. 溶胶-喷雾干燥 WCu 前驱体粉末煅烧过程中的相变[J]. 中国有色金属学报, 2008, 18(12): 2202-2206.

LIU Tao, FAN Jing-lian, CHENG Hui-chao, TIAN Jia-min. Phase transformation of sol-spray dried W-Cu precursor powder during calcining[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2202-2206.

[33] 刘贵明, 李 斌, 杜建华, 宋娅玲. 不同纳米相增强铜基复合材料的性能[J]. 粉末冶金材料科学与工程, 2010, 15(5): 450-455.

LIU Gui-min, LI Bin, DU Jian-hua, SONG Ya-ling. Properties of various nano-materials reinforced copper based composites[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(5): 450-455.

[34] NAN C W, SHI Z, LIN Y. A simple model for thermal conductivity of carbon nanotube-based composites[J]. Chemical Physics Letters, 2003, 375(5): 666-669.

[35] CHU K, WU Q, JIA C, LIANG X, NIE J, TIAN W. Fabrication and effective thermal conductivity of multi-walled carbon nanotubes reinforced Cu matrix composites for heat sink applications[J]. Composites Science and Technology, 2010, 70(2): 298-304.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51272073,51154001);湖南省教育厅科学研究资助项目(13C991)

收稿日期:2014-12-09;修订日期:2015-04-13

通信作者:陈小华,教授,博士;电话:13723899609;E-mail:hudacxh@qq.com