基于神经网络的铜闪速熔炼过程工艺参数预测模型

喻寿益,王吉林,彭晓波

(中南大学 信息科学与工程学院,湖南 长沙,410083)

摘 要:基于铜闪速熔炼过程是典型的高温、多相多组分复杂生产过程,熔炼时,闪速炉内发生激烈而迅速的化学反应,冰铜品位、冰铜温度和渣中铁硅比是铜熔炼过程的关键三大工艺参数,在线检测时存在成本高、滞后大,实现困难等问题,在分析影响工艺参数因素的基础上,提出一种基于BP神经网络的三大工艺参数预测方法,通过收集现场生产数据,挖掘其中隐含的工艺参数信息,建立预测模型。仿真结果表明,这三大工艺参数的最大绝对误差分别为0.630,6.680和0.051,最大相对误差分别为1.16%,0.55%和3.40%,说明模型预测结果与实际生产数据较吻合,该预测模型可用来指导实际生产操作,并可用于铜闪速熔炼过程参数优化。

关键词:铜闪速熔炼;BP神经网络;预测模型

中图分类号:TP13 文献标识码:A 文章编号:1672-7207(2007)03-0523-05

Prediction model of craft parameters based on neural network during the process of copper flash smelting

YU Shou-yi, WANG Ji-lin, PENG Xiao-bo

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Copper flash smelting is a complex industrial process with multiple phases and multiple components at high temperature. During the process of smelting, the reactions occur fiercely and rapidly in flash furnace, and matte grade, matte temperature and mass rate of Fe and SiO2 are the three key technology parameters during the process of copper flash smelting. The measurement method of these parameters is not only hard to be detected on-line, but also has time-delaying and costs a lot. A back propagation neural network prediction model was presented to predict these parameters, and its simulation experiment was given. The simulative results show that the biggest absolute error of the three parameters are 0.630, 6.680 and 0.051 and the biggest relative error are 1.16%, 0.55% and 3.40%, respectively. These results indicate that the prediction results of the model is in accordance with the practical data very well, and thus the model can be used in the parameter optimization for copper flash smelting and can be used to optimize parameters in the practical production.

Key words: copper flash smelting; back propagation neural network; prediction model

铜闪速熔炼是一个典型的高温、多相多组分的复杂生产过程,熔炼时,闪速炉内反应迅速,所有反应在2~3 s内完成。当处理料量不变时,闪速炉产出的冰铜品位、冰铜温度、渣中铁硅比(质量比)等参数是铜闪速炉熔炼过程的综合判断指标,只要稳定这三大参数,就可以实现熔炼、吹炼以及硫酸生产过程的稳定[1-2]。计算机对闪速熔炼过程的控制,实际上就是对冰铜品位、冰铜温度和渣中铁硅比这三大工艺参数进行在线控制。目前,在生产中为了使这实现三大工艺参数稳定,某冶炼厂采用从日本引进的消耗式热电偶,在炉前冰铜出口测量冰铜温度[3-4]。这种一次性热电偶测出的温度存在不可重复性,只能在放出冰铜时进行测量,而冰铜每隔一段时间才从冰铜出口放出,这样测得的温度不能及时反映生产过程的变化,是一种滞后的测量方法。冰铜品位和渣中铁硅比通过取样化验计算获得,存在严重的时间滞后。在此,本文作者采用一种基于BP神经网络预测模型的方法实现三大工艺参数的软测量。

1 工艺参数的神经网络预测模型

1.1 模型的确定

在铜闪速熔炼过程中,影响冰铜温度、冰铜品位和渣中铁硅比等参数的因素很多,主要包括入炉料干矿成分、操作参数预热空气量、工业氧气量等。用x表示影响三大工艺参数的因素,用y表示三大工艺参数,x和y的输入输出关系可以表示为

y=f(x)。 (1)

其中:f是x和y的非线性映射函数。若影响因素x不同,则其对输出y作用的权重也不同。BP神经网络是一种前向神经网络,它具有较强的非线性逼近能力,各因素的权重可通过它的权值来反映;BP神经网络的自学习与自调整功能,使得实际输出可以不断逼近期望输出,且性能稳定可靠[5-6],因此,选用BP网络拟合x和y的输入输出关系。图1所示为BP神经网络拓扑结构。其中:输入层有n个节点,对应输入x1~xn;输出层有m个节点,对应输出y1~ym;隐含层有q个节点,对应输出z1~zq;输入层与隐含层之间的权值为vik;隐含层与输出层之间的权值为wkj。

图1 BP神经网络拓扑结构

Fig.1 The structure of BP neural network

根据BP网络拓扑结构,确定预测目标(三大工艺参数)与各影响因素之间的关系原理如图2所示[7]。

图2 基于BP神经网络的工艺参数模型原理图

Fig.2 Schematic diagram of technology parameters model based on BP neural network

图2中,网络输入为影响工艺参数的各个影响因素,与BP网络的输入层相对应,网络输出为冰铜温度、冰铜品位和渣中铁硅比这三大工艺参数,与BP的输出层相对应。可以看出,模型由数据流的前向计算(正向传播)和误差信号的反向传播2个过程构成。正向传播时,根据输入数据和各层的传递函数计算网络输出(数据传播方向为输入层→隐层→输出层);当输出层没达到期望的输出时,根据网络输出值与生产过程实际输出的差值来修改网络权值vik和wkj以及阈值Тk和θj,可以通过反向传播学习算法来实现[8-9]。该算法的步骤为:

a. 给全部权值vik和wkj以及阈值Тk和θj赋予较小的随机值(一般取0~1之间的值)。

b. 从学习样本中取出一个输入样本s,计算节点输出值。

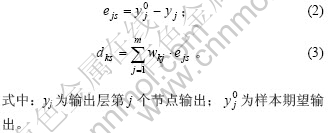

c. 计算输出层的误差ejs和隐含层误差dks,计算公式为:

d. 修改权值wkj和vik,调整公式为

e. 调整阈值θj和Тk,调整公式为

f. 取下一个样本,重复步骤b.~e.,若样本已完,则进入步骤g。

g. 计算总误差。若总误差E小于给定误差ε或训练次数大于指定次数,则停止计算;若E>ε,则返回步骤b.重新修改权值和阈值,直到满足E≤ε或达到指定次数为止。

1.2 BP网络结构及节点数的确定

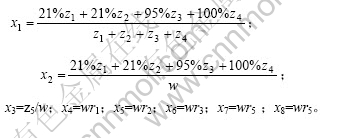

根据BP网络原理,确定三大工艺参数的结构如图3所示。图中BP神经网络共有8个输入量,分别为富氧率(x1)、吨矿氧含量(x2)、熔剂率(x3)、Cu含量(x4)、S含量(x5)、Fe含量(x6)、SiO2含量(x7)和MgO含量(x8);网络输出量对应铜闪速熔炼过程中的三大工艺参数,分别为冰铜品位(y1)、冰铜温度(y2)和渣中铁硅比(y3);z1为空气量;z2为分配风量;z3为工艺氧量;z4为中央氧量;z5为熔剂量;w为精矿量;r1为精矿中铜的含量;r2为精矿中硫的含量;r3为精矿中铁含量;r4为精矿中SiO2含量;r5为精矿中MgO含量。输入变量中前3个分别表示风、氧以及熔剂对输出的影响,后5个变量表示精矿成分对输出的影响。各输入变量xi(i=1~8)的值通过以下公式计算得出:

其中:网络中各层的节点数由输入输出量数目确定。对于此模型,输出层与三大工艺参数对应,故其节点数为3;而输入层与三大工艺参数的影响因素对应,其节点数取8;隐含层节点数n1可据经验公式 确定(式中:n为输入层单元数;m为输出层单元数;α为1~10之间的常数[10-11])。参考经验公式及考虑网络的泛化能力和收敛速度等因 素[12-15],最终确定隐层节点数为15,于是,得到8-15-3的BP网络结构。

确定(式中:n为输入层单元数;m为输出层单元数;α为1~10之间的常数[10-11])。参考经验公式及考虑网络的泛化能力和收敛速度等因 素[12-15],最终确定隐层节点数为15,于是,得到8-15-3的BP网络结构。

图3 工艺参数预测模型结构图

Fig.3 The structure of technology parameters prediction model

2 仿真结果及分析

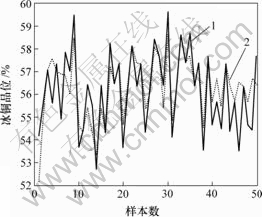

为验证上述BP网络模型的可行性,利用matlab7.0对其进行训练和仿真。在仿真过程中,隐含层、输出传递函数分别为sigmoid( )和tansig( )[16-17]。神经网络训练和仿真数据来自生产现场DCS系统,并经过数据完备性处理和时间同步处理的数据记录,取60组生产数据对上述神经网络模型进行训练和仿真,其中50组作为训练样本,另外10组对网络模型进行检验。训练结果如图4~6所示。

1—冰铜品位实际值;2—冰铜品位训练值

图4 50组冰铜品位训练结果

Fig.4 The matte grade training results of 50 training samples

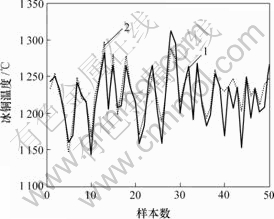

1—冰铜温度实际值;2—冰铜温度训练值

图5 50组冰铜温度训练结果

Fig.5 The matte temperature training results of 50 training samples

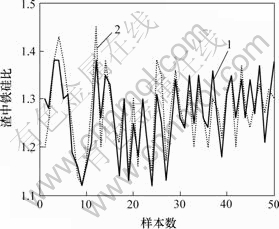

1—渣中铁硅比实际值2—渣中铁硅比训练值

图6 50组渣中铁硅比训练结果

Fig.6 Rates of Fe and SiO2 in slag training result of50 training samples

训练结果表明:BP神经网络训练结果(图中虚线)和实际生产数据(图中实线)较吻合,说明网络已经挖掘生产实际数据中隐含的工艺参数信息。

仿真结果如表1所示。可以看出:神经网络模型仿真的冰铜品位、冰铜温度及渣中铁硅比与检验样本实际值的最大绝对误差分别为0.630,6.680和0.051,最大相对误差分别为1.16%,0.55%和3.40%,网络输出与实际生产数据较吻合。这表明该神经网络模型的泛化能力强,能根据输入参数较精确地预测冰铜品位、冰铜温度及渣中铁硅比等目标值。同时,在实际运算中采用此方法,能在很短的时间内,利用以往的历史数据获得当前的参数预测值,很好地解决以往测量的滞后问题。因此,此模型可用于铜闪速熔炼过程的在线生产操作指导和优化控制。

表1 神经网络模型仿真数据与检验样本对照表

Table 1 Comparison of datum between simulation results of neural network and checking samples

3 结 论

a. 基于BP神经网络建立铜闪速熔炼过程中冰铜品位、冰铜温度和渣中铁硅比这三大工艺参数的预测模型,模型预测结果与实际生产结果基本吻合,最大绝对误差分别为0.630, 6.680和0.051,最大相对误差分别为1.16%, 0.55%和3.40%,说明BP模型准确地挖掘了生产数据中的隐含信息,模型具有可行性。

b. 该模型实现简单,通过输入数据就能预测铜闪速熔炼过程关键工艺参数,因而对实现铜熔炼生产的在线控制具有参考价值。

参考文献:

[1] 曾青云. 铜闪速熔炼操作数据的回归分析[J]. 有色金属, 1994(5): 4-6.

ZENG Qing-yun. Regression analysis of operation datum for copper flash smelting[J]. Nonferrous Metals, 1994(5): 4-6.

[2] 梅 炽,姚俊峰,胡 军,等. 粗铜冶炼中铜锍品位的动态预测模式—AR(p)与指数平滑最优组合法[J]. 中南工业大学学报:自然科学版, 2000, 31(1): 34-36.

MEI Chi, YAO Jun-feng, HU Jun, et al. The dynamic pre-estimating model of the grade of copper matte in the course of raw copper metallurgy: the best combined approach of auto regressive and exponential smoothing [J]. Journal of Central South University of Technology: Natural Science, 2000, 31(1): 34-36.

[3] 张卫华. 冰铜温度测量方法研究[J]. 江西铜业工程, 1999(4): 1-5.

ZHANG Wei-hua. Study on measurement of matte temperature[J]. Jiangxi Copper Engineering, 1999(4): 1-5.

[4] 周 璇, 喻寿益. 分布参数系统参数辨识的最佳测量位置[J]. 中南大学学报: 自然科学版, 2004, 35(1): 97-100.

ZHOU Xuan, YU Shou-yi. Optimal sensor location for the parameter identification in the distributed parameter system[J]. Journal of Central South University: Science and Technology, 2004, 35(1): 97-100.

[5] 飞思科技产品研发中心. 神经网络理论与实现[M]. 北京: 电子工业出版社, 2005.

Feisi Technology R&D Center. Application and theory of neural network[M]. Beijing: Electronics Industry Press, 2005.

[6] 范 磊, 张运陶, 程正军. 基于Matlab的改进BP神经网络及其应用[J]. 西华师范大学学报, 2005, 26(1): 71-73.

FAN Lei, ZHANG Yun-tao, CHENG Zheng-jun. Application of improved BP neural network based on Matlab[J]. Journal of China West Normal University, 2005, 26(1): 71-73.

[7] 汪金良, 曾青云, 汪仁良. 应用神经网络技术建立铜闪速熔炼温度模型[J]. 有色金属, 2002(1): 12-14.

WANG Jin-liang, ZENG Qing-yun, WANG Ren- liang. Study on the temperature model for copper flash smelting based on neural network[J]. Nonferrous Metals, 2002(1): 12-14.

[8] Cichocki A, Unbehauen R. Neural networks for optimization and signal processing[M]. New York: John Wilcy & Sons Ltd, 1993: 53.

[9] 邹明虎, 王志云, 高福生, 等. 基于模糊神经网络的雷达印制板故障智能诊断系统研究[J]. 微计算机信息, 2004, 12(4): 12-15.

ZOU Ming-hu, WANG Zhi-yun, GAO Fu-sheng,et al. Research on the fault intelligent diagnosis system of radar printed plates based on the fuzzy neural network[J]. Microcomputer Information, 2004, 12(4): 12-15.

[10] 曾青云, 汪金良. 铜闪速熔炼神经网络模型的建立[J]. 南方冶金学院学报,2003, 24(5): 15-18.

ZENG Qing-yun, WANG Jin-liang. Developing of the copper flash smelting model based on neural network[J]. Southern Institute of Metallurgy, 2003, 24(5): 15-18.

[11] 伍春香, 刘 琳. 三层BP网络隐层节点数确定方法的研究[J]. 武汉测绘科技大学学报, 1999, 24(2): 177-178.

WU Chun-xiang, LIU Lin. Study on the method of determining of hidden layer’ nodes for three-layer network[J]. Journal of Wuhan Technical University of Surveying and Mapping, 1999, 24(2): 177-178.

[12] Li B, Chow M Y, Tipsuwan Y, et al. Neural-network-based motor rolling bearing fault diagnosis[J]. IEEE Transactions on Industrial Electronics, 2000, 47(5): 1060-1069.

[13] TANG Wan-Mei. The study of the optimal structure of BP neural network[J]. System Engineering Theory and Practice, 2005, 25(10): 95-100.

[14] Ng S C, Cheung C C, Leung S H. Fast convergence for back-propagation network with magnified gradient function[J]. IEEE International Joint Conference on Neural Networks, 2003, 9(3): 1903-1908.

[15] Ng S C, Cheung C C, Leung S H, et al. A new adaptive learning algorithm using magnified gradient function[C]//Proceedings of the International Joint Conference on Neural Networks. 2001: 156-159.

[16] Deduth H, Beatle M. Neural network toolbox for use with MATLAB[M]. MA: The Math Works Inc, 2001.

[17] 闻 新. Matlab神经网络仿真与应用[M]. 北京: 科学出版社, 2003.

WEN Xin. Application and simulation of neural network based on Matlab[M]. Beijing: Science Press, 2003.

收稿日期:2006-11-08

基金项目:国家自然科学重点基金资助项目(60634020);国家自然科学基金资助项目(60574030);湖南省自然科学基金资助项目(06FD007);国家发改委专项基金资助项目(2004-1113-17);中国博士后科学基金资助项目(20060400885)

作者简介:喻寿益(1940-),男,江西南昌人,教授,从事自适应控制、过程控制和进化计算理论及应用等研究

通讯作者:彭晓波,男,博士研究生;电话:13973353860;E-mail: pengxiaobo88@yahoo.com.cn